Miniature pipe two-way hydraulic forming device

A two-way hydraulic and forming device technology, applied in the field of micro tube forming, to achieve the effect of avoiding communication, high measurement accuracy and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

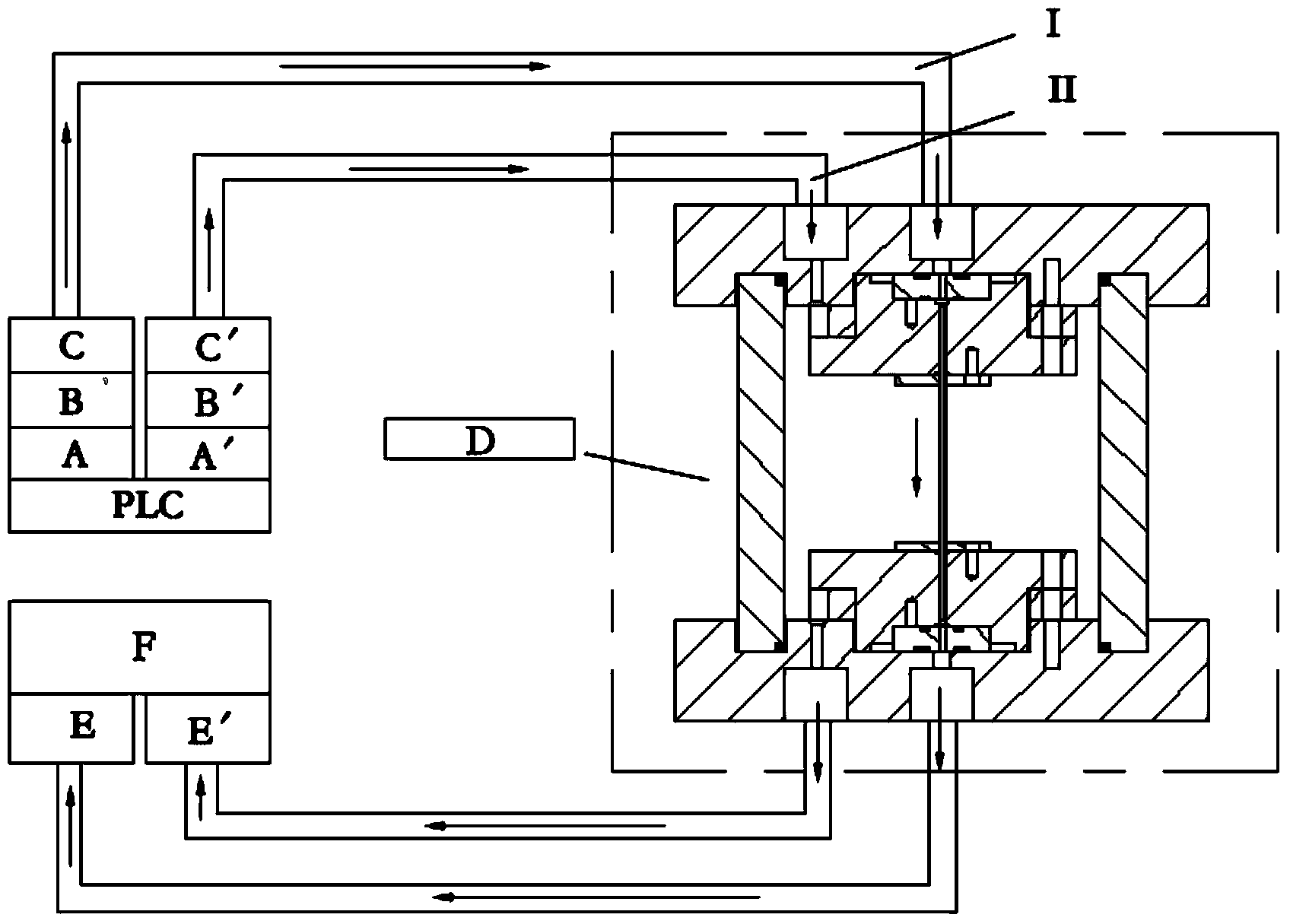

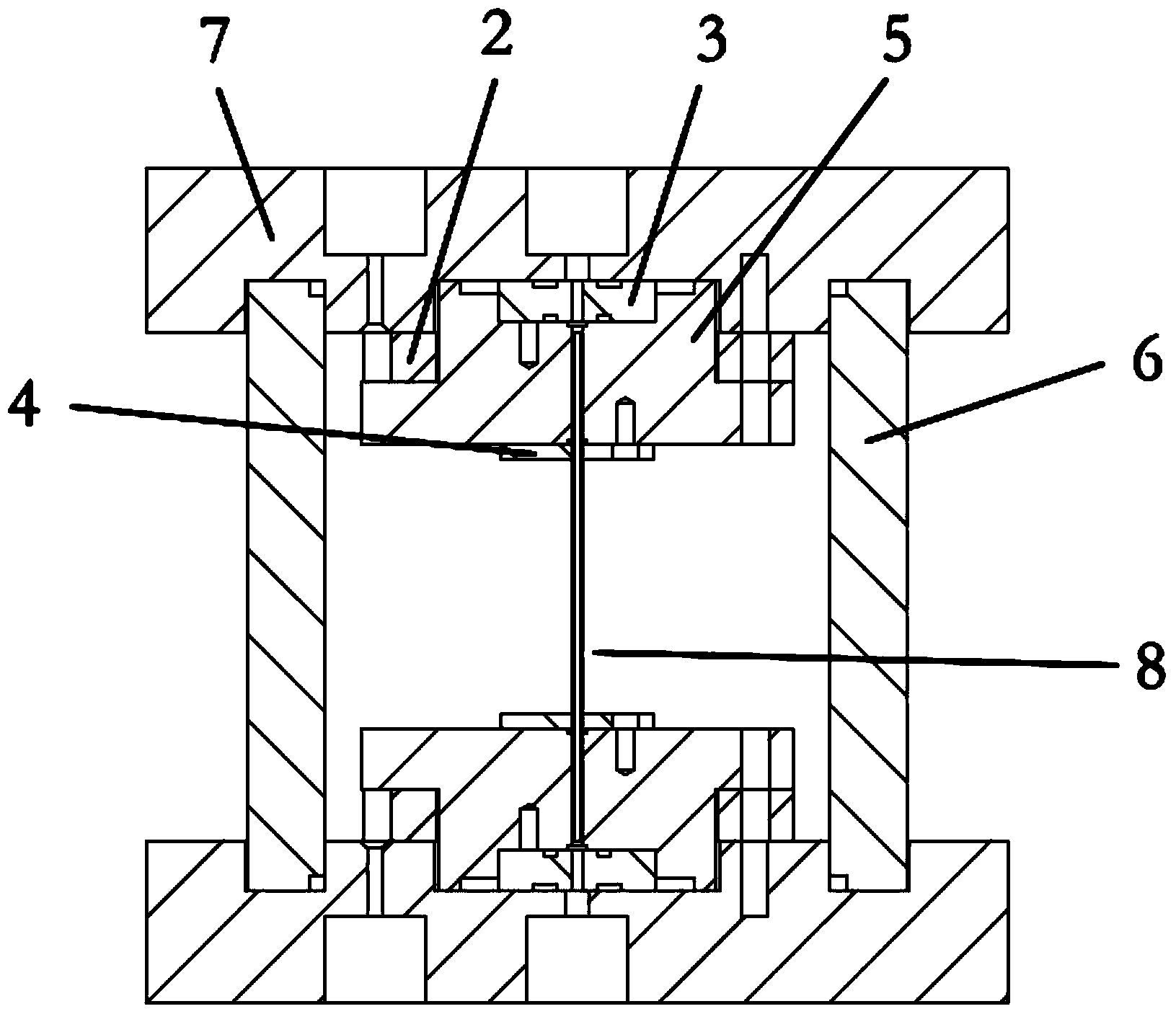

[0015] The present invention is a micro-tube two-way hydraulic forming device, including a PLC control module, an internal pressure pump A, an external pressure pump A', an internal pressure booster B, an external pressure booster B', and an internal pressure one-way valve C , external pressure one-way valve C', internal pressure high-pressure needle valve E, external pressure high-pressure needle valve E', fuel tank F molding die D; wherein, the molding die includes a guide block 7, a cylindrical shell 6, an insert 5, a blank holder Ring 4 and sealing block 3; one end surface of guide block 7 is provided with two holes, one of which is the microtube internal pressure liquid port located at the center of guide block 7, and the other hole is a microtube located at the eccentric position of guide block 7 The external pressure liquid port, the other end surface of the guide block 7 has an annular groove with the axis of the guide block 7 as the center of the circle, and the guide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com