Preparation method of high-compactness WC/Co composite material hard alloys

A composite material and cemented carbide technology, which is applied in metal processing equipment, metal material coating technology, liquid chemical plating, etc. High, low cost, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

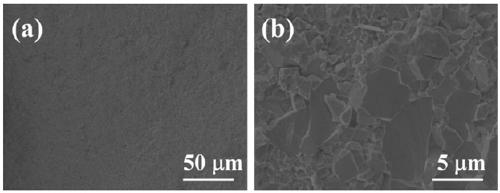

Image

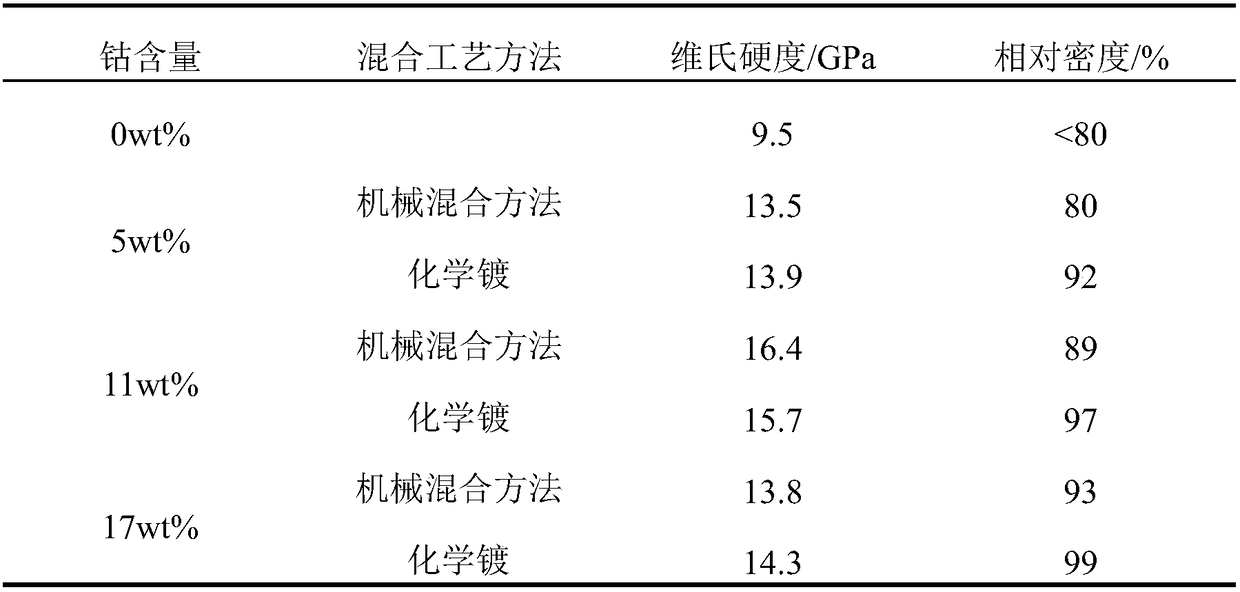

Examples

Embodiment 1

[0027] This example provides a method for preparing a high-density WC / Co composite cemented carbide, and the preparation steps are as follows:

[0028] (1) Take 2g of WC powder with an average particle size of 5 μm, add the WC powder into the hydrofluoric acid-nitric acid solution of the coarsening liquid, and coarsen it under the action of ultrasonic dispersion, wherein the concentration of hydrofluoric acid is 60ml / L, and the concentration of nitric acid is 40ml / L, the ultrasonic frequency is 30kHz, and the ultrasonic power is 100W. Filter and dry the coarsened powder and put it into the activation solution cobalt sulfate-sodium hypophosphite solution. Soak in the same ultrasonic dispersion environment as the coarsening process, and activate The content of cobalt sulfate heptahydrate in the liquid is 40g / L, the content of sodium hypophosphite monohydrate is 40g / L, and the soaking time is 60min; then put the soaked powder into a crucible and use a box furnace for heat treatmen...

Embodiment 2

[0031] This example provides a method for preparing a high-density WC / Co composite cemented carbide, and the preparation steps are as follows:

[0032]1) Take 2g of WC powder with an average particle size of 3μm, add tungsten carbide powder to the roughening solution, and roughen under the action of ultrasonic dispersion. The concentration of hydrofluoric acid is 60ml / L, the concentration of nitric acid is 40ml / L, and the ultrasonic frequency is 40kHz, ultrasonic power is 120W. Filter and dry the roughened powder into the cobalt sulfate-sodium hypophosphite activation solution and soak in the same ultrasonic dispersion environment as the coarsening process. The sodium phosphate content is 40g / L, and the soaking time is 120min. Then put the soaked powder into the crucible and use a box furnace for heat treatment. The heating rate is 5°C / min, the heat treatment temperature is 160°C, and the heat preservation is 60min to obtain the activated powder; the pretreated powder Put in...

Embodiment 3

[0035] This example provides a method for preparing a high-density WC / Co composite cemented carbide, and the preparation steps are as follows:

[0036] 1) Take 2g of WC powder with an average particle size of 4μm, add tungsten carbide powder into the roughening solution, and roughen under the action of ultrasonic dispersion. The concentration of hydrofluoric acid is 60ml / L, the concentration of nitric acid is 40ml / L, and the ultrasonic frequency is 35kHz, ultrasonic power is 150W. Filter and dry the roughened powder into the cobalt sulfate-sodium hypophosphite activation solution and soak in the same ultrasonic dispersion environment as the coarsening process. The sodium phosphate content is 50g / L, and the soaking time is 30min. Then put the soaked powder into a crucible and use a box furnace for heat treatment. The heating rate is 8°C / min, the heat treatment temperature is 220°C, and the heat preservation is 100min to obtain the activated powder; after the cobalt salt activa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com