Brick paving equipment for municipal engineering

A brick laying equipment and engineering technology, applied in roads, road repairs, roads, etc., can solve the problems of inconvenient compaction, poor laying effect, poor brick laying effect, etc., to achieve good laying effect, avoid gaps, and sturdy use The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

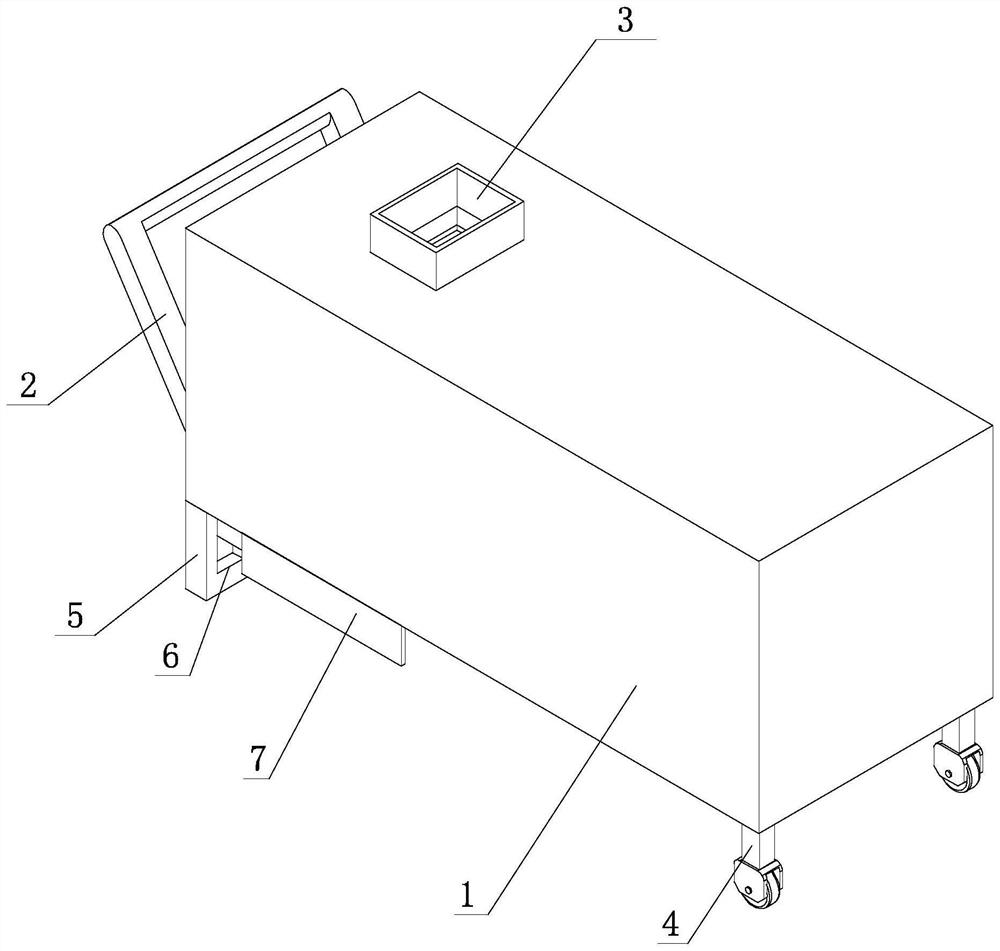

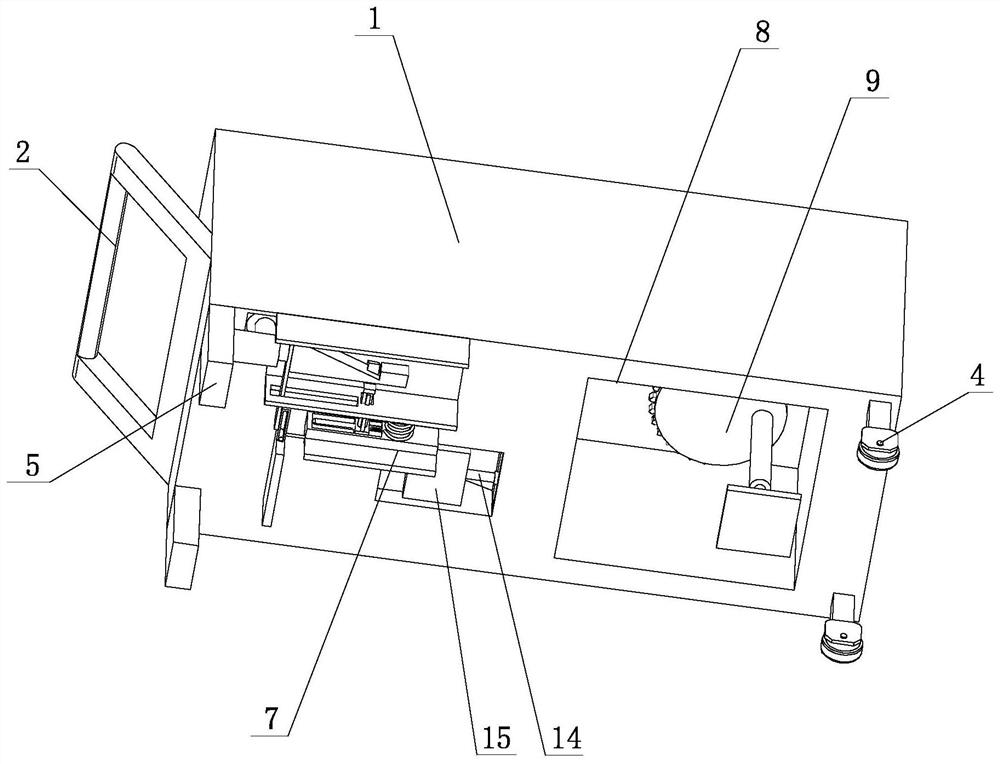

[0030] see Figure 1-Figure 2 , Figure 5-Figure 6, the present invention provides a technical solution: a kind of brick laying equipment for municipal engineering, including equipment body 1, auxiliary leveling device 7 and comprehensive compacting device 9, one side outer wall of equipment body 1 is fixedly connected with push handle 2, equipment The top outer wall of the main body 1 is fixedly equipped with a hopper 3, the bottom outer wall of the equipment body 1 is fixedly connected with two rollers 4, and the bottom outer wall of the equipment body 1 away from the side of the rollers 4 is fixedly connected with two support columns 5, the support column 5 A limit chute 6 is provided on one side of the device body 1, an auxiliary flattening device 7 is fixedly connected to the bottom of the device body 1, and an accommodation groove 8 is provided at the bottom of the equipment body 1, and a comprehensive compacting device 9 is fixedly connected to the inner wall of the acc...

Embodiment 2

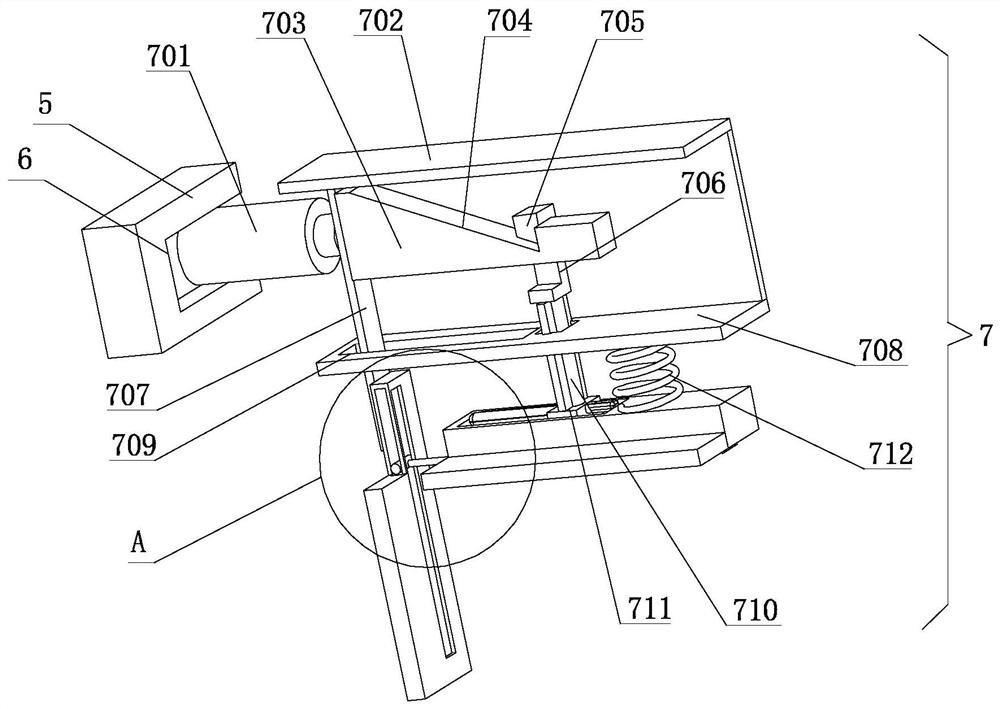

[0033] like Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution downwards: the auxiliary flattening device 7 includes a driving cylinder 701, the bottom outer wall of the equipment body 1 is fixedly connected with a bonding plate, and the bottom outer wall of the equipment body 1 passes through The bonding plate is fixedly connected with a fixed plate 1 702, one side of the driving cylinder 701 is fixedly connected with a moving block 703, one side of the moving block 703 is provided with a wedge-shaped groove 704, and one side of the moving block 703 is slidingly connected with a moving column 705, and the moving column One side of 705 is provided with a trapezoidal groove 706, the side of the moving block 703 close to the driving cylinder 701 is fixedly connected with a connecting plate 707, the bottom of the device body 1 is fixedly connected with a fixed plate 2 708 through a laminating plate, and the inside of the fixed p...

Embodiment 3

[0036] like Figure 1-7 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution downwards: the comprehensive compaction device 9 includes a drive motor 901, and the bottom of the drive motor 901 is connected with a motor shaft 902 for rotation, and the motor shaft 902 The outer wall of the motor shaft 902 is fixedly connected with a rotating plate 903, the bottom of the motor shaft 902 is fixedly connected with a driving gear 904, the top inner wall of the receiving tank 8 is fixedly connected with a rotating seat 905, and the bottom of the rotating seat 905 is rotatably connected with a rotating rod 906. The bottom is fixedly connected with a rotating gear 907, the top of the rotating gear 907 is fixedly connected with a rotating column 908, the bottom of the rotating gear 907 is fixedly connected with a compacting cylinder 909, and the bottom of the compacting cylinder 909 is fixedly connected with a compacting plate 910. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com