A low-cost method for preparing niobium-based alloys

A niobium-based alloy, low-cost technology, applied in the field of low-cost preparation of niobium-based alloys, can solve the problems of restricting the application of powder metallurgy niobium-based alloys, low yield of fine particle size powder, difficulty in popularization and application, etc., to achieve large lattice distortion , Low preparation cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

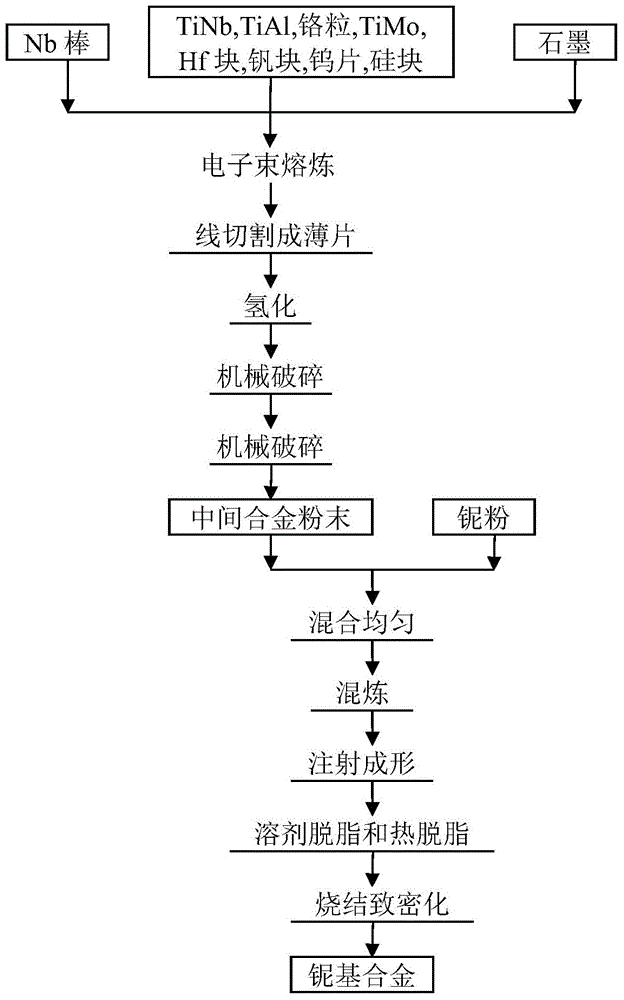

[0018] Example 1: Preparation of Nb-15%Ti-3%Al-4.5%Cr-5%V-0.5%Mo-3%W-2.5Hf-0.04%C alloy

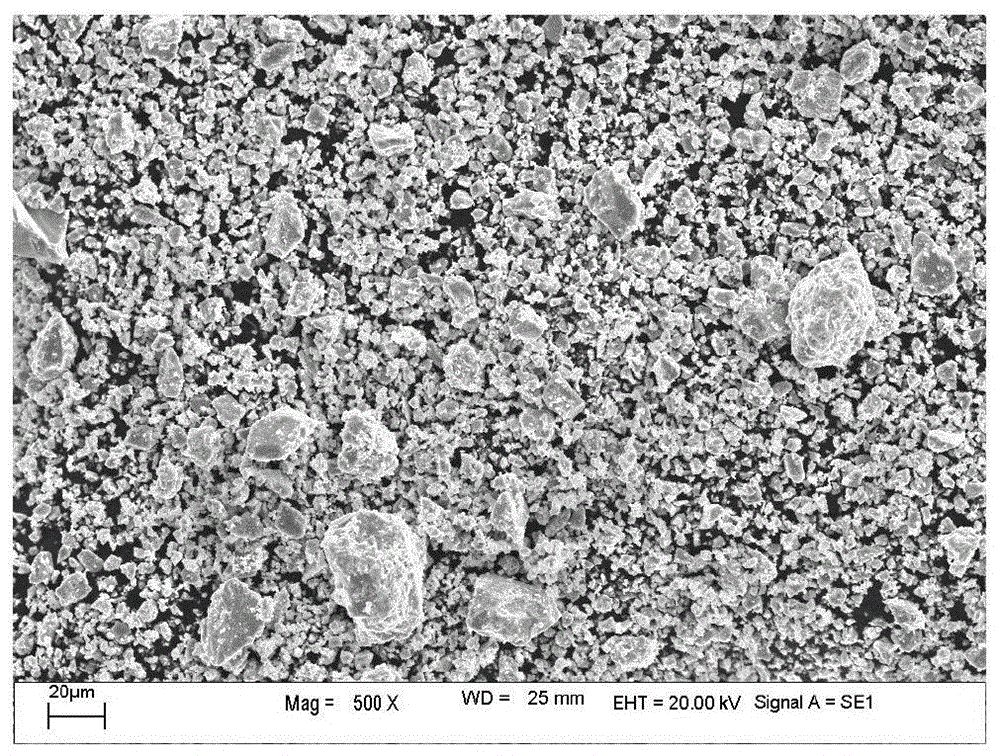

[0019] Design the composition of the master alloy according to the composition of the target niobium-based alloy. The composition of the master alloy is: 21.4% Ti, 4.3% Al, 6.4% Cr, 7.1% V, 0.7% Mo, 4.3% W, 3.6% Hf, 0.057% C and The balance niobium. Weigh TiNb alloy, TiAl alloy, chromium block, vanadium block, TiMo alloy, tungsten sheet, Hf particles, graphite powder and Nb rod according to the composition of the intermediate alloy. Various raw materials are smelted in an electron beam melting furnace to obtain a master alloy ingot. The niobium-based alloy ingot was cut into 1mm thick slices by wire cutting, and then hydrogenated in high-purity hydrogen at a hydrogenation temperature of 550°C, holding for 4 hours, and a cooling rate of 0.5°C / min. During the hydrogenation process, a small amount of strong reducing magnesium particles are placed in the furnace to absorb impurity oxygen in th...

Embodiment 2

[0020] Example 2: Preparation of Nb-16%Ti-4%Al-4.5%Cr-4%V-0.5%Mo-3%W-2.8Hf-0.05%C alloy

[0021] Design the composition of the master alloy according to the composition of the target niobium-based alloy. The composition of the master alloy is: 21.3% Ti, 5.3% Al, 6% Cr, 5.3% V, 0.7% Mo, 4% W, 3.7% Hf, 0.067% C and The balance niobium. Weigh TiNb alloy, TiAl alloy, chromium block, vanadium block, TiMo alloy, tungsten sheet, Hf particles, graphite powder and Nb rod according to the composition of the intermediate alloy. Various raw materials are smelted in an electron beam melting furnace to obtain a master alloy ingot. The niobium-based alloy ingot was cut into 2mm thick slices by wire cutting, and then hydrogenated in high-purity hydrogen, the hydrogenation temperature was 750°C, the holding time was 2 hours, and the cooling rate was 1°C / min. During the hydrogenation process, a small amount of calcium particles with strong reducibility are placed in the furnace to absorb impurit...

Embodiment 3

[0022] Example 3: Preparation of Nb-14%Ti-3.5%Mo-3.5%V-2%Si-0.75%Hf-0.03%C alloy

[0023] The composition of the master alloy is designed according to the composition of the target niobium-based alloy. The composition of the master alloy is: 18.7% Ti, 4.7% Mo, 4.7% V, 2.7% Si, 1% Hf, 0.04% C and the balance niobium. Weigh TiNb alloy, TiMo alloy, vanadium block, silicon particles, graphite powder and Nb rod according to the composition of the intermediate alloy. Various raw materials are smelted in an electron beam melting furnace to obtain a master alloy ingot. The niobium-based alloy ingot is cut into 2mm thick slices by wire cutting, and then hydrogenated in high-purity hydrogen, the hydrogenation temperature is 800°C, the holding time is 1 hour, and the cooling rate is 0.5-3°C / min. During the hydrogenation process, a small amount of strongly reducing lithium chips are placed in the furnace to absorb impurity oxygen in the atmosphere. The hydrogenated alloy flakes are mechani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com