A high-entropy ceramic material with excellent tribological properties and its preparation method

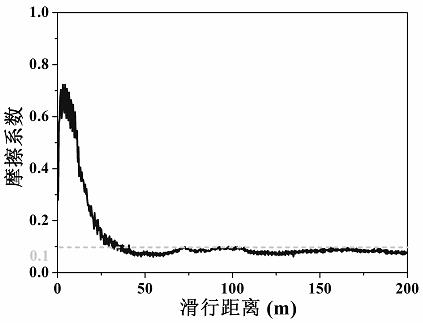

A ceramic material and tribology technology, applied in the field of high-entropy ceramic materials and their preparation, can solve the problem of very little research on tribological properties, and achieve the effects of being beneficial to sintering, easy to densify, and simple to prepare.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

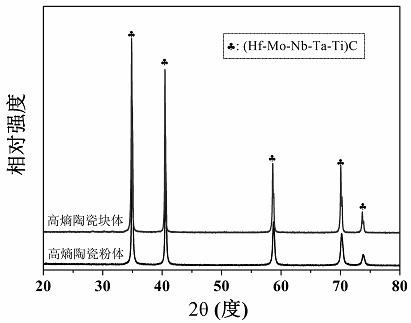

[0033] Example 1 A high-entropy ceramic material with excellent tribological properties, the material is in the form of a block, its composition is (Hf-Mo-Nb-Ta-Ti-)C, and it is made from the following raw materials in mass percentage: HfO 2 21.2%, MoO 3 14.5%, Nb 2 o 5 13.4%, Ta 2 o 5 22.3%, TiO 2 8.0% and graphite powder 20.6%.

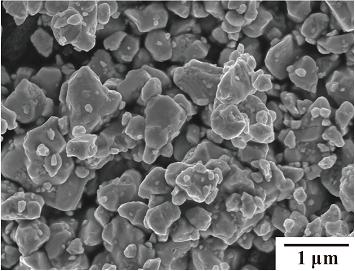

[0034] The preparation method of the high-entropy ceramic material: firstly weigh each raw material according to the proportion, put each raw material in a ball mill, then add anhydrous ethanol 0.25 times its mass to the mixed raw material, mix evenly, dry, pass through Sieve to obtain mixed powder with a particle size of 5-20 μm; put the mixed powder into a graphite mold, place it in a spark plasma sintering furnace and undergo spark plasma sintering. ℃ / min, the sintering temperature is 1750 ℃, the pressure is 15 MPa, and the holding time is 30 min. After sintering, the sintered product was pulverized in a high-energy ball mill to obtain a h...

Embodiment 2

[0035] Example 2 A high-entropy ceramic material with excellent tribological properties, the material is in the form of a block, its composition is (Hf-Mo-Nb-Ta-Ti-)C, and it is made from the following raw materials in mass percentage: HfO 2 21.9%, MoO 3 15.0%, Nb2 o 5 13.8%, Ta 2 o 5 23.0%, TiO 2 8.3% and graphite powder 18.0%.

[0036] The preparation method of the high-entropy ceramic material: firstly weigh each raw material according to the proportion, and place each raw material in a ball mill, then add anhydrous ethanol 0.35 times its mass to the mixed raw material, mix evenly, dry, pass through Sieve to obtain mixed powder with a particle size of 5-20 μm; put the mixed powder into a graphite mold and place it in a spark plasma sintering furnace for spark plasma sintering. The sintering conditions refer to a vacuum degree below 0.08 Pa and an average heating rate of 150°C / min, the sintering temperature is 1850°C, the pressure is 5MPa, and the holding time is 20 mi...

Embodiment 3

[0037] Example 3 A high-entropy ceramic material with excellent tribological properties, the material is in the form of a block, its composition is (Hf-Mo-Nb-Ta-Ti-)C, and it is made from the following raw materials in mass percentage: HfO 2 21.5%, MoO 3 14.7%, Nb 2 o 5 13.6%, Ta 2 o 5 22.7%, TiO 2 8.1% and graphite powder 19.4%.

[0038] The preparation method of the high-entropy ceramic material: firstly weigh each raw material according to the proportion, and place each raw material in a ball mill, then add anhydrous ethanol 0.30 times its mass to the mixed raw material, mix evenly, dry, pass through Sieve to obtain mixed powder with a particle size of 5-20 μm; put the mixed powder into a graphite mold and place it in a spark plasma sintering furnace for spark plasma sintering. / min, sintering temperature 1800 ℃, pressure 10MPa, holding time 25 min. After sintering, the sintered product is pulverized in a high-energy ball mill to obtain a high-entropy ceramic powder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com