Patents

Literature

40results about How to "Easy to compact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

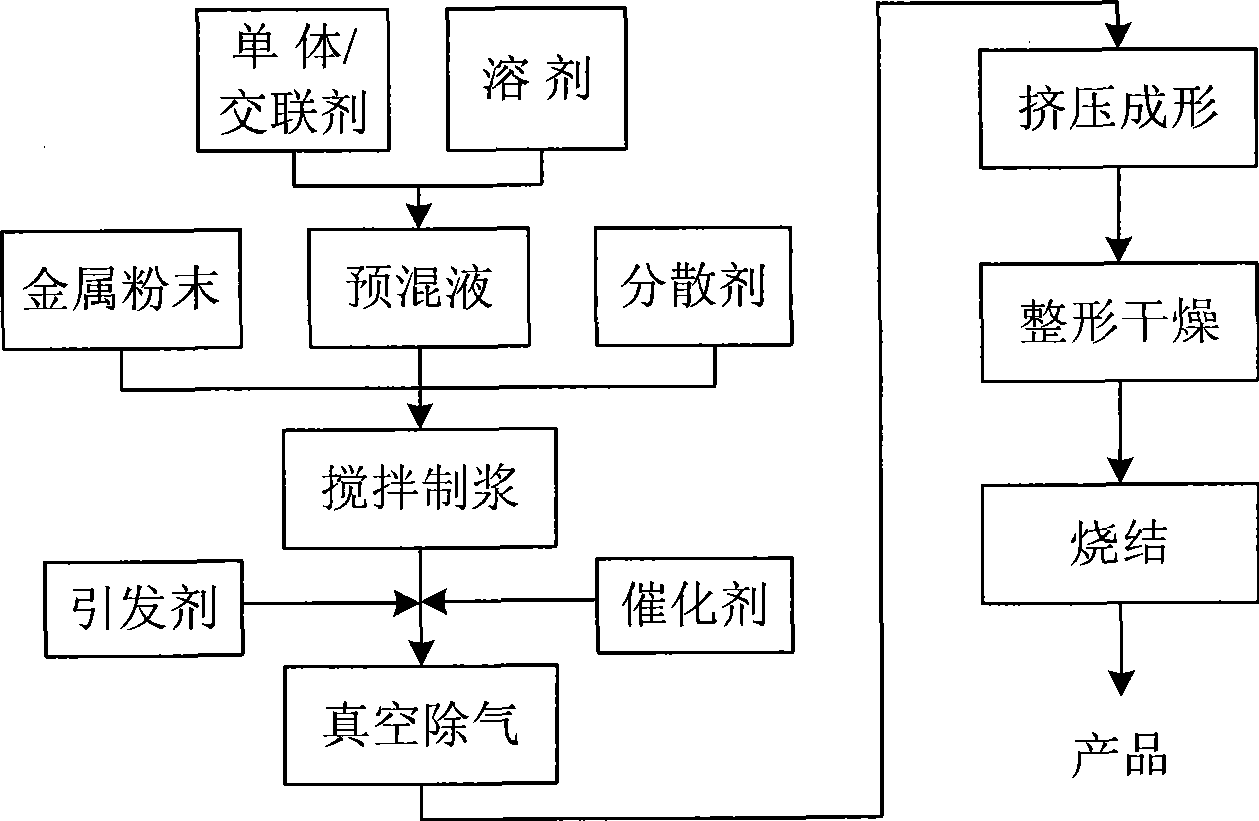

Method for extruding and molding metal powder gelatin

The invention relates to a method for extruding and molding metal powder gelatin, which belongs to the field of metal part preparation in powder metallurgic production technology. The method is characterized by comprising the steps: firstly, premixed liquid with finite concentration is prepared; then, metal powder is added into the premixed liquid to prepare a stable gelatin system; the stable gelatin system is extruded and molded to prepare a blank body; and finally, the blank body is sintered into a part. The invention breaks through the traditional molding technology and can prepare metal products with large sizes and complicated shapes. Compared with the pressure molding, the invention solves the problems of complicated shape limitation and energy consumption caused by overlarge pressure needed by molding, and greatly improves the molding condition. Compared with the injection molding and the hot pressure casting molding which need to be added with a lot of organic binding agents, the method does not need a special degreasing step, has simple technology and can greatly reduce the production cost.

Owner:UNIV OF SCI & TECH BEIJING

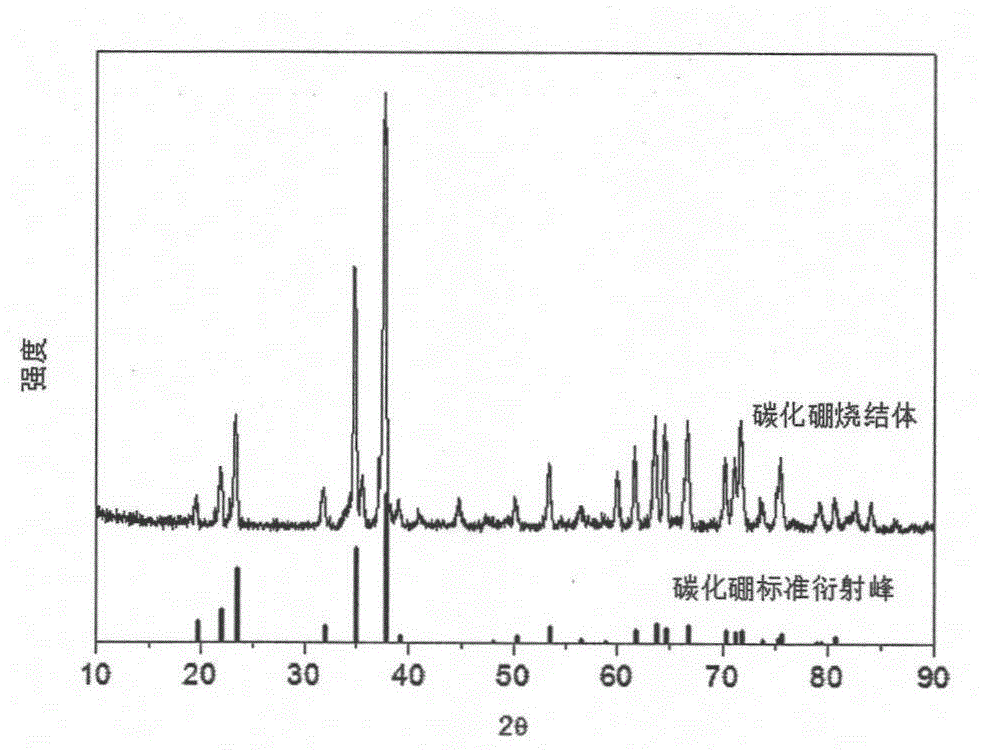

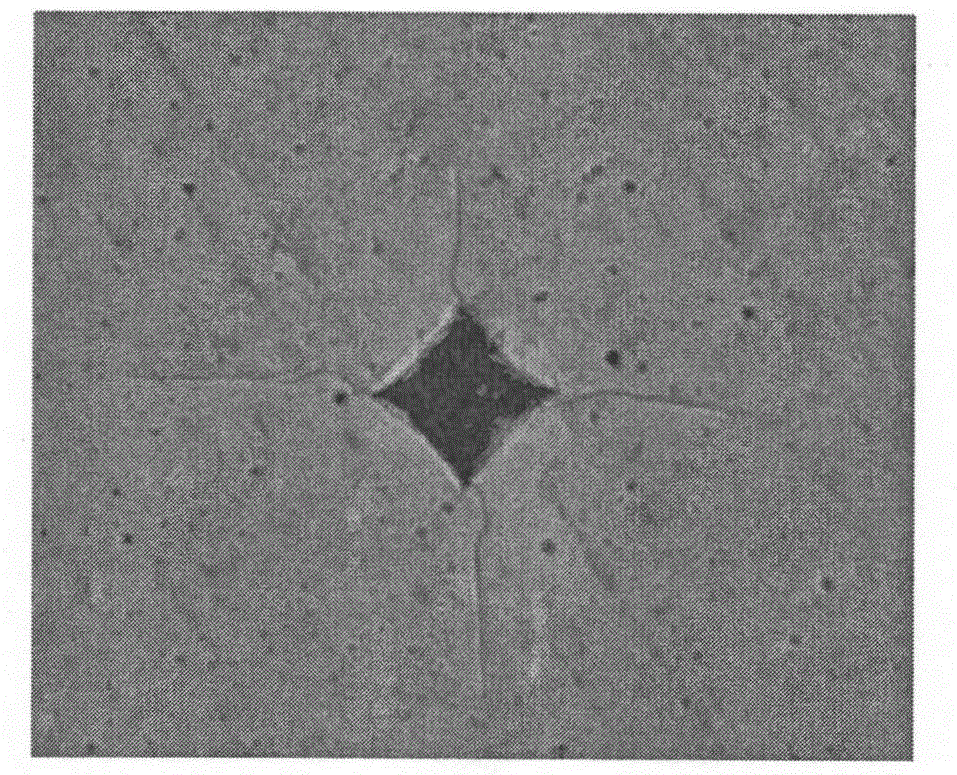

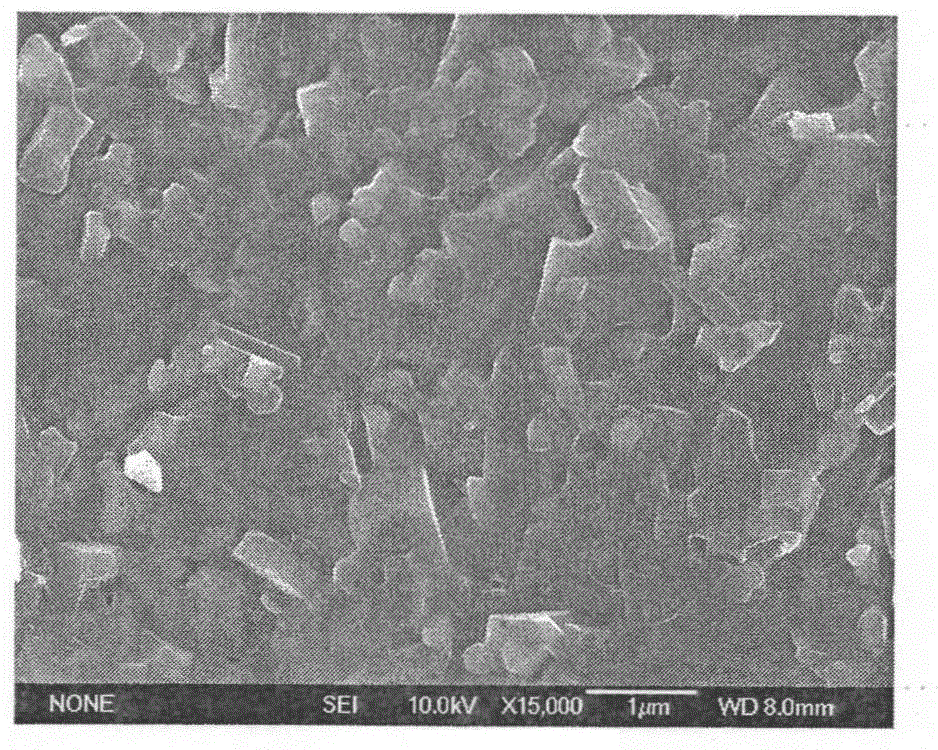

Method for preparing boron carbide ceramic material through low-temperature fast sintering

The invention provides a method for preparing a boron carbide ceramic material through low-temperature fast sintering. The method is characterized in comprising the following steps: a hard template is adopted as a structure-directing agent; porous boron carbide powder is synthesized with a nano-scale casting method; the porous boron carbide powder is added into a graphite mold, and the mold is placed into a chamber of a spark plasma sintering furnace; sintering is carried out under vacuum and in an inert or reductive atmosphere; after sintering, the product is cooled to room temperature with the furnace; and grinding is carried out, such that the boron carbide ceramic material is obtained. According to the low-temperature fast sintering boron carbide ceramic preparation method, the porous boron carbide powder is adopted as a sintering raw material. The porous boron carbide powder has the advantages of large specific surface area, high surface energy, good sintering activity, and the like, such that the powder is easier to be densified during sintering. Also, pressurization can be realized during a sintering process with a spark plasma sintering technology, such that pore collapse and densification of the porous boron carbide powder can be facilitated, and thus the boron carbide ceramic can be obtained under a relatively low temperature. The technology has advantages of fast temperature increasing speed, short sintering time, and the like. The method is an energy-saving and environment-friendly preparation method, and has good application prospect.

Owner:DONGHUA UNIV +1

Sintering method of ZrB2-SiC superhigh temperature ceramics

The invention discloses a sintering method of ZrB2-SiC superhigh temperature ceramics and relates to a sintering method of superhigh temperature ceramics. The invention aims at solving the problems of high sintering temperature and high energy consumption in the existing process of preparing ZrB2-SiC superhigh temperature ceramics. The method comprises the following steps of: weighing ZrB2 powder, SiC powder and citric acid; ball-milling and mixing to obtain slurry; drying the slurry to obtain composite powder; and performing vacuum sintering at the temperature of 1500 to 1600 DEG C to obtain the ZrB2-SiC superhigh temperature ceramics. According to the sintering method of the ZrB2-SiC superhigh temperature ceramics provided by the invention, the sintering temperature is lowered by about 300 DEG C, thus energy consumption is reduced. The density of the obtained product can achieve 98%, thus the requirement of being used in oxygen-containing atmosphere at the temperature of 1800 DEG C is met. The method is used for preparing the ZrB2-SiC superhigh temperature ceramics.

Owner:HARBIN INST OF TECH

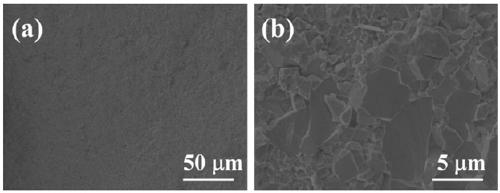

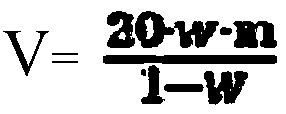

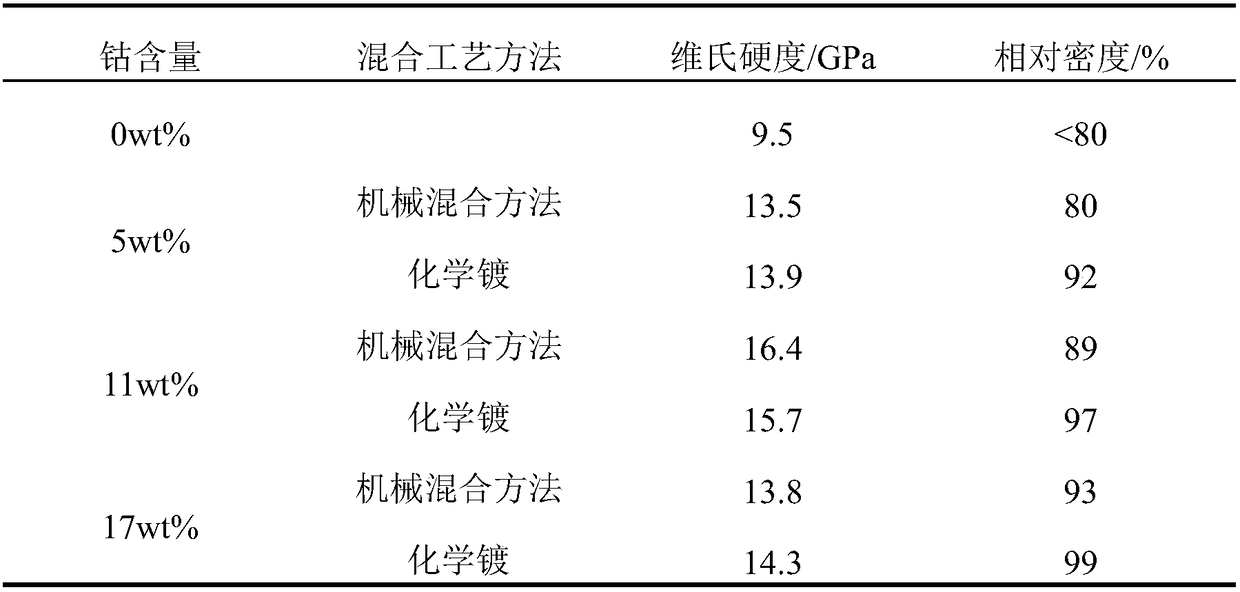

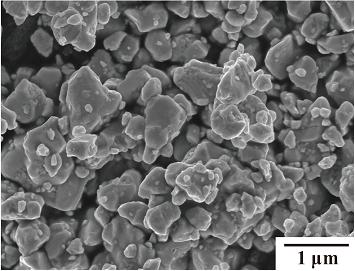

Preparation method of high-compactness WC/Co composite material hard alloys

InactiveCN109338197AHigh densityEvenly heatedTransportation and packagingMetal-working apparatusMaterials preparationCobalt salt

The invention belongs to the technical field of ceramic material preparation, and in particular, relates to a preparation method of high-compactness WC / Co composite material hard alloys. Firstly, after carbide powder is activated through cobalt salt, a layer of uniform metal cobalt is coated on the surface of the carbide powder by adopting a chemical plating method; and then, the discharge plasmasintering is performed on the carbide powder, coated with the cobalt layer on the surface, to prepare the WC / Co composite material hard alloys. The preparation method is simple in operation in the preparation process, short in preparation period, low in pollution and low in cost; and prepared composite materials are high in compactness, and can serve as magnetic materials and alloy materials to beapplied to such fields as mine tools and constructions.

Owner:HOHAI UNIV

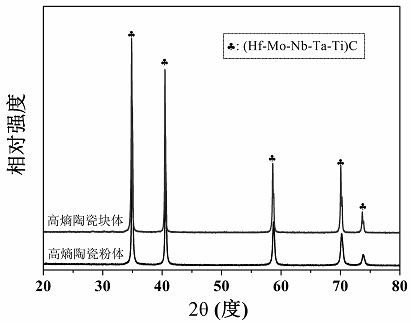

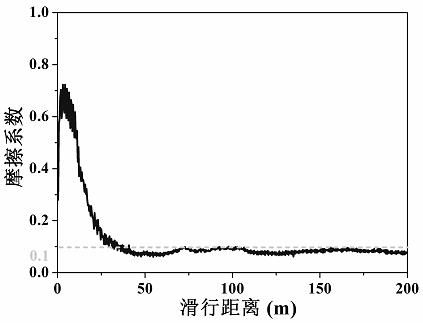

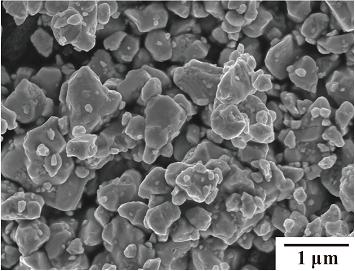

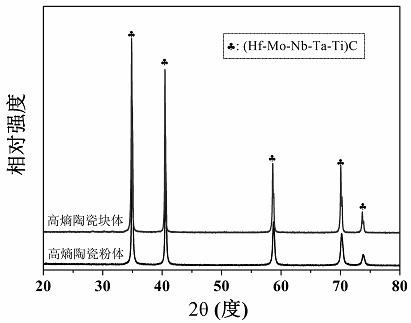

High-entropy ceramic material with excellent tribological properties and preparation method thereof

The invention relates to a high-entropy ceramic material with excellent tribological properties. The material is block-shaped, the composition of the material is (Hf-Mo-Nb-Ta-Ti-) C, the ceramic material is prepared from the following raw materials in percentage by mass: 1.2 to 21.9 percent of HfO2, 14.5 to 15.0 percent of MoO3, 13.4 to 13.8 percent of Nb2O5, 2.3 to 23.0 percent of Ta2O5, 8.0 to 8.3 percent of TiO2 and 18.0 to 20.6 percent of graphite powder. Meanwhile, the invention further discloses a preparation method of the high-entropy ceramic material. The ceramic material provided by the invention has good tribological properties and mechanical properties in a wide temperature range, and can realize lubrication at a specific temperature, thus realizing structural / lubricating function integrated design of the ceramic material.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

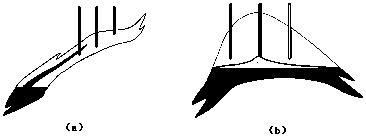

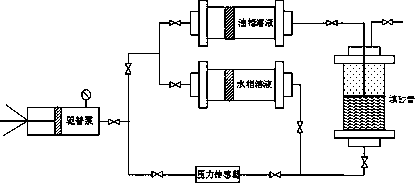

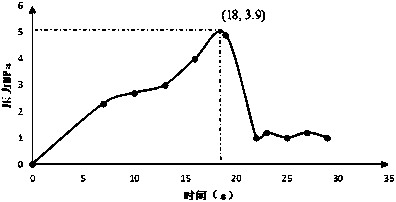

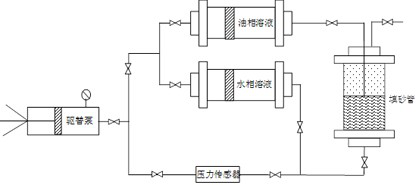

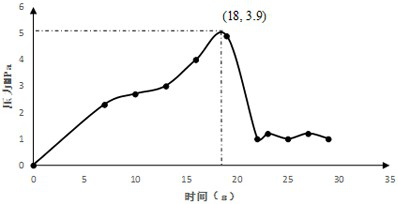

Water plugging method of establishing large-area chemical partition plate in gas-water interface of water-bearing gas reservoir

ActiveCN110685637AHigh strengthThickness is easy to controlDrilling compositionSealing/packingPhysical chemistryOil phase

The invention relates to a water plugging method of establishing a large-area chemical partition plate in a gas-water interface of a water-bearing gas reservoir. The method comprises the following steps that (1) an aqueous-phase solution is injected into a gas-water interface of a gas reservoir and is transported to a water layer under the effect of diffusion and dispersion; (2) an oil-phase solution is injected into the gas-water interface of the gas reservoir and is spread in the gas-water interface to replace the gas-water interface with an oil-water interface; (3) an aqueous-phase monomeris diffused towards the oil layer, and a region, close to an oil phase, of the oil-water interface generates polymerization reaction with an oil-phase monomer to form a microporous polymer interlayer;and (4) formation water permeates into the polymer interlayer under the effect of a pressure difference, and mineral ions and impurities continuously deposit to form scales on the polymer interlayerto form a water-impermeable polymer interlayer. The method is reliable in principle and simple and convenient to operate, can effectively solve the problems of small plugging range, low plugging strength and the like of a common water plugging system in the process of water invasion treatment of the edge-bottom water-bearing gas reservoir and has a great practical significance of efficient miningthe edge-bottom water-bearing gas reservoir.

Owner:SOUTHWEST PETROLEUM UNIV

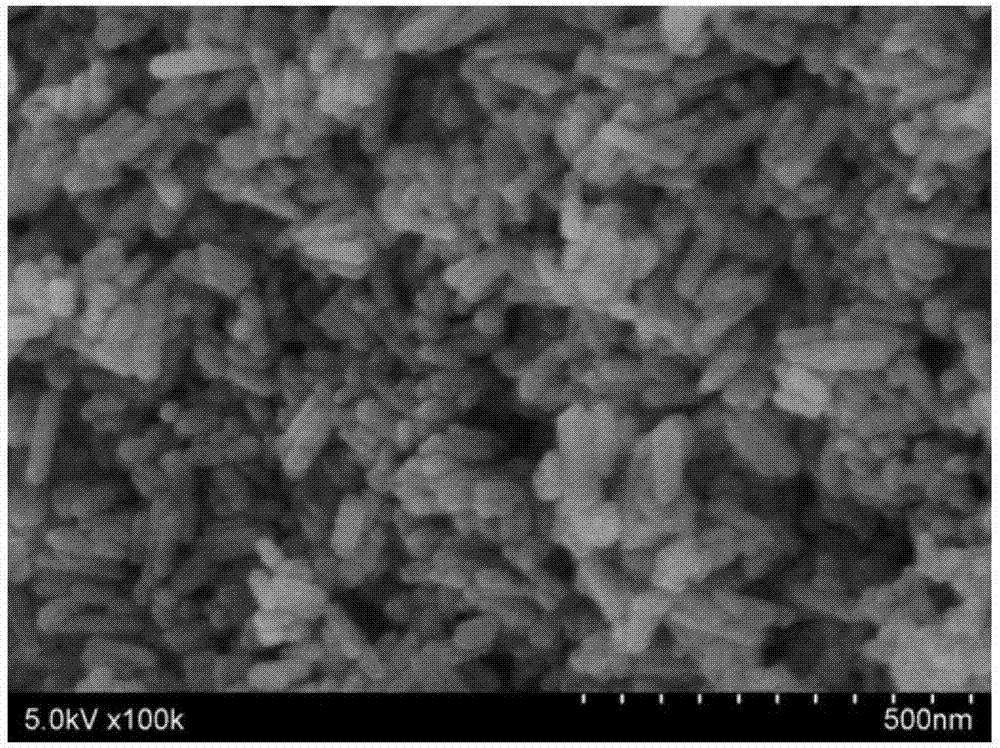

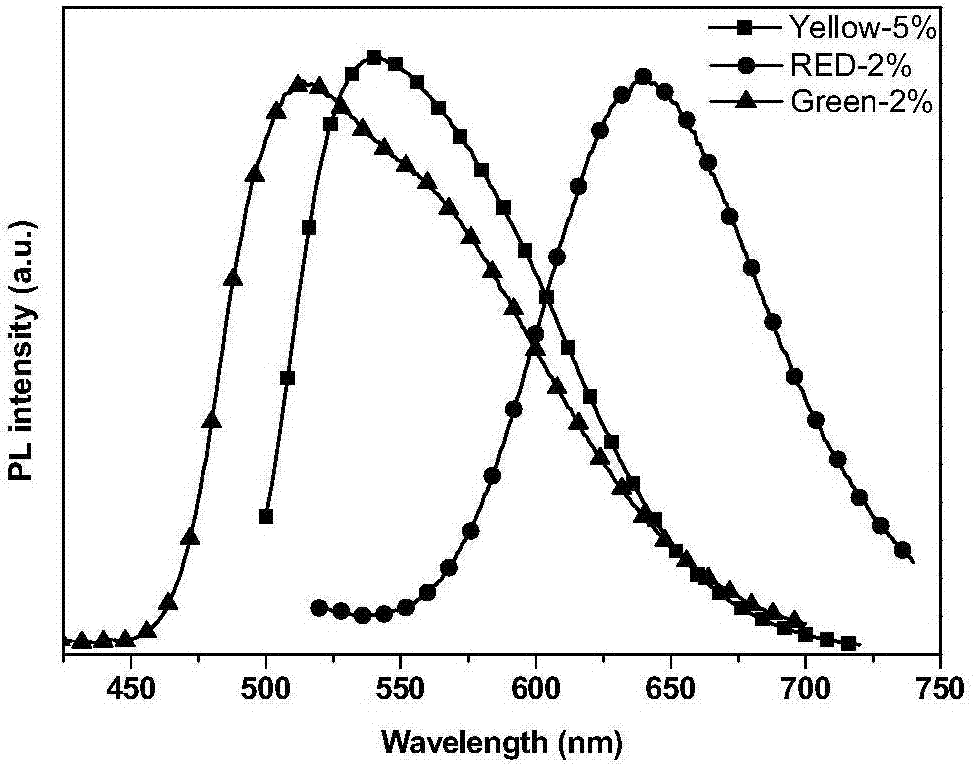

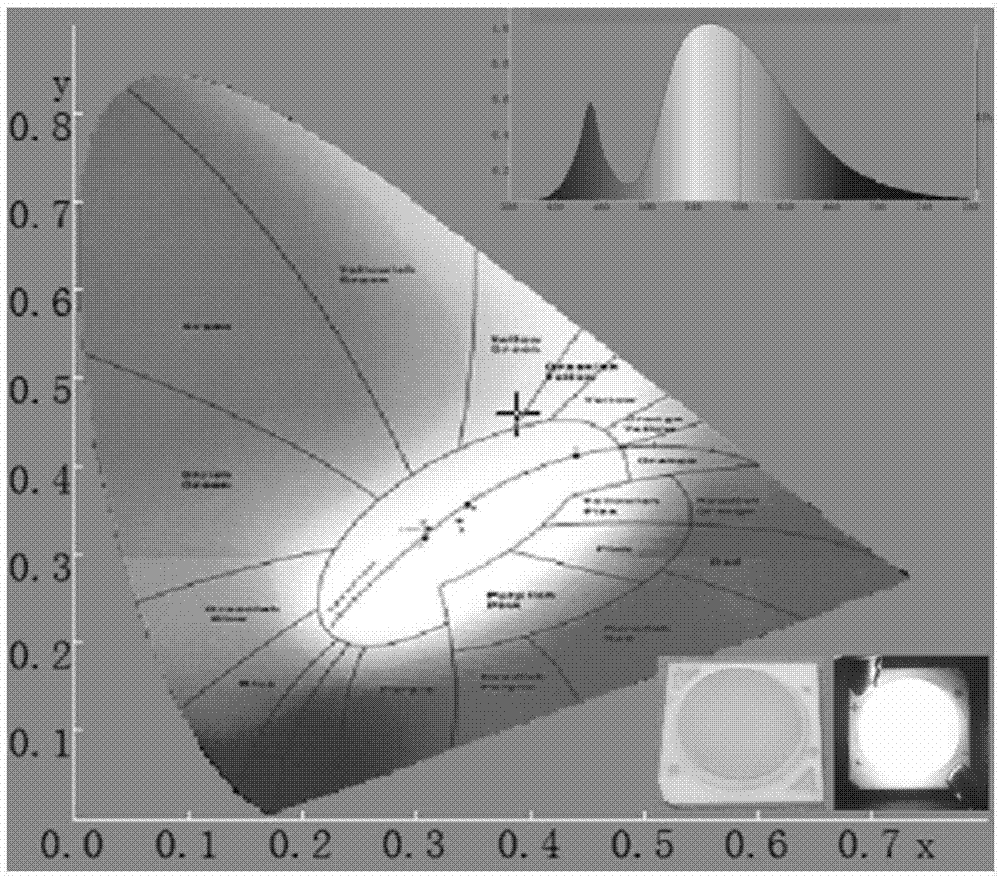

Hydroxyapatite-based fluorescent ceramic material and preparation method thereof

The invention relates to a hydroxyapatite-based fluorescent ceramic material and a preparation method thereof. The hydroxyapatite-based fluorescent ceramic material is prepared from the following raw materials in percentages by weight: 95-99% of hydroxyapatite matrix and 1-5% of fluorescent powder. The preparation method comprises the steps of mixing the hydroxyapatite matrix with the fluorescent powder evenly; loading the mixed raw materials into a graphite mold, putting the graphite mold into a spark plasma sintering furnace, sintering in a vacuum environment to obtain transparent ceramic; and finally grinding and polishing to obtain the hydroxyapatite-based fluorescent ceramic material. By adopting hydroxyapatite nano powder, the sintering temperature of the fluorescent ceramic is effectively reduced, the sintering time of the fluorescent ceramic is effectively shortened, the luminescence characteristic of fluorescent powder can be effectively reserved; meanwhile, by adopting the ceramic as the matrix, the thermal conductivity of an LED packaging material can be significantly improved, and the heat resistance and the stability of the fluorescent ceramic material are effectively improved; the preparation technology is simple and convenient; and the hydroxyapatite-based fluorescent ceramic material can be directly used as a packaging material to replace a traditional organic polymer or silica gel packaging material, and has a good application prospect.

Owner:台州优瑞精工科技有限公司

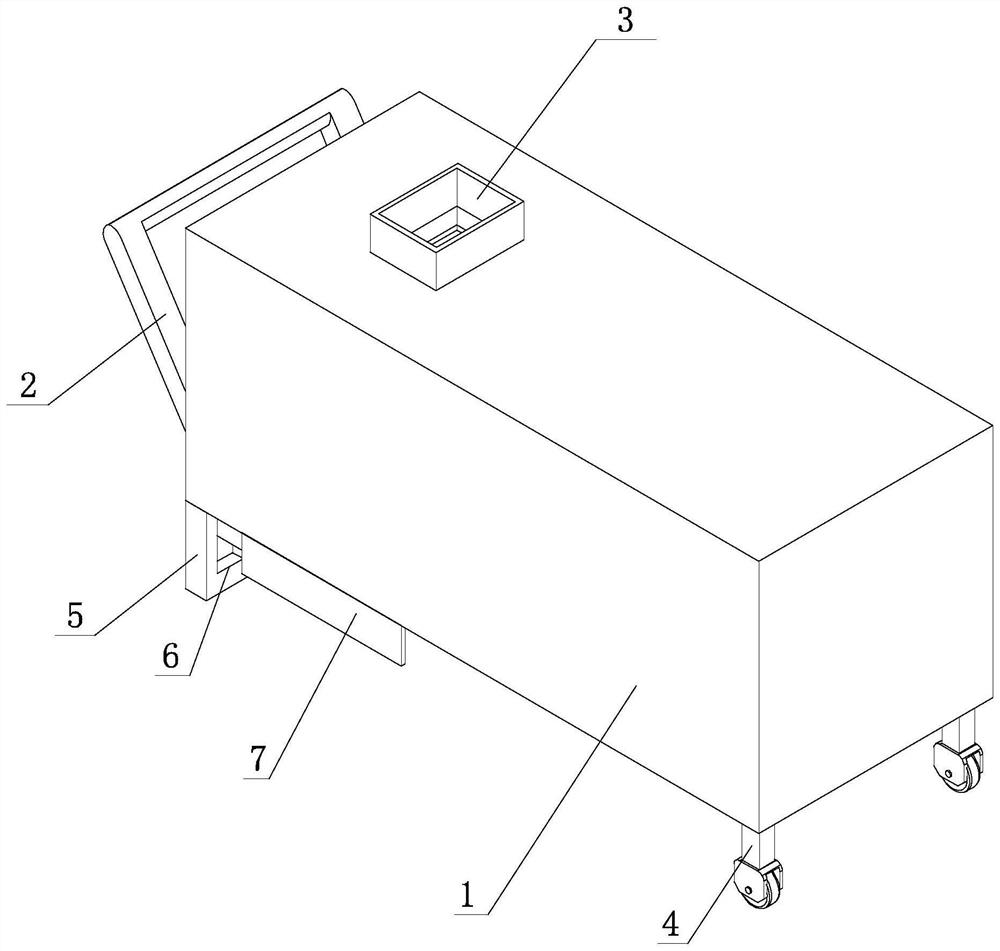

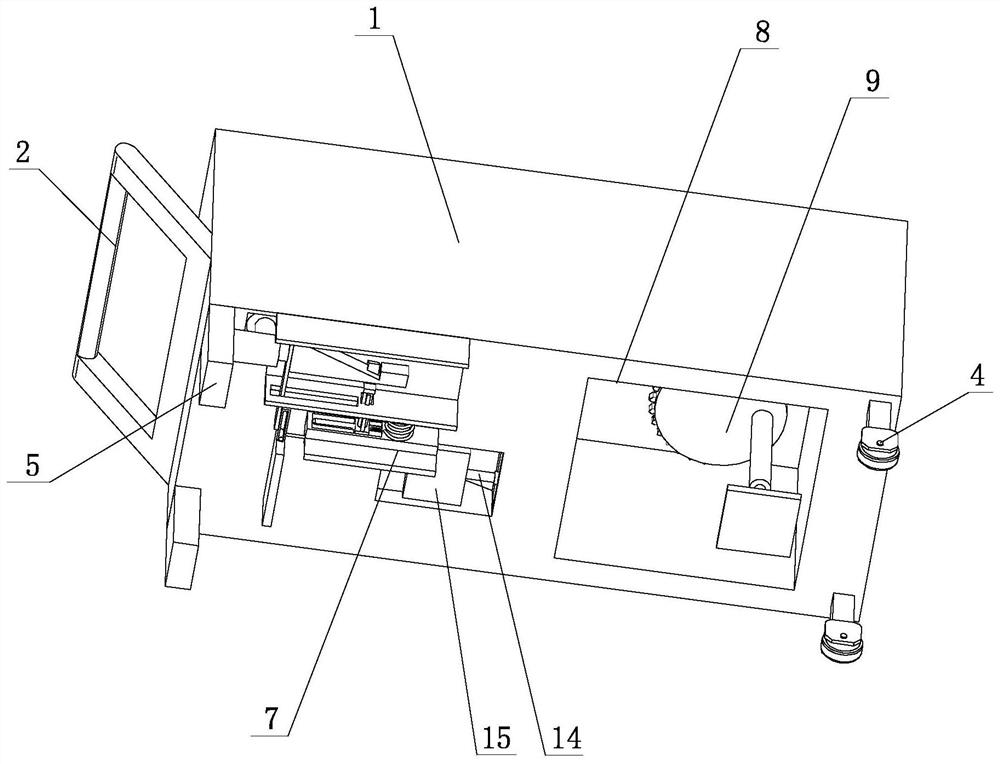

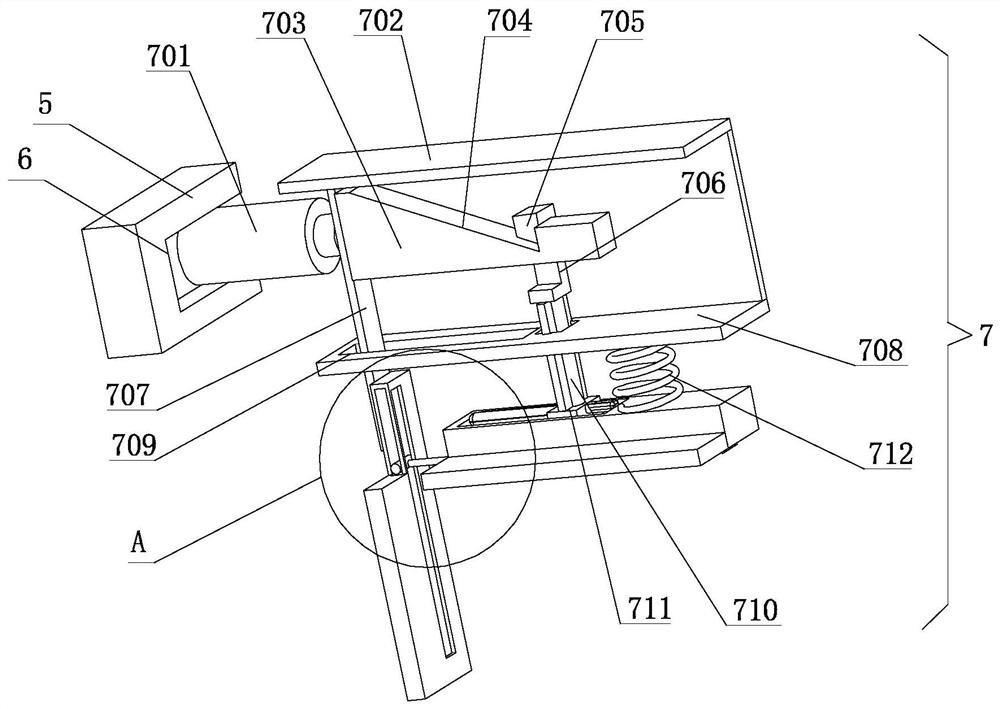

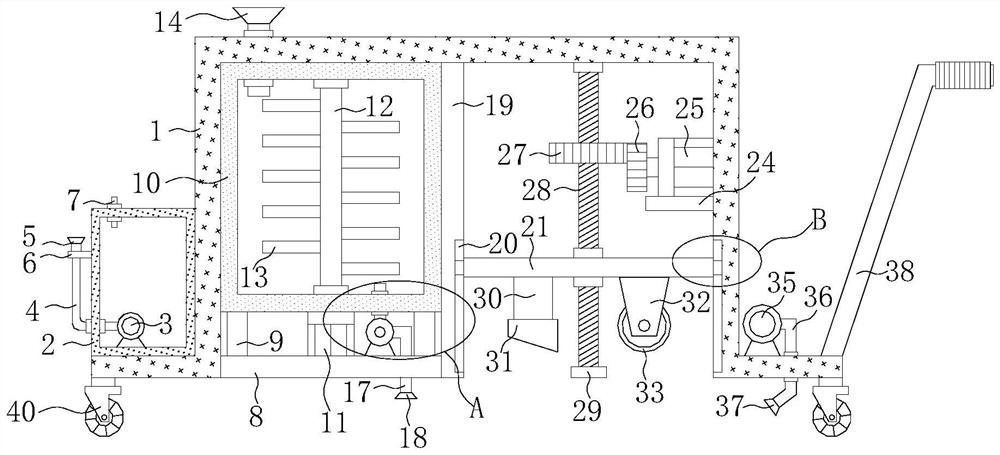

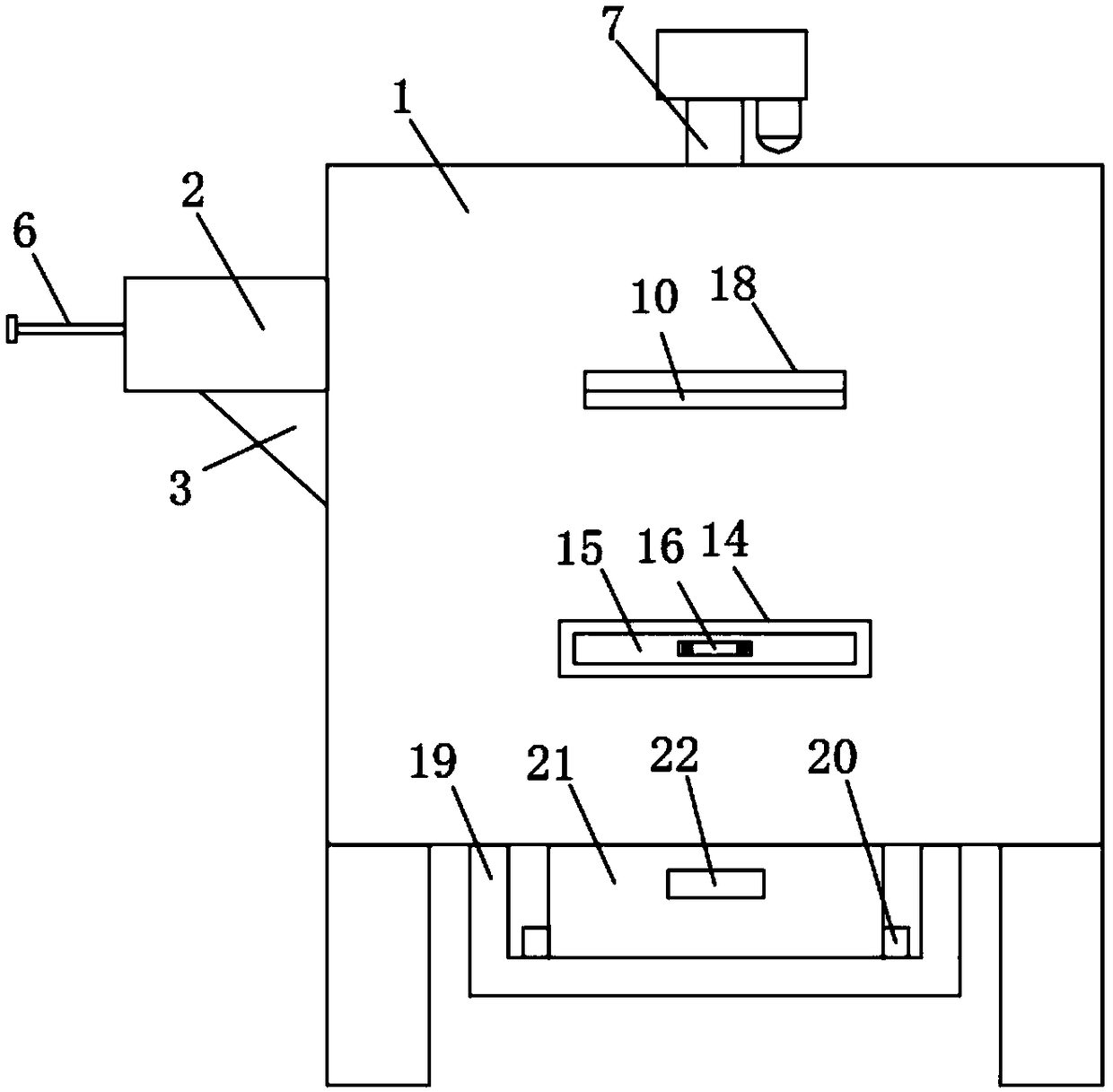

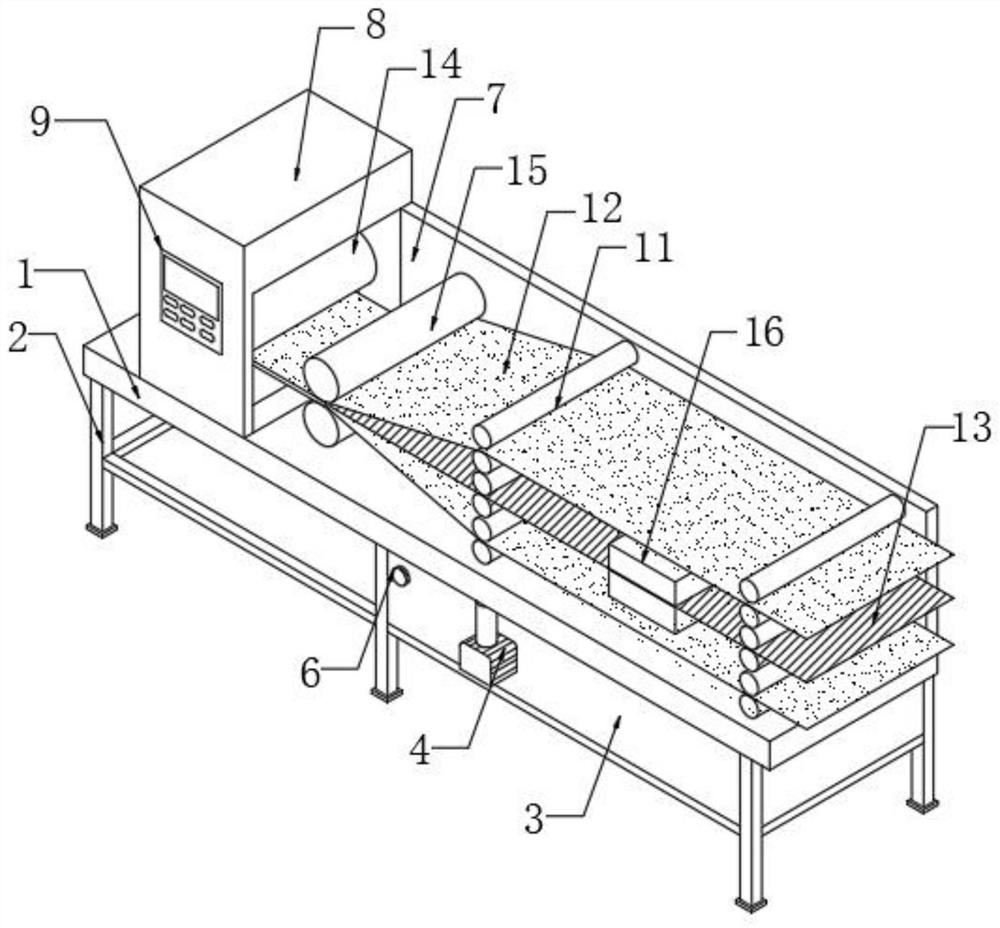

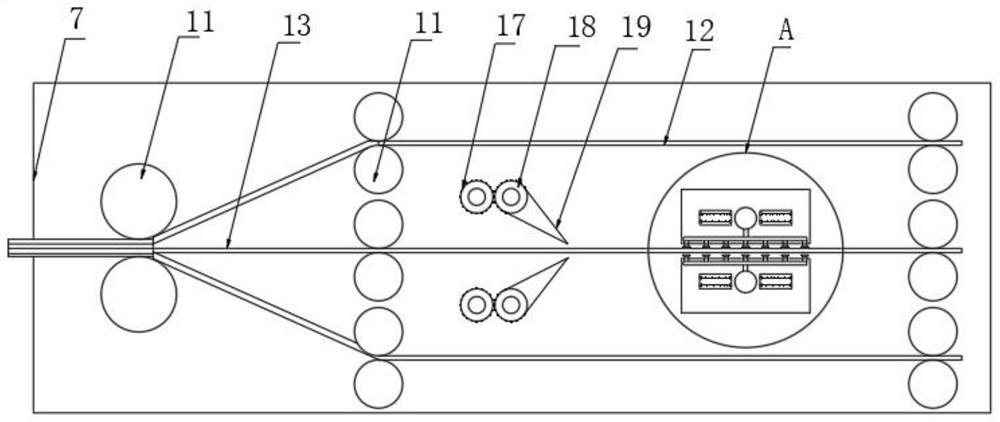

Brick paving equipment for municipal engineering

The brick paving equipment for municipal engineering. The equipment comprises an equipment body, an auxiliary bulldozing device and a comprehensive compaction device, wherein a push handle is fixedlyconnected to the outer wall of one side of the equipment body, a feeding hopper is fixedly installed on the outer wall of the top of the equipment body, and two rolling wheels are fixedly connected tothe outer wall of the bottom of the equipment body. Through the arrangement of the auxiliary bulldozing device, when two hydraulic cylinders are started at the same time, a driving air cylinder and an attaching plate move downwards at the same time, and when the auxiliary bulldozing device moves to one side of a laid brick, the driving air cylinder is started, a moving block and a connecting plate move rightwards at the same time, and the inner wall of a wedge-shaped groove slides on the inner wall of a trapezoidal groove; when the connecting plate moves, the second push plate is driven to move towards the side close to the first push plate, the first push plate and the second push plate gradually get close to each other to conduct bulldozing treatment on the newly laid bricks, the distance between the bricks and the last brick is made to be closer, gaps are small, and loosening between the bricks is avoided; the laying effect is better.

Owner:岑颖明

Pavement patching device for highway machinery

InactiveCN111996888APoor qualityEasy to useRoads maintainenceAgricultural engineeringStructural engineering

The invention discloses a pavement patching device for highway machinery, and relates to the technical field of highway machinery. The pavement patching device for the highway machinery comprises a frame. A water tank is fixedly mounted at the top of the frame, a fixed base is fixedly mounted on the inner wall of one side of the frame, a stirring box is arranged above the fixed base, and supporting legs are fixedly mounted at the top of the fixed base. According to the pavement patching device for highway machinery, a water tank, a water pump, a hose, a nozzle, a fixing groove and an water inlet pipe are used cooperatively; the hose and the spray head are clamped and mounted on the fixing groove; a user can take the spray head to spray water to clean the ground and cracks needing to be repaired; and the handheld spray head is convenient for a user to use, and a situation that the repaired ground is not cleaned up so that the repairing of the pavement is influenced, the asphalt concreteis not in full contact with a repairing area, a repairing effect of the pavement is influenced, and the quality of the repaired pavement is poor is avoided.

Owner:湖州前锋机械配件厂

Preparation method of molybdenum-tungsten alloy sputtering target material

InactiveCN111254396AHigh sintering activityEasy to densifyVacuum evaporation coatingSputtering coatingGrindingTungsten trioxide

The invention provides a preparation method of a molybdenum-tungsten alloy sputtering target material. The preparation method includes the following steps that step 1, a certain proportion of molybdenum powder, tungsten powder and tungsten trioxide powder are taken, ball milling and mixing are performed under a protective atmosphere, and the materials are mixed uniformly; step 2, the uniformly mixed materials are subjected to powder filling in a rubber sleeve, and then cold isostatic pressing forming is performed to obtain a blank body; step 3, the blank body is sintered in two stages under ahydrogen protective atmosphere to obtain a sintered blank; step 4, the sintered blank is heated under the protection of hydrogen or argon, then hot rolling and leveling are performed, and finally, annealing is performed under hydrogen or vacuum to obtain a molybdenum-tungsten alloy slab; and step 5, the molybdenum-tungsten alloy slab is subjected to grinding and other machining as required to obtain a molybdenum-tungsten alloy product. The preparation method is simple in preparation step, the purity and relative density of the prepared molybdenum-tungsten alloy sputtering target material bothmeet the usage requirements in the TFT-LCD display film-coating field, the production cost is low, the product size is wide, and industrial mass production is convenient.

Owner:LUOYANG SIFON ELECTRONICS

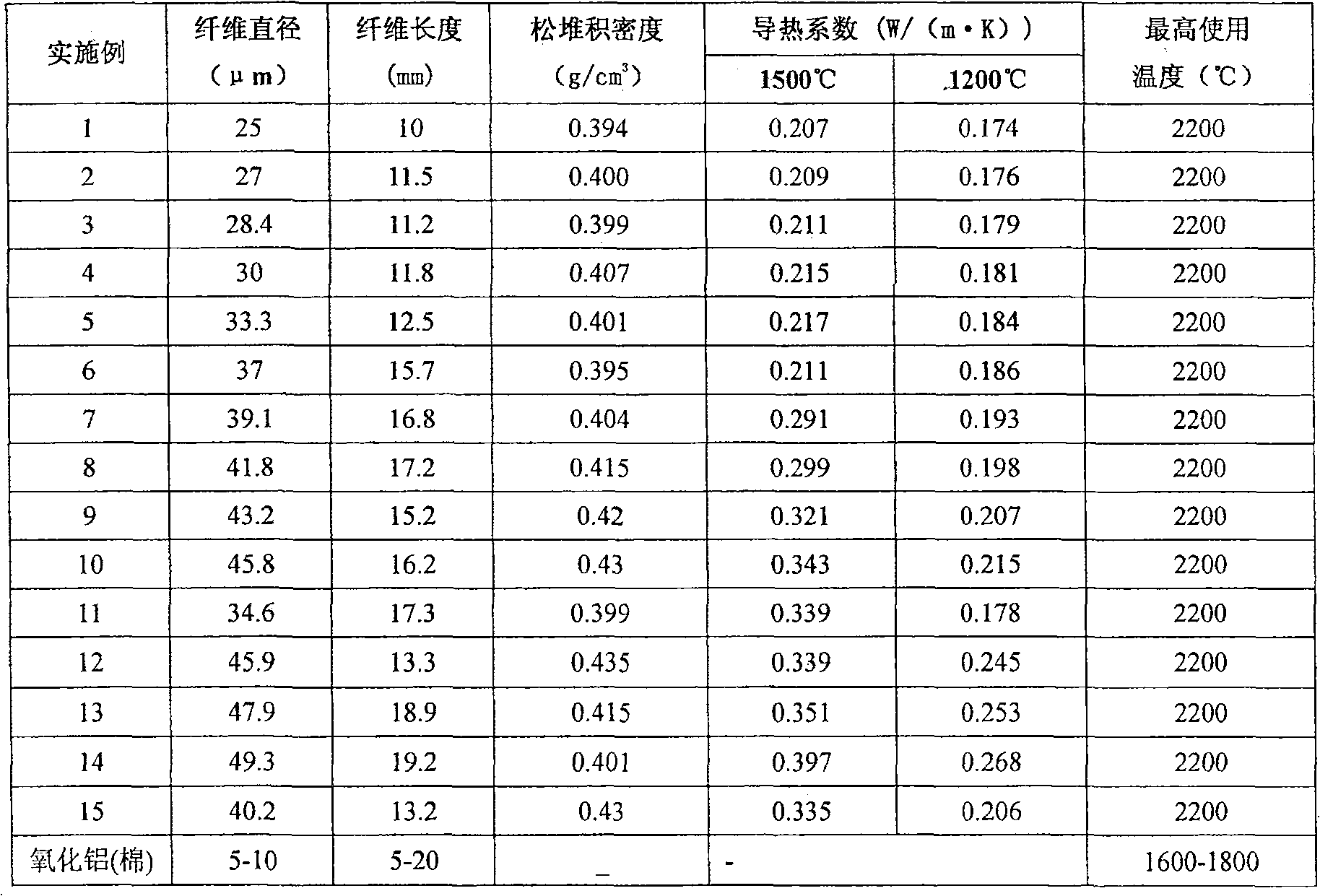

Method for producing zirconium oxide fibre and the produced zirconium oxide fibre

The invention discloses a preparation method of polycrystalline zirconia fibre. The method comprises the steps as follows: mixing ultrafine polycrystalline zirconia powder and dispersant with water to form slurry, adopting an extrude-concentration method to mold, preparing zirconia fibre precursor through extruding concentration bath in the hole with the diameter of 50 to 30 um, and sintering theprecursor to gain the zirconia fibre. The invention adopts ultrafine zirconia powder and innocuity water dispersant to make the water-based zirconia slurry with the solid phase content being about 35to 50 vol percent, wherein, the content of zirconia in the slurry is high. Through directly preparing the zirconia fibre precursor out of the slurry, the precursor is easy to be densified in the sintering process. The method is a rather perfect zirconia fibre preparation method. The prepared zirconia fibre has the advantages of small granularity, dense structure and good heat-insulation and preservation performance.

Owner:CHINA BUILDING MATERIALS ACAD

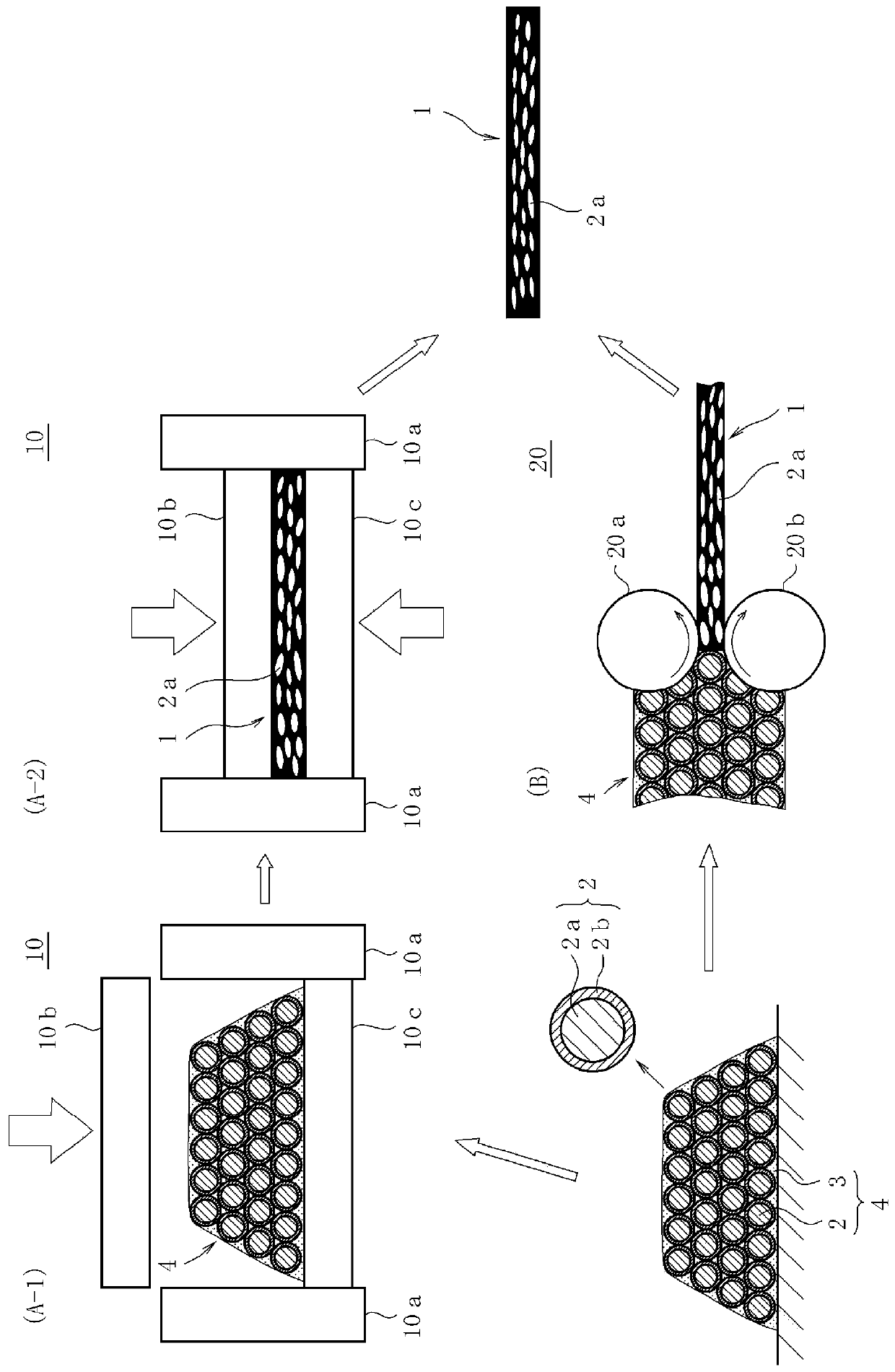

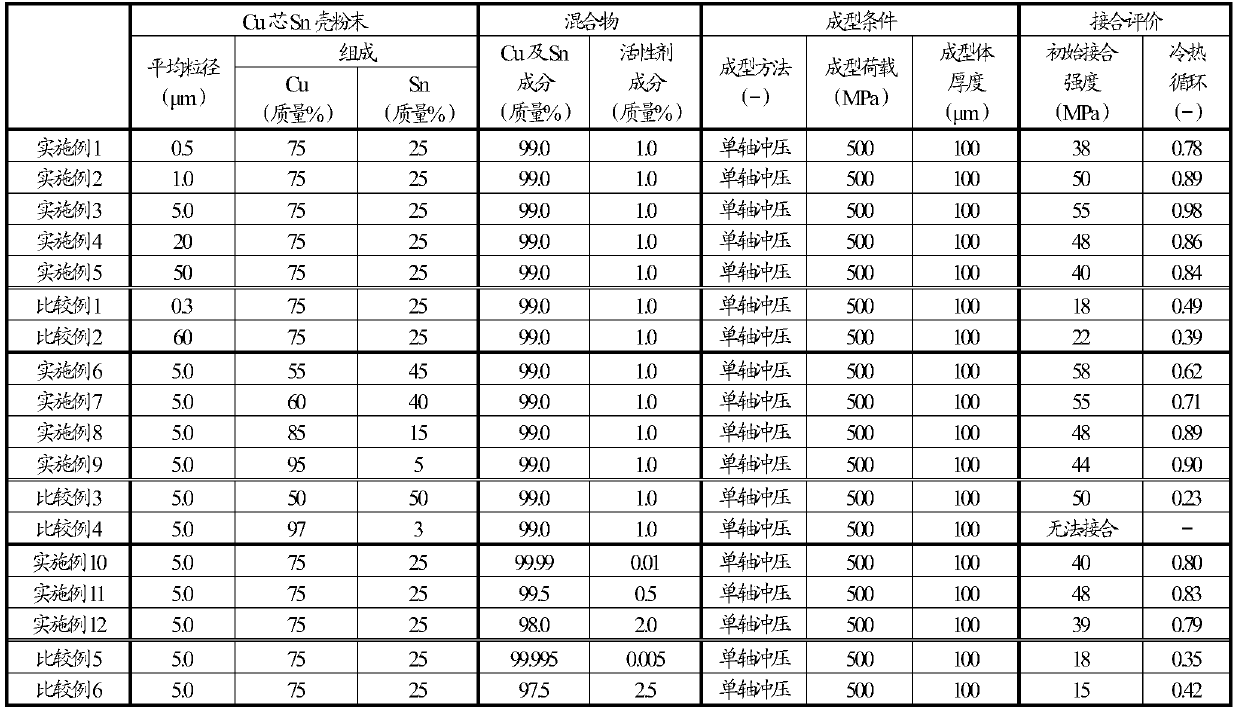

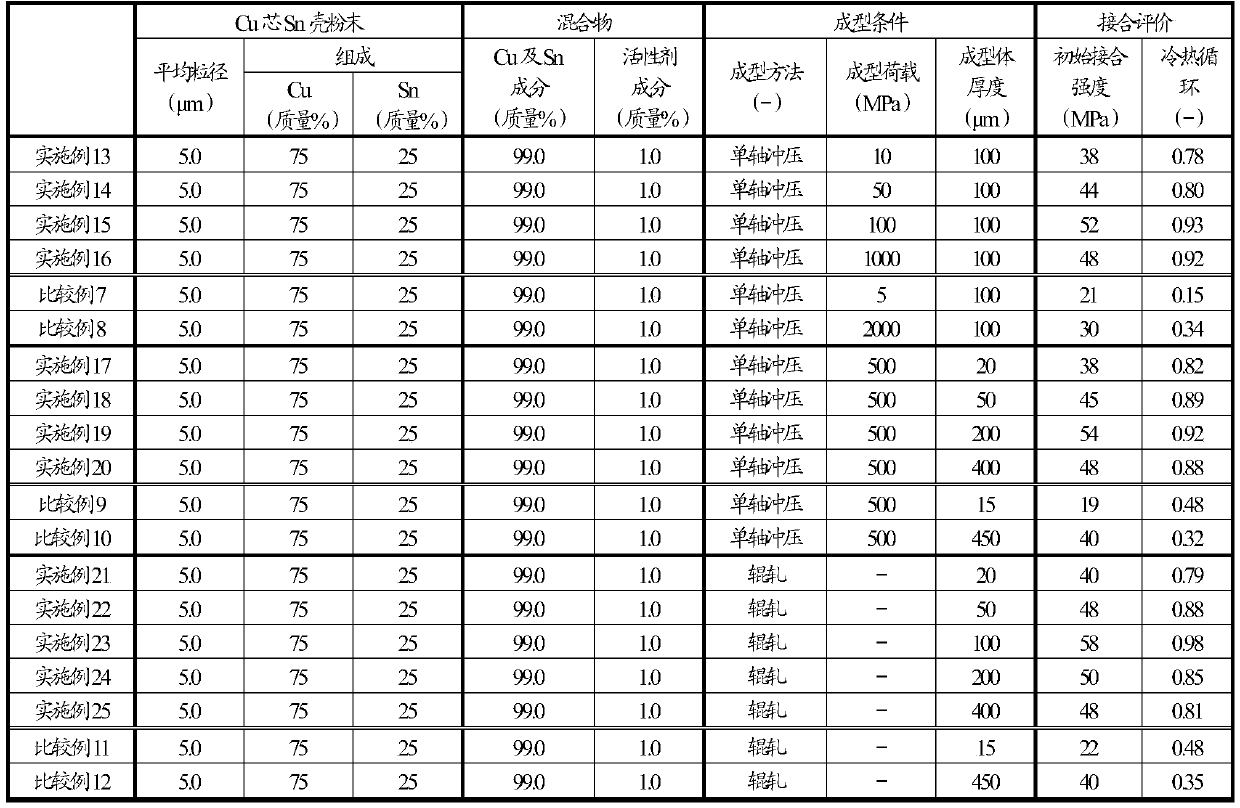

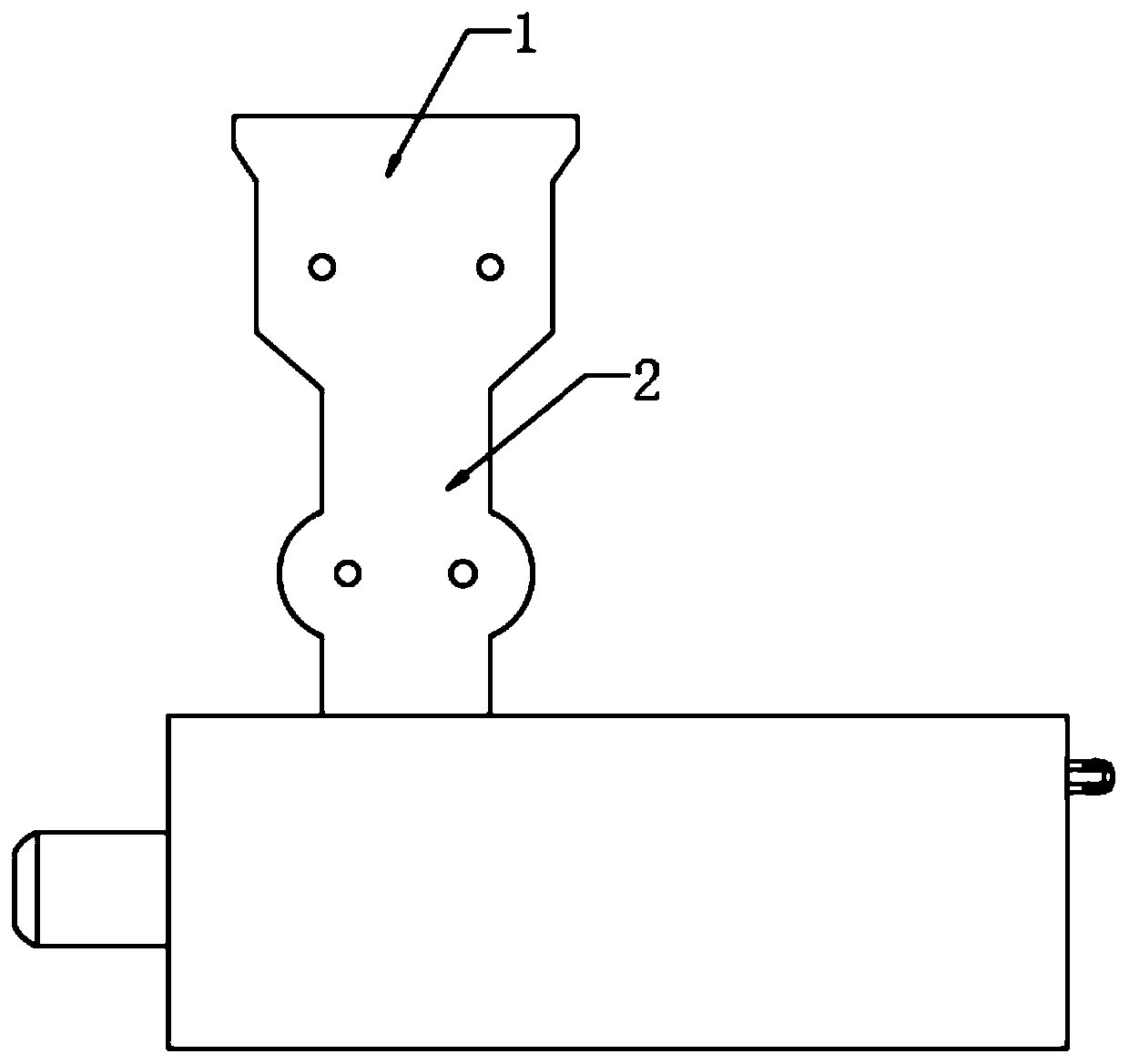

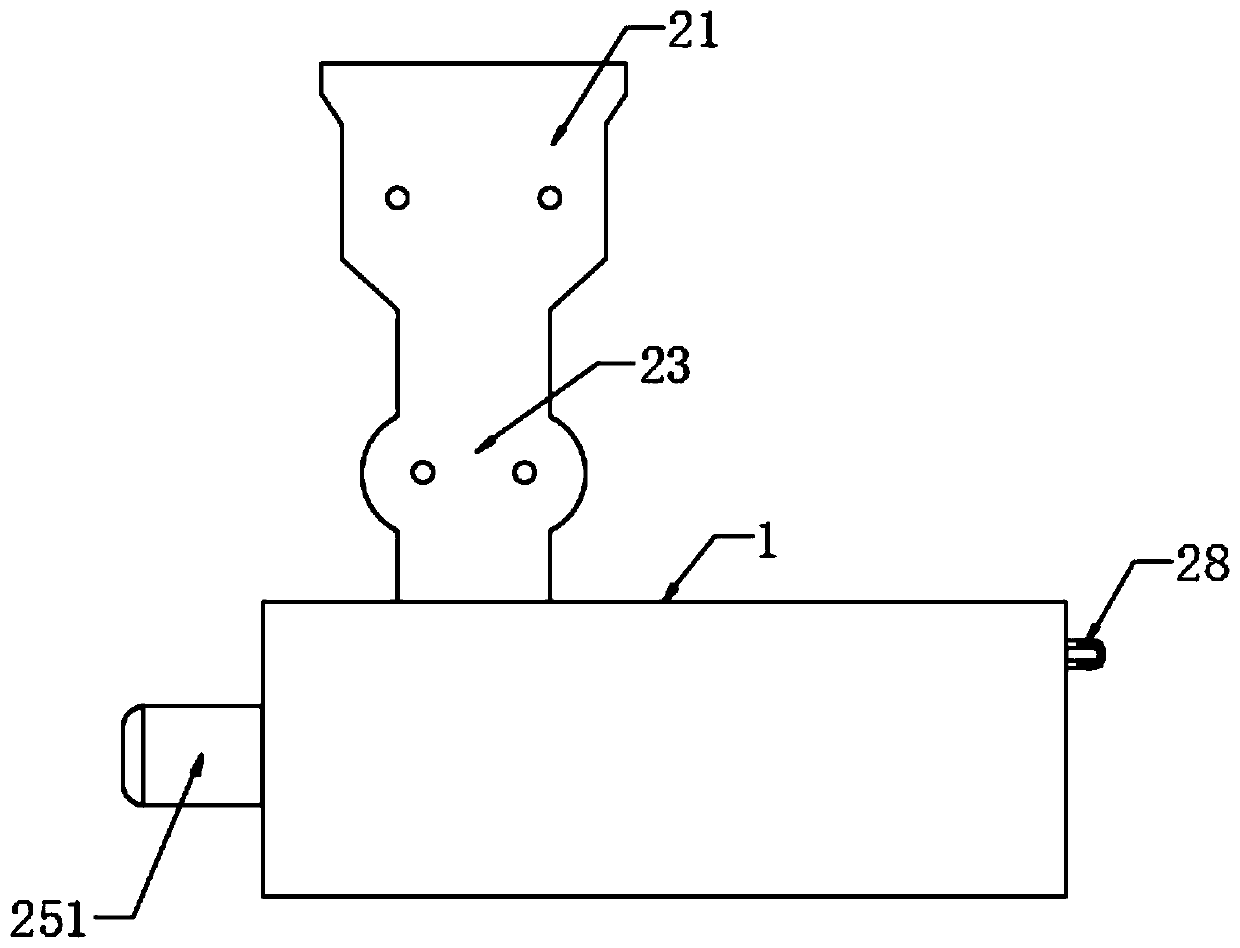

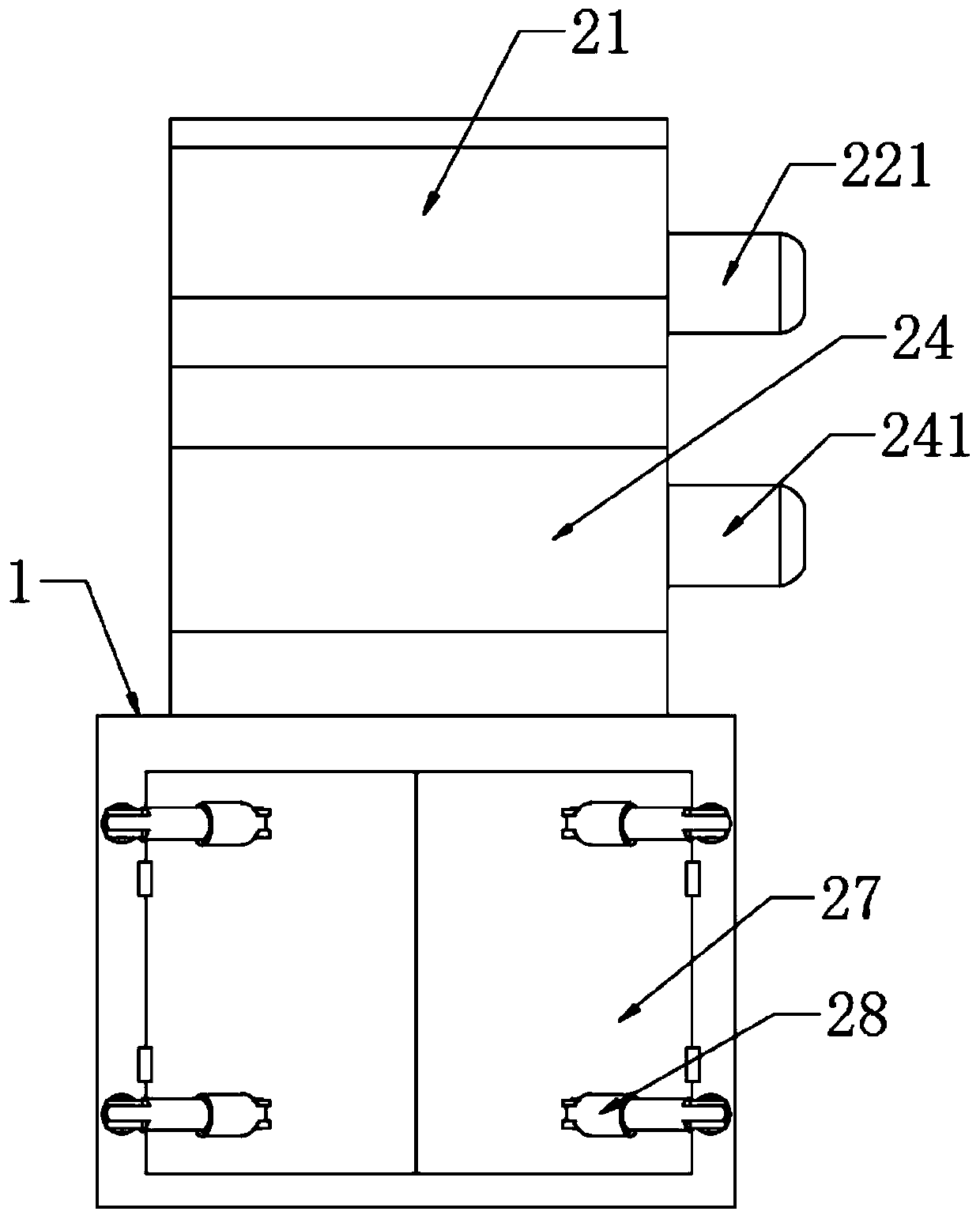

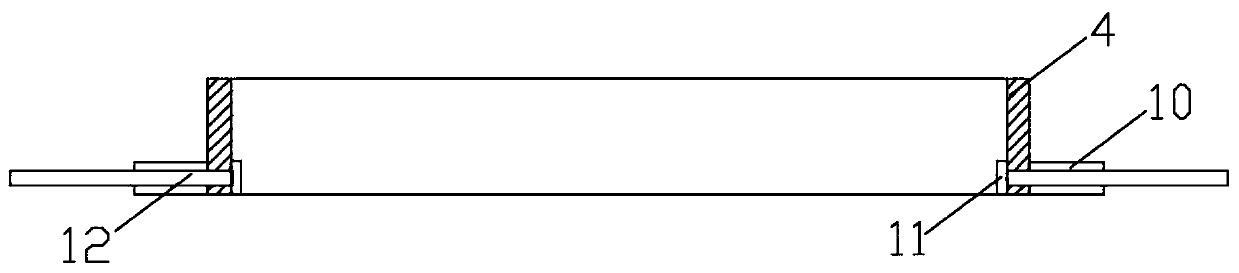

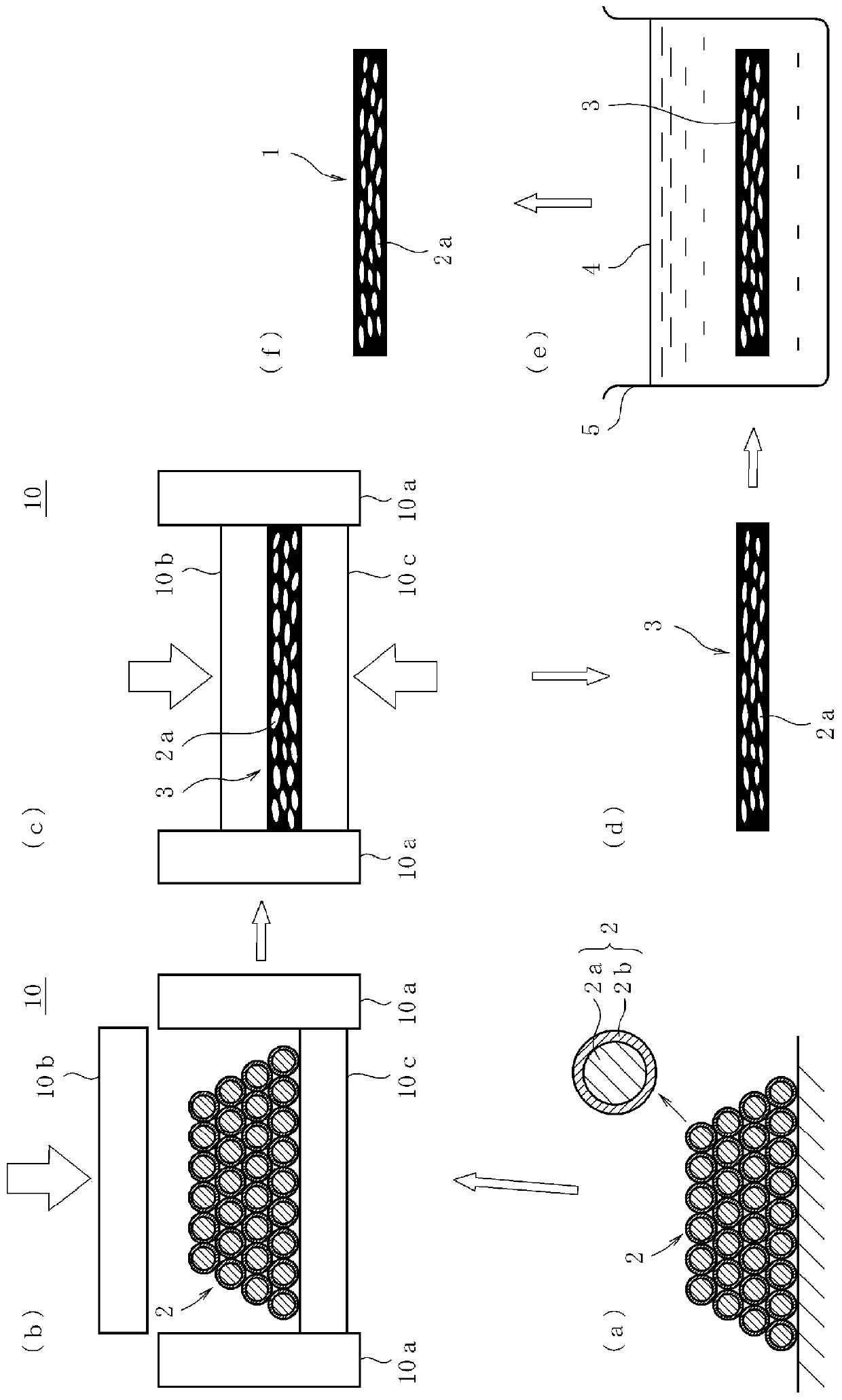

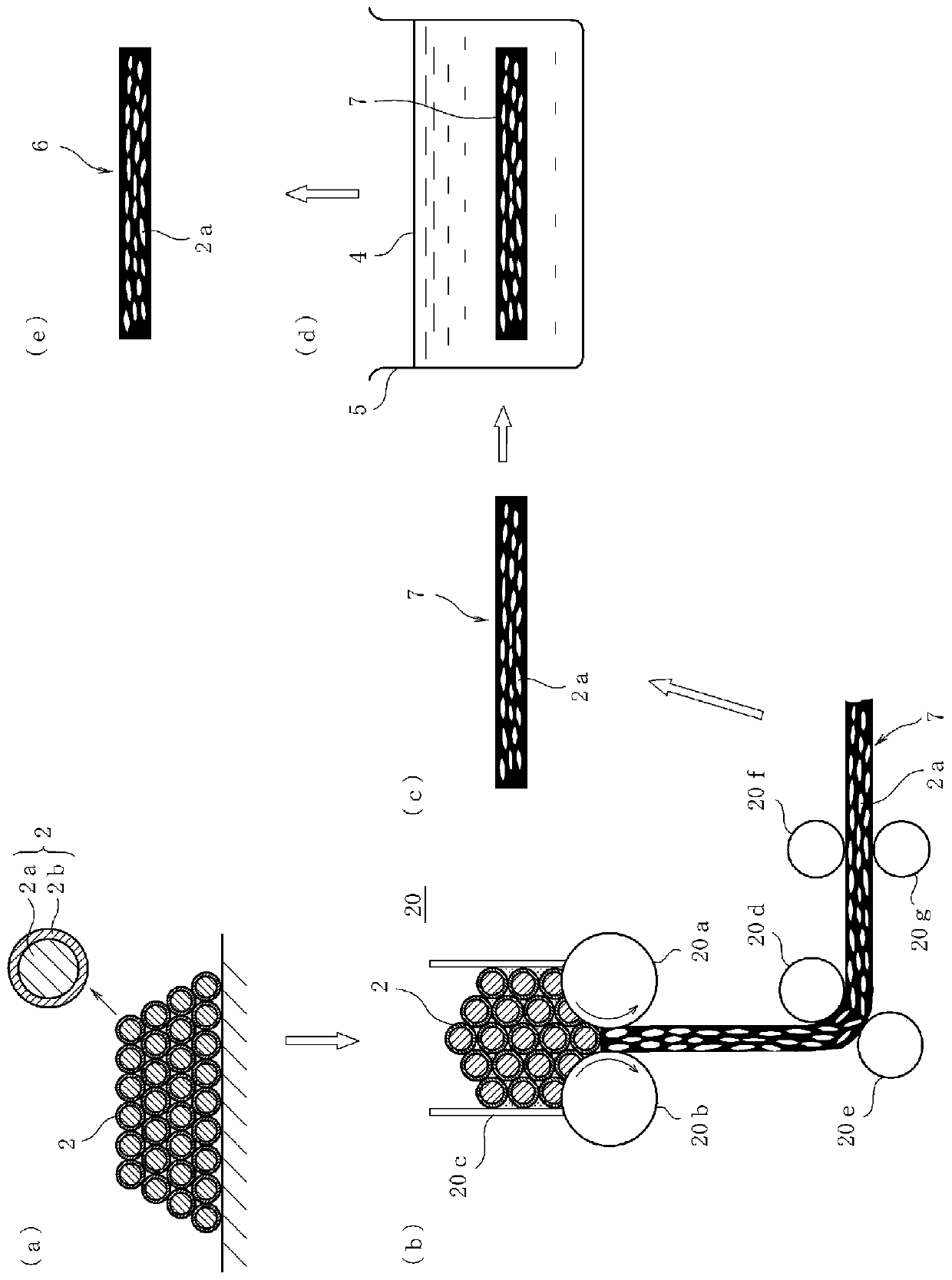

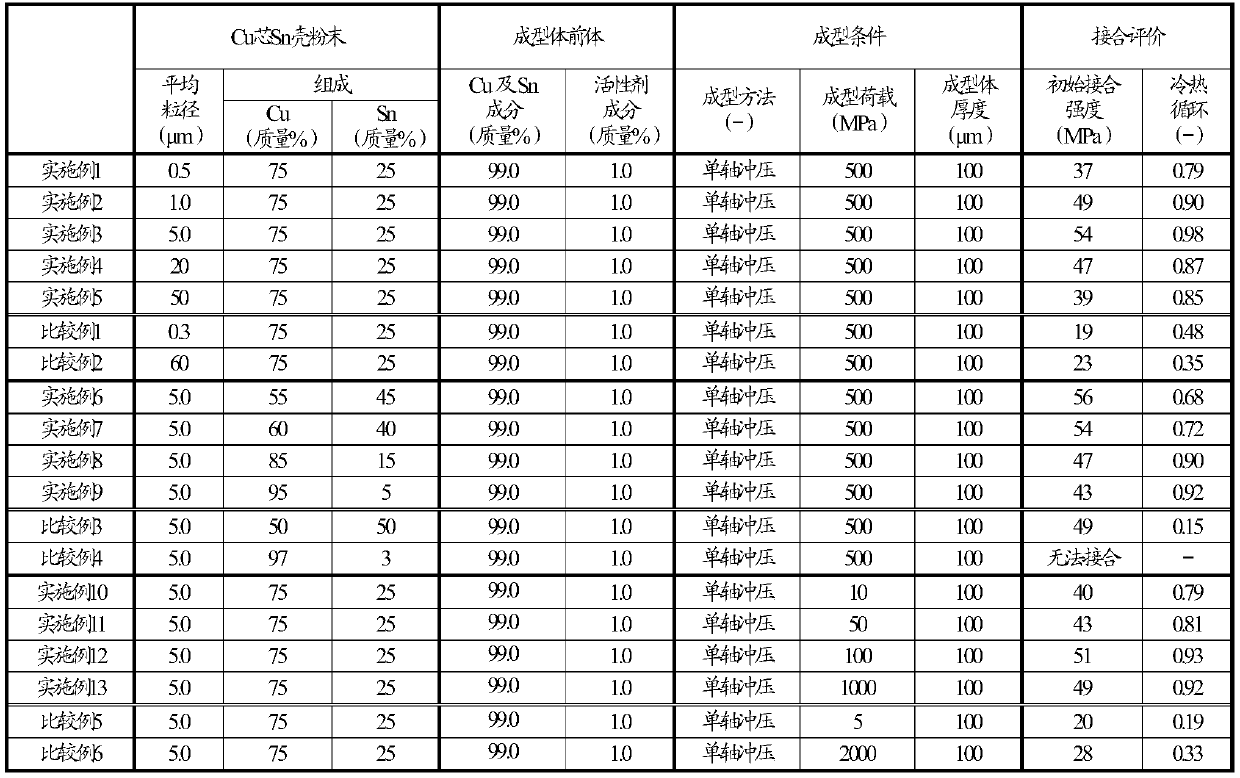

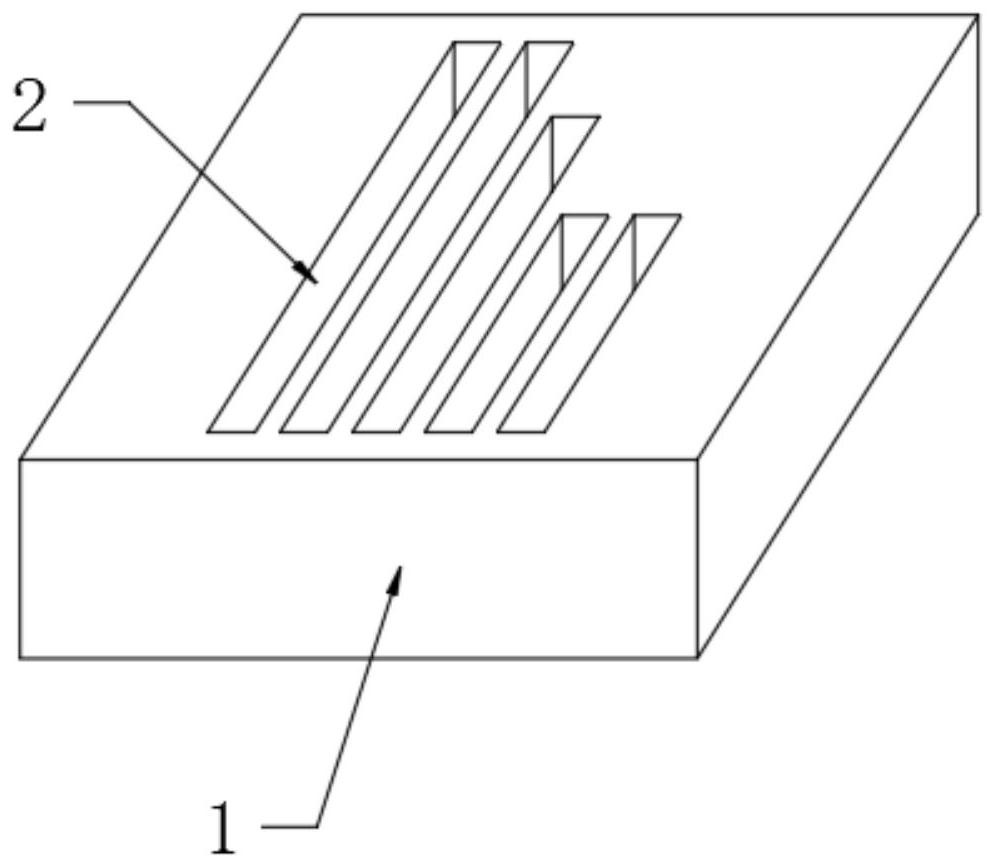

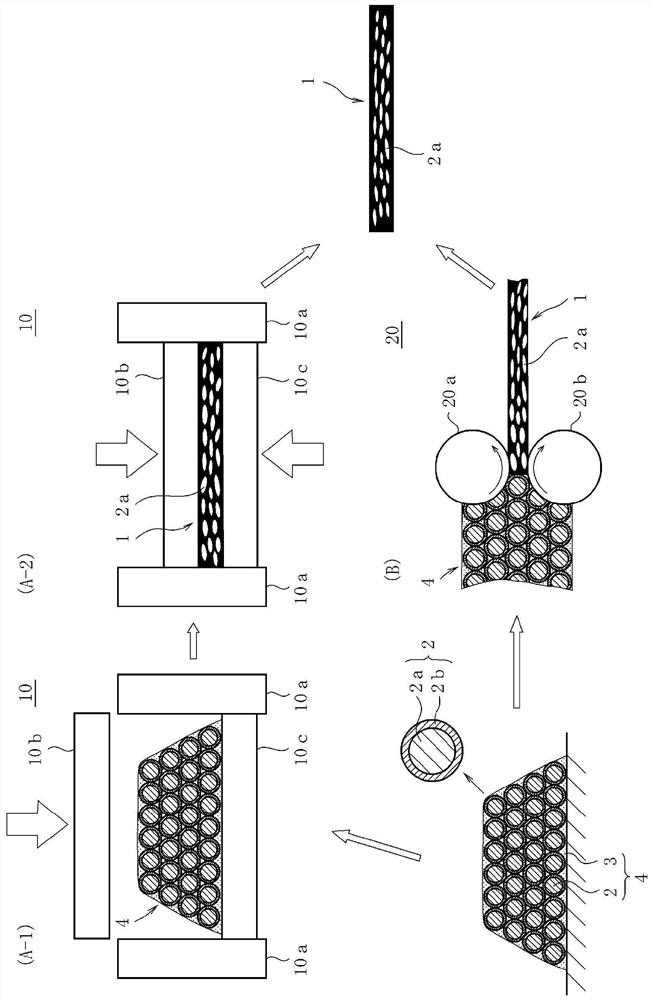

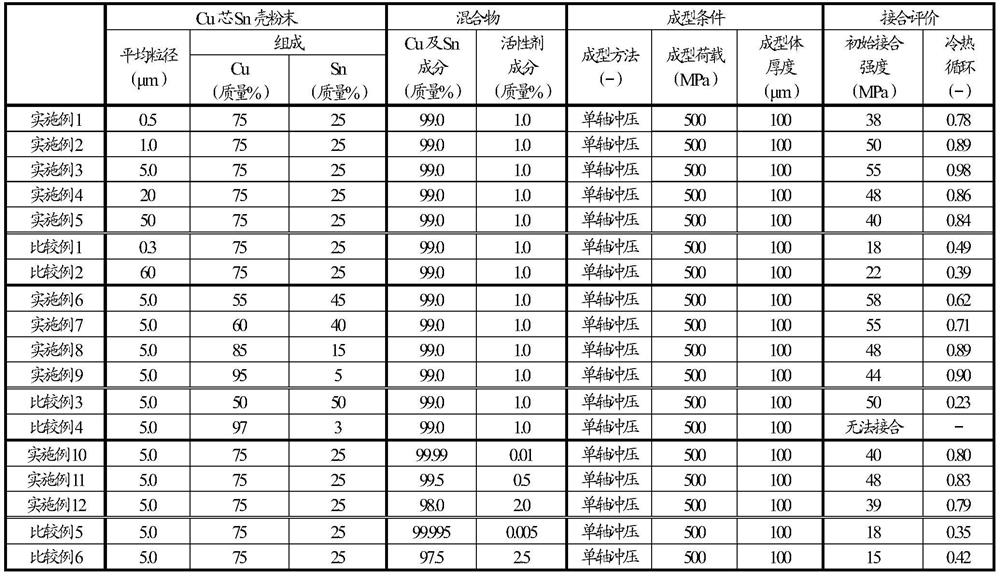

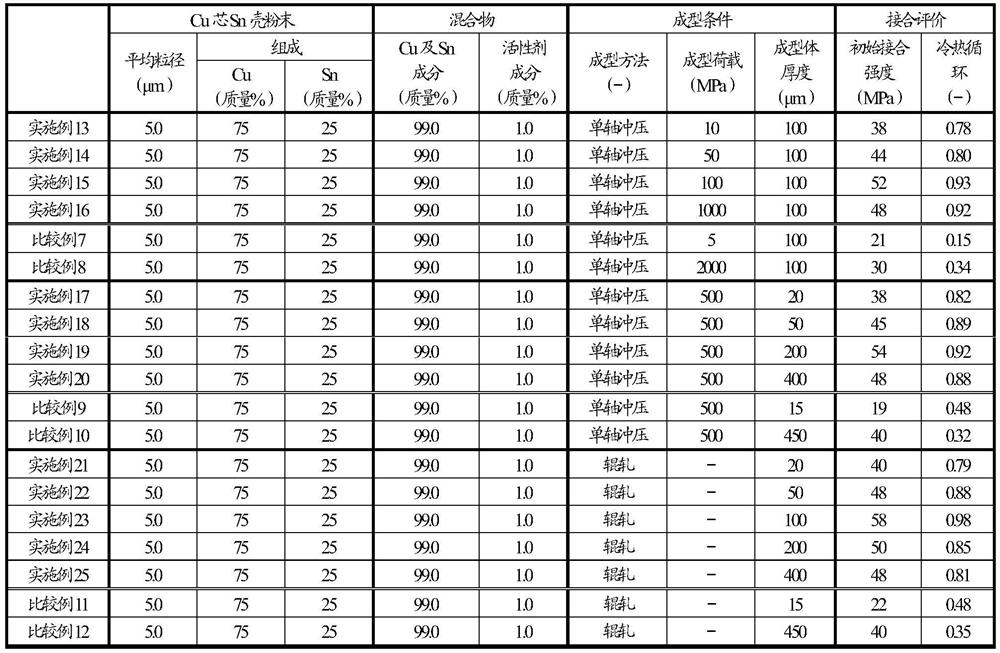

Molded body for joining and method for manufacturing same

ActiveCN110402180APrevent oxidationImprove thermal conductivityTransportation and packagingSemiconductor/solid-state device detailsPolymer scienceActive agent

The present invention is a molded body (1) for joining constituted by an aggregate in which Cu-core Sn-shell powder has been compressed. There is an activating agent-containing substance (3) for removing oxides from surfaces of the powder in both open holes and closed holes present inside the molded body for joining. The molded body for joining contains 55-95 wt.% of Cu and 45-5 wt.% of Sn. The activating agent in the activating agent-containing substance is included in a ratio of 0.01-2 wt.% to 100 wt.% of the molded body for joining. The thickness is 20-400 [Mu]m.

Owner:MITSUBISHI MATERIALS CORP

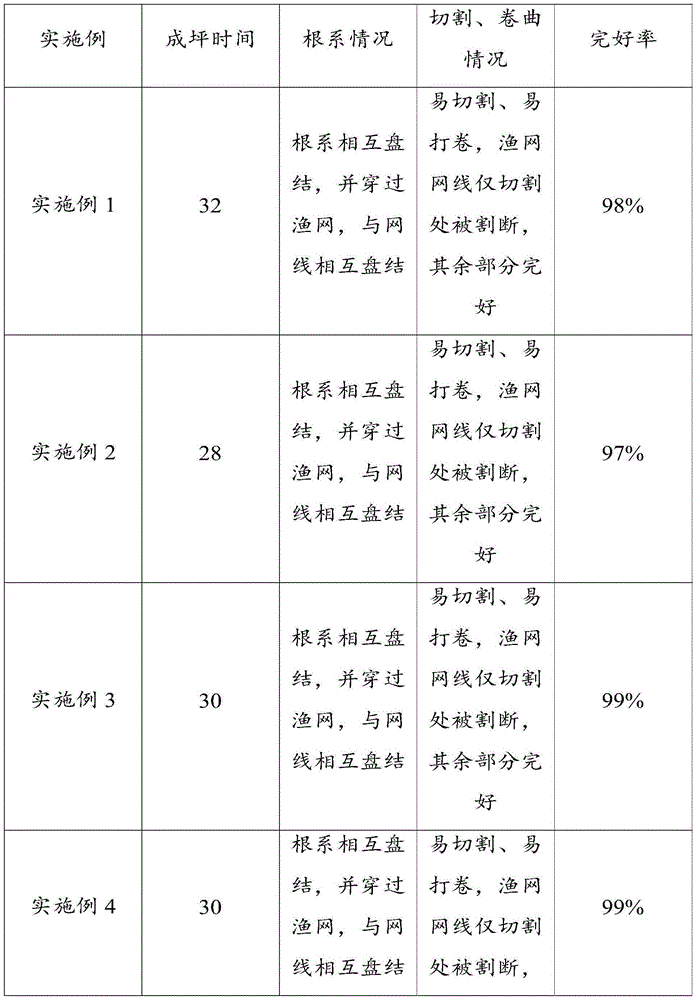

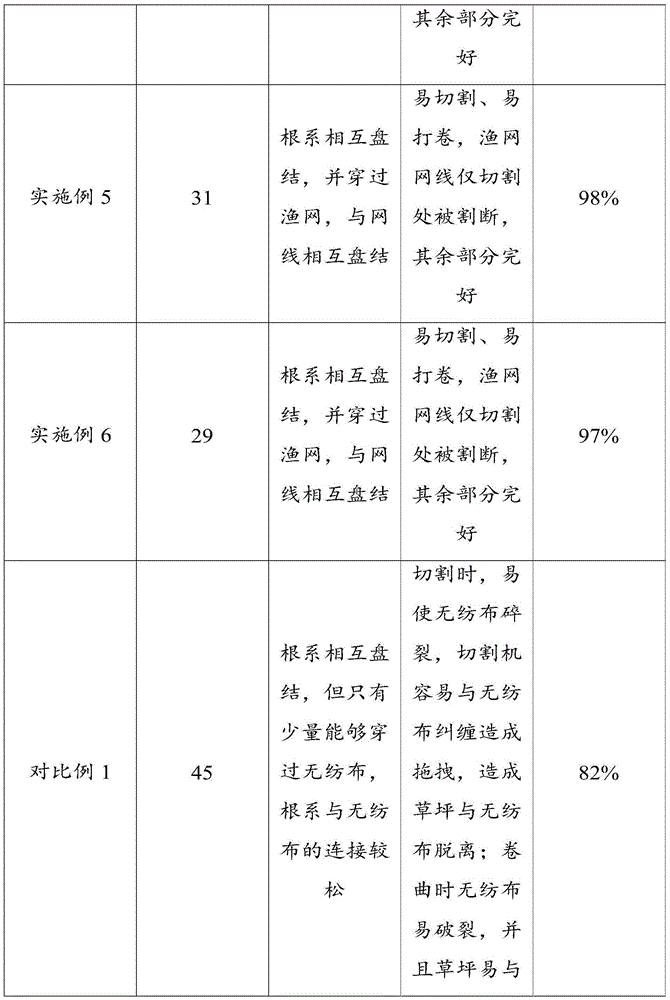

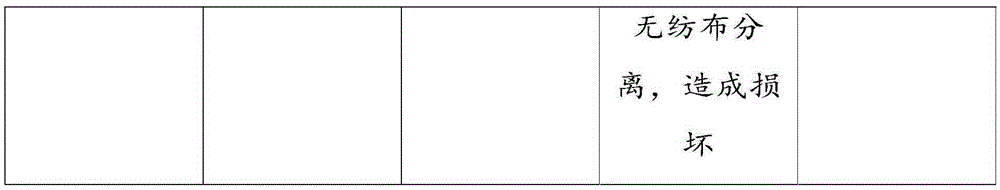

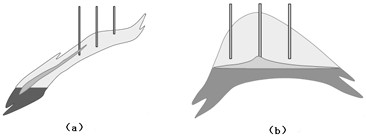

Carpet lawn and preparation method thereof

The invention provides a carpet lawn and a preparation method thereof. Fishing nets are added in a lawn planting process to obtain the novel carpet lawn. The preparation method of the carpet lawn is simple in technical process, low in cost and quick in lawn forming, and a quantitative proportion of a penetration medium to an adhesion medium of a root system of the lawn is increased by means of improvement of porosity of the adhesion medium; the perfectness ratio of the lawn is increased in a lawn cutting and transporting process by means of improvement of flexibility of the adhesion medium. The carpet lawn is low in cost, easy to cut and high in perfectness ratio due to transport in a rolled manner. A laying method of the carpet lawn is simple, a rejuvenation period can be shortened while management cost is reduced, and an optimal landscape effect of the lawn is achieved. Due to high flexibility of the fishing nets, the lawn is easy to stretch and compact in a laying process, the lawn can closely contact with soil by means of trimming and jointing, and high flatness, quickness in rooting of the root system and excellent landscape effect are achieved.

Owner:山东艺匠旅游规划设计有限公司

Coal mining sampling device capable of conveniently cleaning chippings

PendingCN112485043AEasy to cleanRealize automatic reclaimingWithdrawing sample devicesCleaning using toolsSlagMining engineering

The invention discloses a coal mining sampling device capable of conveniently cleaning chippings. The coal mining sampling device comprises a sampling pipe body, an extension pipe body, a gear motor and a storage battery, the extension pipe body is installed in the upper side of the sampling pipe body, and the lower end of the extension pipe body is fixedly connected with a connecting block; ,crushing claws are fixedly connected to the outer side wall of the lower end of the sampling pipe body at equal angles through bolts, a mounting pipe is mounted on the inner side of the lower end of the sampling pipe body, a gear motor is mounted in the upper end of the sampling pipe body through bolts, a threaded rod is fixedly connected to the output end of the gear motor and the threaded rod is connected with the square rod part of the push rod in a penetrating manner. According to the coal mining sampling device capable of conveniently cleaning chippings, automatic material taking of samples is achieved, the samples can be conveniently compacted, the integrity of the samples is guaranteed, in addition, automatic cleaning of the inner wall of the storage tank is achieved while discharging is conducted, and subsequent use is prevented from being affected by coal slag residues.

Owner:叶兵倩

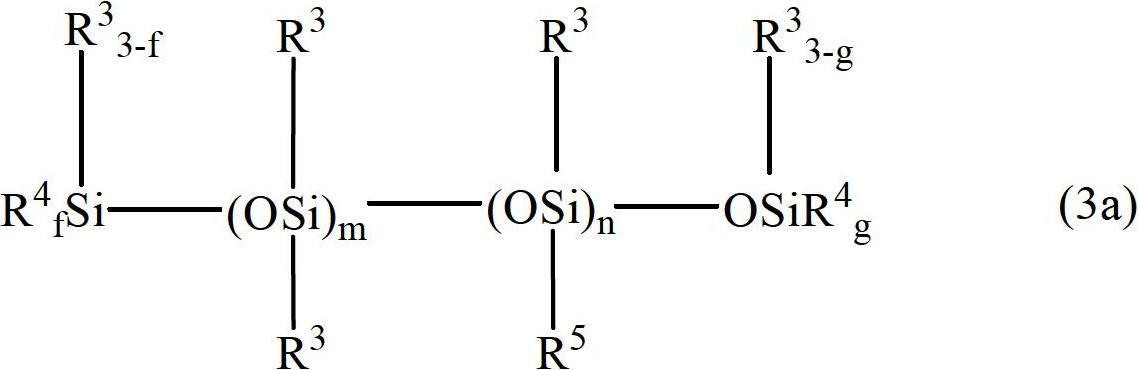

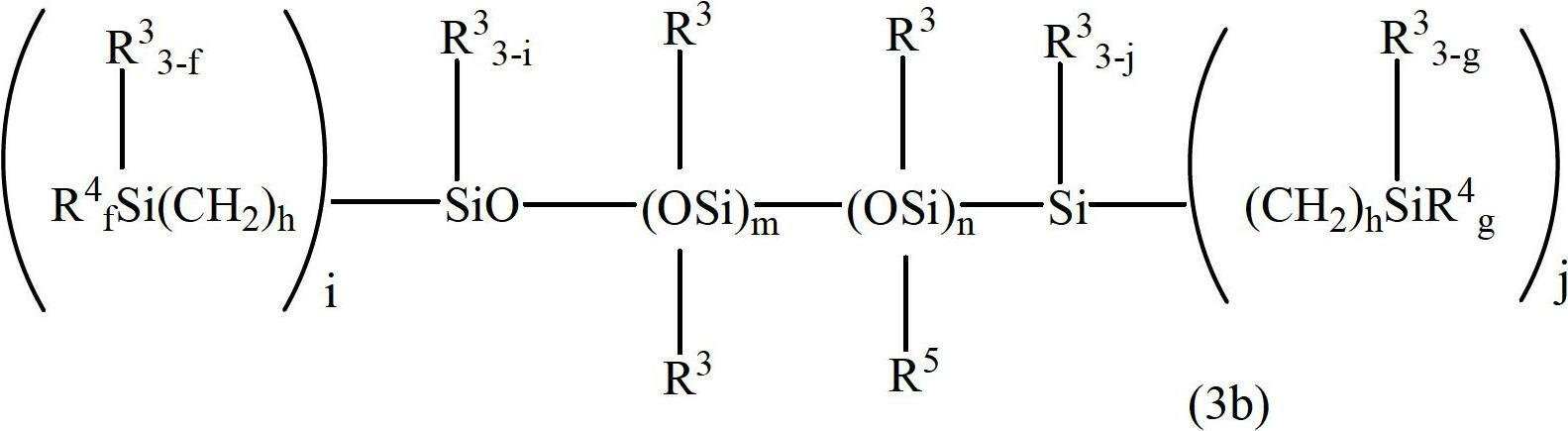

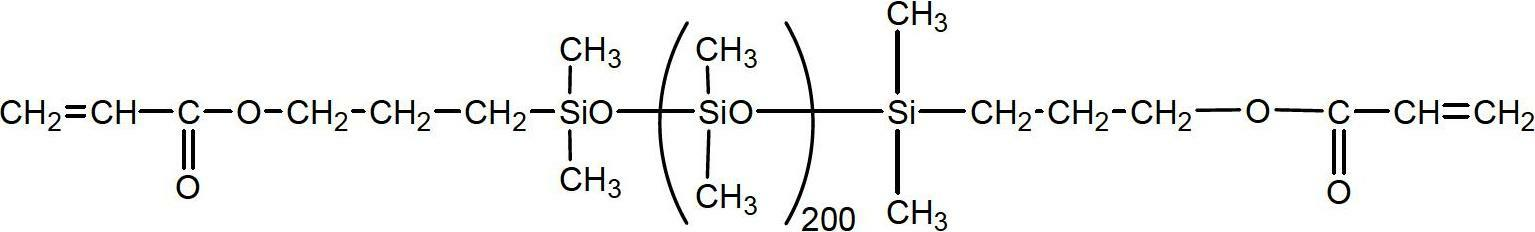

Method for densifying porous silicon carbide base

InactiveCN102686538AEasy to fillEasy to impregnateGroup 4/14 element organic compoundsThin material handlingPorous silicon carbideSilicone

Disclosed is a densified silicon carbide body which has excellent mechanical strength. The densified silicon carbide body is able to be obtained by a method for densifying a porous silicon carbide base, said method comprising a step in which a porous silicon carbide base is impregnated with a curable silicone composition that contains a silicon carbide powder, then the composition is cured therein, and then the cured product is thermally decomposed in a non-oxidizing atmosphere. Consequently, the porous silicon carbide base is able to be easily densified and modified.

Owner:SHIN ETSU CHEM IND CO LTD

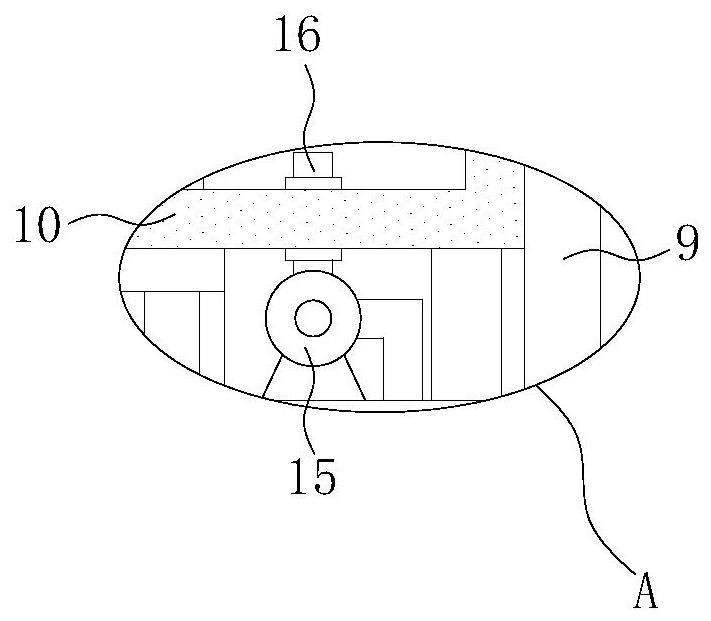

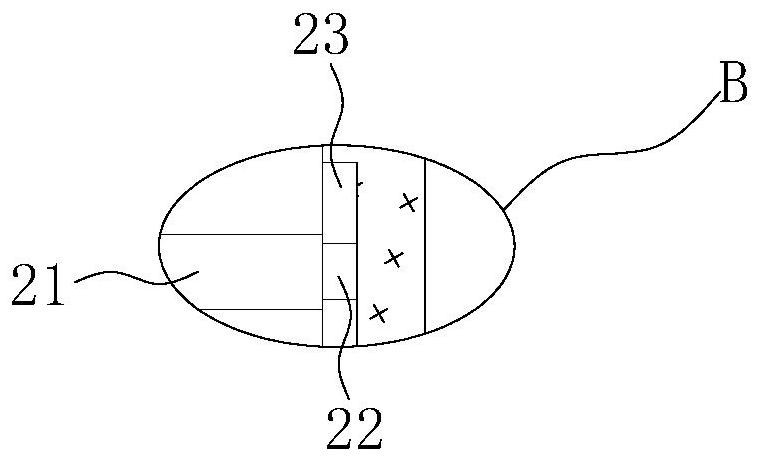

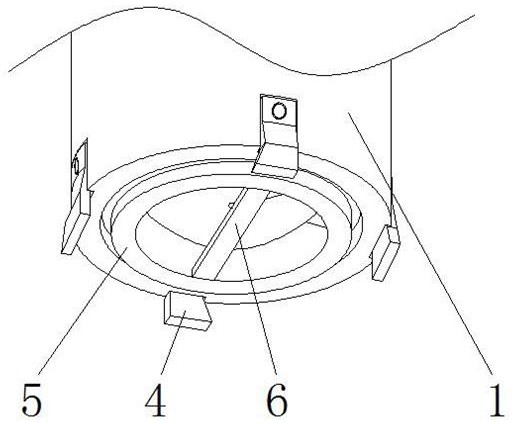

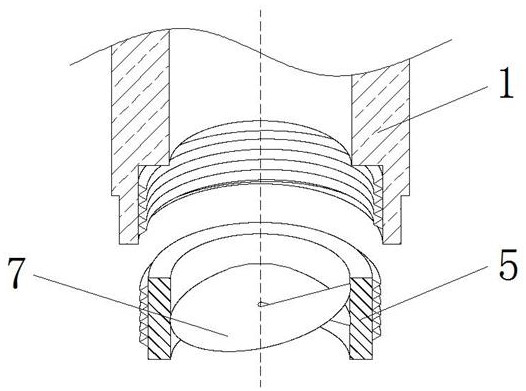

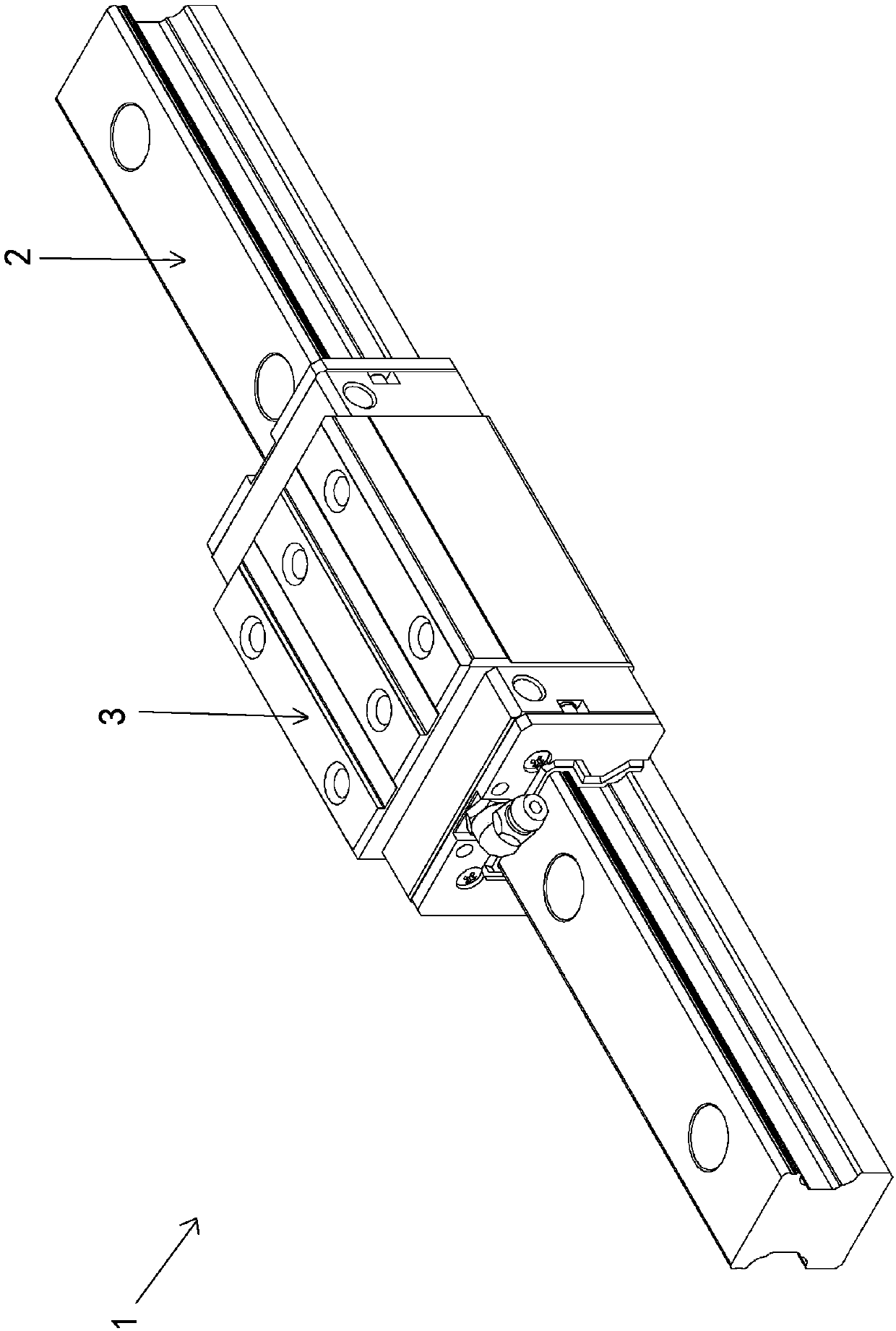

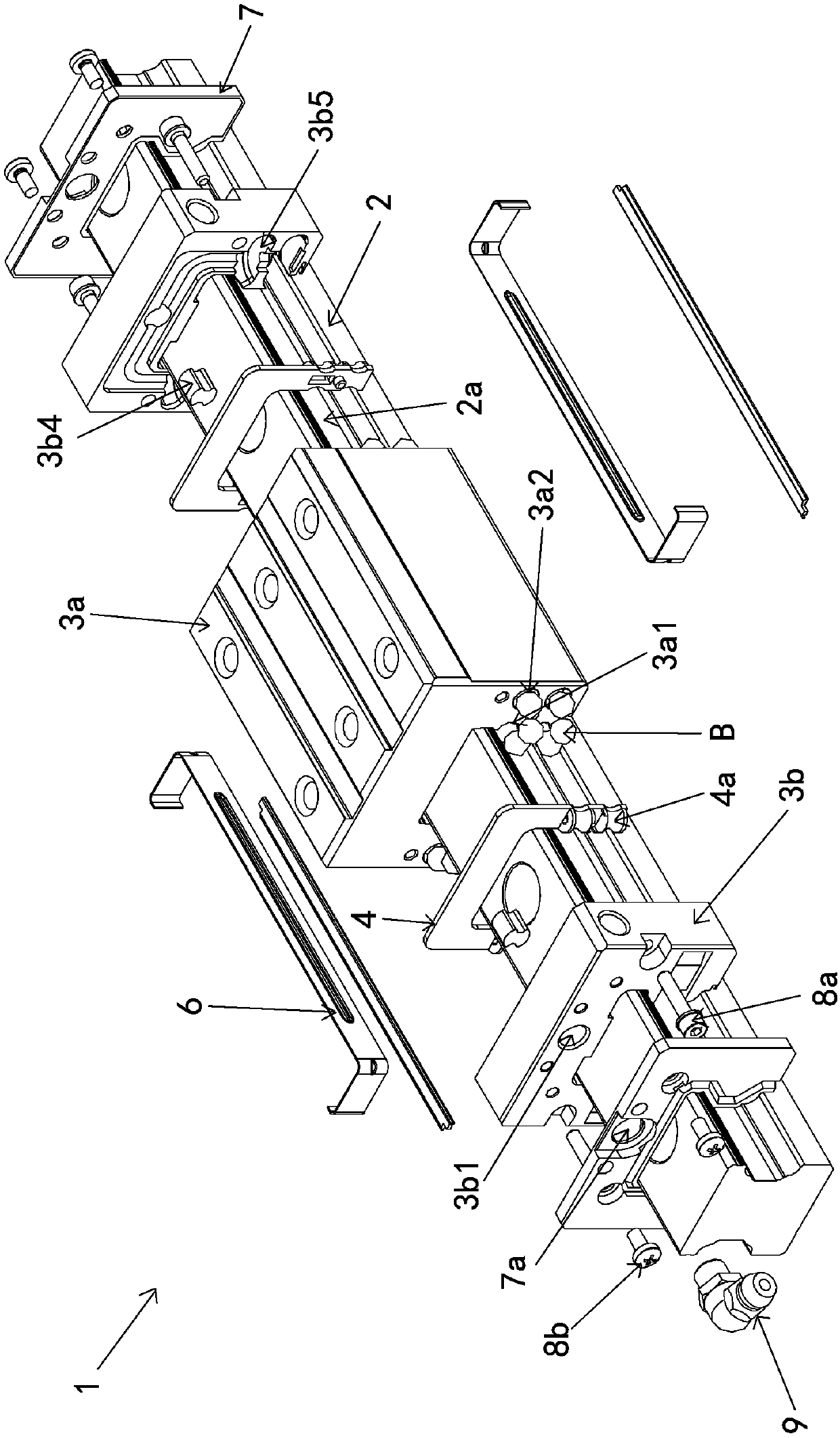

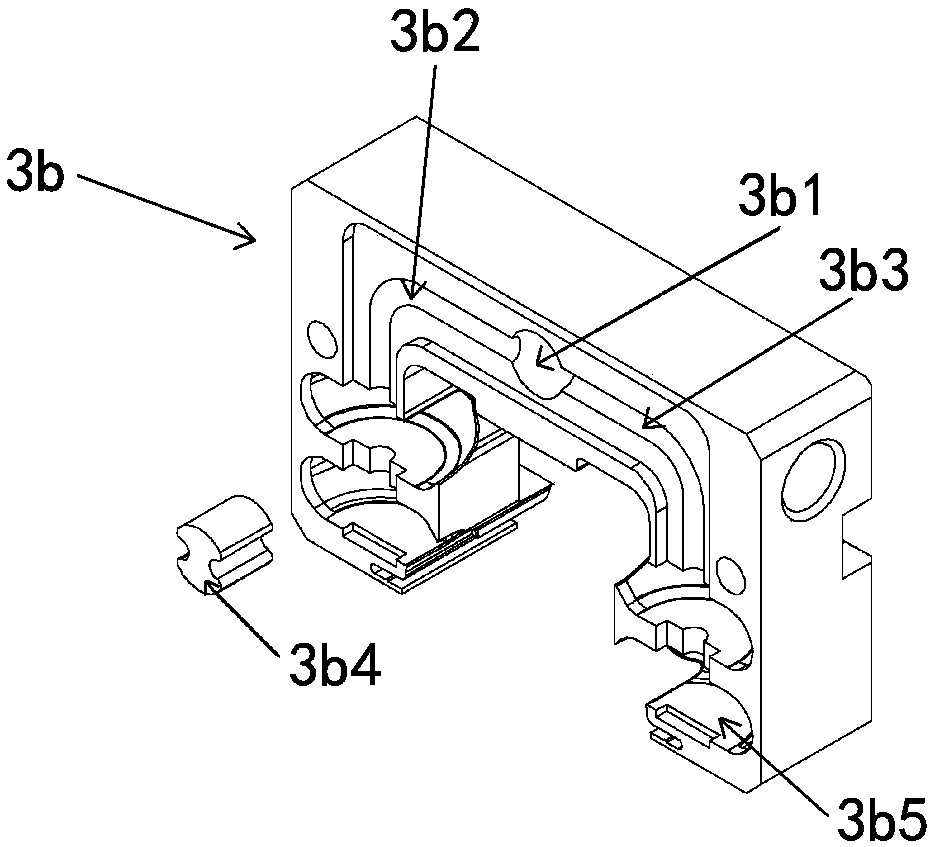

Motion guiding device and cover body used in motion guiding device

ActiveCN110439925AEasy to miniaturizeEasy to compactLinear bearingsBearing componentsGravitationMoving body

The invention provides a motion guiding device and a cover body. The motion guiding device is provided with a supporting body and a moving body, the moving body is provided with a moving body main body and the cover body, and direction switching ways used for allowing rolling bodies to achieve direction switching are arranged in the motion guiding device; the cover body is provided with an oil supply portion, a first oil way, a second oil way and an oil way separating mechanism; the first oil way is used for enabling the oil supply portion to communicate with the direction switching way located on any one of a left foot and a right foot of the cover body; the second oil way is used for enabling the oil supply portion to communicate with the direction switching way located on the other oneof the left foot and the right foot of the cover body; and the oil way separating mechanism is used for enabling the first oil way and the second oil way to be separated. According to the motion guiding device, the oil way separating mechanism is arranged, when the motion guiding device is used in the postures such as wall hanging and inclining, the problem that lubricating oil is difficult to arrive at the oil way close to the upper portion due to influences of the gravity can be solved, the good lubricating effect can be achieved, and then long life and long-term free maintenance of the motion guiding device can be achieved.

Owner:THK CO LTD

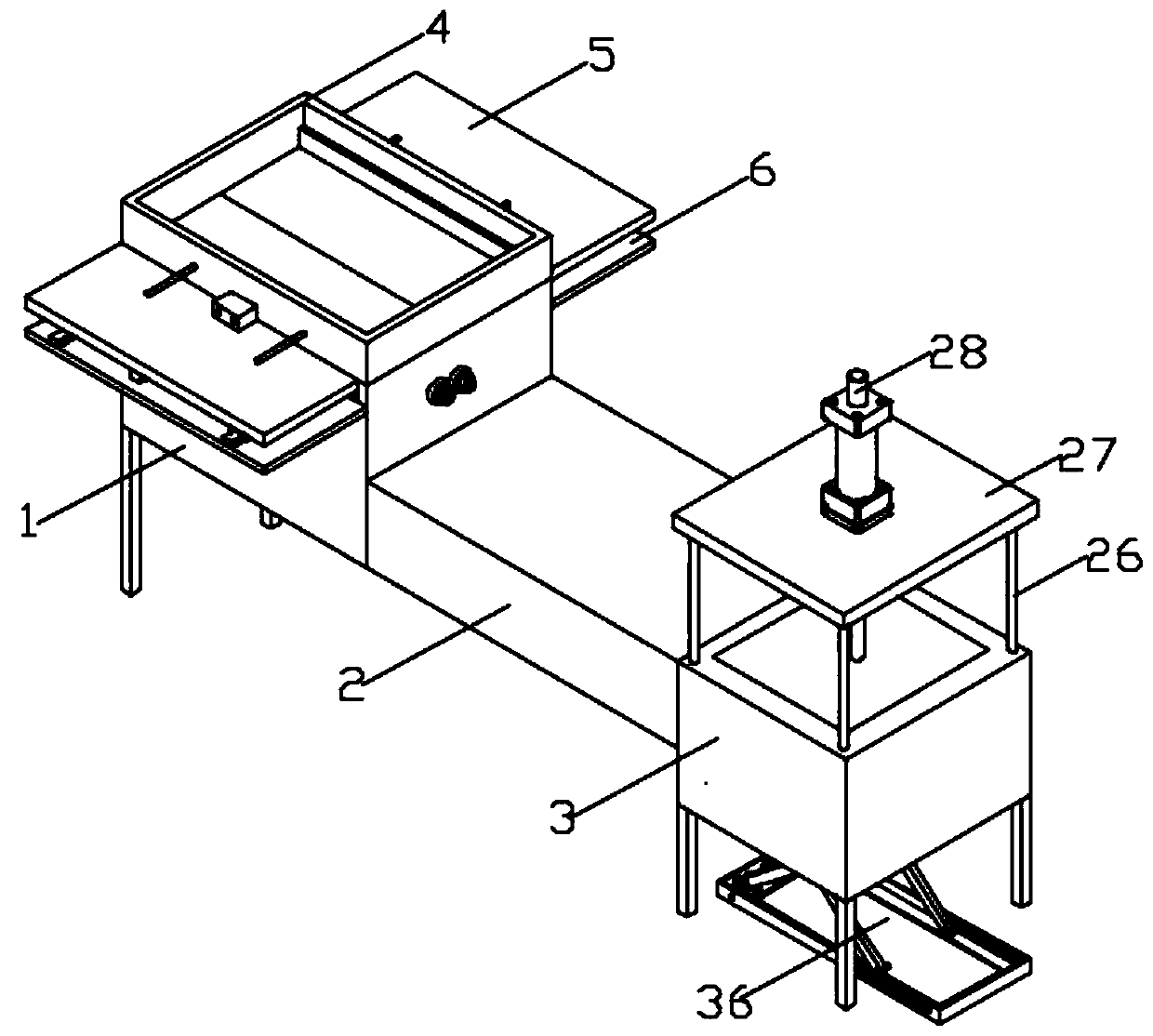

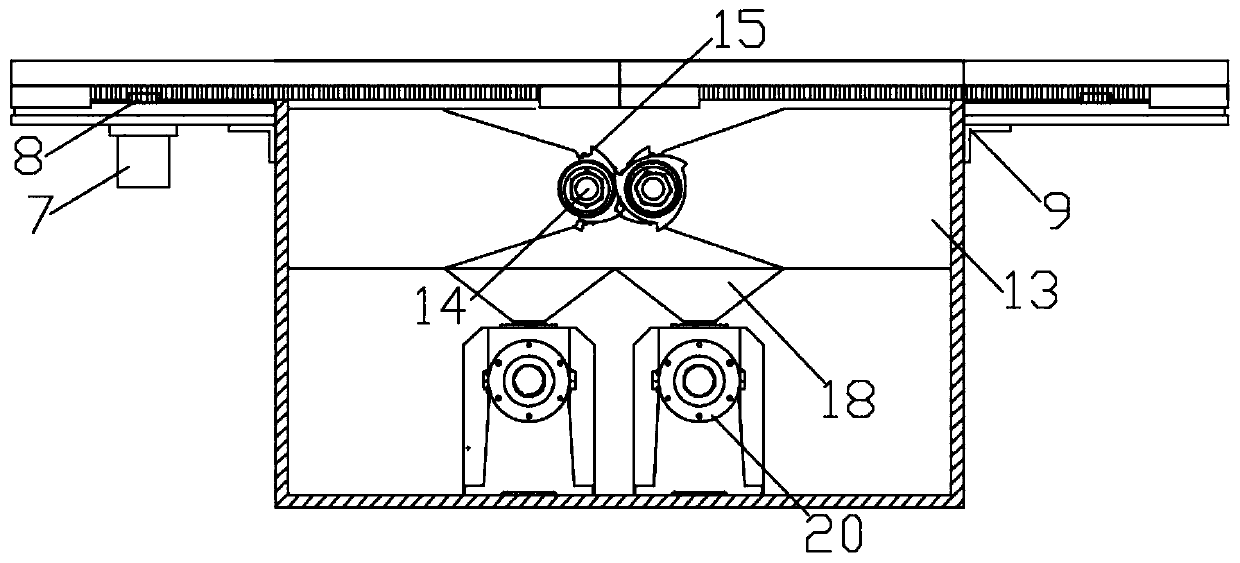

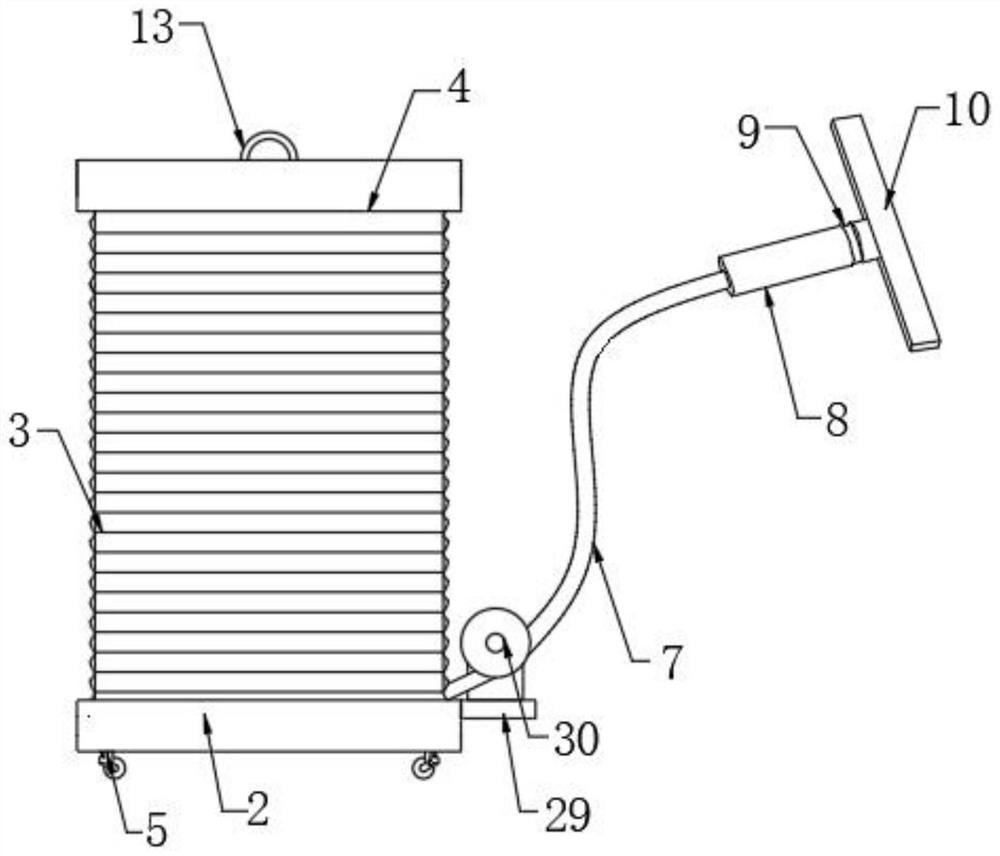

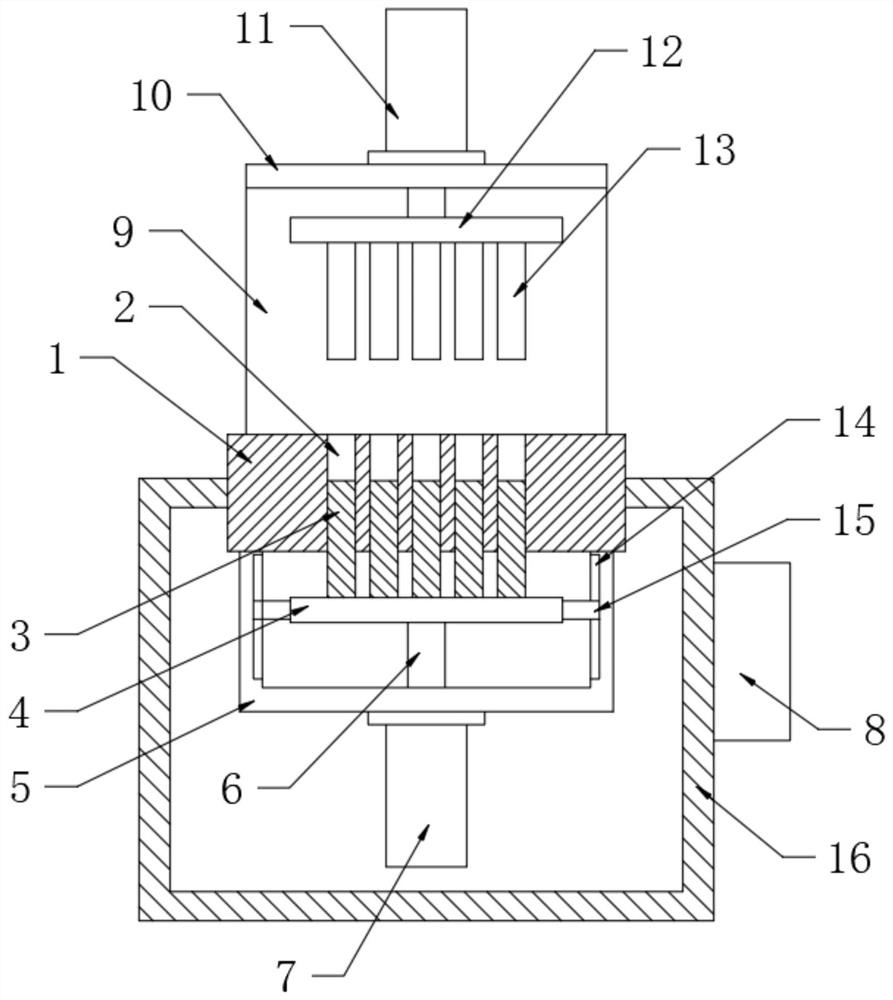

Device capable of packing and compacting rural straws

InactiveCN110202817ASolve the problem of not being able to effectively pack and compact in high densityImproved compaction of high-density balesPressesHigh densityVolumetric Mass Density

The invention provides a device capable of packing and compacting rural straws. The device comprises a teasing roller, a roller pressing chamber, double pressing rollers, a conveying chamber, a forming chamber, a spring rod, a teasing motor, a roller pressing motor, a spiral conveyor motor and a spiral conveyor shaft, wherein the teasing roller is arranged inside a feeding groove, the teasing motor is arranged on the rear side of the teasing roller, the roller pressing chamber is formed in the lower side of the feeding groove, the double pressing rollers are arranged inside the roller pressingchamber, the roller pressing motor is installed on the rear sides of the double pressing rollers, the conveying chamber is formed in the lower side of the roller pressing chamber, the spiral conveyorshaft is arranged inside the conveying chamber, the spiral conveyor motor is installed on the left side of the spiral conveyor shaft, the forming chamber is formed in the right side of the conveyingchamber, and the spring rod is arranged on the right side of a discharging door. According to the design, the problem that an original straw packaging and compacting machine cannot effectively realizehigh-density packaging and compaction is solved, the structure of the device is reasonable, and the straws can be conveniently packed and compacted in a high-density manner.

Owner:王星

Waste disposal equipment for factory production

The invention discloses waste disposal equipment for factory production. The waste disposal equipment comprises a box body, wherein a scrap iron box is fixedly mounted above the left side of the box body; the scrap iron box is fixedly mounted at the upper end of the left side of the box body, so that scrap iron is conveniently stored into the scrap iron box; the inner wall of the left side of thescrap iron box is connected with a pushing plate through a telescopic pole; the left side wall of the pushing plate is equipped with a pushing rod, so that scrap iron in front of the pushing plate canbe pushed into a guide tube; the telescopic pole achieves the guide effect and the fixing effect on the pushing plate; an electric pushing rod is fixedly mounted above the box body; the lower end ofthe electric pushing rod is fixedly equipped with a compacting disc, so that scrap iron inside an extruding barrel is compacted conveniently; a glass plate is mounted above the front wall of the box body, so that height of the scrap iron inside the extruding barrel is conveniently observed; and a baffle plate is placed on a fixed plate for sealing the lower end of the extruding barrel, and a leaking hole is formed in the middle part of the fixed plate, so that the compacted scrap iron is leaked conveniently.

Owner:许荣夫

Chip recovery device for wood product processing and use method of chip recovery device

InactiveCN111590702APracticalEasy to cleanDrying solid materials with heatWood particle dryingElectric machineryManufacturing engineering

The invention discloses a chip recovery device for wood product processing and a use method of the chip recovery device. The chip recovery device comprises a refining box, a drying box and a compacting box, wherein the drying box is arranged between the refining box and the compacting box, a chip blocking frame is installed at the top of the refining box, and through holes are formed in two sidesof the refining box. According to the chip recovery device for the wood product processing and the use method of the chip recovery device, wooden products are placed in the chip blocking frame on therefining box to be processed, chips generated during the machining fall on two processing plates in the chip blocking frame, the processed wooden products are taken away, two first air cylinders are started, piston rods of the first air cylinders push chip pushing plates, the chip pushing plates push the chips on the two processing plates towards each other, then, two first motors are started, output shafts of the first motors drive first gears to rotate, the first gears match with racks to drive machining plates to horizontally move, the two machining plates horizontally move in reverse directions, and the chips on the surfaces of the machining plates are pushed into the refining box by the chip pushing plates. The technical problems that in the prior art, a chip recovery device for the wood product processing cannot provide a wood product machining station and is poorer in practicability are solved.

Owner:安徽省阜南志峰工艺品有限公司

A water shutoff method for establishing a large-area chemical partition at the gas-water interface of a water-bearing gas reservoir

ActiveCN110685637BHigh strengthThickness is easy to controlDrilling compositionSealing/packingPhysical chemistryOil phase

The invention relates to a water blocking method for establishing a large-area chemical partition at the gas-water interface of a gas reservoir with water, including: (1) injecting a water-phase solution into the gas-water interface of the gas reservoir, and the water-phase solution plays the role of diffusion and dispersion Migrate downward to the water layer; (2) Inject the oil phase solution into the gas-water interface of the gas reservoir, and the oil phase solution spreads on the gas-water interface, replacing the gas-water interface with the oil-water interface; (3) The water phase monomer diffuses to the oil layer , in the oil-water interface close to the oil phase, the polymerization reaction occurs with the oil phase monomer to form a microporous polymer interlayer; (4) formation water penetrates into the polymer interlayer under the action of pressure difference, and mineral ions and impurities continue to Scale is deposited on the polymeric barrier to form a water-impermeable polymeric barrier. The invention is reliable in principle and easy to operate, can effectively solve the problems of small plugging range and low plugging strength in commonly used water shutoff systems in the process of water invasion control of edge-bottom water gas reservoirs, and has great significance for efficient exploitation of edge-bottom water gas reservoirs. Practical significance.

Owner:SOUTHWEST PETROLEUM UNIV

Joining molded article and method for manufacturing same

ActiveCN110418692APrevent oxidationImprove joint strengthTransportation and packagingSolid-state devicesOxide

The present invention is a joining molded article (1), composed of a compressed aggregate of a Cu-core Sn-shell powder (2), an activator-containing substance (4) for removing an oxide from a powder surface being present in open pores in a surface part and inside of the joining molded article, and the joining molded article containing Cu in a ratio of 55-95% by mass and Sn in a ratio of 45-5% by mass and having a thickness of 20-400 [mu]m.

Owner:MITSUBISHI MATERIALS CORP

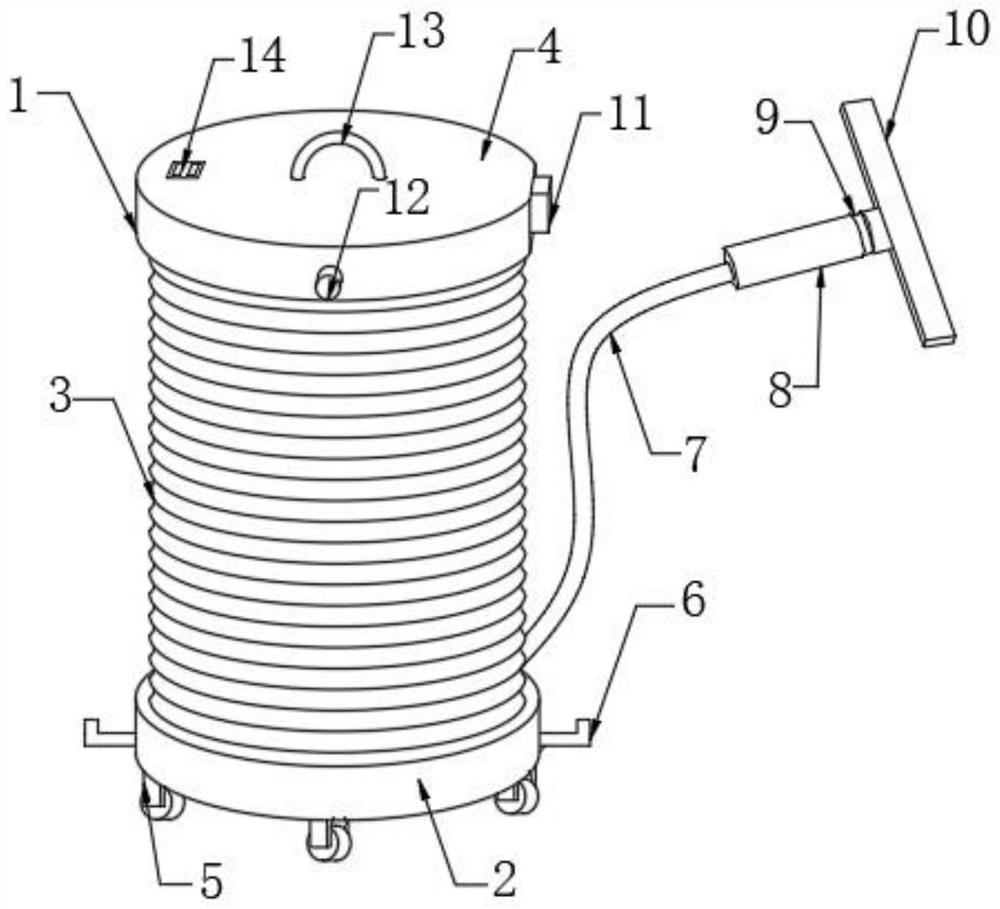

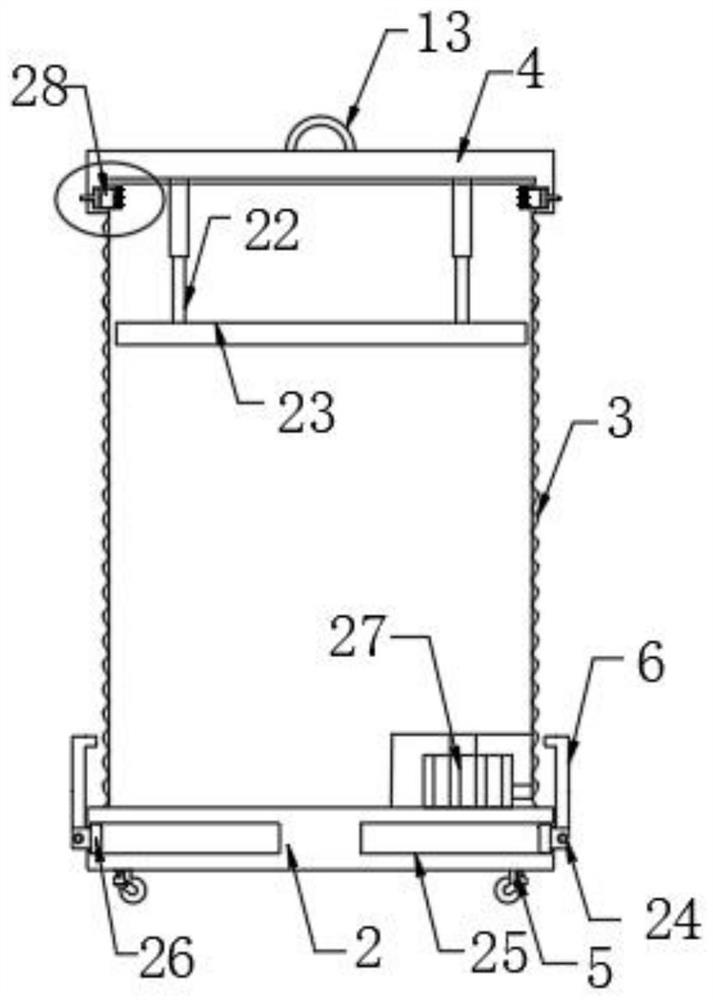

Folding dust remover for clothes

The invention discloses a folding dust remover for clothes, which belongs to the technical field of clothing manufacturing, and comprises a dust collecting cylinder, the dust collecting cylinder is composed of a base, a folding cylinder and a top cover, the top end of the base is fixedly connected with the bottom end of the folding cylinder, and the tops of the two sides of the folding cylinder are both provided with grooves; a plurality of reset springs are fixedly installed on the groove walls of one sides of the two grooves at equal intervals. According to the folding dust remover for the clothes, through an installed handle, a person can conveniently take the handle to move on the surface of the clothes, an electrostatic dust removal wheel installed in the installation groove adsorbs dust on the surface of the clothes to the surface of the electrostatic dust removal wheel, and the dust remover works to generate suction force; dust on the surface of the electrostatic dust collection wheel is adsorbed into the folding cylinder through the suction nozzle to be collected and treated, dust on the surface of clothes is effectively removed, meanwhile, the handle is manually held, local dust of the clothes can be conveniently removed for multiple times, and the dust removal effect is guaranteed.

Owner:秦娟

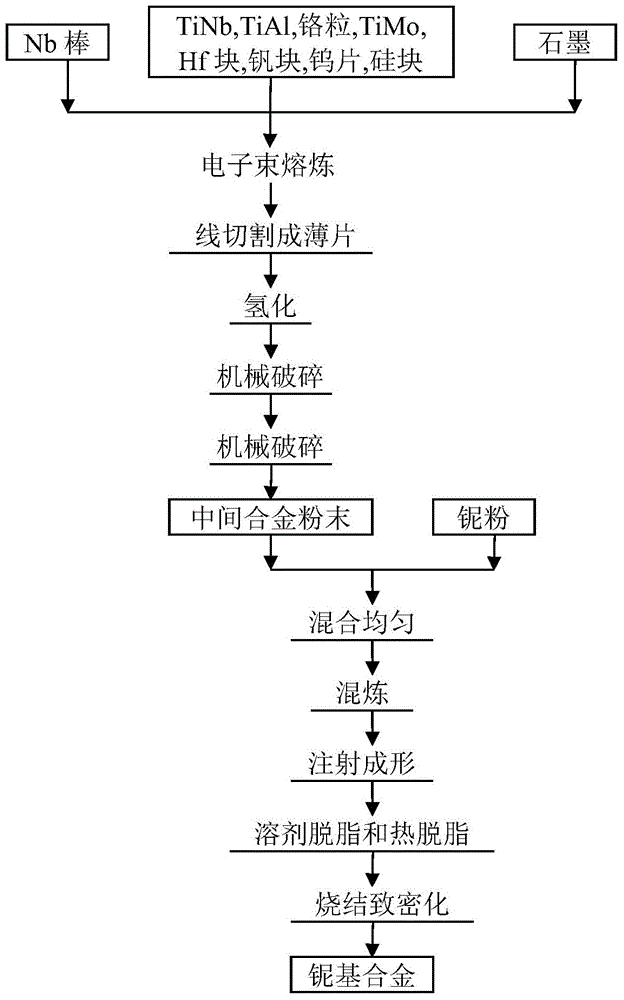

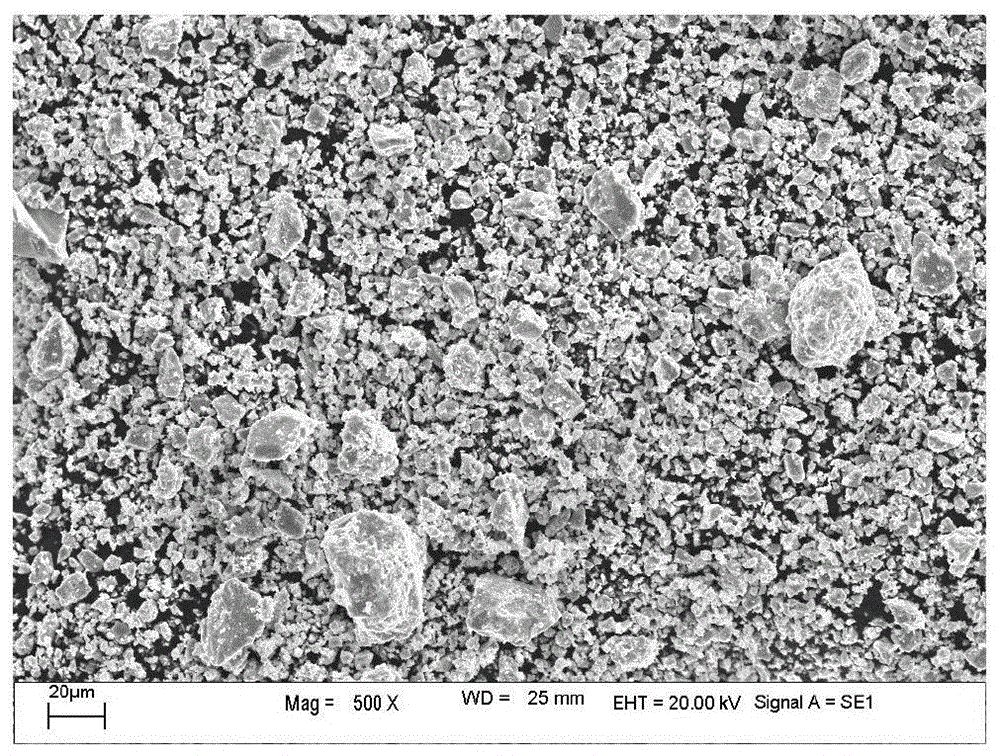

A low-cost method for preparing niobium-based alloys

Owner:UNIV OF SCI & TECH BEIJING

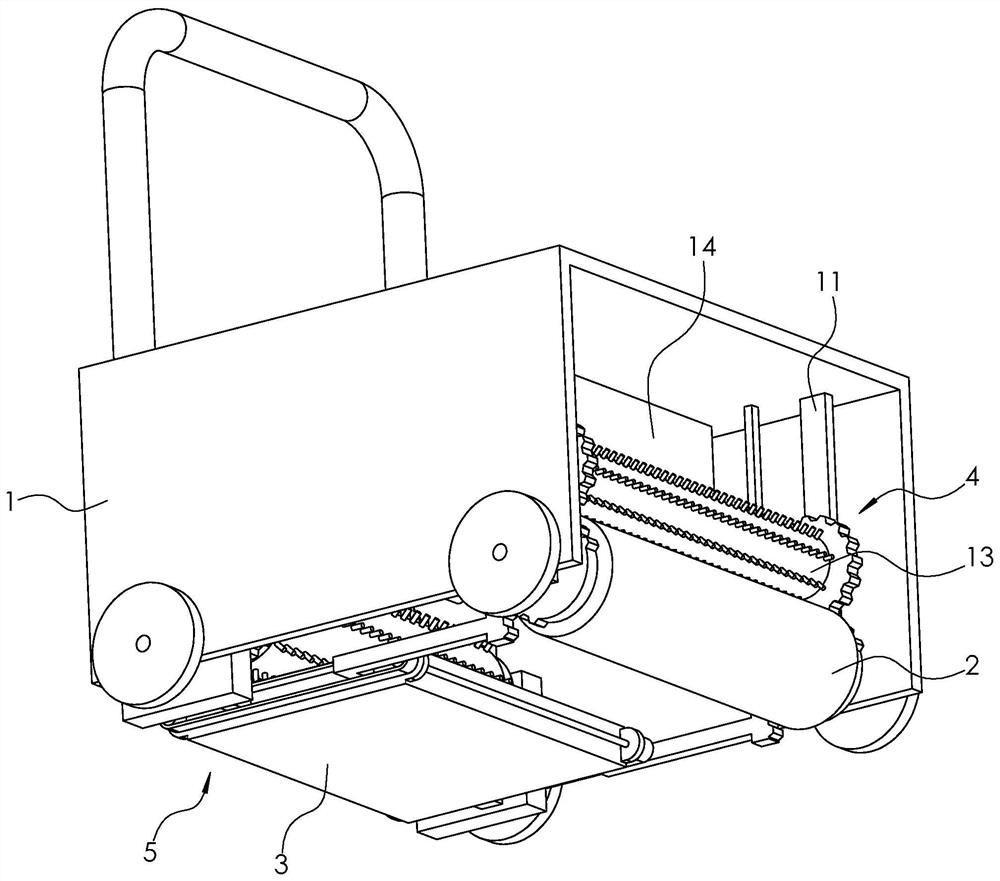

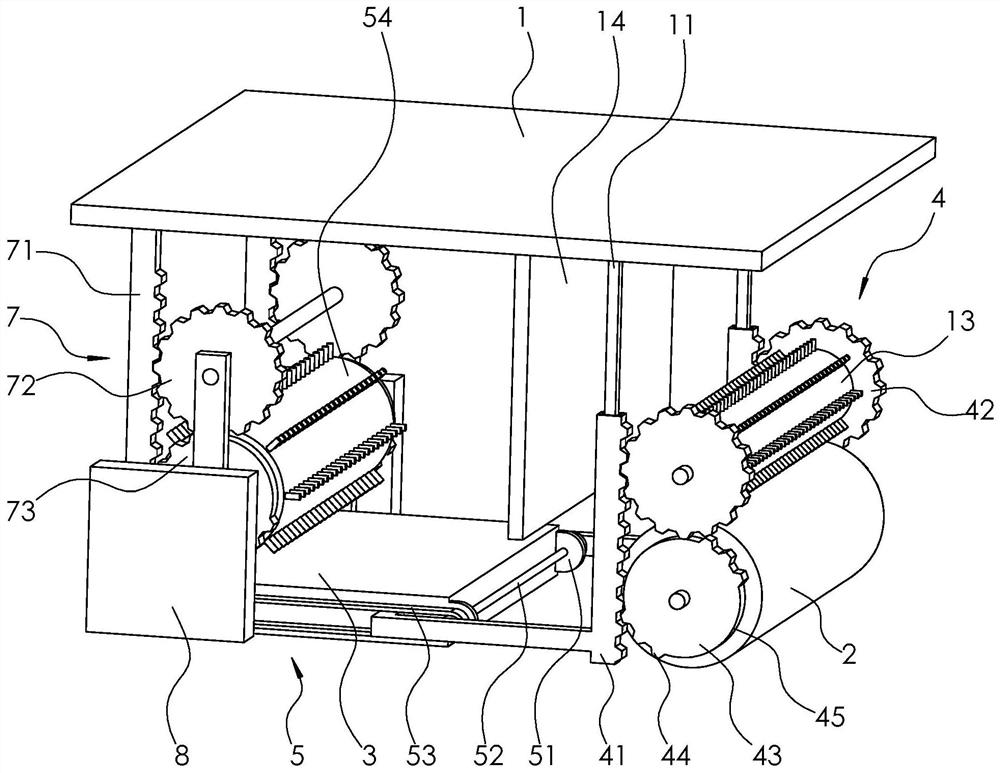

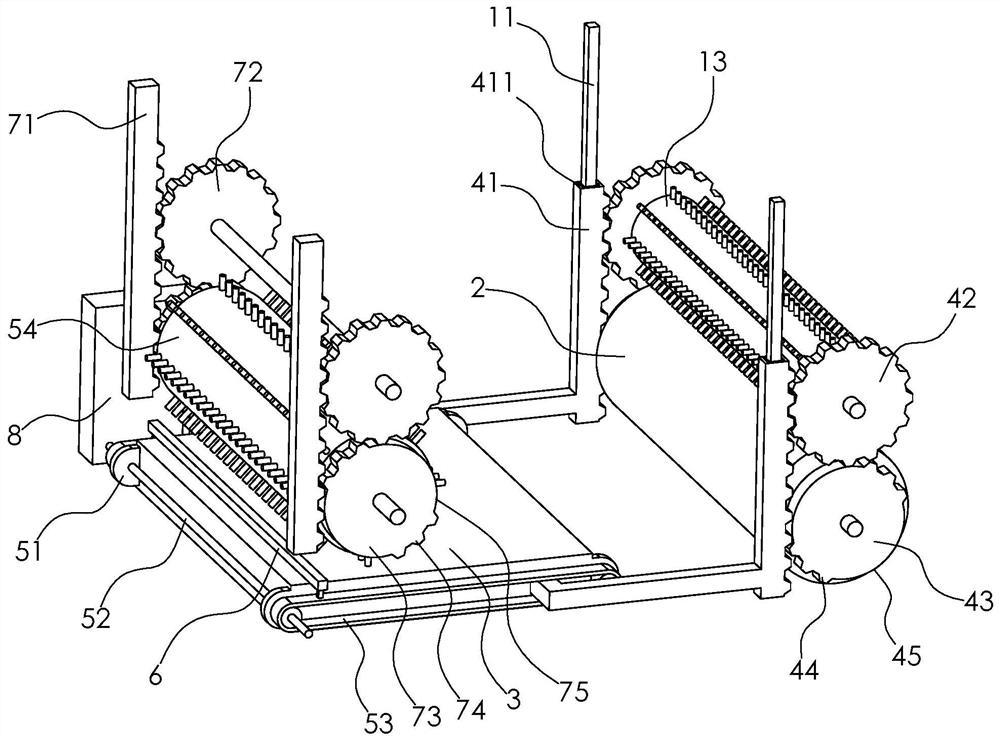

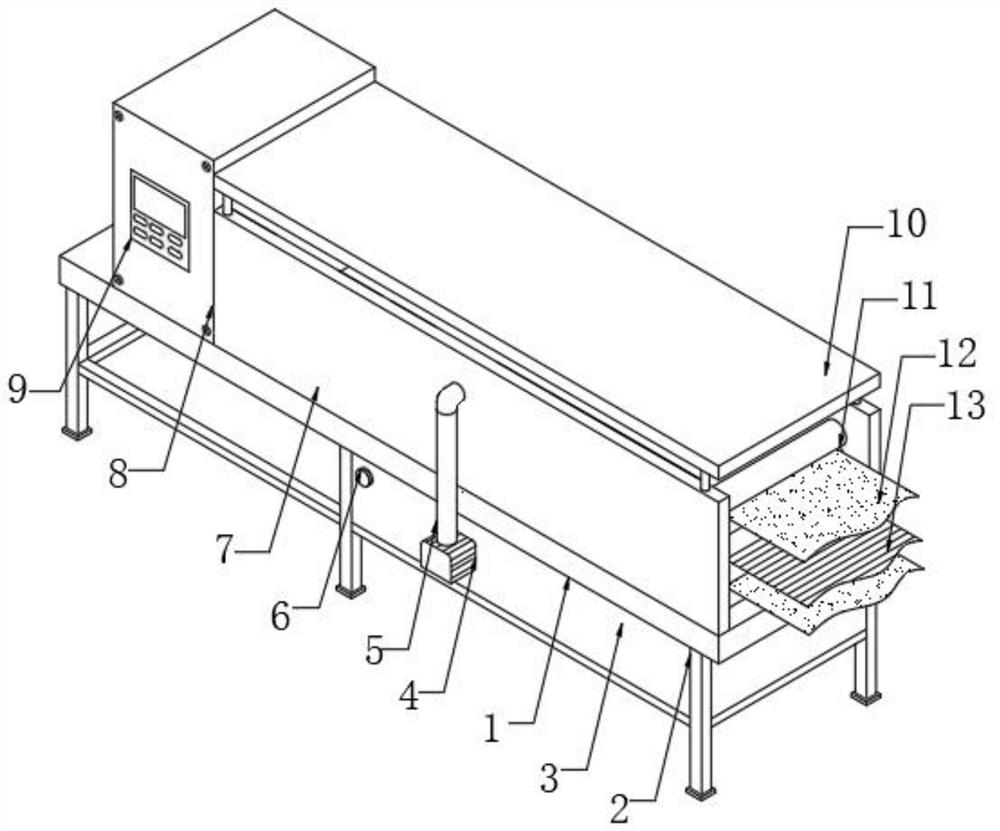

Roadbed compaction equipment for road construction

ActiveCN113550290AEasy to compactImprove compactionCleaning using toolsSoil preservationCartRoad construction

The invention relates to the technical field of road construction, in particular to roadbed compaction equipment for road construction. The roadbed compaction equipment comprises a cart, a press roller and a press plate which are horizontally arranged, the press roller is rotatably connected to the cart and abuts against the ground, and the roadbed compaction equipment further comprises a first driving mechanism; the first driving mechanism comprises a first rack arranged on the press plate, a first gear rotatably connected to the cart and a first rotating wheel arranged on the press roller in a sleeving mode. The first rack is vertically arranged and slidably connected to the cart in a vertical direction. The first gear is meshed with the first rack; two groups of first latch units are arranged on the outer wall of the first rotating wheel in a circumferential direction; the first latch units are rotatably engaged with the first rack and the first gear, and two sets of first blank areas which are symmetrically arranged are arranged between the two groups of first latch units. According to the roadbed compaction equipment for road construction, the subgrade compaction can be facilitated .

Owner:河南派普建工集团有限公司

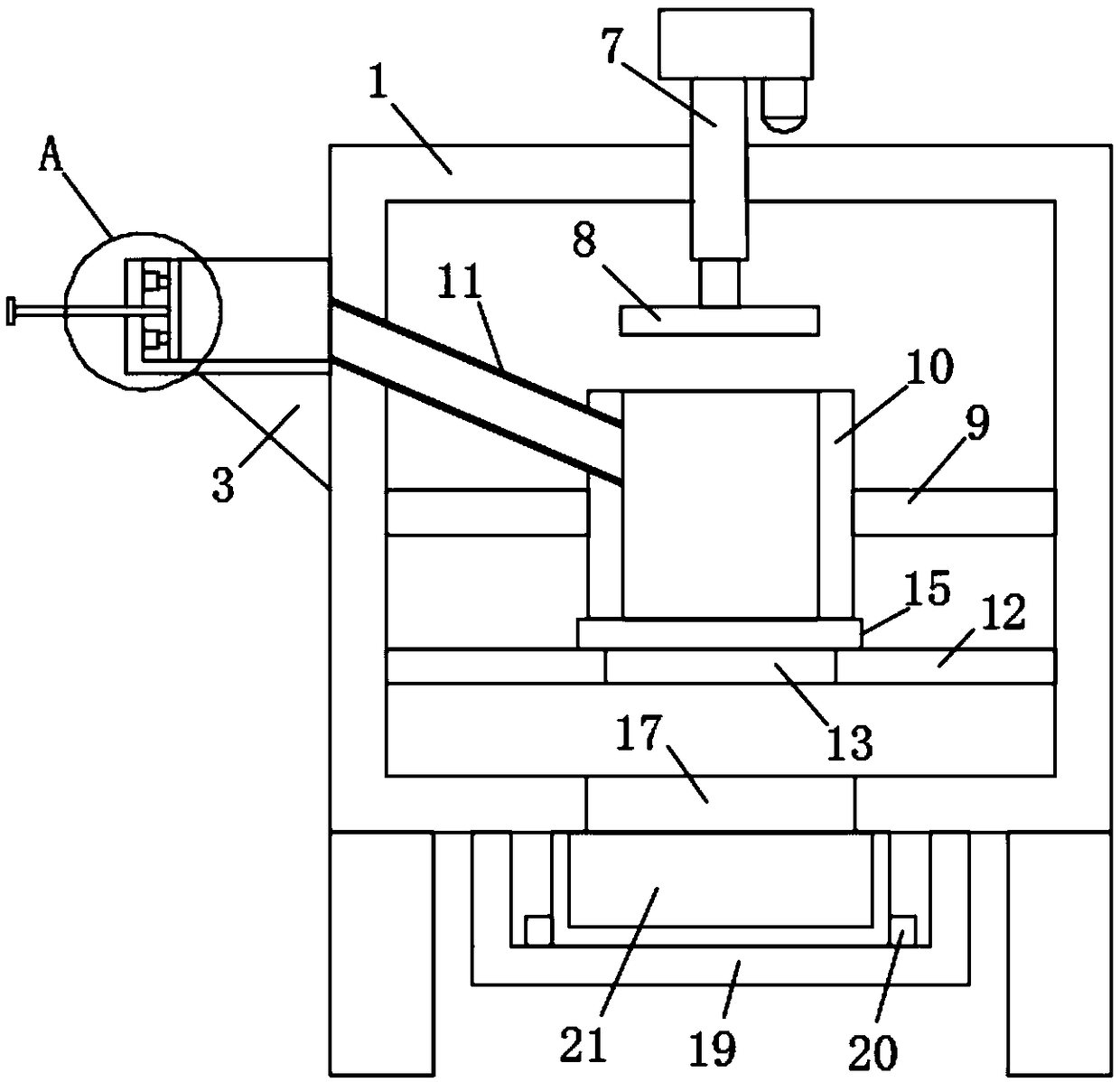

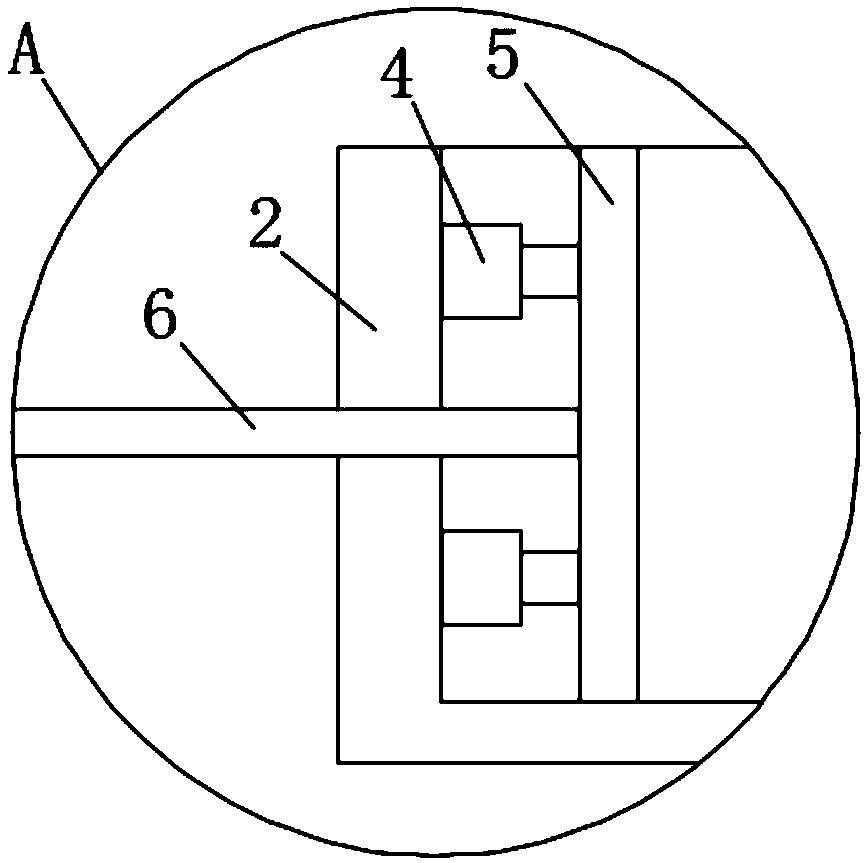

Compacting device for human hair processing

The invention discloses a compacting device for human hair processing. The compacting device comprises a compacting table, wherein a compacting hole is formed in the compacting table; a lower compacting block is inserted into the lower side of the compacting hole; a lower supporting plate is mounted on the lower side of the lower compacting block; the lower side of the lower supporting plate is intransmission connection with a first air cylinder through a telescopic rod; a vertical wall is mounted on one side of the upper end of the compacting table; a top plate is mounted on one side of thetop of the vertical wall; a second air cylinder is mounted in the middle of the upper side of the top plate; the lower side of the second air cylinder is in transmission connection with an upper supporting plate; and an upper compacting block is mounted on the lower side of the upper supporting plate. According to the compacting device disclosed by the invention, a wig to be compacted is placed inthe compacting hole; the lower compacting block and the upper compacting block are arranged, so that the upper side and the lower side of the wig can be compacted at the same time, and the compactingeffect is good; and the compacted wig can be moved out of the compacting hole through lifting adjustment of the lower compacting block, so that unloading is convenient and quick, and improvement of the compacting efficiency is facilitated.

Owner:太和县伊贝露发制品有限公司

Molded article for joining and method for producing the same

ActiveCN110402180BPrevent oxidationImprove thermal conductivityTransportation and packagingSemiconductor/solid-state device detailsActive agentComposite material

The present invention is a molded body for joining (1) composed of an aggregate of compressed Cu-core Sn-shell powder, and an active agent content ( 3) The activator-containing material (3) is used to remove oxides on the surface of the powder, and the molded body for joining contains Cu in a ratio of 55 to 95% by mass and Sn in a ratio of 45 to 5% by mass. The active agent in the active agent-containing material is contained in a ratio of 0.01 to 2 mass % with respect to 100 mass % of the molded body for joining, and the thickness of the molded body for joining is 20 to 400 μm.

Owner:MITSUBISHI MATERIALS CORP

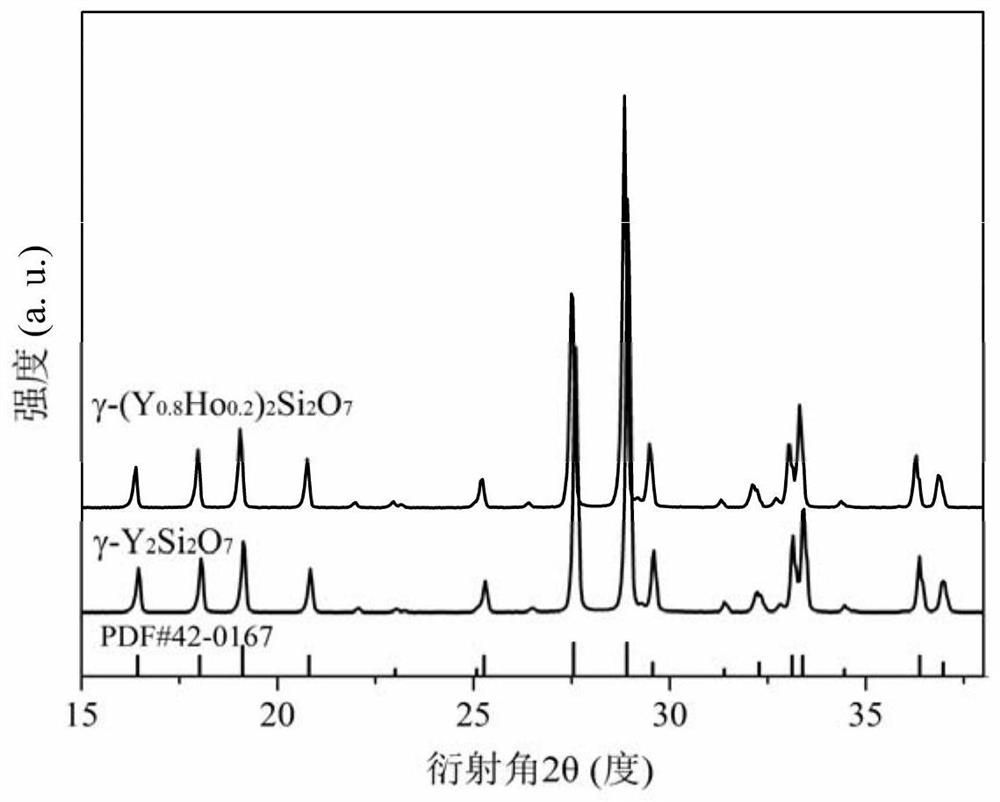

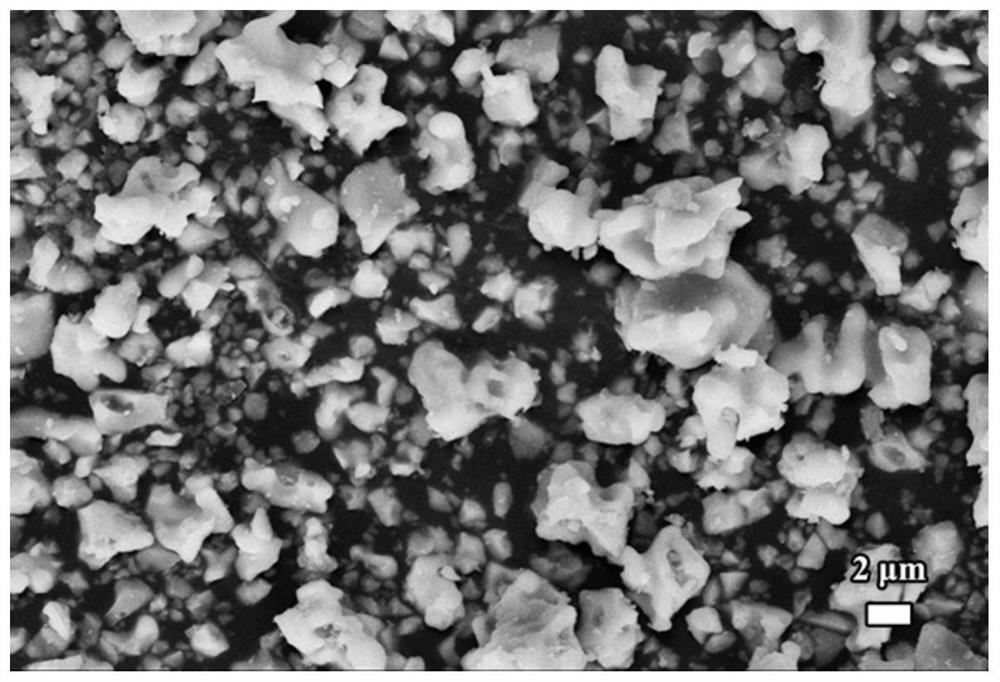

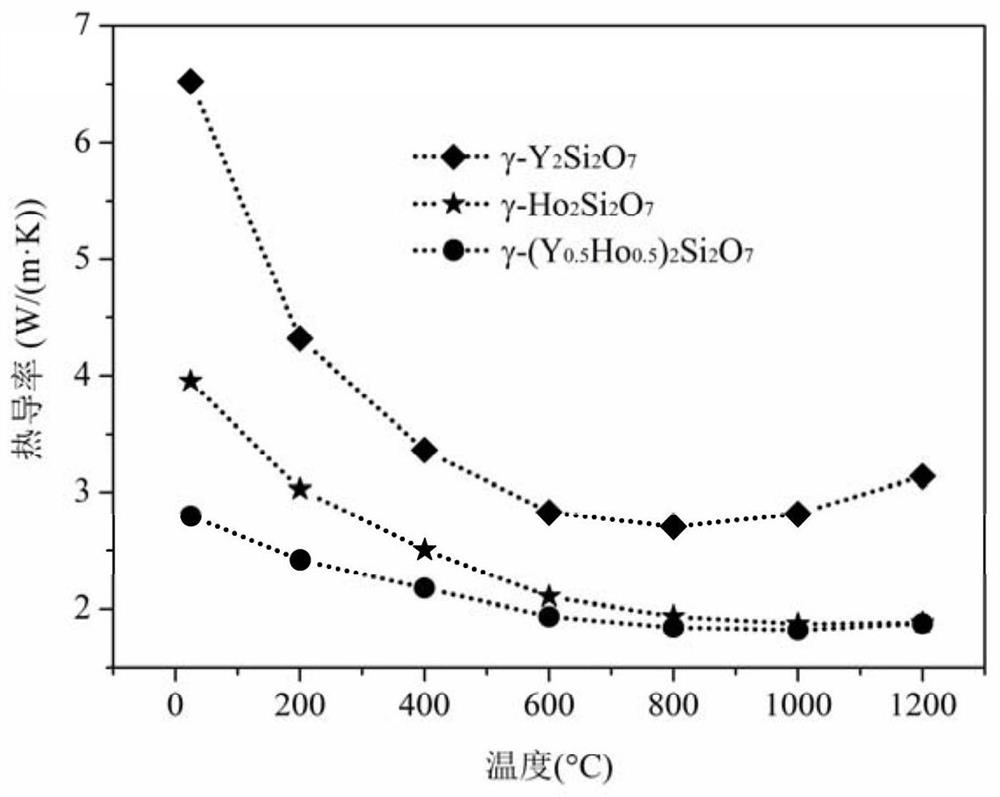

A (y 1-x ho x ) 2 the si 2 o 7 Solid solution material and preparation method thereof

The invention relates to the fields of low thermal conductivity and refractory materials, specifically a kind of (Y 1‑x Ho x ) 2 Si 2 o 7 Solid solution materials and methods for their preparation. Synthesized (Y 1‑x Ho x ) 2 Si 2 o 7 The solid solution is the γ phase that can exist stably from room temperature to 1450 °C, where the value of x is in the range of 0 <x<1。首先,以氧化钇、氧化钬和二氧化硅混合粉末作为原料,以乙醇为介质,进行球磨混合8~24h,形成浆料;接着,浆料烘干后筛成粉末,然后在马弗炉中烧结,烧结温度为1500~1600℃,烧结时间为0.5~1.5小时,最后得到(y1‑xHo x ) 2 Si 2 O 7 Solid solution powder. The solid solution powder is loaded into a graphite grinding tool and cold-pressed, and sintered in a hot-pressing furnace with a protective atmosphere to prepare (Y 1‑x Ho x ) 2 Si 2 O 7 Solid solution bulk. The present invention prepares (Y 1‑x Ho x ) 2 Si 2 O 7 solid solution material.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Corrugated board processing and bonding device

InactiveCN112356515AProlong clotting timeAffects the firmness of the bondMechanical working/deformationSandwich boardEngineering

The invention discloses a corrugated board processing and bonding device. The corrugated board processing and bonding device comprises a working table, wherein two side plates are fixedly mounted on one side of the working table; a conveying mechanism is fixedly mounted on one side of the two side plates; the conveying mechanism comprises six guide rollers; a box paper board, a wave sandwich boardand a box paper board are sequentially embedded between every two adjacent guide rollers from top to bottom; and one end of each of the six guide rollers is connected with a third circular tooth in asleeving manner. According to the corrugated board processing and bonding device, a gluing device is mounted, a glue pump is used for pumping glue in a glue storage box into a discharging groove in afixing block, the glue is uniformly sprayed on two surfaces of the wave sandwich board through a spray head at the bottom end of the fixing block, and in the spraying process, glue liquid is heated through electric heating wires mounted in cavities on two sides of the discharging groove, so that the solidification time of the glue is prolonged, manual gluing is replaced, the labor intensity is effectively reduced, and meanwhile, the influence on the firmness of bonding between the box paper boards and the wave sandwich boards due to premature solidification of the glue in the bonding processis avoided.

Owner:黄丹

A method for preparing high-performance powder metallurgy ti6al4v alloy

ActiveCN111545742BGuaranteed purityRaw materials are easy to getTransportation and packagingMetal-working apparatusAl powderHydrogenation process

The invention provides a method for preparing high-performance powder metallurgy Ti6Al4V alloy, which belongs to the field of powder metallurgy titanium. The present invention proposes to TiCl 2 , VCl 3 And aluminum powder as raw materials, mixed evenly in a certain proportion, after heat treatment-ball milling-forming-sintering, finally obtain high-performance Ti6Al4V alloy. During powder heat treatment, TiCl 2 , VCl 3 Redox reaction with aluminum powder respectively, Cl will be gaseous AlCl 3 The matrix is removed in the form of Ti, V, and Al are further reacted and diffused. After being crushed by ball milling, fine Ti6Al4V powder is obtained. After forming and sintering, a high-performance Ti6Al4V powder with an oxygen content of <0.12wt.% and a density of ≥99% is finally obtained. Ti6Al4V alloy. The preparation process of the present invention is simple, the densification of Ti6Al4V can be achieved by pressureless sintering, the grain size is small, the loss of alloy elements caused by the hydrogenation process is effectively avoided, and the high oxygen increase caused by the element powder mixing method is also avoided. The preparation of high-performance Ti6Al4V alloy provides a new idea.

Owner:UNIV OF SCI & TECH BEIJING

A high-entropy ceramic material with excellent tribological properties and its preparation method

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com