A hot stamping forming triple lock type connecting device and method

A technology of hot stamping forming and connecting devices, which is applied in the field of stamping devices, can solve the problems of reducing the corrosion resistance and impact resistance of plates, affecting the dimensional accuracy of connection points, and failing to achieve reliable connections, etc., to achieve high fatigue strength, strength and hardness Improvement, easy molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

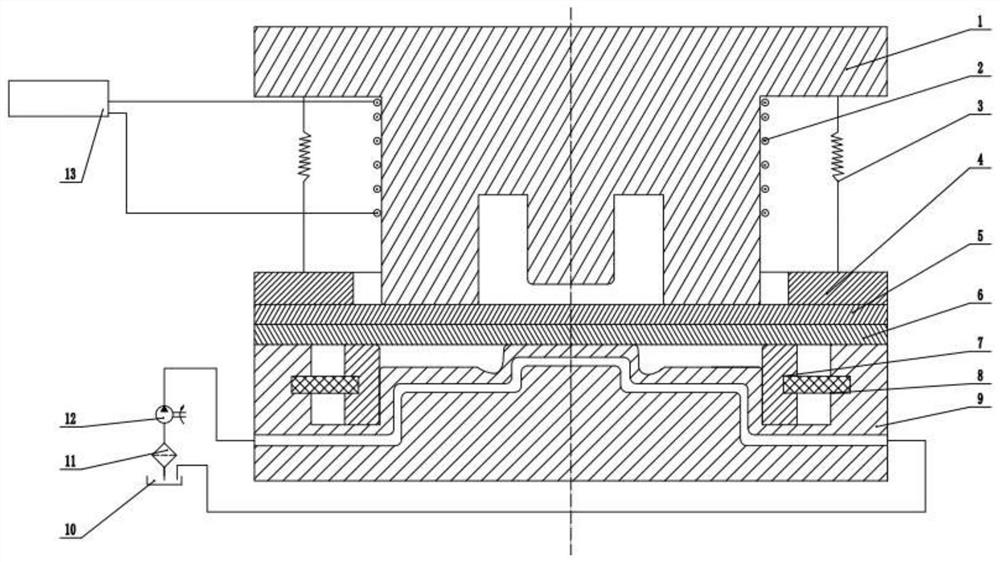

[0046] The embodiment of the present invention also provides a specific implementation of a hot stamping triple lock connection device, including:

[0047] Such as figure 1 As shown, first, the outer ring of the upper mold 1 contacts the upper plate 5, the induction heating device 13 starts to work, the electromagnetic coil 2 is energized, and the upper mold 1 is rapidly heated under the action of electromagnetic induction, and the heat is transferred to the upper plate 5 and the lower plate 6 , after heating for a period of time, the induction heating device 13 stops working, and the plastic deformation ability of the upper plate 5 and the lower plate 6 is significantly enhanced.

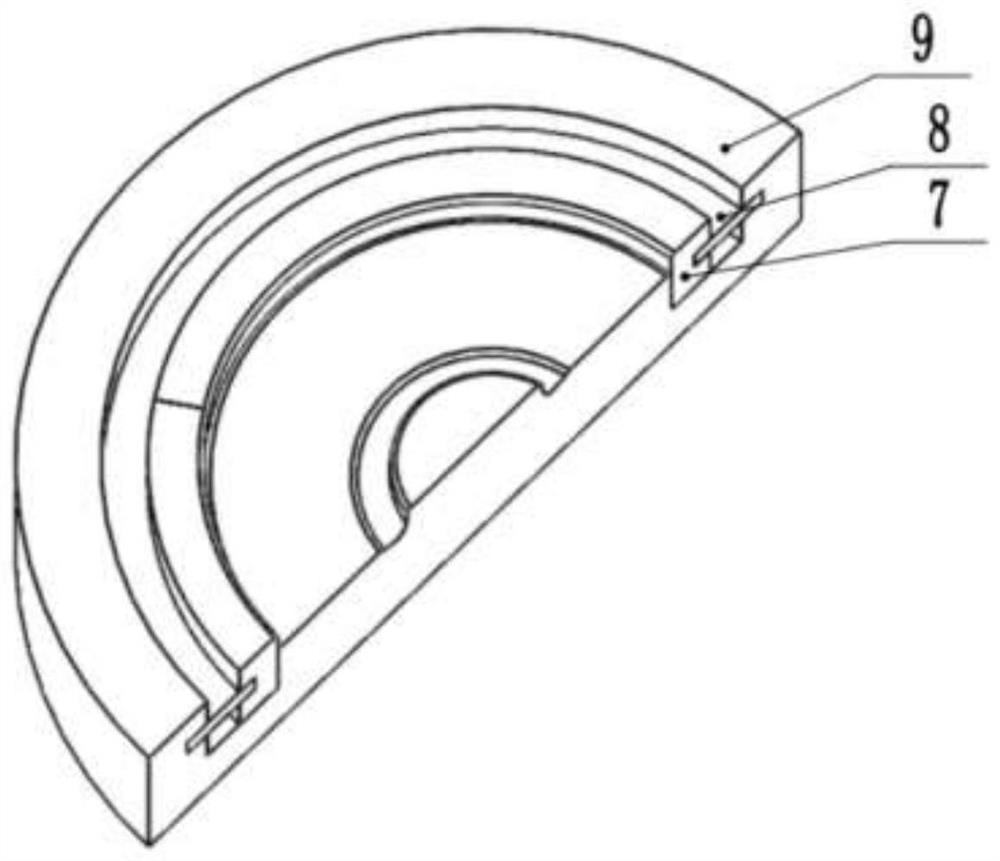

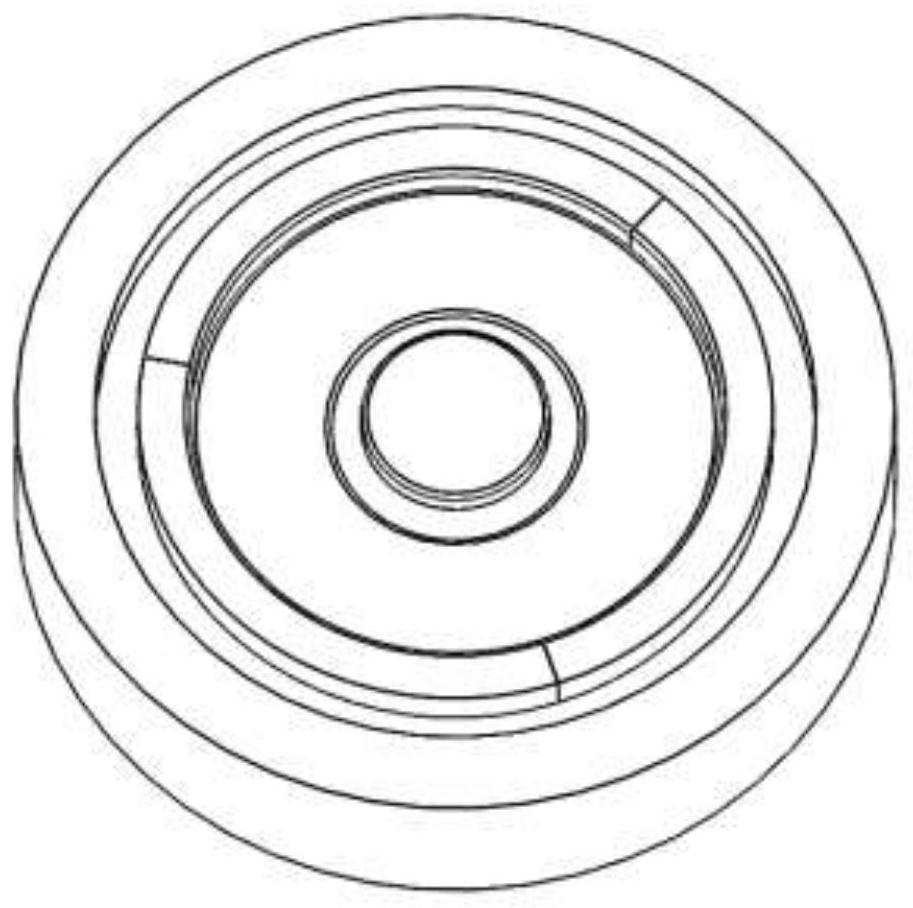

[0048] Such as Figure 2-4 As shown, the upper die 1 moves downward to start punching. With the increase of the descending depth, the elastic force of the spring 3 gradually increases to compress the upper sheet 5 and the lower sheet 6 to prevent the upper sheet 5 and the lower sheet 6 from wrinkl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com