Method and device for directly hot-forming bimetal composite pipe fitting from metal pipe

A bimetallic composite pipe and metal pipe technology, applied in the field of bimetallic composite pipe fittings, can solve the problems of difficult deformation and compounding of two kinds of pipes, high cost, and failure to composite pipe fittings, etc., achieve high plastic forming performance, realize large plastic forming, The effect of small deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

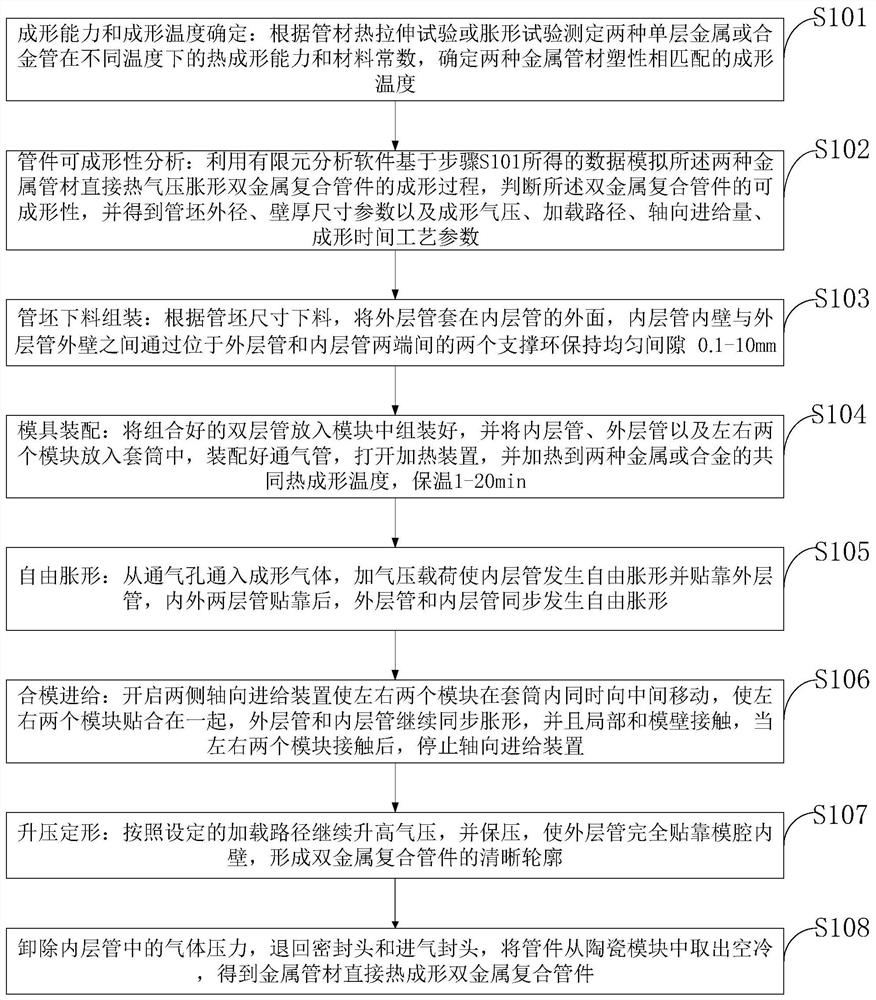

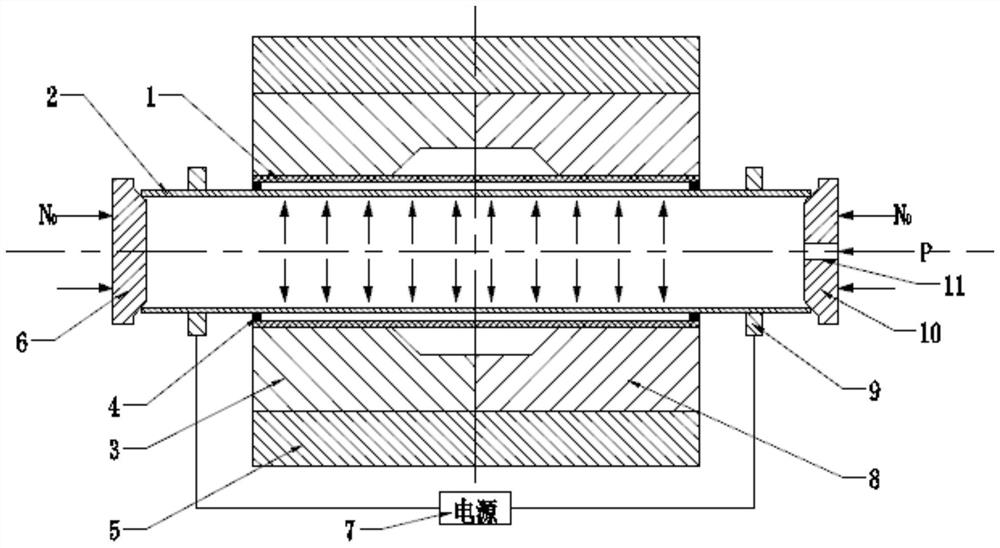

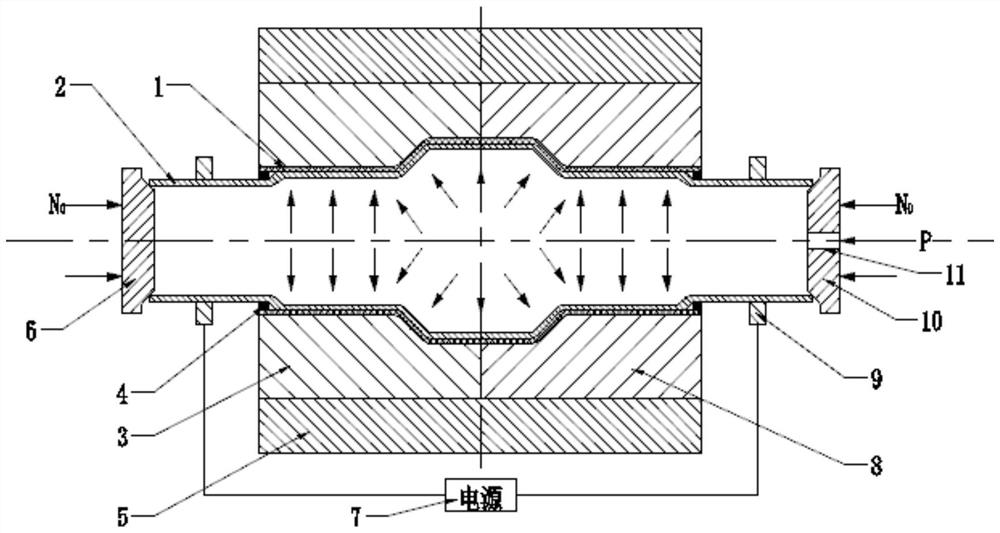

[0081] (like figure 2 , image 3 shown) includes the following steps:

[0082] Step 1. Determine the hot forming ability and material constant of the superalloy single-layer pipe and titanium alloy single-layer pipe at different temperatures according to the pipe thermal tensile test or bulge test, and determine that the plasticity of the superalloy pipe 1 and the titanium alloy pipe 2 match The forming temperature is 940°C;

[0083] Step 2, using the finite element analysis software to simulate the forming process of the two kinds of metal pipes directly thermally expanded bimetallic composite pipe fittings based on the data of step 1, and judge the formability of the GH4169 / Ti-6Al-4V bimetallic composite pipe fittings, And get the available GH4169 tube blank and Ti-6Al-4V tube blank such as outer diameter, wall thickness and other dimensional parameters and process parameters such as forming air pressure, loading path, forming time and so on.

[0084] Step 3: According t...

Embodiment approach 2

[0091] like Figure 4-Figure 7 Shown: Forming of magnesium / aluminum (AZ31 / 7475) bimetallic stepped composite pipe fittings.

Embodiment approach

[0092] This implementation mode includes the following steps:

[0093] Step 1. According to the hot tensile test or bulging test of the pipe, the hot forming ability and material constant of the AZ31 magnesium alloy single-layer pipe and the 7475 aluminum alloy single-layer pipe at different temperatures are determined, and the plasticity of the magnesium pipe 19 and the aluminum pipe 18 is matched. The forming temperature is 440°C.

[0094] Step 2. Using the finite element analysis software to simulate the forming process of the direct hot air expansion bimetal composite pipe fittings of the two metal pipes based on the data in step 1, judge the formability of the AZ31 / 7475 bimetal composite pipe fittings, and obtain Available AZ31 magnesium alloy and 7475 aluminum alloy tube blanks have dimensional parameters such as outer diameter and wall thickness, as well as process parameters such as forming air pressure, loading path, axial feed, and forming time.

[0095] Step 3: Acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com