Method for extruding and molding metal powder gelatin

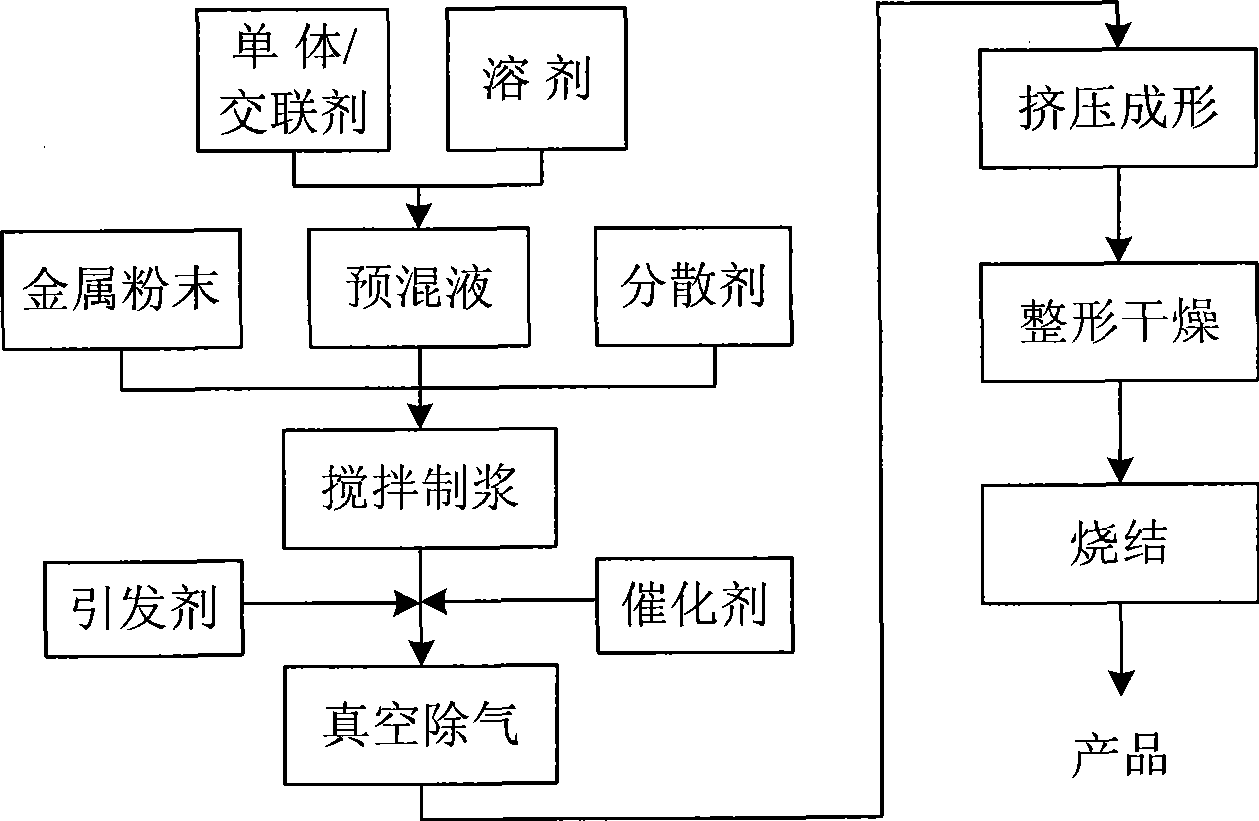

A technology of metal powder and extrusion forming, which is applied in the field of metal powder gel extrusion forming, can solve the problems of low production efficiency, tedious time-consuming, high production energy consumption, etc., and achieve the goals of reduced production cost, excellent comprehensive performance and improved strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the gel extrusion molding of YG6 cemented carbide rod

[0021] 1. Weigh 1.5kg of YG6 cemented carbide powder, add 56ml of hydroxyethyl methacrylate and 56ml of toluene into the organic solution, mix and stir evenly;

[0022] 2. Weigh 4g of Solsperse-6000 hyperdispersant and add it to the slurry in the first step, and stir evenly to make a high-concentration suspension slurry;

[0023] 3. Measure 0.4g of catalyst benzoyl peroxide and 3.6ml of initiator dimethylaniline into the high-concentration suspension slurry in the second step, stir evenly and degas under vacuum for 3 minutes;

[0024] 4. Inject the vacuum-degassed slurry in step 3 into the extrusion die, close the extrusion port of the extrusion die, apply a pressure of 1.2 MPa under vacuum to pre-press the billet, and use pressure to induce solidification and densification to make it densified and Preform;

[0025] 5. Open the extrusion port of the extrusion equipment, set the pressure of 3MPa and ...

Embodiment 2

[0028] Example 2: Gel extrusion of titanium-cobalt alloy parts

[0029] 1. Weigh 1.6kg of titanium powder and 50g of cobalt powder, and mix the powder in a planetary ball mill for 2 hours to make a mixed powder;

[0030] 2. Dissolve 135g of monomeric acrylamide and 0.1g of cross-linking agent N,N'-methylenebisacrylamide in 750ml of deionized water, add the mixed powder in step 1, and stir evenly;

[0031] 3. Measure 3.5ml of dispersant oleic acid and add it to the solution in the second step, stir evenly to make a slurry;

[0032] 4. Exhaust the slurry in step 3 for 15 minutes under high vacuum;

[0033] 5. Measure 3.5ml of catalyst N, N, N', N'-tetramethylethylenediamine and 4ml of initiator ammonium persulfate (to ensure sufficient injection molding time), add to the slurry in step 4, stir evenly, Simultaneously vacuum degassing.

[0034] 6. Inject the slurry into the extrusion die under vacuum, close the extrusion port of the extrusion die, apply 0.8MPa pressure under va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com