Method for preparing zirconia-alumina composite oxide carrier

A composite oxide and alumina technology, which is applied in the direction of catalyst carrier, chemical instrument and method, chemical/physical process, etc., can solve the problems of wide particle size distribution, rapid precipitation of zirconia, dispersion of pore size distribution, etc., and achieve narrow pore size distribution , easy vulcanization, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

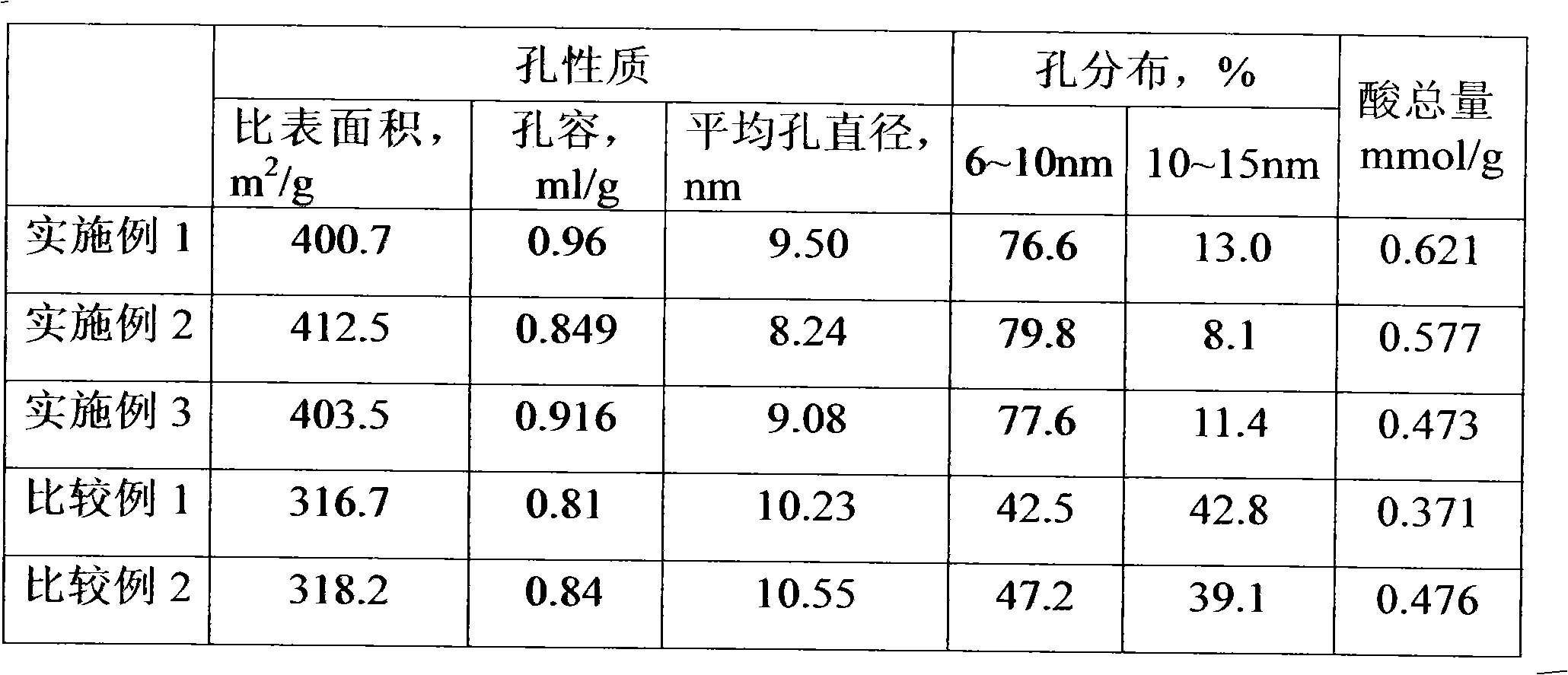

Embodiment 1

[0032] Mix 1000ml 2mol / L aluminum nitrate with 20ml silica gel (containing SiO 2 25 wt%), mixed with ammonia water to adjust the pH value to 7, and reacted at 80°C to obtain Sol A. 1mol / l ZrCl 4 The solution and dilute ammonia water were added dropwise in a beaker filled with ethanol and deionized water, the ethanol accounted for 15v% of the water, the pH value was controlled at 6.5, and the reaction temperature was 45°C to obtain sol B. Mix sol B and sol A, stir for 2 hours, heat up to 50°C, age for 2 hours, add 200ml of ethanol, filter with suction, wash with deionized water for 3 times, dry at 120°C for 3 hours, and pulverize to obtain the composite oxide dry glue. Calcined at 600°C for 3 hours to obtain a composite oxide, in which the content of zirconia is 60wt%, and the content of silicon oxide is 1.5wt%. The main properties are listed in Table 1.

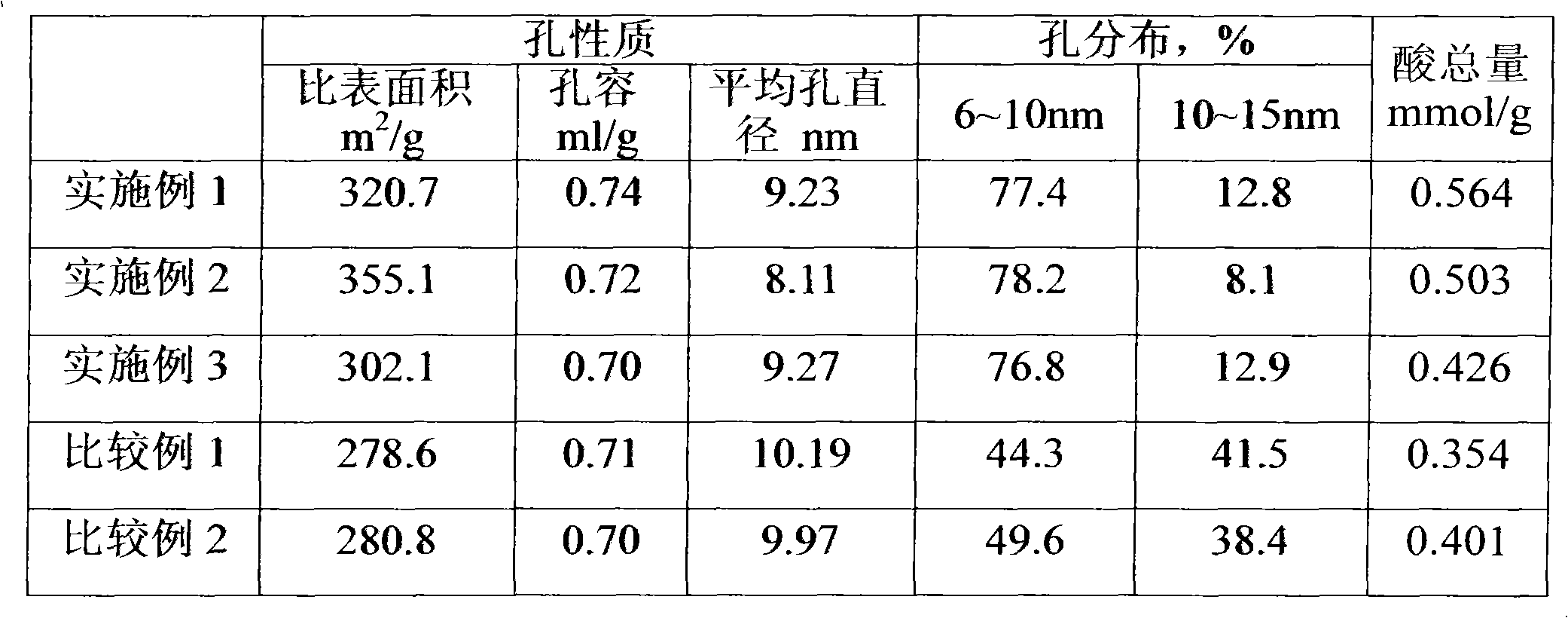

[0033] Take 123g of composite oxide dry glue, 13.9g of SB powder, add 3g of scallop powder, 5ml of dilute nitric acid, kn...

Embodiment 2

[0035] Mix 100ml 2mol / L aluminum nitrate with 20ml silica gel (containing SiO 2 25 wt%), mixed with ammonia water to adjust the pH value to 7.0, and reacted at 60°C to obtain Sol A. Under the condition of stirring, oxalic acid (0.1mol / l) was slowly dropped into 0.1mol / l zirconium nitrate to make the pH value = 5.5, and after continuing to stir for 10 minutes, put it into a three-necked flask and heat it to 95°C, and reflux at a constant temperature for 2 Sol B was obtained in 1 hour. Dilute sol B twice with distilled water and mix it with sol A, stir for 2 hours, heat up to 50°C, age for 2 hours, add 200ml of ethanol, filter with suction, wash 3 times with deionized water, dry at 120°C for 3 hours and pulverize to obtain The composite oxide dry glue was calcined at 600°C for 3 hours to obtain a composite oxide, in which the content of zirconia was 30wt%, and the content of silicon oxide was 2wt%. The main properties are listed in Table 1.

[0036] Take 114g of composite oxid...

Embodiment 3

[0038] Mix 1 mol / L aluminum sulfate and 1 mol / L sodium aluminate in parallel, adjust the pH value to 7.0, and react at 50°C to obtain Sol A. All the other are identical with embodiment 1. Wherein the content of zirconia in the composite oxide is 10wt%, and its main properties are listed in Table 1.

[0039] Take 132g of composite oxide dry glue, 13.9g of SB powder, add 3g of scallop powder, 5ml of dilute nitric acid, knead, extrude, dry at 120°C for 3 hours, and roast at 600°C for 3 hours to obtain a composite oxide carrier. The properties are listed in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com