Manufacturing method of flexible zirconia nanofiber phosphorylated peptide enrichment material

A technology of nanofibers and phosphorylated peptides, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, and fabric surface trimming, etc. It can solve the problems of complex preparation process and poor fiber strength, and achieve good continuity, large specific surface area, and high efficiency. The effect of effective enrichment and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

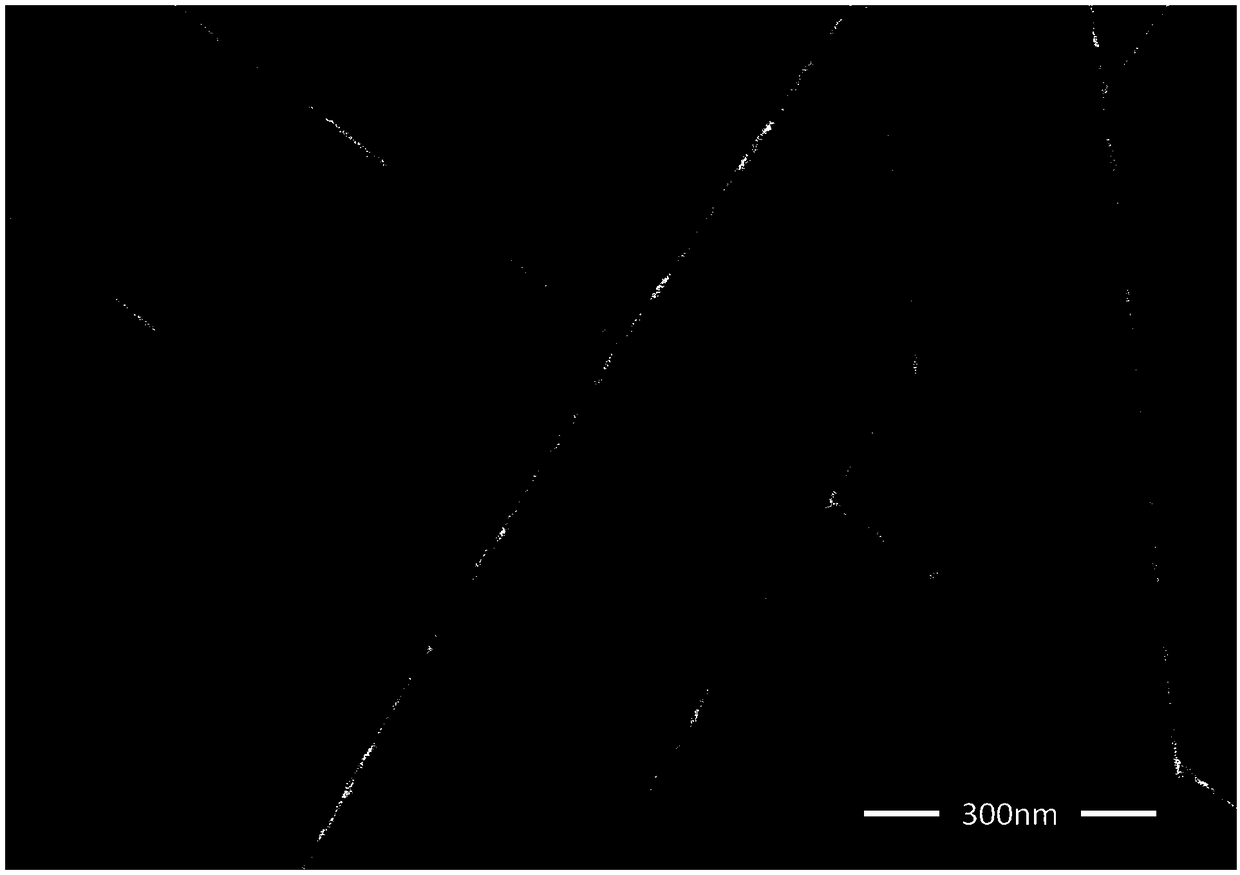

[0046] Step 1: Dissolve zirconyl nitrate, zirconium acetate and tetrabutyl titanate in the mixed solvent of ethanol / water / acetic acid in sequence, first stir for 10 minutes, then add chelating agent acetylacetone, and continue stirring for 20 minutes, wherein zirconium oxynitrate and acetic acid The mass ratio of zirconium is 1:1, the molar ratio of zirconium oxynitrate, zirconium acetate and tetrabutyl titanate is 100:0.8, the ratio of zirconium oxynitrate, zirconium acetate and ethanol / acetic acid is 1g:40ml, ethanol / water / acetic acid The volume ratio of zirconium oxynitrate and chelating agent acetylacetone is 1:1:1, and the molar ratio of zirconyl nitrate and chelating agent acetylacetone is 1:0.3; mix uniformly to make a uniform and stable precursor solution with a dynamic viscosity of 5Pa s, and the molecular chain in the precursor solution It has a three-dimensional stable polycyclic structure formed by acetylacetone ligands and central metal zirconium ions, and its stru...

Embodiment 2

[0057] Step 1: Dissolve zirconium hydroxide and tin oxalate successively in the mixed solvent of acetic acid / hydrochloric acid, add chelating agent nitrosalicylic acid after first stirring 50min, continue to stir again 20min, wherein the mol ratio of zirconium hydroxide and tin oxalate is 100:0.05, the ratio of zirconium hydroxide to acetic acid / hydrochloric acid is 1g:20ml, the volume ratio of acetic acid to hydrochloric acid is 1:2, the molar ratio of zirconium hydroxide to chelating agent nitrosalicylic acid is 1:0.4; mix well A uniform and stable dynamic viscosity is prepared as a precursor solution of 0.2Pa·s, and the molecular chain in the precursor solution has a three-dimensional stable polycyclic structure similar to that of Example 1;

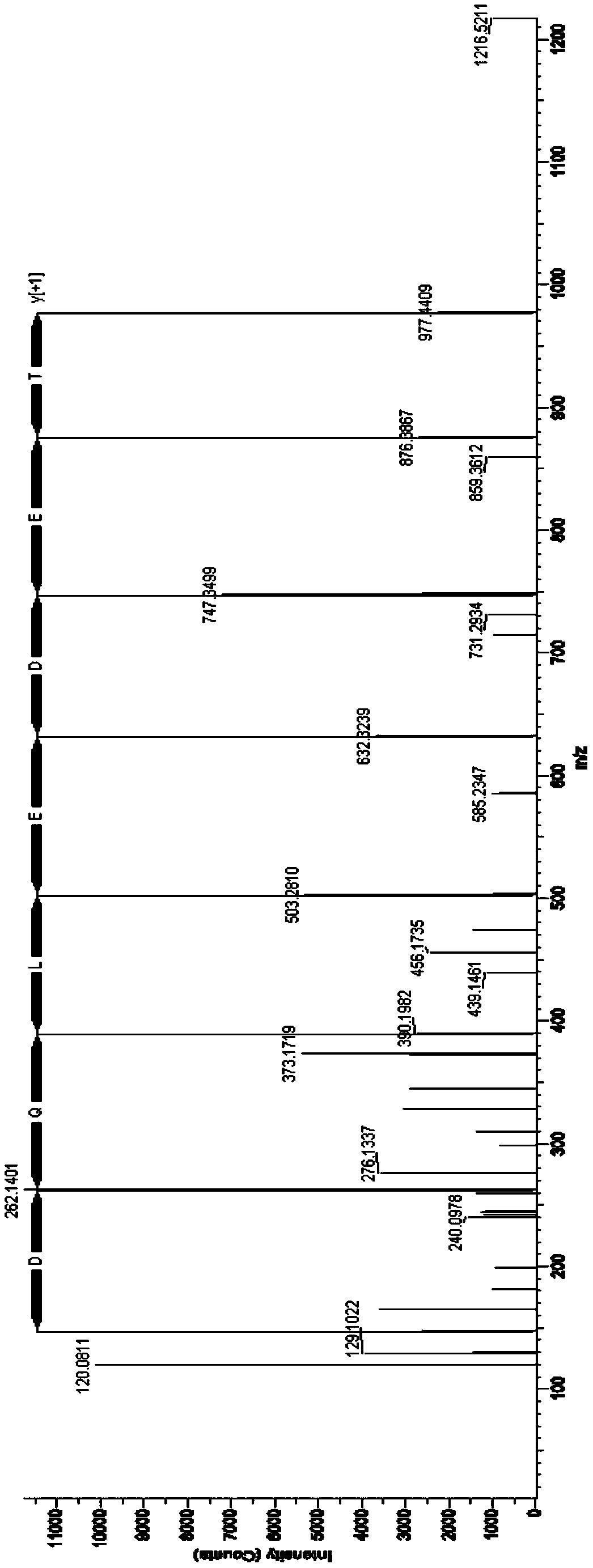

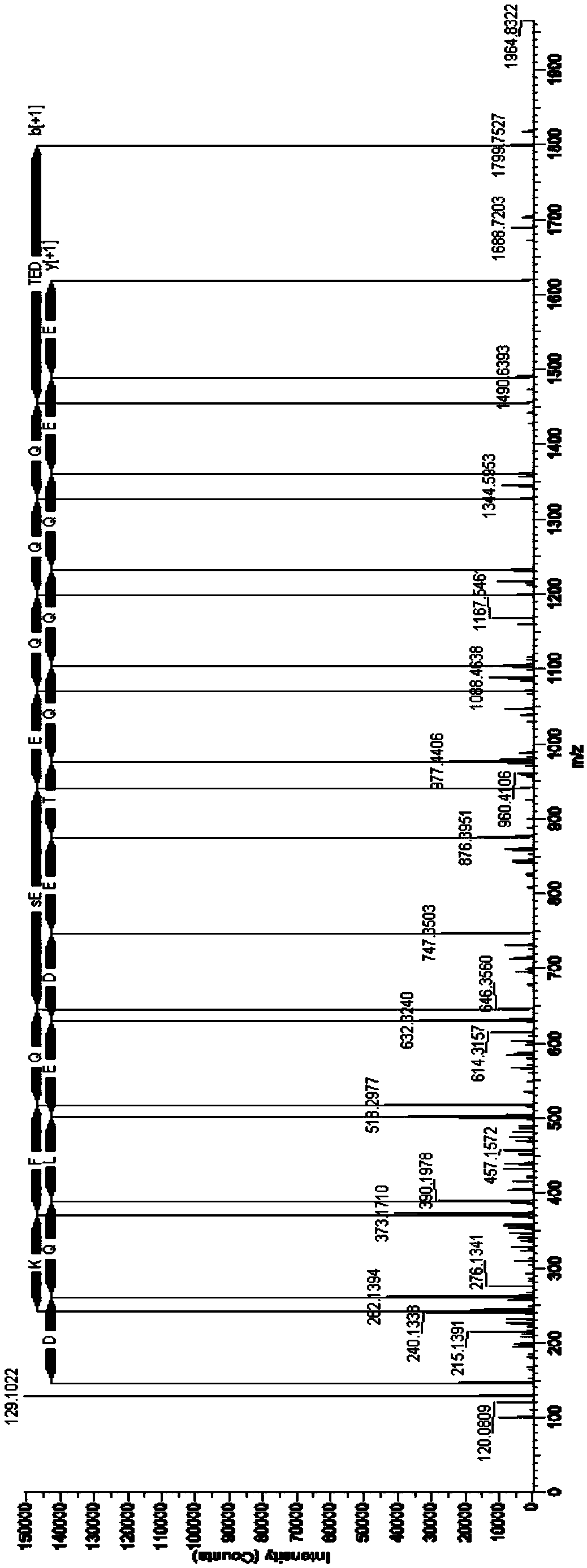

[0058] Table 2 Commercial TiO 2 Phosphorylated peptides detected in β-casein digests

[0059]

[0060] Step 2: The above-mentioned precursor solution is made into a precursor nanofiber through an electrospinning forming process. ...

Embodiment 3

[0063] Step 1: Dissolve zirconium acetate and ferrous sulfide in the mixed solvent of ethanol / acetic acid in sequence, first stir for 130 minutes, then add the chelating agent diethylenetriamine-pentamethylene phosphonic acid, and continue stirring for 60 minutes, in which the zirconium acetate The molar ratio to ferrous sulfide is 100:10, the ratio of zirconium acetate to ethanol / acetic acid is 1g:50ml, the volume ratio of ethanol to acetic acid is 1:1, zirconium acetate and chelating agent diethylenetriamine-pentamethylene The molar ratio of phosphonic acid is 1:0.2; uniformly mixed to make a uniform and stable dynamic viscosity of 0.05Pa s precursor solution, the molecular chain in the precursor solution has a three-dimensional stable polycyclic structure similar to that of Example 1;

[0064] Step 2: The above-mentioned precursor solution is made into a precursor nanofiber through an electrospinning forming process. Electrospinning process parameters: spinning temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com