High-silicon aluminum alloy swash plate die-forging process and die

A high-silicon aluminum alloy, die forging technology, used in manufacturing tools, metal processing equipment, forging/pressing/hammer devices, etc. The effect of poor formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

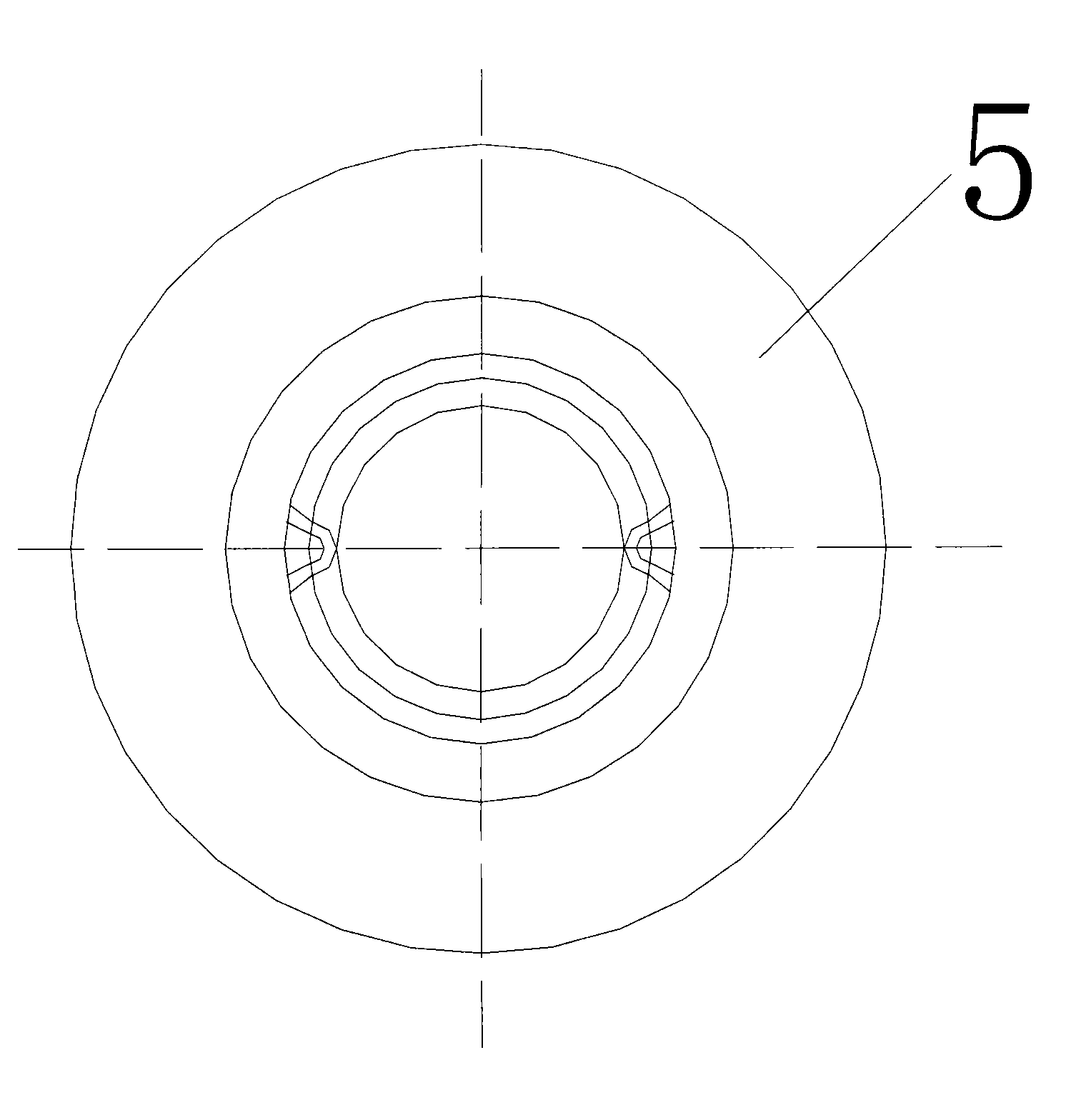

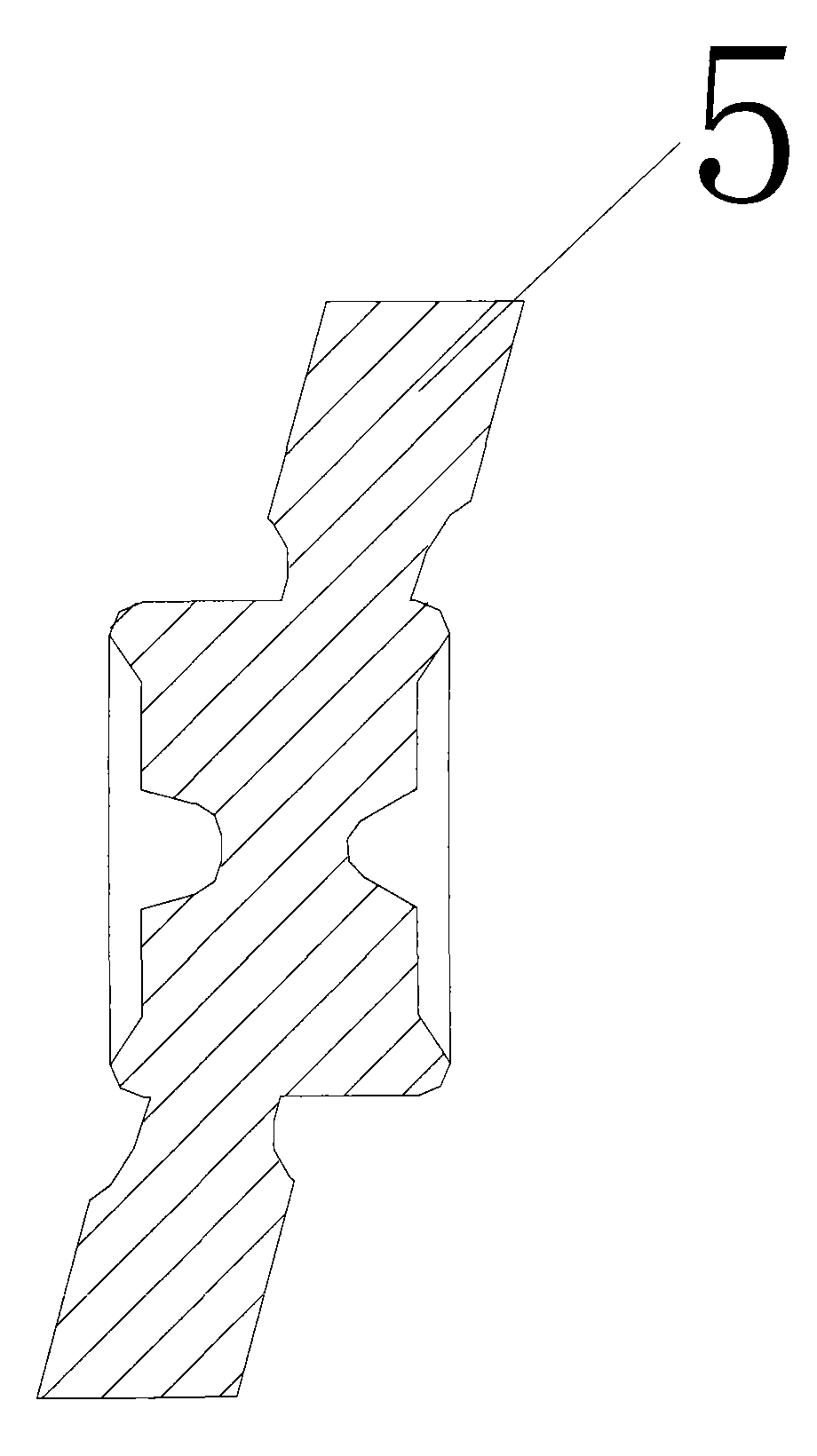

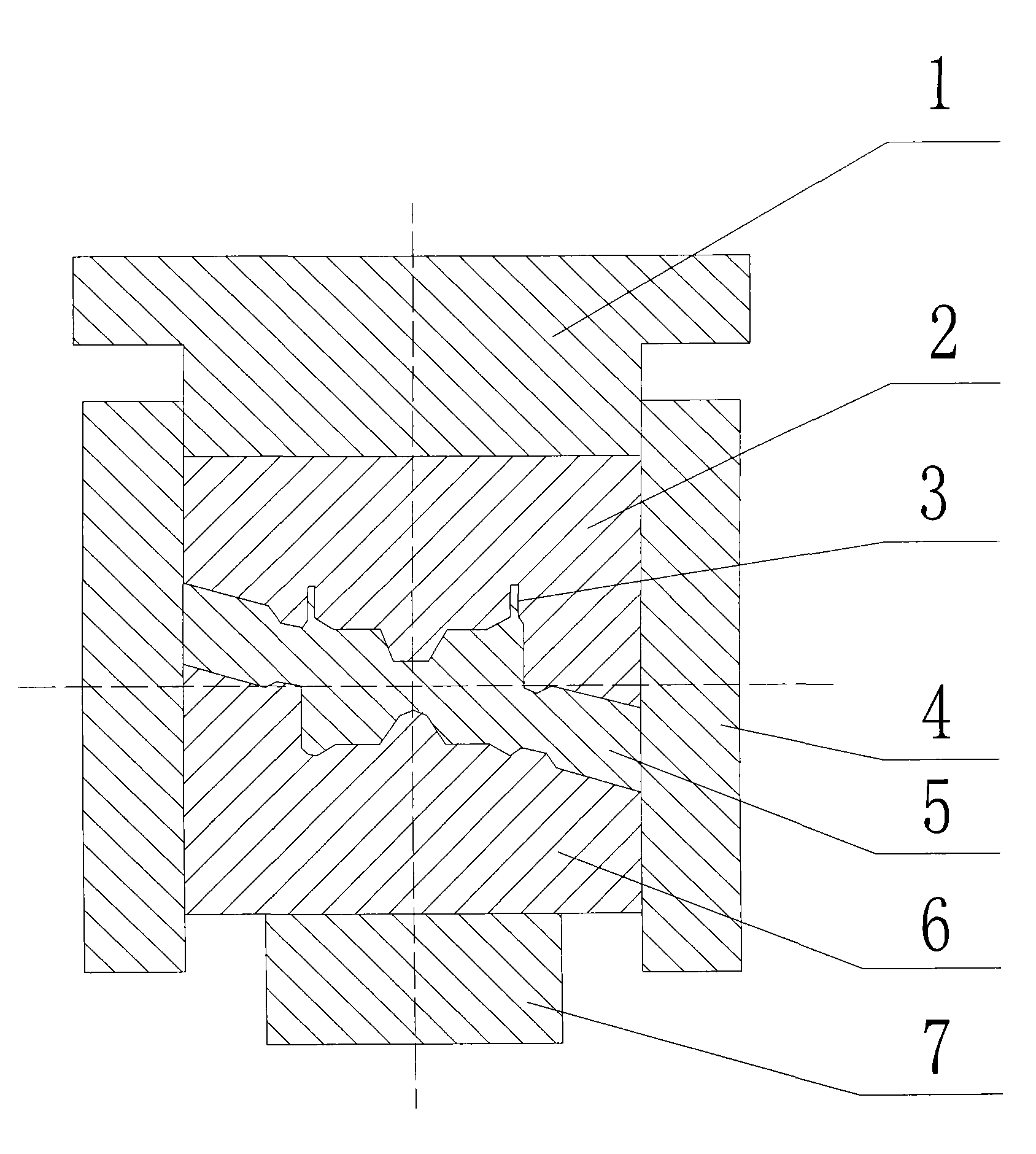

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 shown.

[0026] The high-silicon aluminum alloy described in the present invention refers to the high-silicon aluminum alloy with the brand name: A390. The Si element content in the A390 aluminum alloy is 16-18%. Silicon alloy material, the alloy has good wear resistance, corrosion resistance, low thermal expansion coefficient and high air tightness, and is suitable for manufacturing swash plate parts; there is no specific brand corresponding to it in China.

[0027] High-silicon aluminum alloy swash plate die forging process, the process flow is: A390 extruded bar material→cutting→heating→forging plastic forming→subsequent processing, the blank is accurately blanked according to the principle of equal volume, and the heating temperature of the blank is 500℃± 5°C, the preheating temperature of the die is 200°C±5°C, and the small flash die forging process directly die-forges th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com