A micro-channel heat exchanger with multi-stage micro-channels and its manufacturing method

A technology of a microchannel heat exchanger and a manufacturing method, which are applied to indirect heat exchangers, cooling/ventilation/heating transformation, modification by conduction heat transfer, etc. Multi-stage micro-grooves, complex work roll grooves, etc., achieve the effect of low equipment requirements, easy implementation and good forming quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

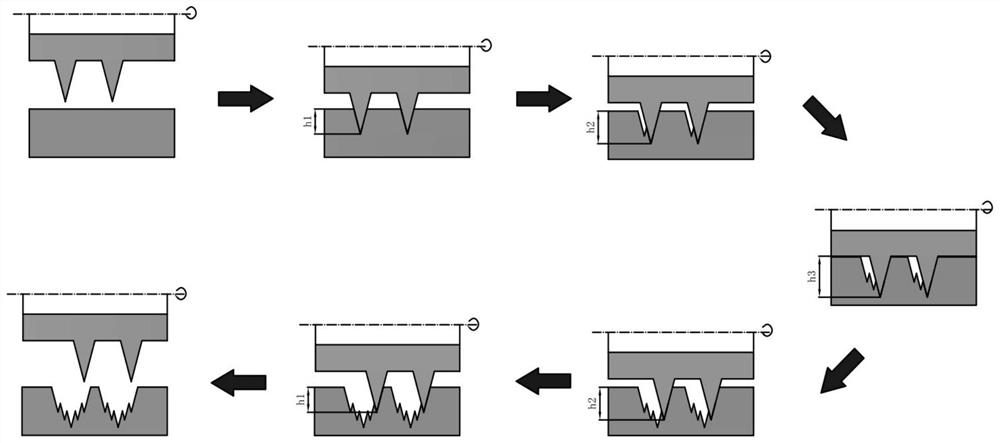

[0031] The following embodiments will further illustrate the present invention with reference to the accompanying drawings, but the present invention is not limited thereto.

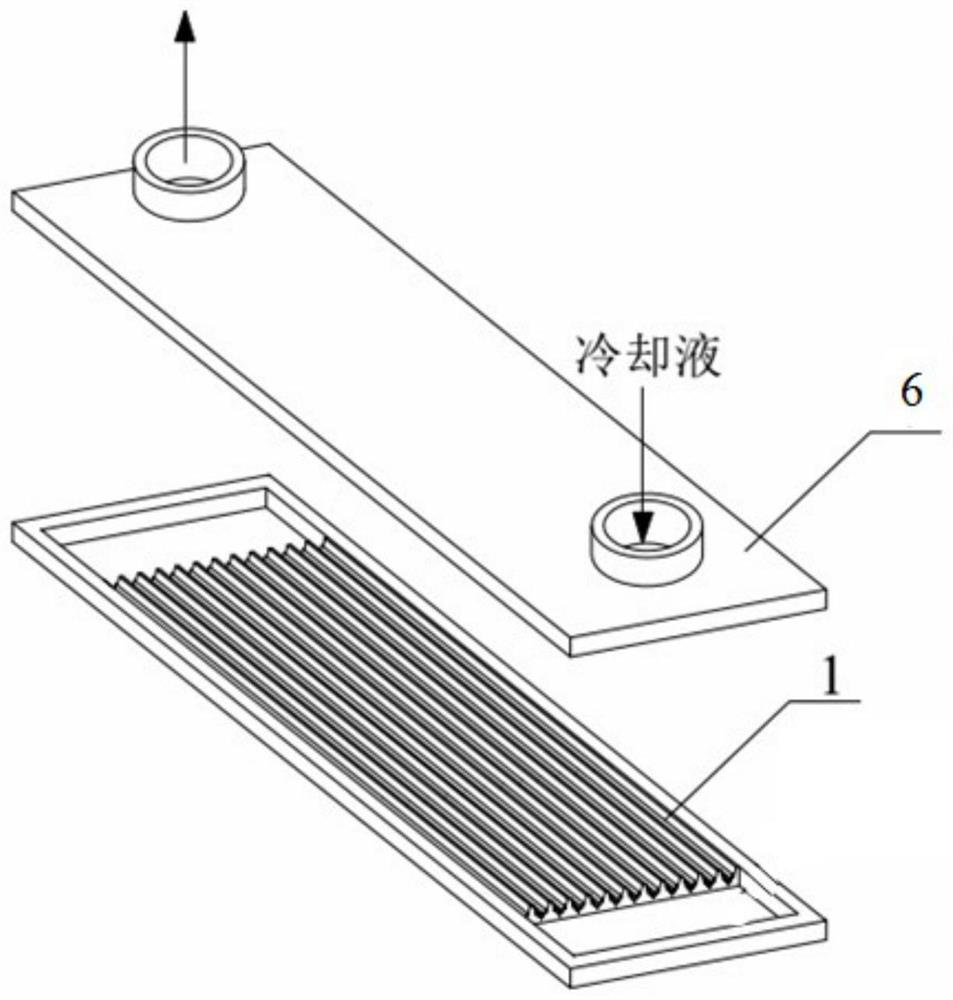

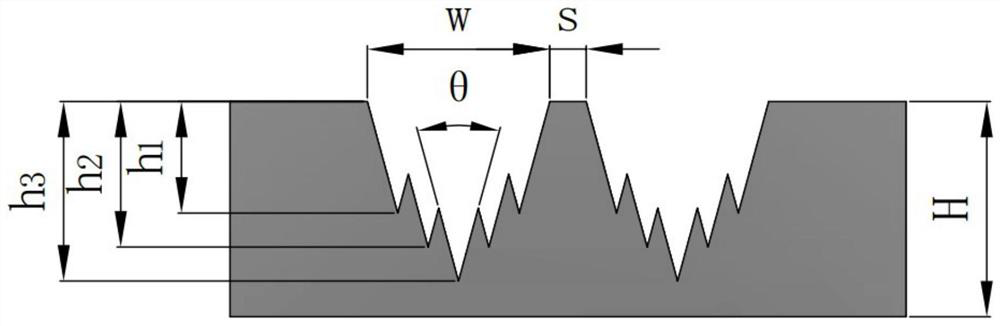

[0032] combine figure 1 , figure 2 , a microchannel heat exchanger with multi-stage microchannels of the present invention, the microchannel heat exchanger includes an upper cover plate 7, a lower cover plate 6, and a metal microchannel substrate 1. The metal microchannel substrate 1 has a plurality of microchannels arranged in parallel and spaced arrays, and the two side walls of the microchannels respectively have an array of protruding sub-microchannels, and the sub-microchannels are symmetrically distributed in the microchannels. Among the two adjacent sub-micro-channels, the bottom of the sub-micro-channel near the long axis of the micro-channel is lower than the bottom of the other sub-micro-channel, and the top of the groove is higher than the bottom of the other sub-micro-channel .

[0033] O...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com