Magnesium-aluminum layered composite board and preparation method thereof

A composite plate and composite plate technology, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., to achieve the effect of refining grain size, improving strength and plastic forming ability, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing a magnesium-aluminum layered composite board, including:

[0039] (1) Magnesium alloy and aluminum alloy are smelted in separate furnaces at the same time, the melting temperature of magnesium alloy is 700°C, and the melting temperature of aluminum alloy is 735°C.

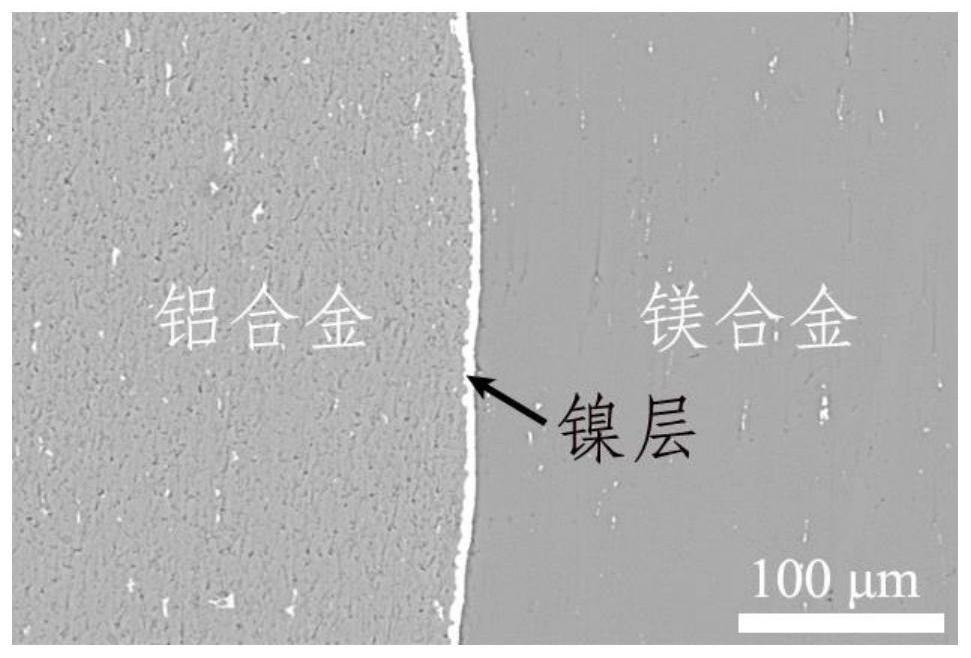

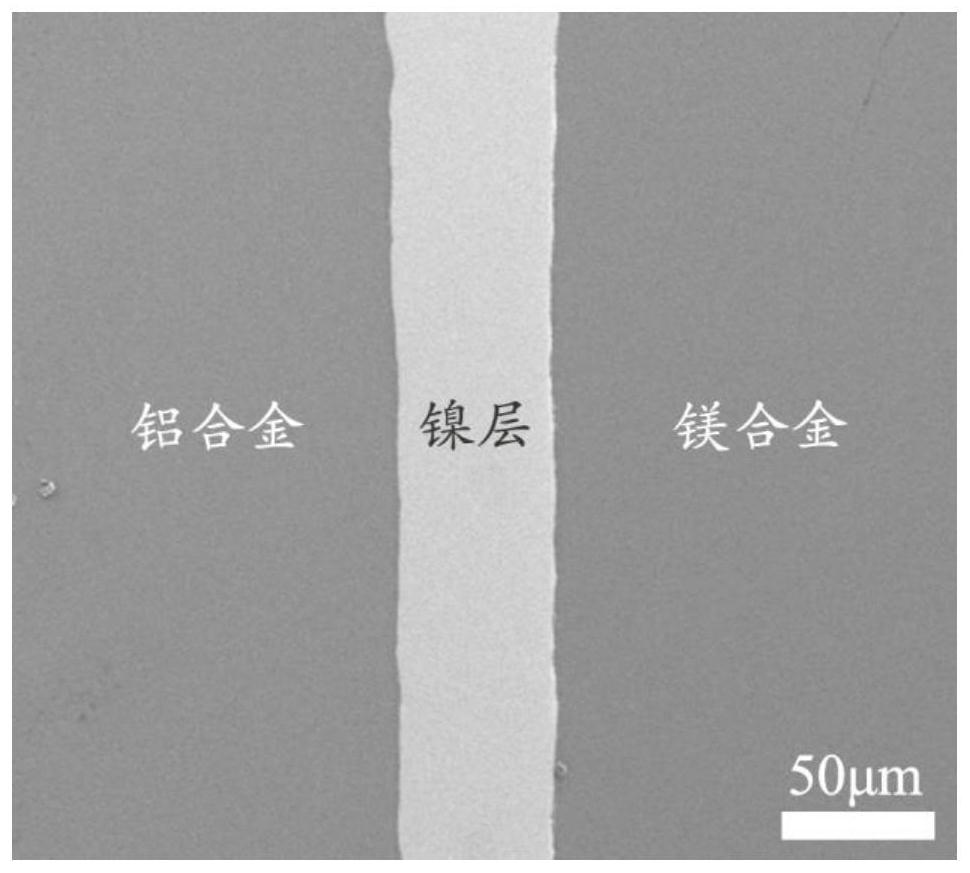

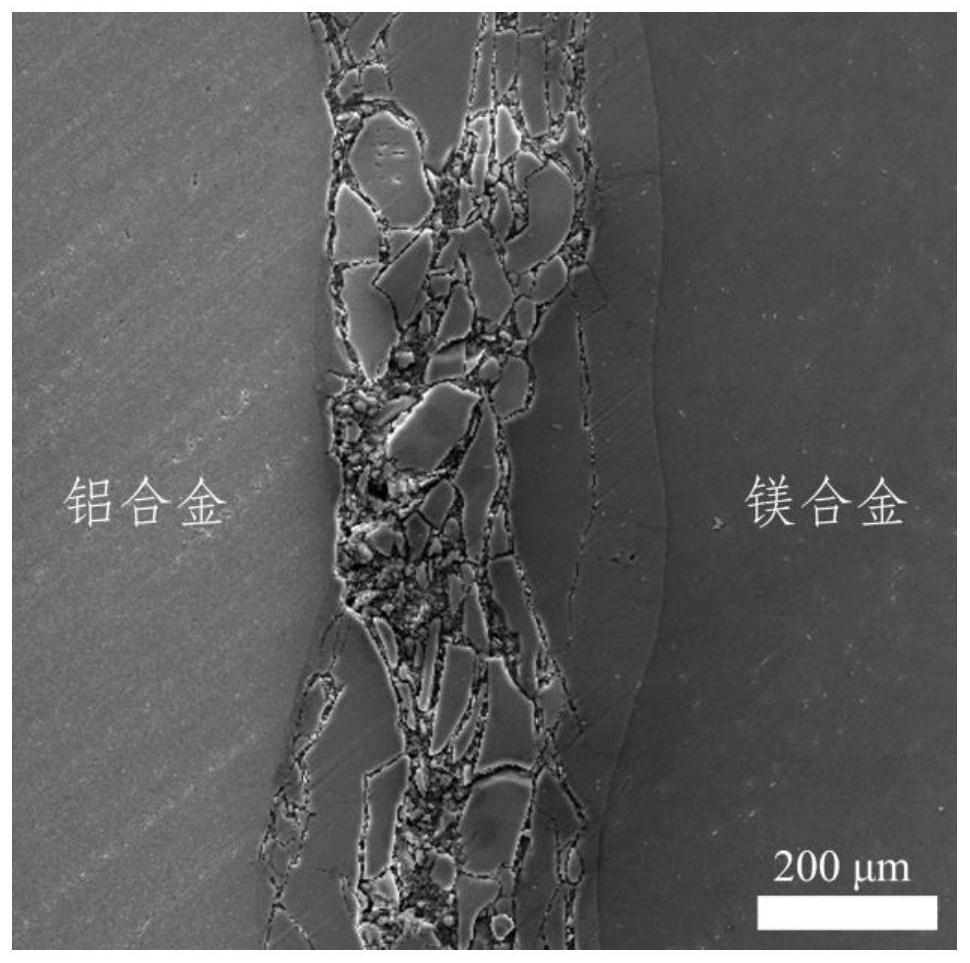

[0040] (2) First pour the molten aluminum alloy into the drum-type centrifugal casting metal mold at a pouring temperature of 660°C. After the molten liquid is cooled and solidified, the surface is treated to obtain a nickel alloy coating. The thickness of the coating is 10 μm. Immediately after the surface treatment, the molten magnesium alloy is poured, the pouring temperature is 670°C, and the composite tube blank is obtained after cooling.

[0041] (3) Open along the axial direction of the composite tube blank, and level the unfolded composite tube blank by a leveler.

[0042] (4) The flattened composite tube billet is first rolled through a rolling mill,...

Embodiment 2

[0046] This embodiment provides a method for preparing a magnesium-aluminum layered composite board, including:

[0047] (1) Magnesium alloy and aluminum alloy are smelted in separate furnaces at the same time, the melting temperature of magnesium alloy is 715°C, and the melting temperature of aluminum alloy is 745°C.

[0048] (2) First pour the molten aluminum alloy into the drum-type centrifugal casting metal mold at a pouring temperature of 660°C. After the molten liquid is cooled and solidified, the surface is treated to obtain a nickel alloy coating. The thickness of the coating is 5 μm. Immediately after the surface treatment, the molten magnesium alloy is poured, the pouring temperature is 670°C, and the composite tube blank is obtained after cooling.

[0049] (3) Open along the axial direction of the composite tube blank, and level the unfolded composite tube blank by a leveler.

[0050] (4) Carry out the initial rolling of the flattened composite tube billet through...

Embodiment 3

[0054] This embodiment provides a method for preparing a magnesium-aluminum layered composite board, including:

[0055] (1) Magnesium alloy and aluminum alloy are smelted in separate furnaces at the same time, the melting temperature of magnesium alloy is 715°C, and the melting temperature of aluminum alloy is 730°C.

[0056] (2) First pour the molten aluminum alloy into the drum-type centrifugal casting metal mold at a pouring temperature of 660°C. After the molten liquid is cooled and solidified, the surface is treated to obtain a nickel alloy coating. The thickness of the coating is 10 μm. Immediately after the surface treatment, the molten magnesium alloy is poured, the pouring temperature is 680°C, and the composite tube blank is obtained after cooling.

[0057] (3) Open along the axial direction of the composite tube blank, and level the unfolded composite tube blank by a leveler.

[0058] (4) The flattened composite tube billet is rolled for the first time through a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com