Method for producing zirconium oxide fibre and the produced zirconium oxide fibre

A technology of zirconia fiber and tetragonal zirconia, which is applied in the field of materials, can solve the problems of large particle size of zirconia powder, thick precursor, and unsatisfactory fiber structure, etc., and achieve the effect of fine grain and dense structure

Active Publication Date: 2010-11-10

CHINA BUILDING MATERIALS ACAD

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this method, in order to ensure the filamentation of the precursor, a large amount of adhesives and resin binders are still used, and the particle size of the zirconia micropowder is relatively large, the precursor is relatively thick, and the fiber structure after firing is not ideal, which cannot meet the thermal insulation requirements. hot need

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Login to View More

Abstract

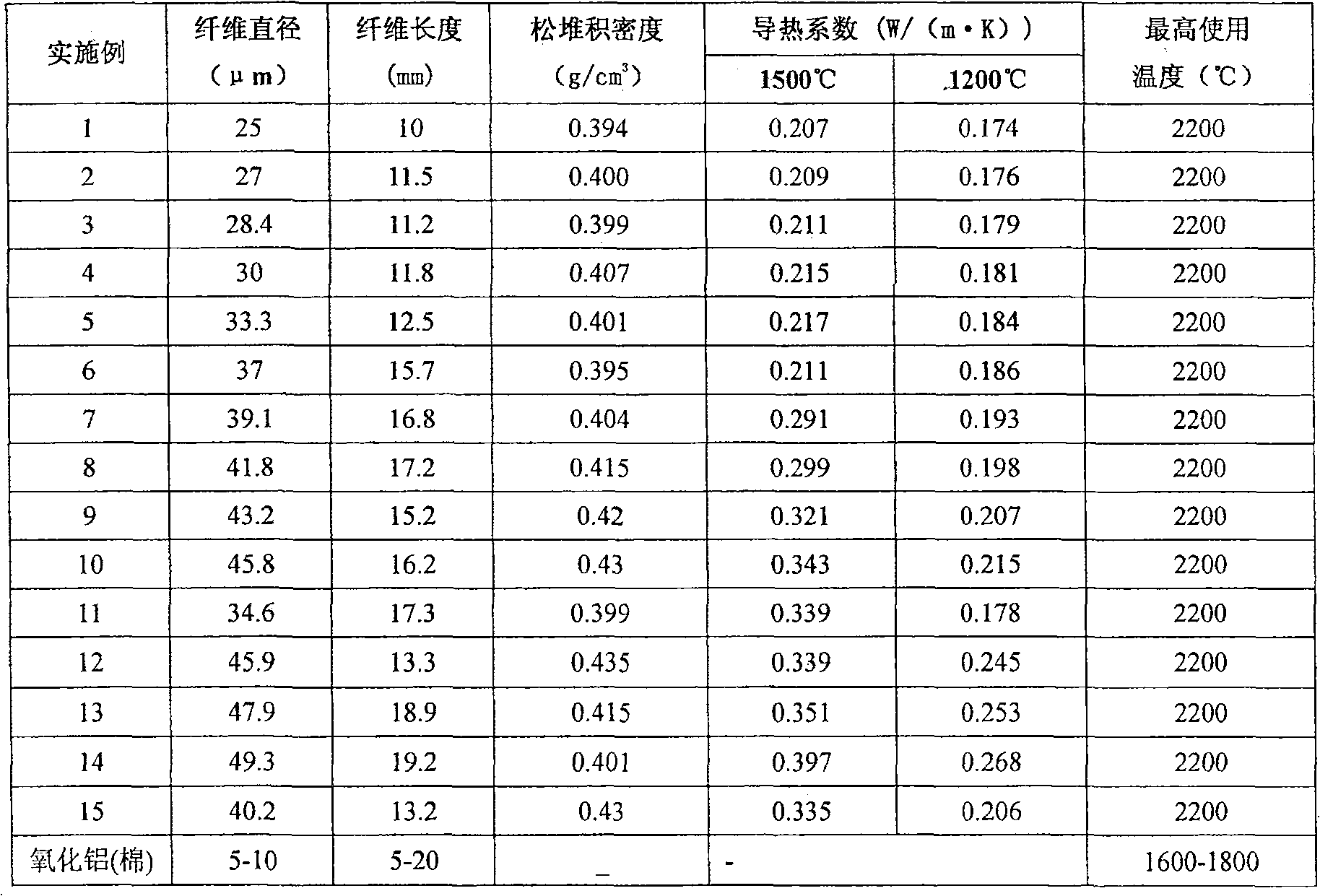

The invention discloses a preparation method of polycrystalline zirconia fibre. The method comprises the steps as follows: mixing ultrafine polycrystalline zirconia powder and dispersant with water to form slurry, adopting an extrude-concentration method to mold, preparing zirconia fibre precursor through extruding concentration bath in the hole with the diameter of 50 to 30 um, and sintering theprecursor to gain the zirconia fibre. The invention adopts ultrafine zirconia powder and innocuity water dispersant to make the water-based zirconia slurry with the solid phase content being about 35to 50 vol percent, wherein, the content of zirconia in the slurry is high. Through directly preparing the zirconia fibre precursor out of the slurry, the precursor is easy to be densified in the sintering process. The method is a rather perfect zirconia fibre preparation method. The prepared zirconia fibre has the advantages of small granularity, dense structure and good heat-insulation and preservation performance.

Description

A kind of preparation method of zirconia fiber and prepared zirconia fiber Technical field: The invention belongs to the field of materials, and in particular relates to the preparation of refractory ceramic fibers. Background technique: Refractory ceramic fiber has become a development hotspot due to its excellent thermal insulation performance. Carbon fiber is a kind of thermal insulation material with excellent performance. . Alumina fiber is also a commonly used thermal insulation material with excellent performance, which can be used again in an oxidizing atmosphere, but its maximum service temperature is 1800°C, which restricts its use in higher temperature environments. Compared with other types of inorganic fiber materials, zirconia ceramic fiber has a high melting point (2710±15°C), a large thermal resistance coefficient, good burning resistance (it can still maintain a good fiber shape at 2500°C in the atmosphere), With the advantages of chemical corrosion resi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B35/48C04B35/66

Inventor 何顺爱李懋强

Owner CHINA BUILDING MATERIALS ACAD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com