A Homogenization Heat Treatment Process for Reducing Anisotropy of Wide Rolled Aluminum Sheet

A homogeneous heat treatment and anisotropic technology, applied in the field of aluminum alloy processing, to reduce the work hardening rate, increase the driving force, and reduce the effect of solid solution strengthening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 : A homogenization heat treatment process for reducing the anisotropy of wide-width rolled aluminum plates, comprising the steps of:

[0019] The ingot of 5052 alloy added with 0.3 wt% Er was used, and then the alloy was subjected to two-stage homogenization heat treatment.

[0020] First, carry out homogenization and heat preservation at 560°C for 30 h (first-level homogenization);

[0021] Subsequently, it was cooled to 300 °C and kept for 10 h (secondary homogenization), and then it was taken out of the furnace and air-cooled to room temperature.

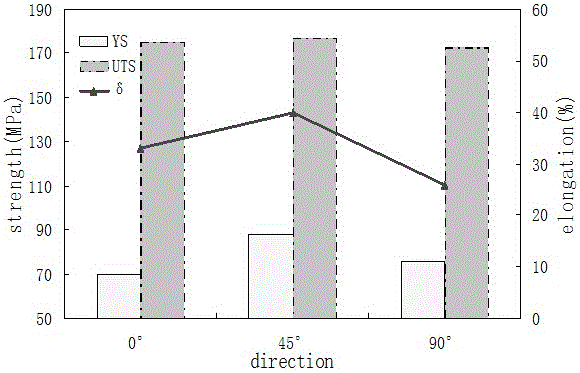

[0022] The ingot that has undergone the above-mentioned two-stage homogenization treatment is hot-rolled at a rolling temperature of 470°C. Before rolling, the rolled billet is preheated at 470°C for 1 h, and the total rolling reduction is 73%. The obtained plate was tested for tensile mechanical properties at room temperature along the rolling direction, vertical rolling direction and 45° direction, and the...

Embodiment 2

[0023] Example 2 : A homogenization heat treatment process for reducing the anisotropy of wide-width rolled aluminum plates, comprising the steps of:

[0024] Add 0.2 wt% (or 0.3 wt% or 0.4wt%) rare earth element Er to the 5052 alloy, and then perform three-stage homogenization heat treatment:

[0025] First, the 5052 alloy ingot added with rare earth element Er was subjected to homogenization and heat preservation at 560 °C for 30 h, that is, first-level homogenization;

[0026] Subsequently, cool to 150°C and hold for 10 h, that is, secondary homogenization;

[0027] Then, the temperature was raised to 300°C, and the temperature was continued for 10 h, that is, three-stage homogenization;

[0028] Finally, take it out of the oven and let it cool to room temperature.

[0029] The ingot that has undergone the above-mentioned three-stage homogenization treatment is hot-rolled at a rolling temperature of 470°C. Before rolling, the rolled billet is preheated at 470°C for 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com