Molded article for joining and method for producing the same

A molded body and bonding strength technology, applied in semiconductor/solid-state device manufacturing, manufacturing tools, welding equipment, etc., can solve the problem of difficult high-strength semiconductor chip components being bonded to the substrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

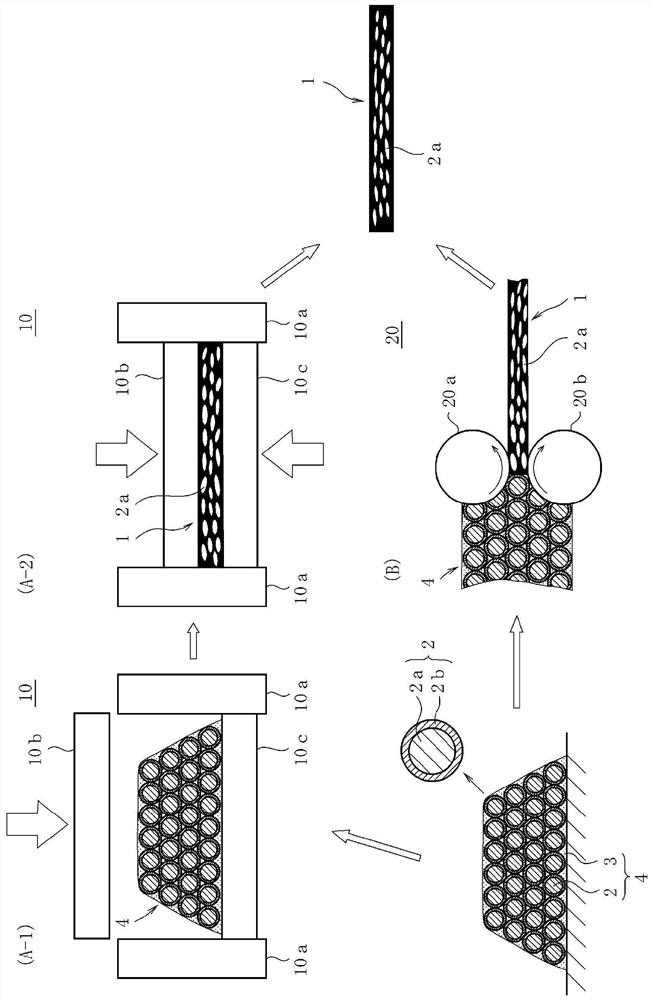

Method used

Image

Examples

Embodiment 1

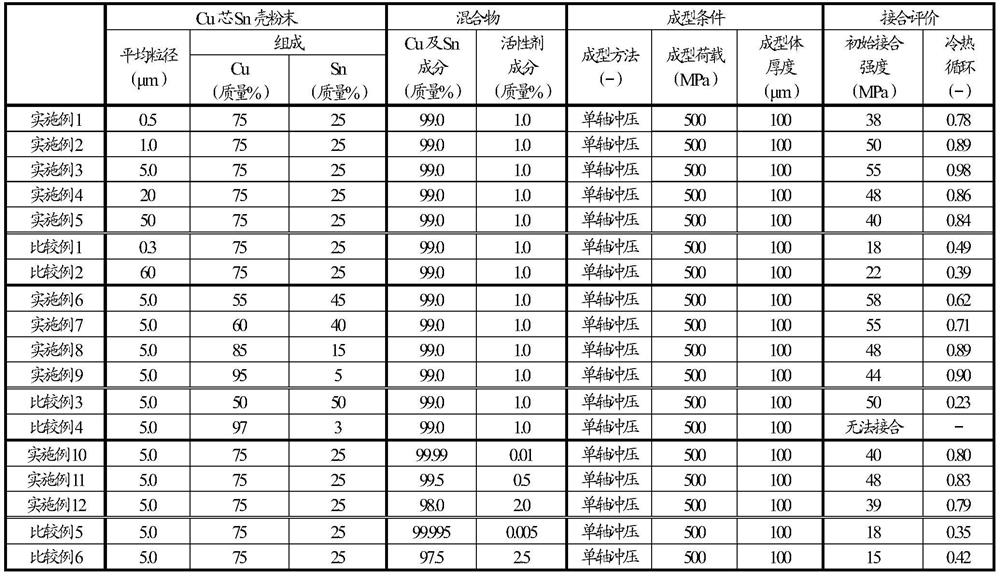

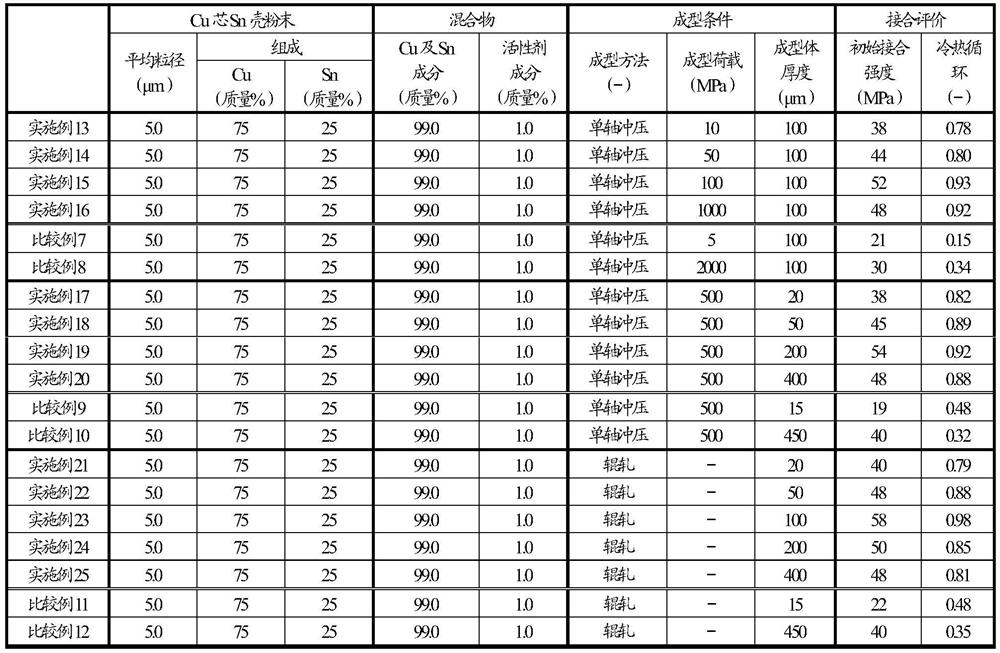

[0034]A Cu core Sn shell powder having an average particle diameter of 0.5 μm, a Cu ratio of 75% by mass, and a Sn ratio of 25% by mass was prepared. Here, the compositional ratio of Cu and Sn in the Cu core Sn shell powder was measured by ICP emission spectroscopy (manufactured by Thermo Fisher Scientific, iCAP-6500Duo). In addition, the crystal structure of the core-shell structure is mainly composed of Cu and Sn, and was confirmed by a powder X-ray diffraction method (manufactured by PANalytical, multi-purpose X-ray diffractometer Empyrean). Next, under a nitrogen atmosphere, the Cu core Sn shell powder was put in a mortar, a general-purpose flux (92MS manufactured by Arakawa Chemical Industries, Ltd.) was added to the Cu core Sn shell powder, and uniformly mixed for 30 minutes to obtain a mixture. In this mixture, the gaps between the Cu core Sn shell powders, that is, the inner walls of the closed cells and the open cells are covered with the active agent content. In the...

Embodiment 2~5 and comparative example 1、2

[0036] In Examples 2 to 5 and Comparative Examples 1 and 2, as shown in Table 1, the average particle diameter of the Cu core Sn shell powder used to produce the molded body for joining was used. The Cu core Sn shell powder was used in the same manner as in Example 1 to obtain a molded body for joining.

Embodiment 6~9 and comparative example 3、4

[0038] In Examples 6 to 9 and Comparative Examples 3 and 4, as shown in Table 1, Cu and Sn compositions different from those in Example 1 were used for the composition of Cu and Sn of the Cu core Sn shell powder used to make the molded body for joining. Cu-core-Sn-shell powder having a Sn composition was obtained in the same manner as in Example 1 to obtain a molded body for joining.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com