Patents

Literature

93results about "Wood particle drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

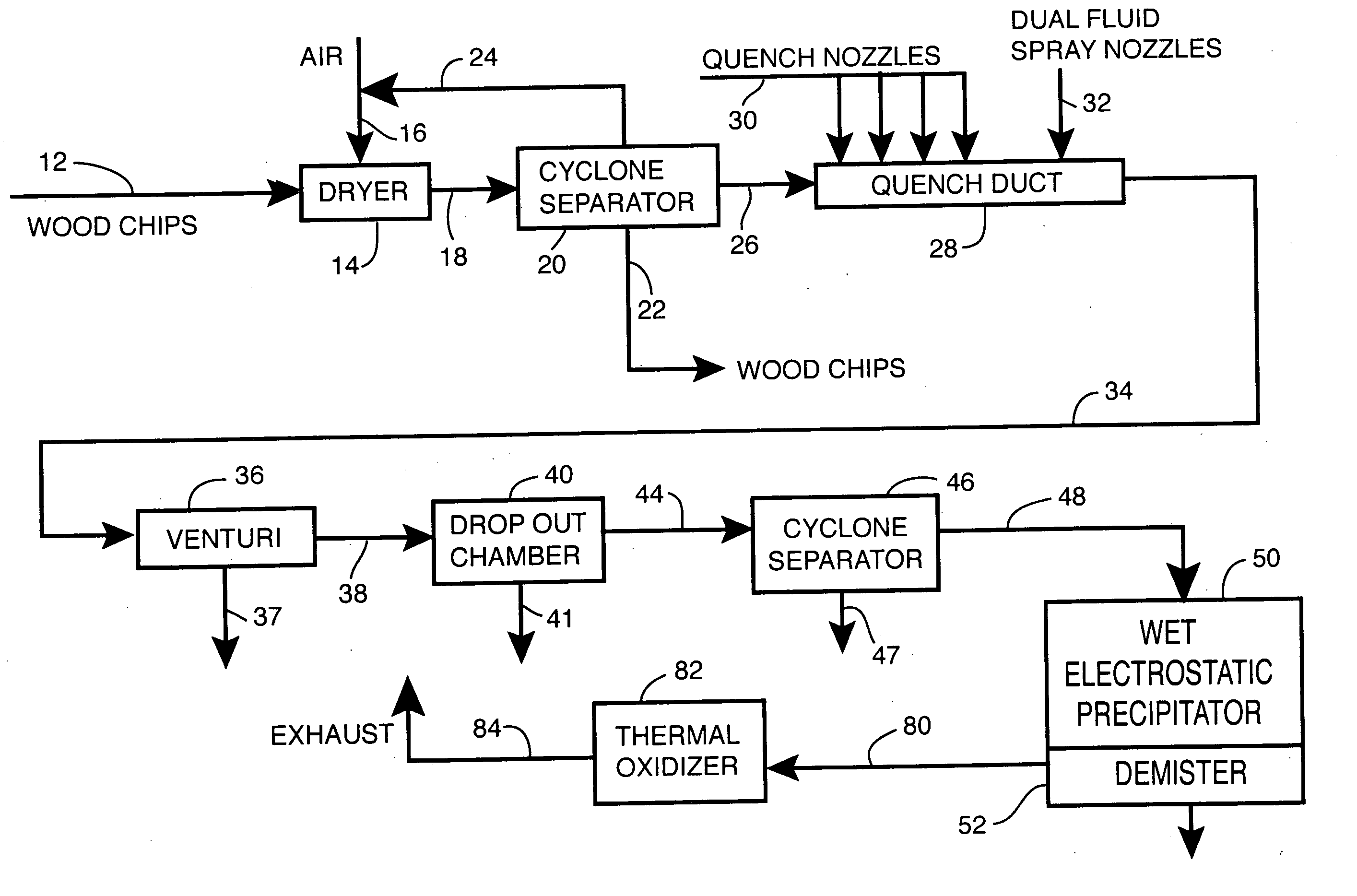

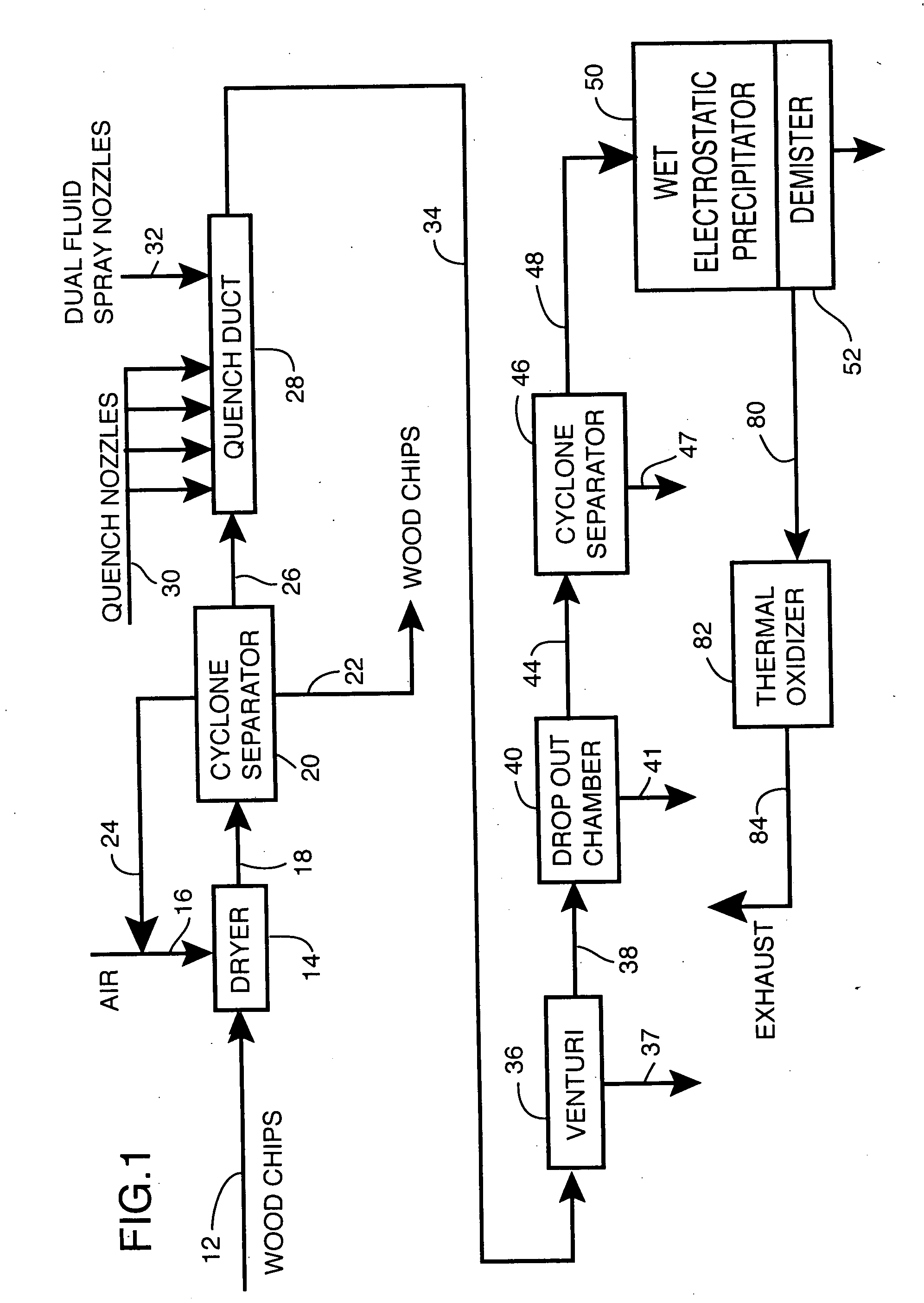

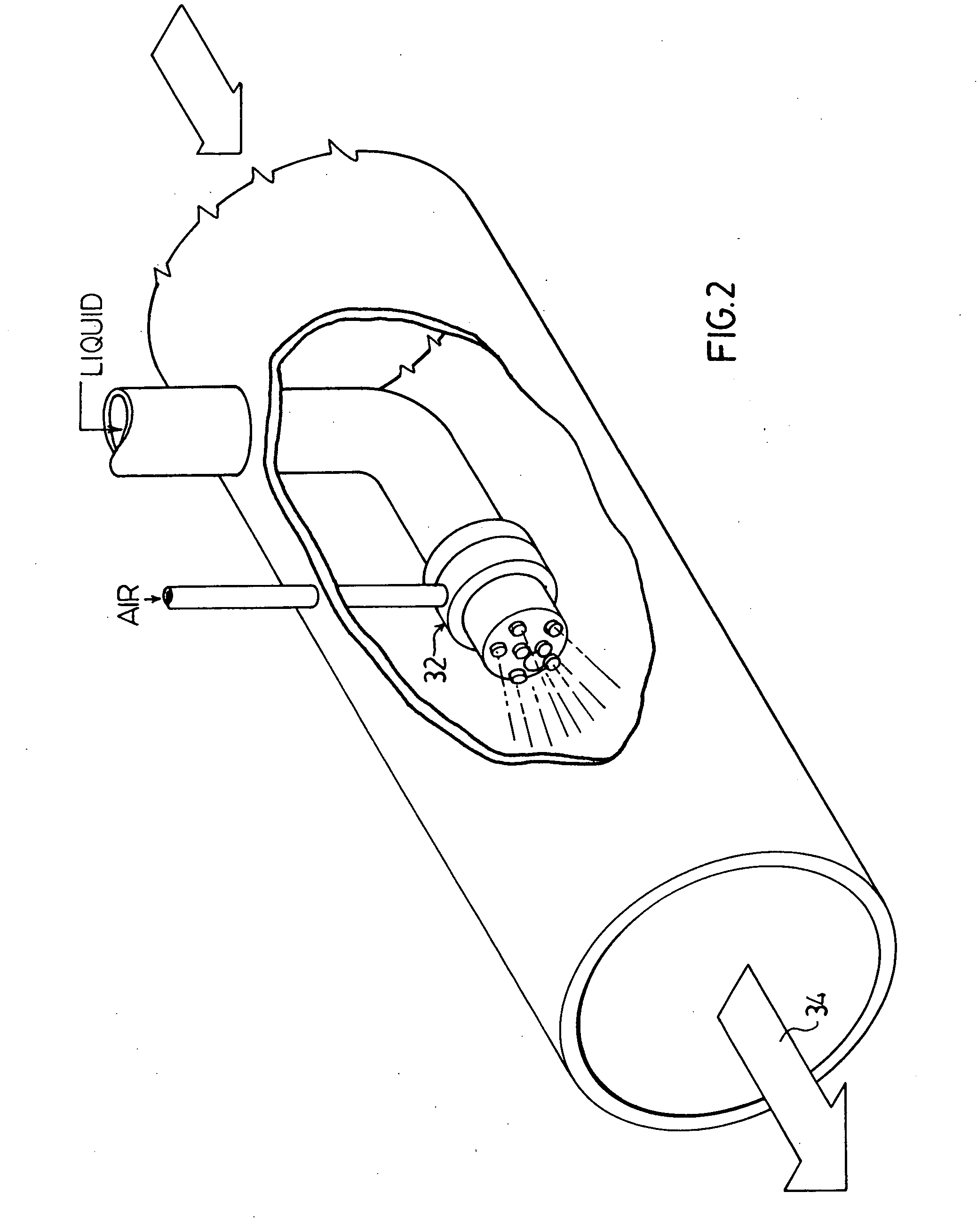

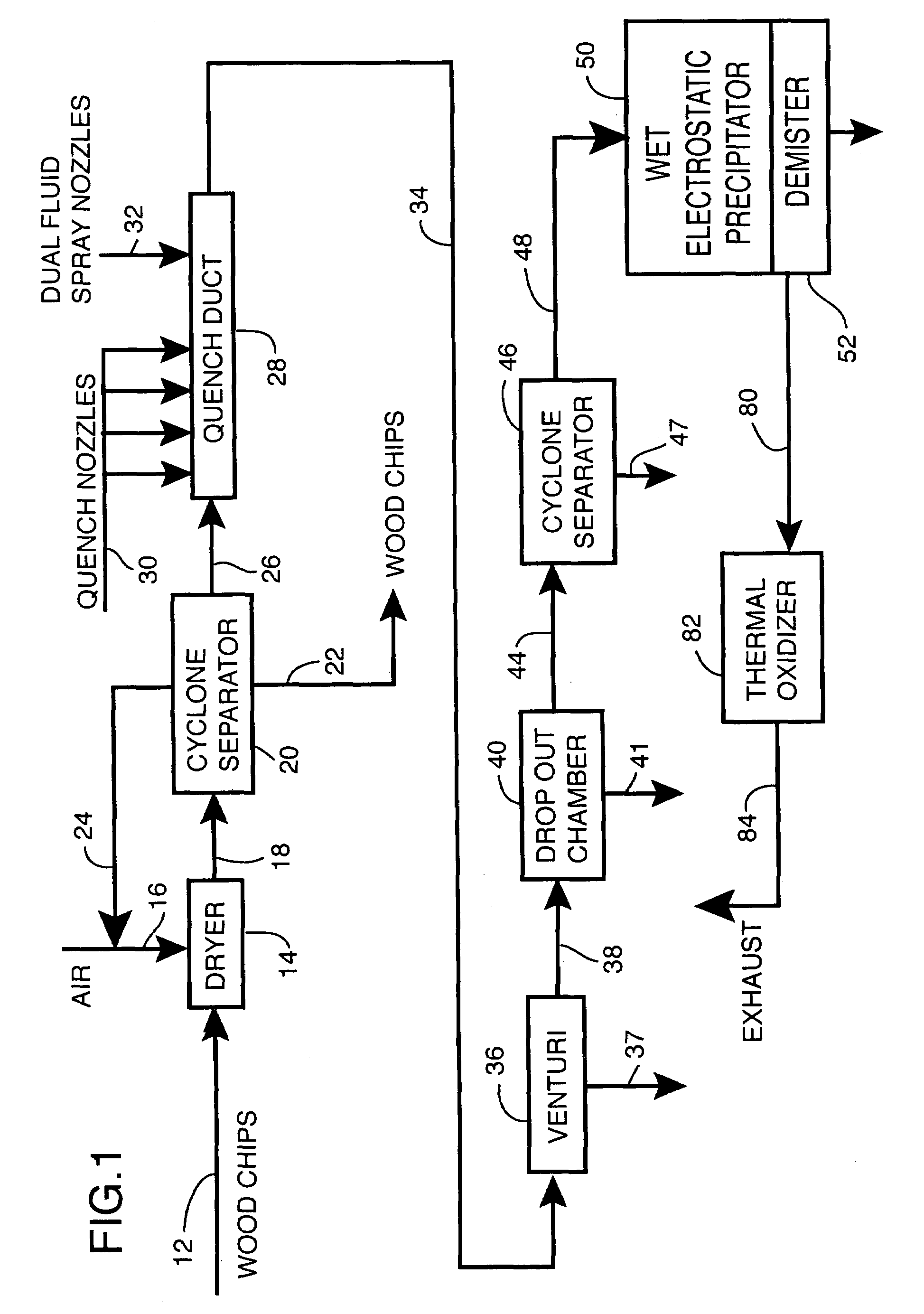

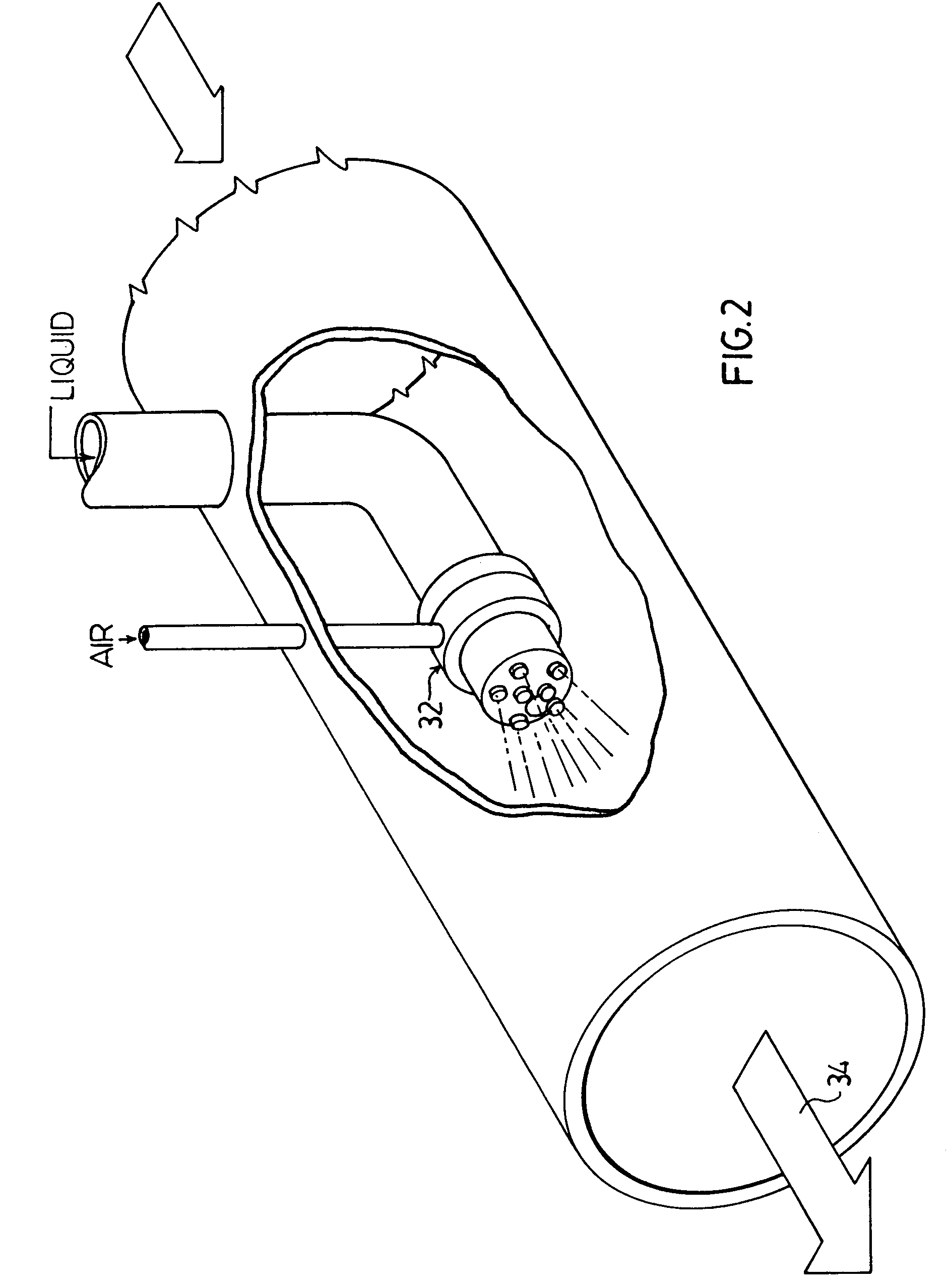

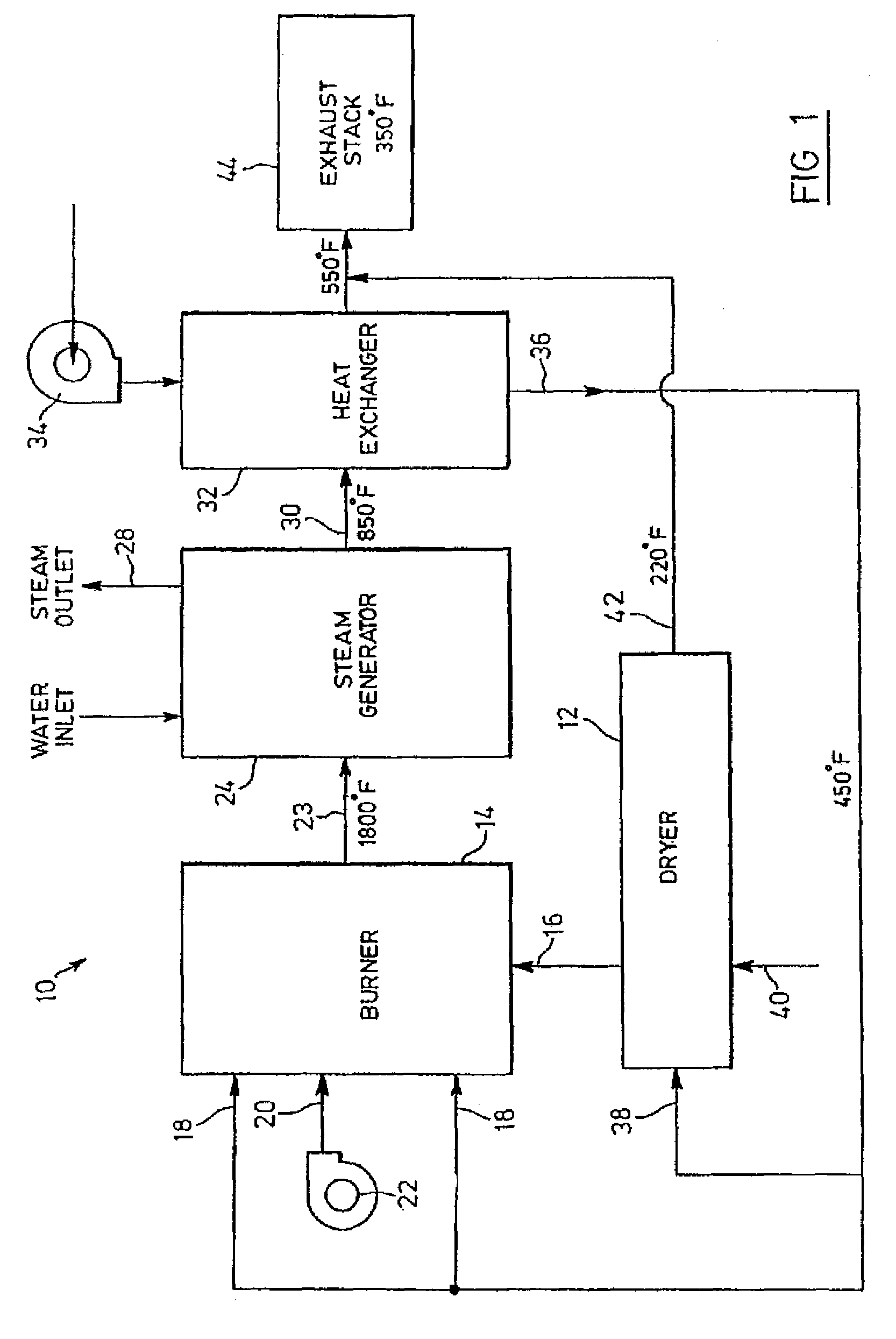

Pollution control in wood products dryer

InactiveUS20050229780A1Reduce gas flowEmission reductionCombination devicesDrying solid materials with heatParticulatesCombustor

Contaminant laden gas streams from wood product dryer operations, and other sources, are purified. The gas stream first is saturated with moisture by contacting the gas stream with fine liquid droplets which entrain particulates. The gas stream then is subjected to a plurality of separate particulate and liquid droplet removal steps before a droplet-free gas stream having substantially reduced particulate contaminant levels is passed to a burner for removal of volatile organic compounds from the gas stream.

Owner:MEGTEC TURBOSONIC

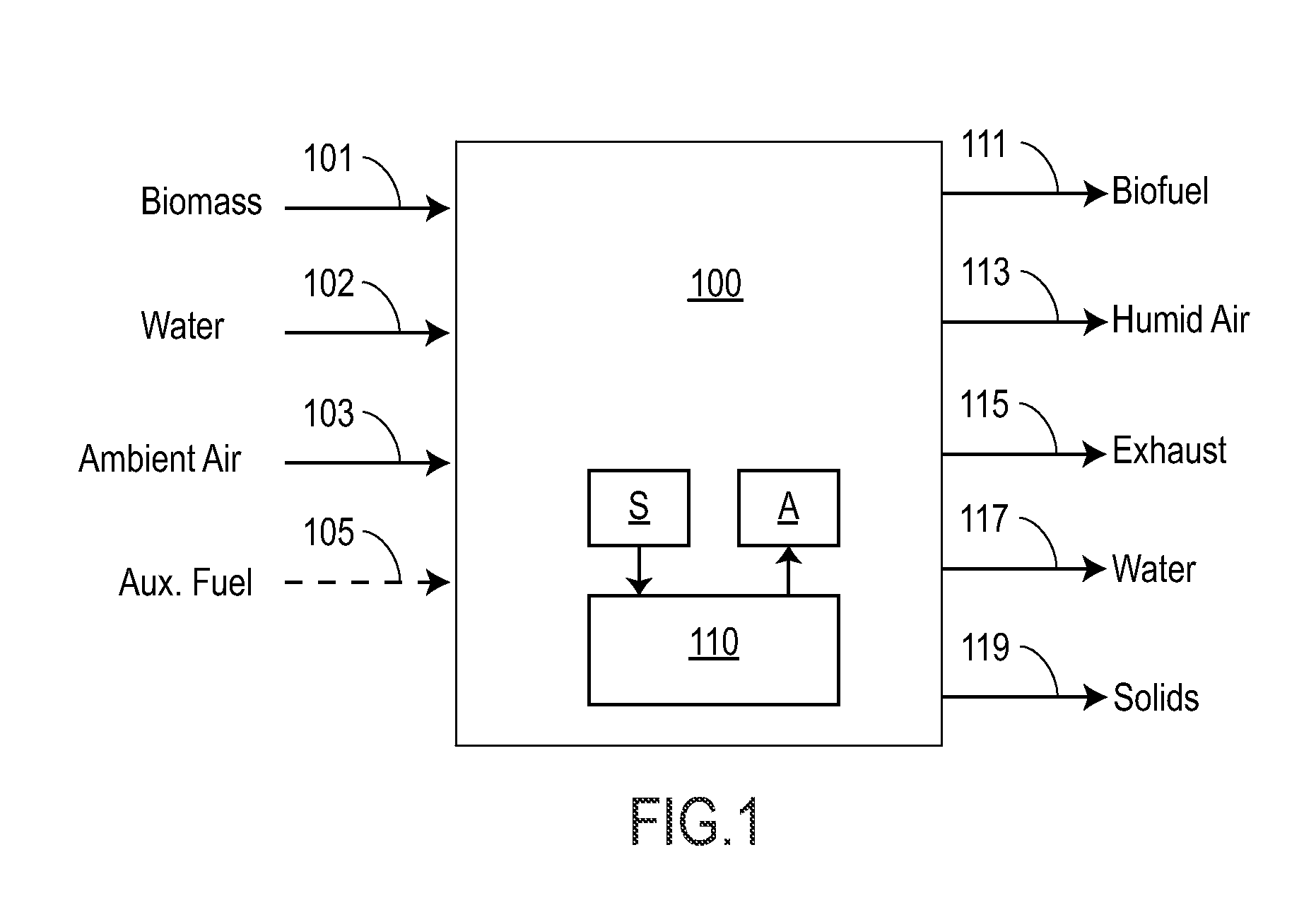

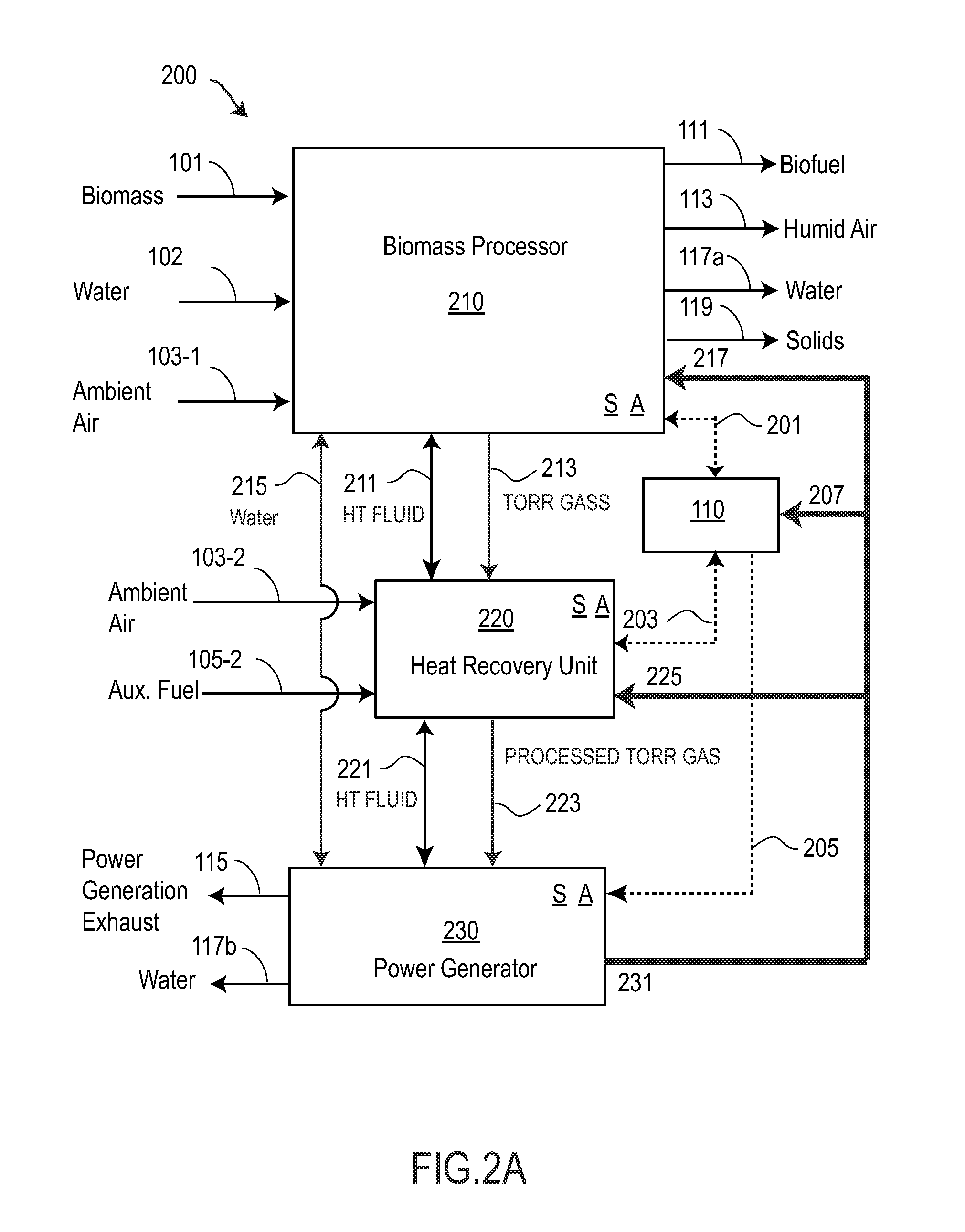

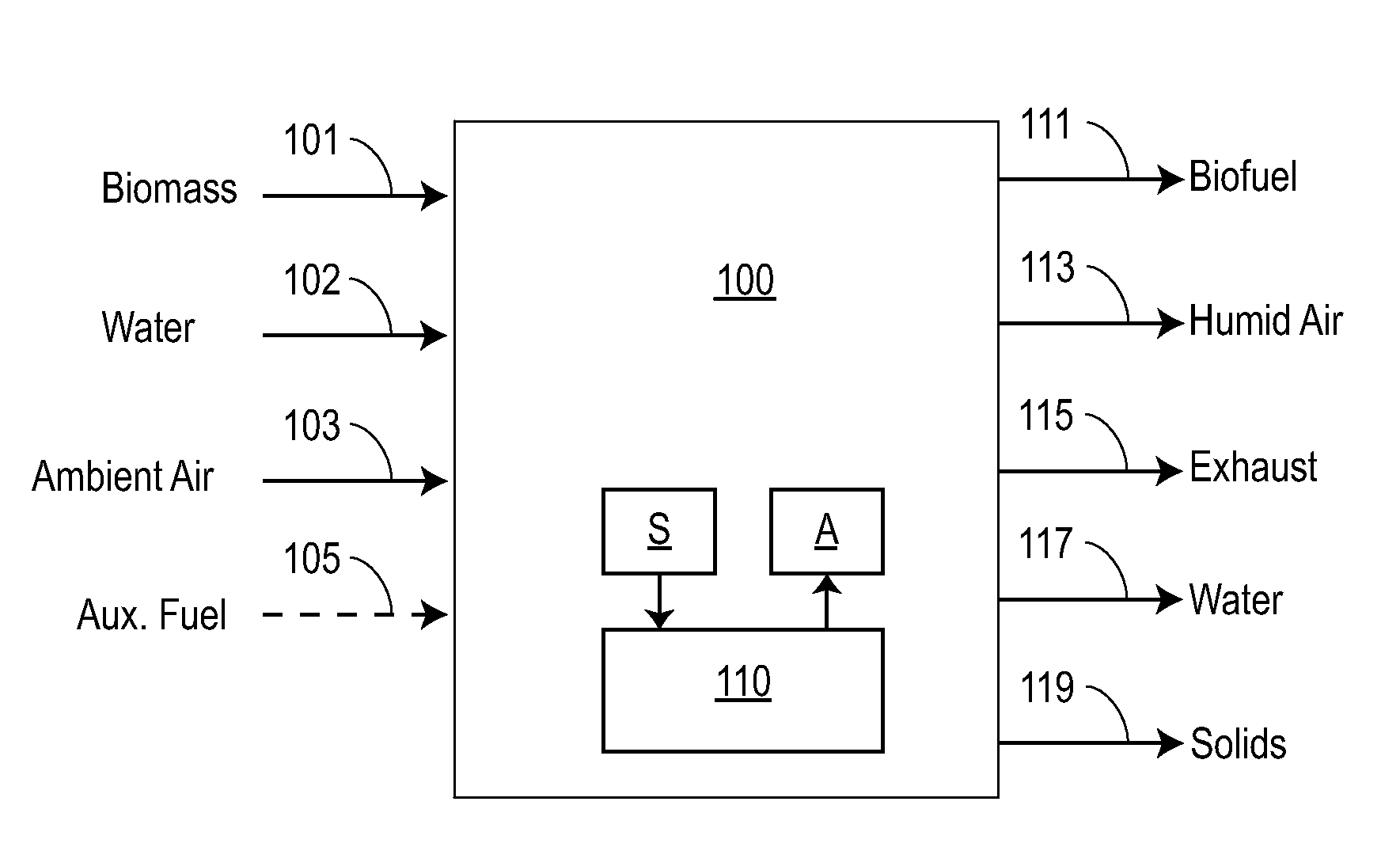

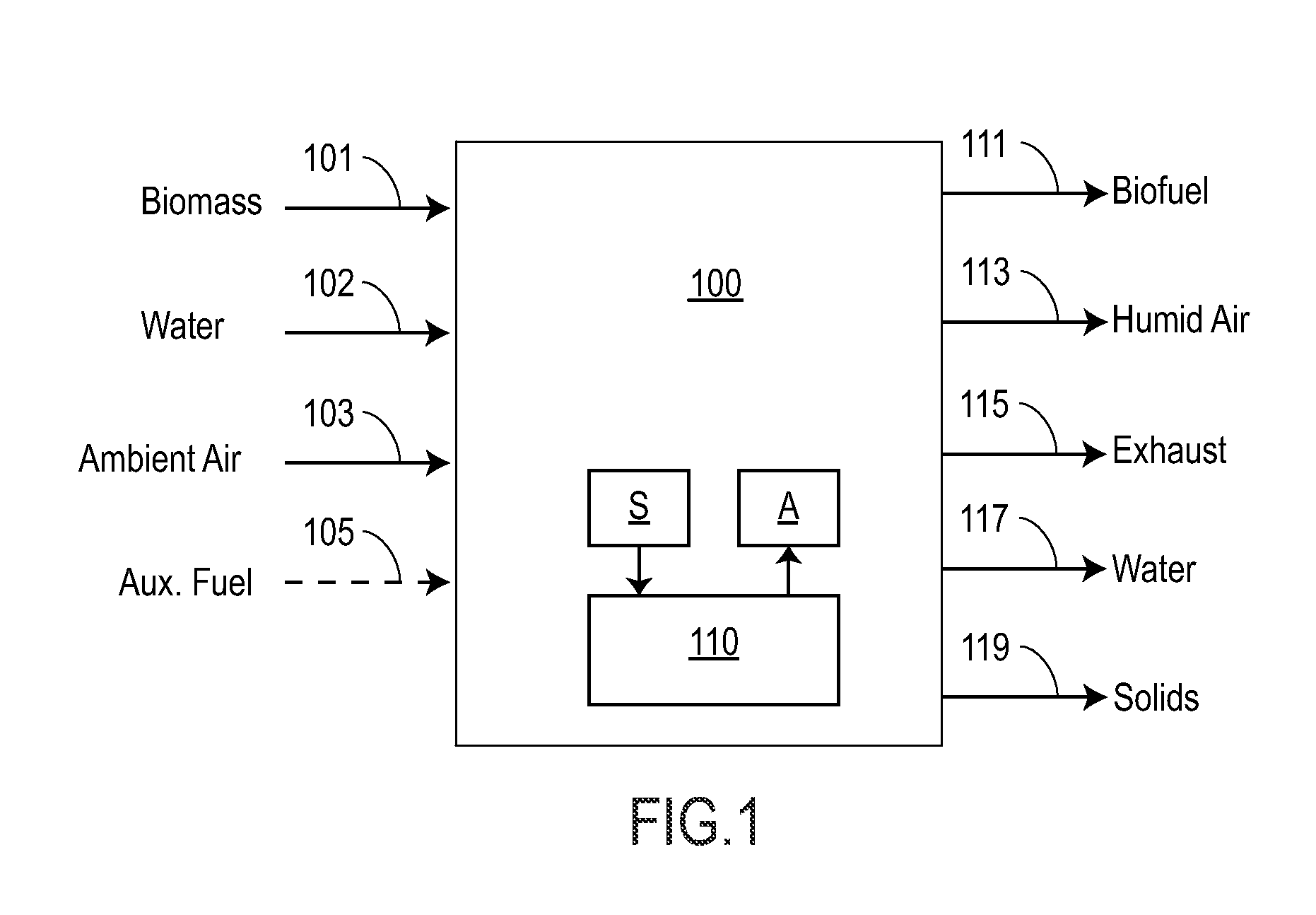

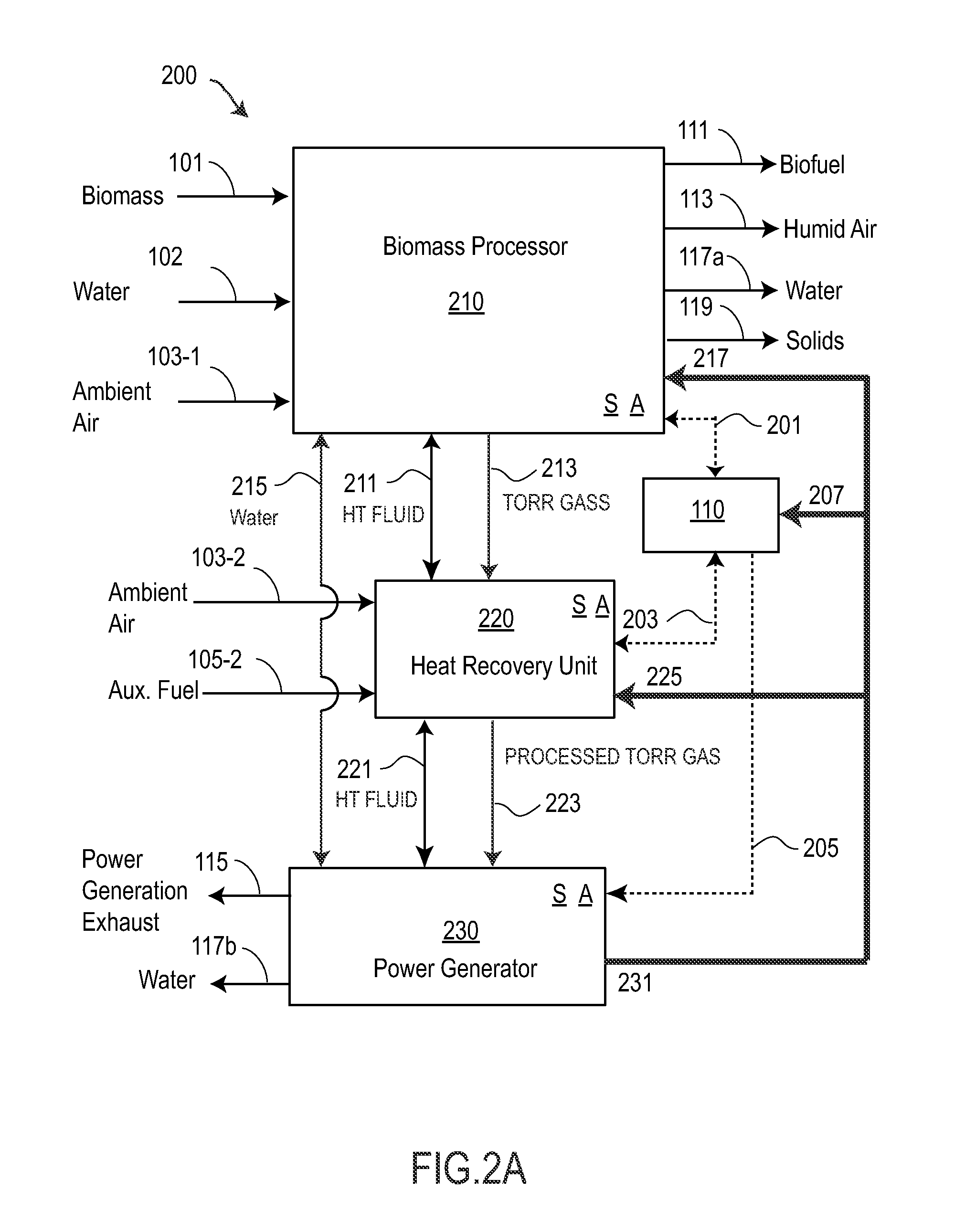

Device and method for controlling the conversion of biomass to biofuel

InactiveUS20120117815A1Drying solid materials with heatDrying solid materials without heatControl systemSolid fuel

Embodiments presented herein describe an apparatus and method to control the conversion of carbonaceous materials, particularly biomass and those biomass resources, into a high performance solid fuel. This method, and the apparatus described as the means to accomplish this method, provides a process having a control system that enables the system to produce a fuel of uniform quality, even with a change in biomass supply.

Owner:RENEWABLE FUEL TECH

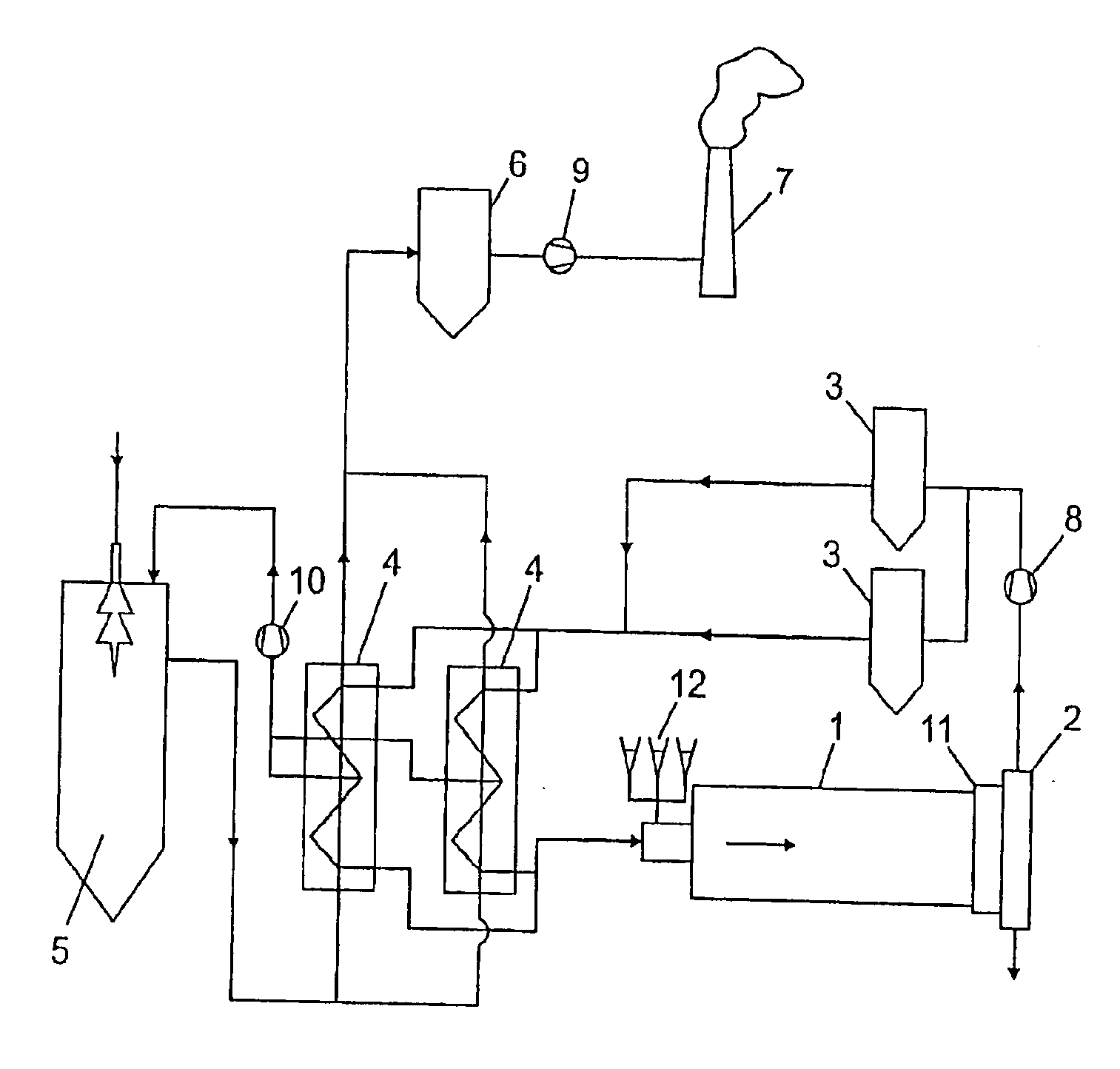

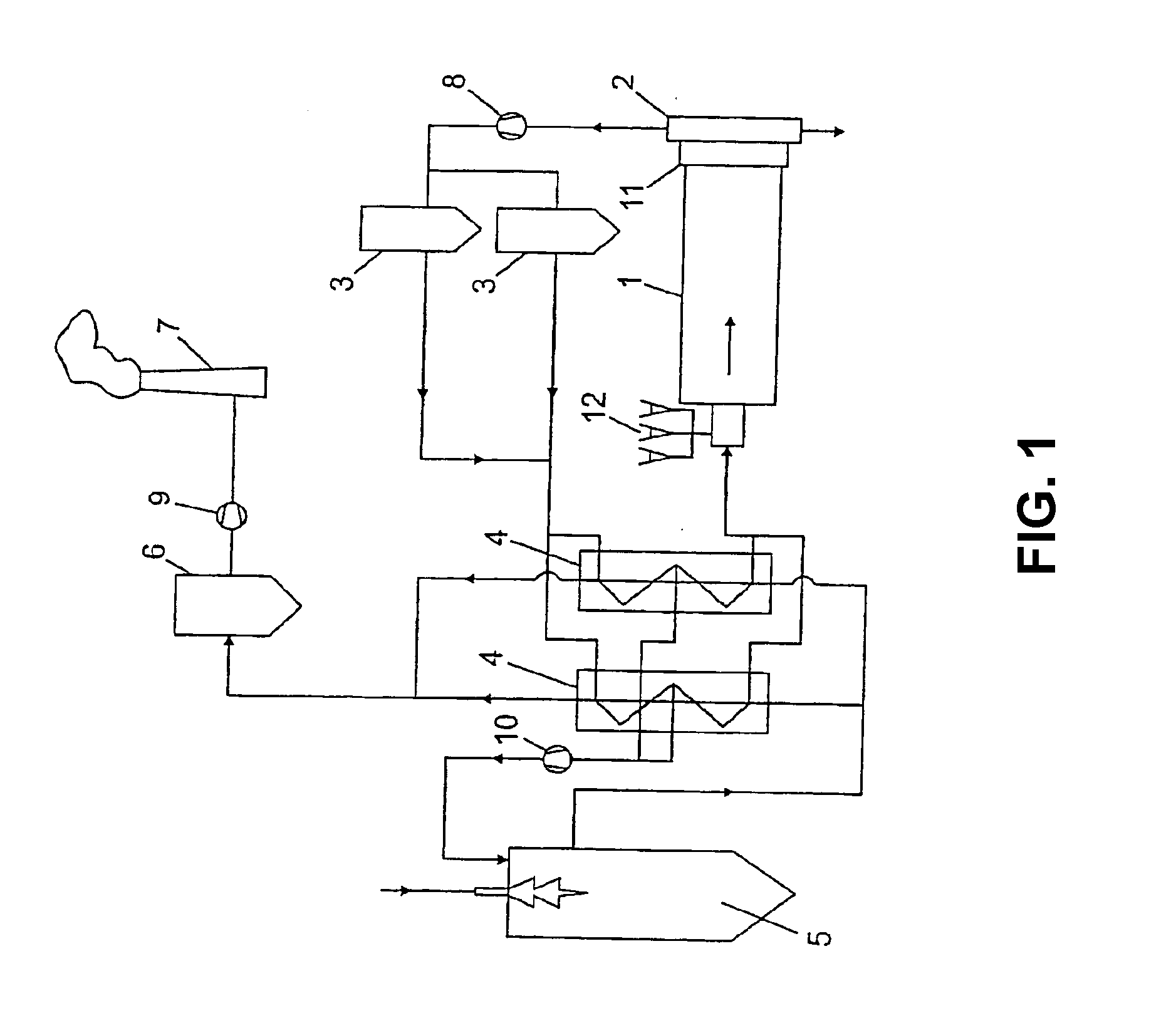

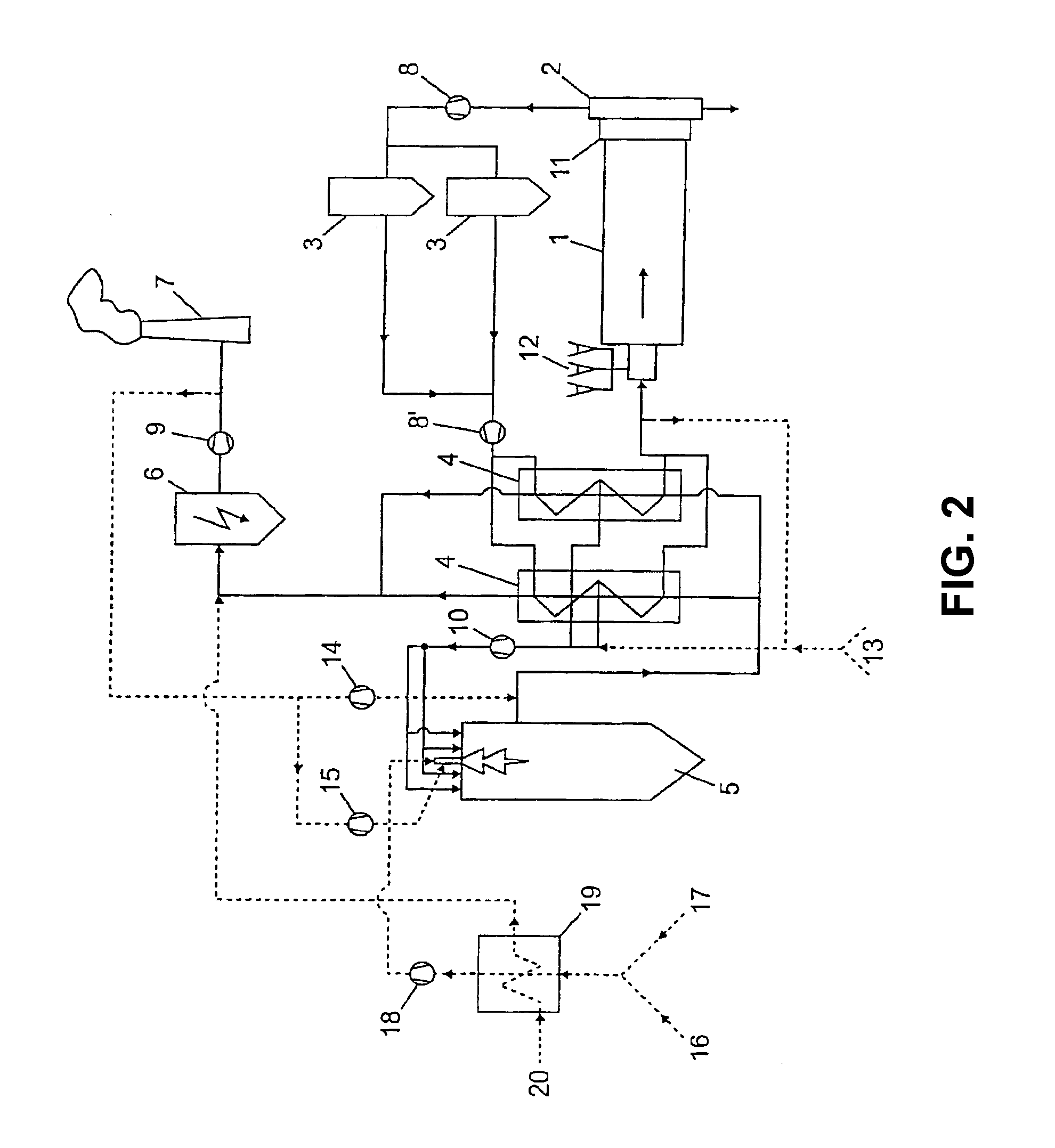

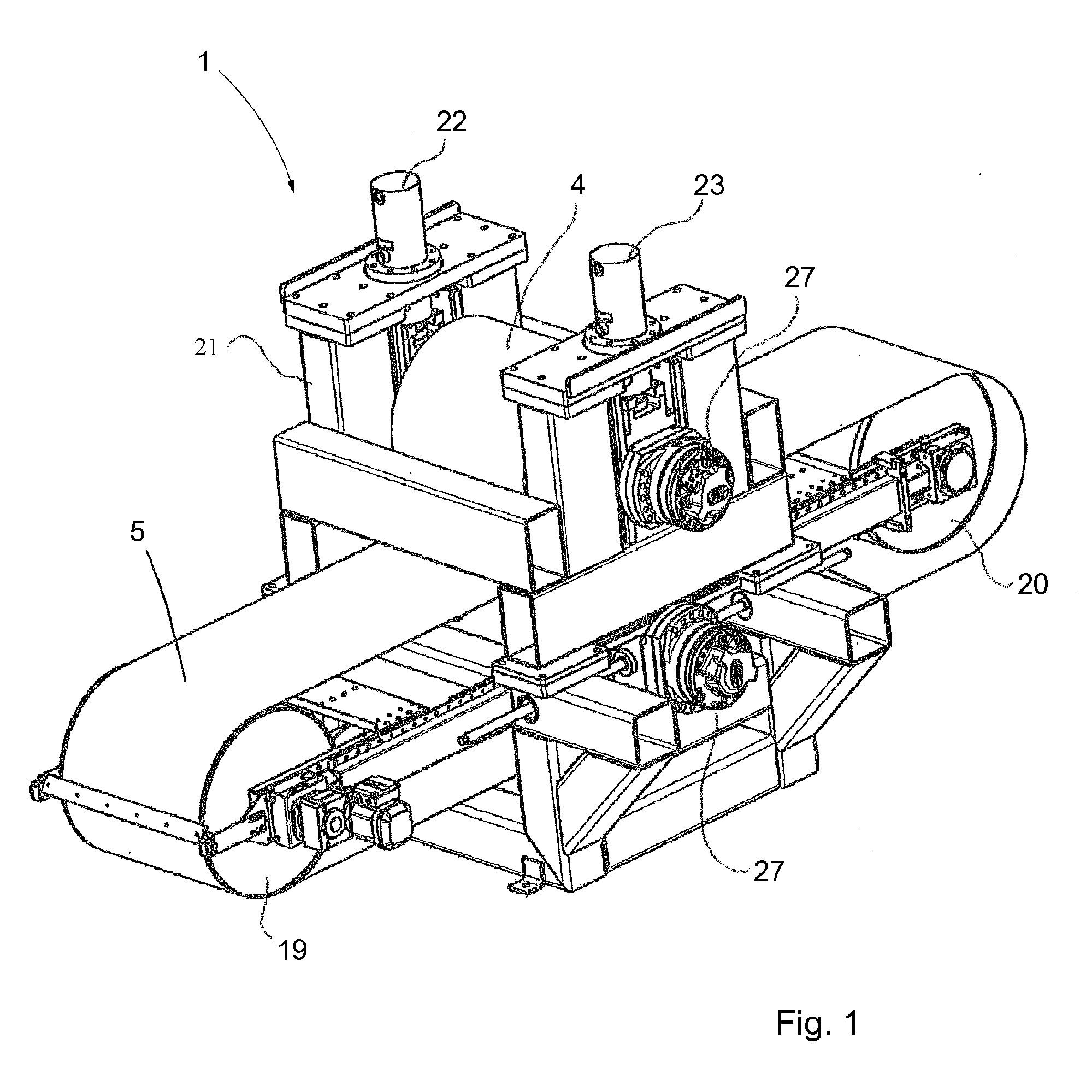

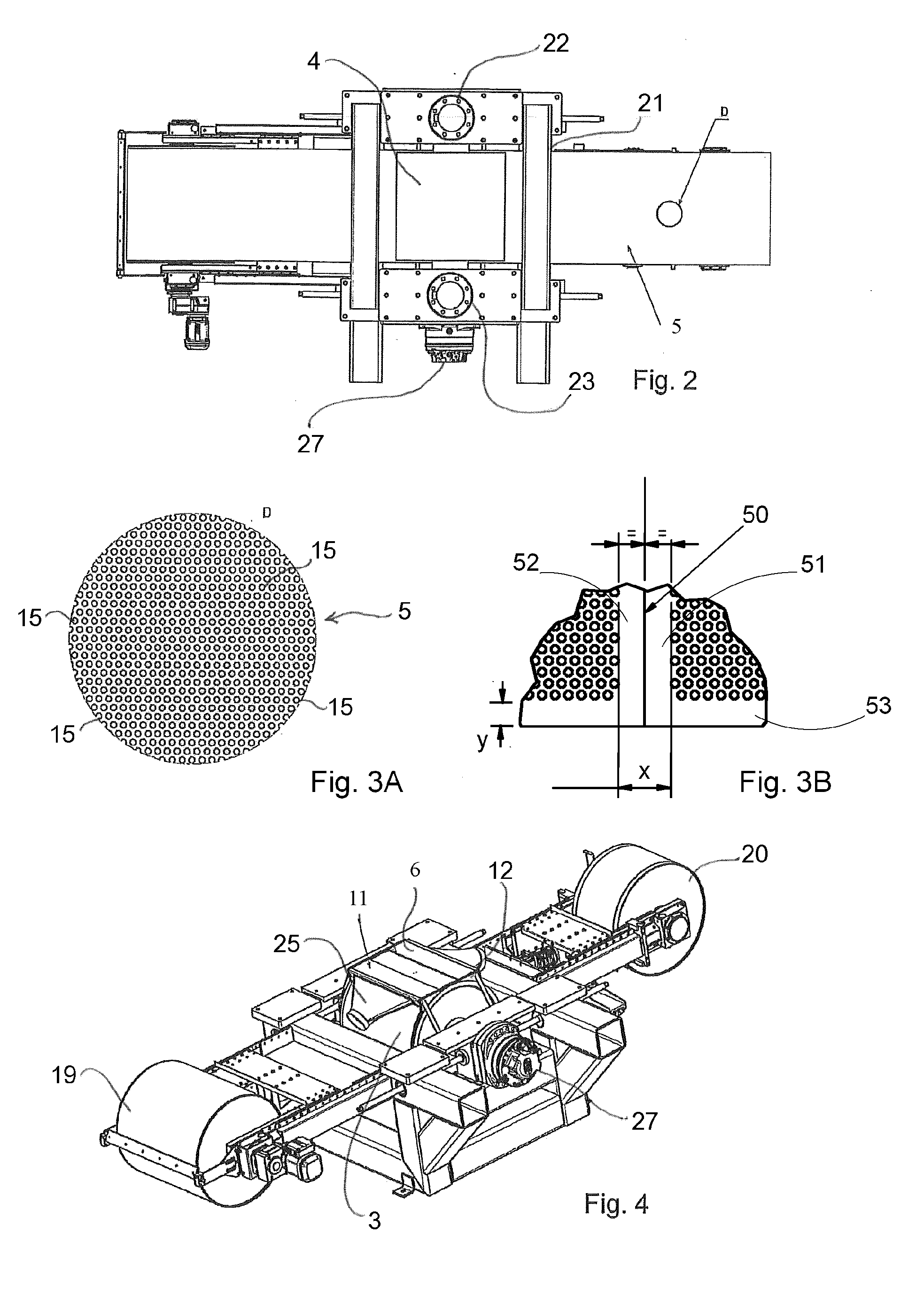

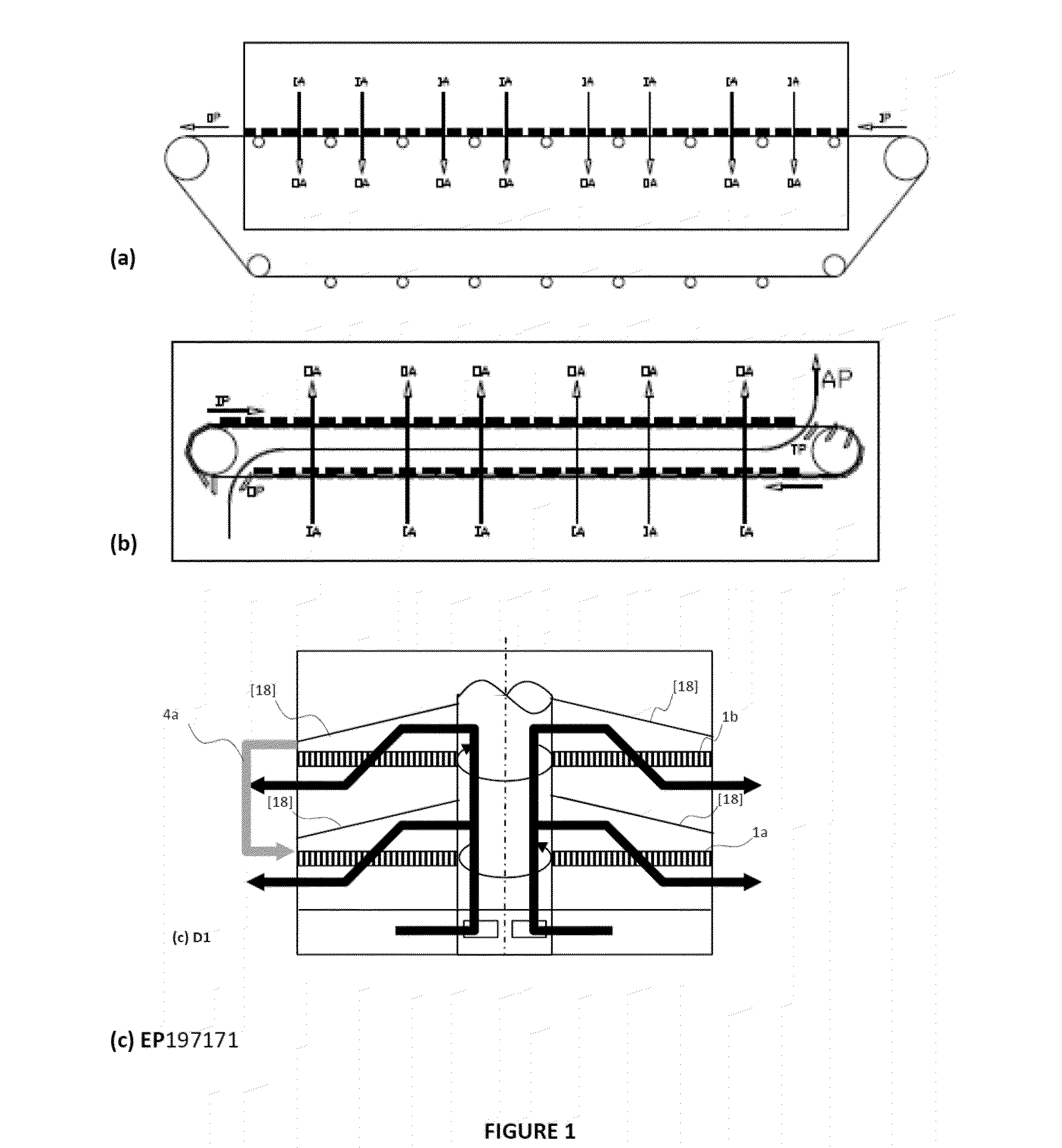

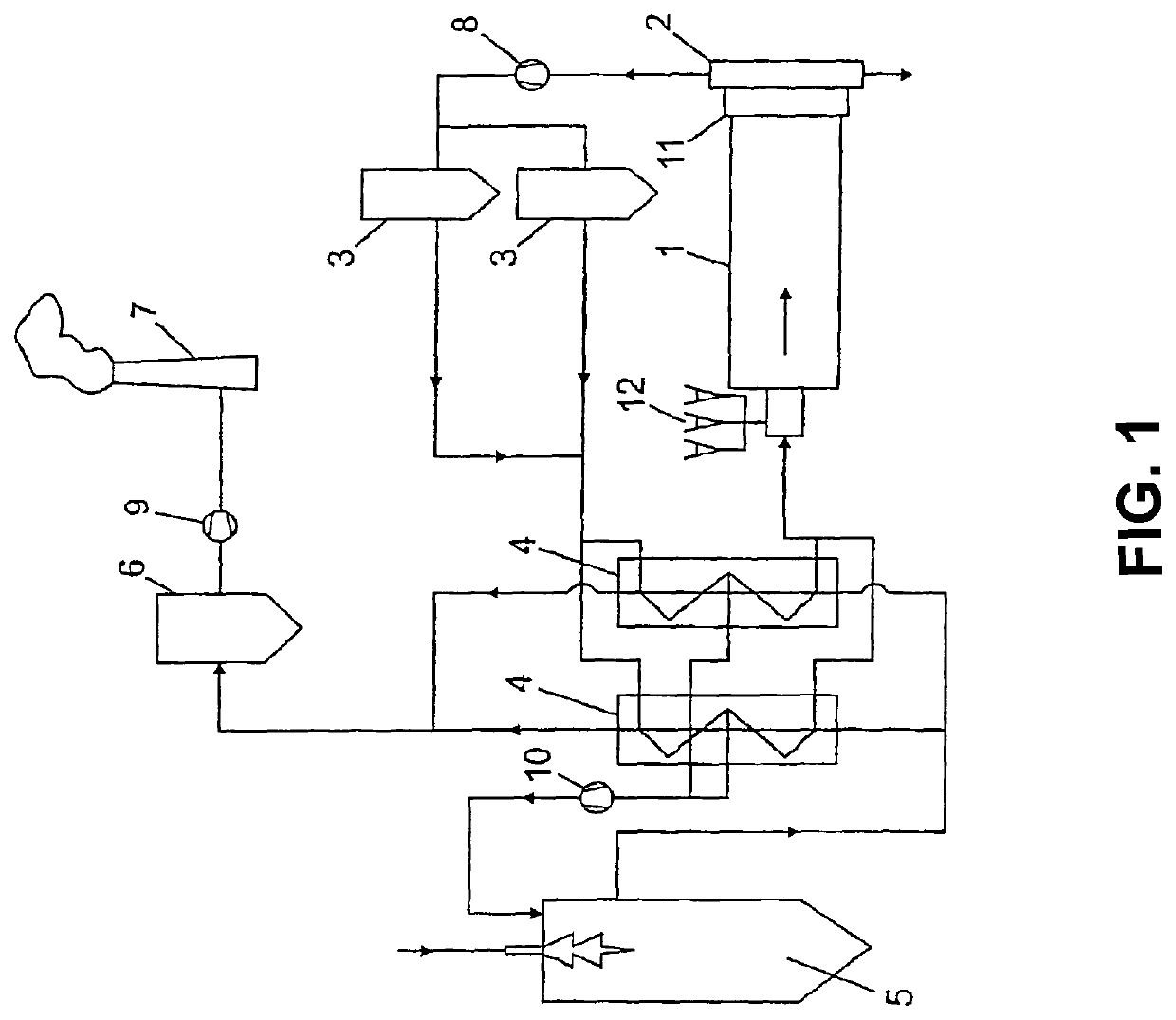

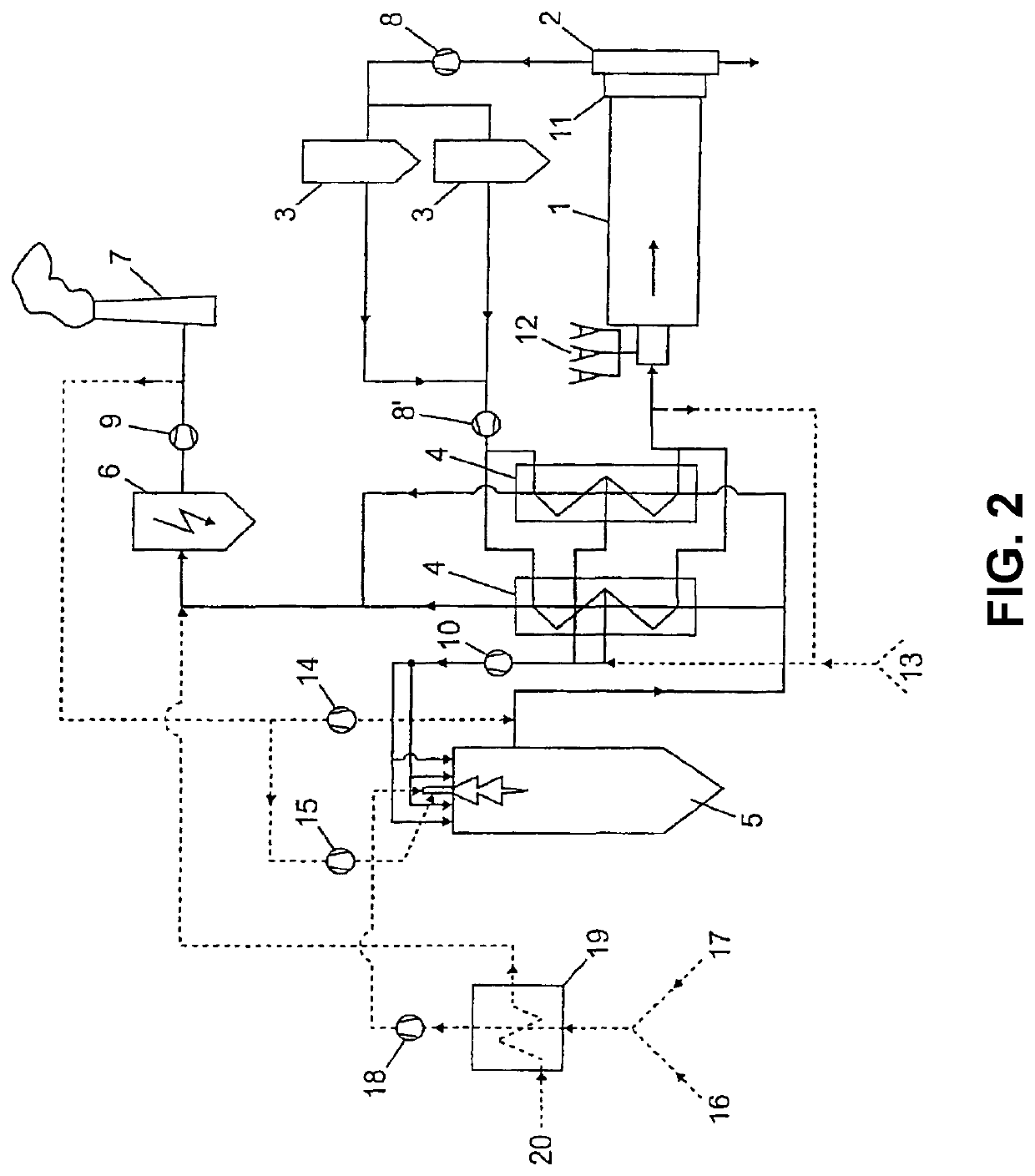

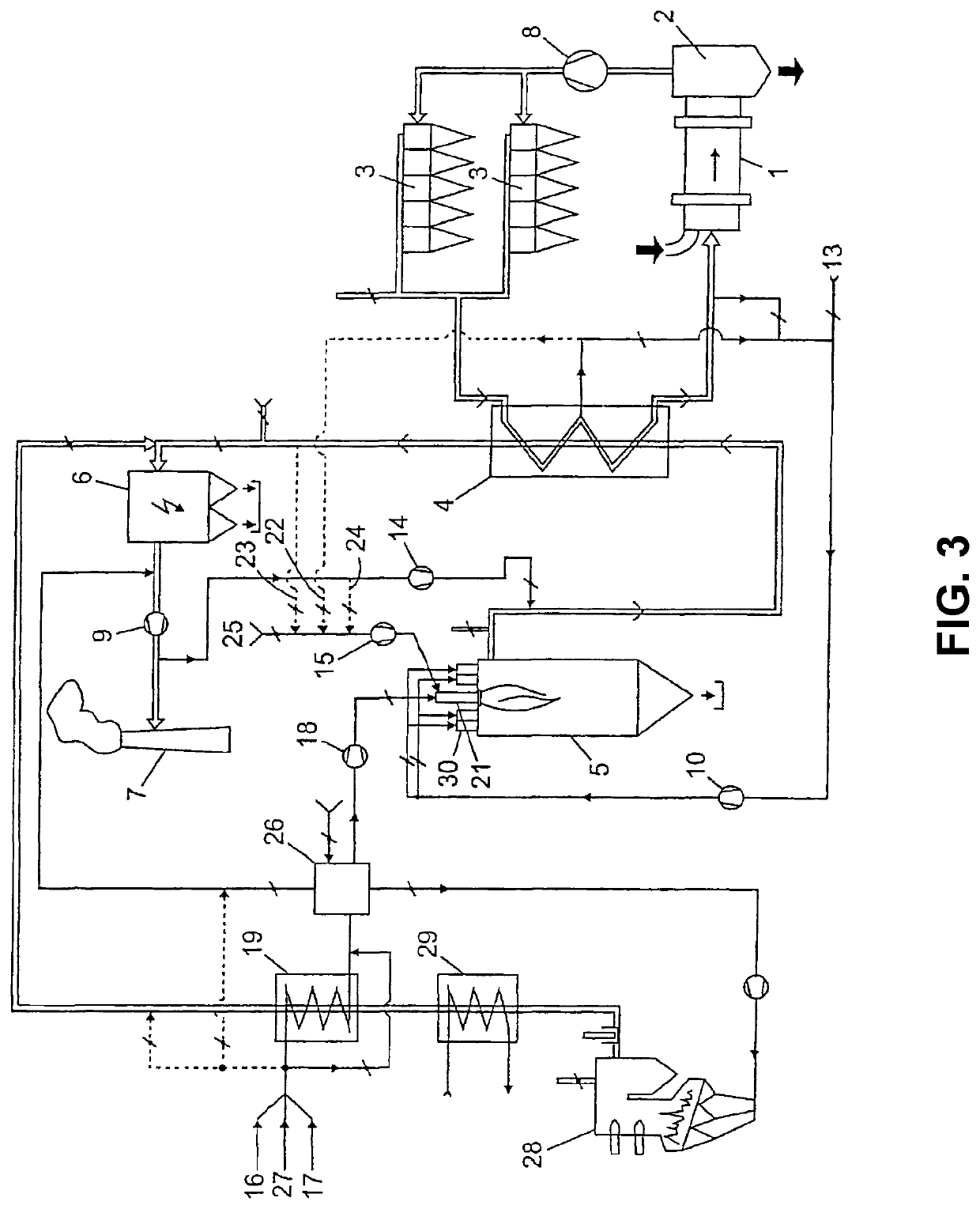

Method for continuously drying bulk goods, in particular wood fibers and/or wood chips

ActiveUS20170051972A1Emit energyPositive to qualityDrying gas arrangementsDrying machines with non-progressive movementsWood fibreProcess engineering

A method for drying bulk goods, in particular wood fibers and / or wood chips, wherein the bulk goods is continuously dried in a dryer (1), in particular a drum dryer. The vapor-gas mixture flows through the drum dryer (1) in a dryer circuit and is indirectly heated via at least one heat exchanger (4) by a burner waste gas that is heated in at least one burner (5). The drying vapors are supplied to the at least one heat exchanger (4). Upstream, downstream and / or within the at least one heat exchanger (4), at least a partial flow of the drying vapors are branched off to be conducted into the burner (5). The remaining partial flow is conducted to the dryer (1) again. The partial flow of drying vapors to the burner (5) is driven by at least one regulable partial vapor fan (10).

Owner:KRONOPLUS LTD

Pollution control in wood products dryer

InactiveUS7160358B2Reduce gas flowEmission reductionCombination devicesDrying solid materials with heatParticulatesCombustor

Owner:MEGTEC TURBOSONIC

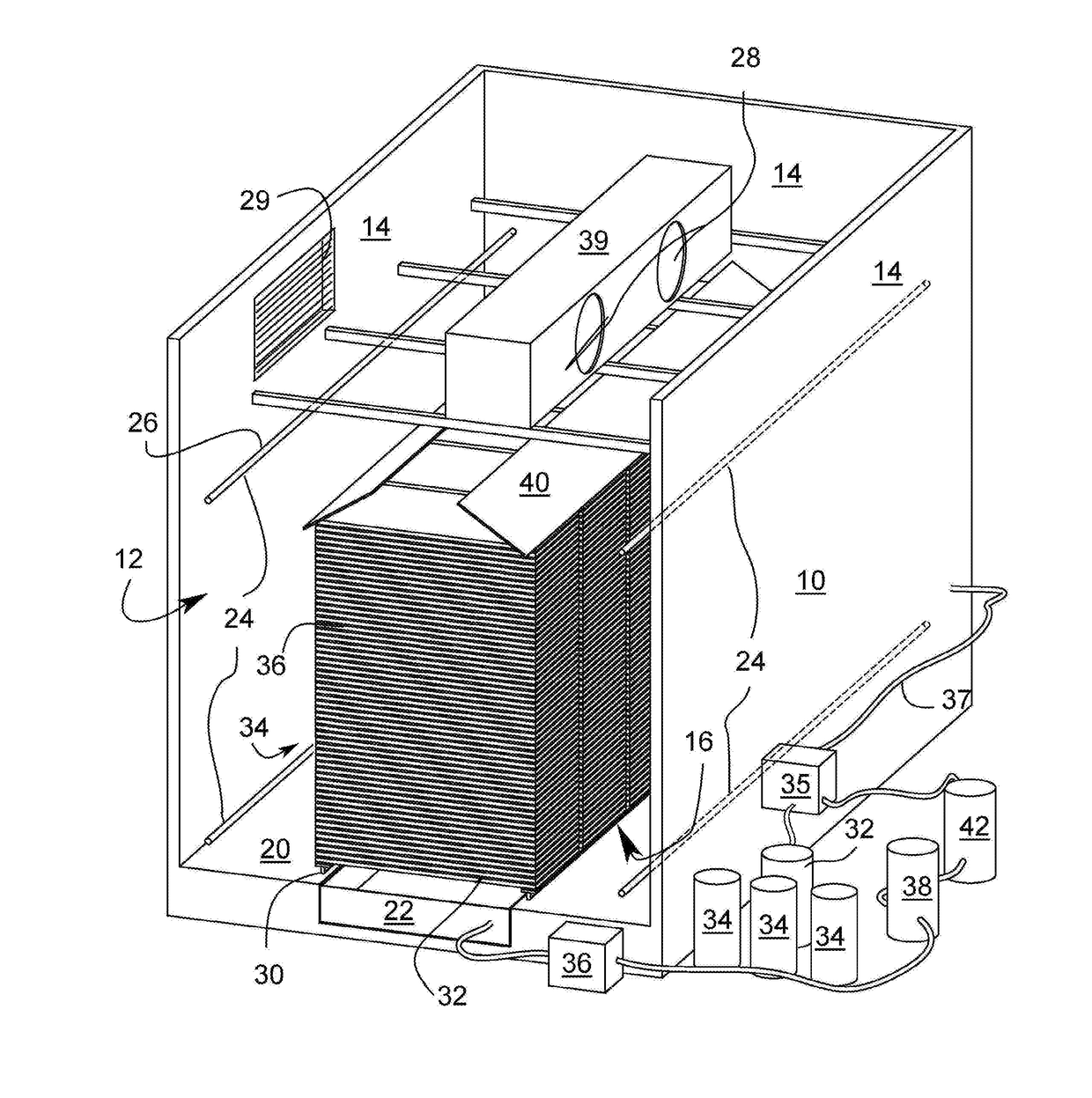

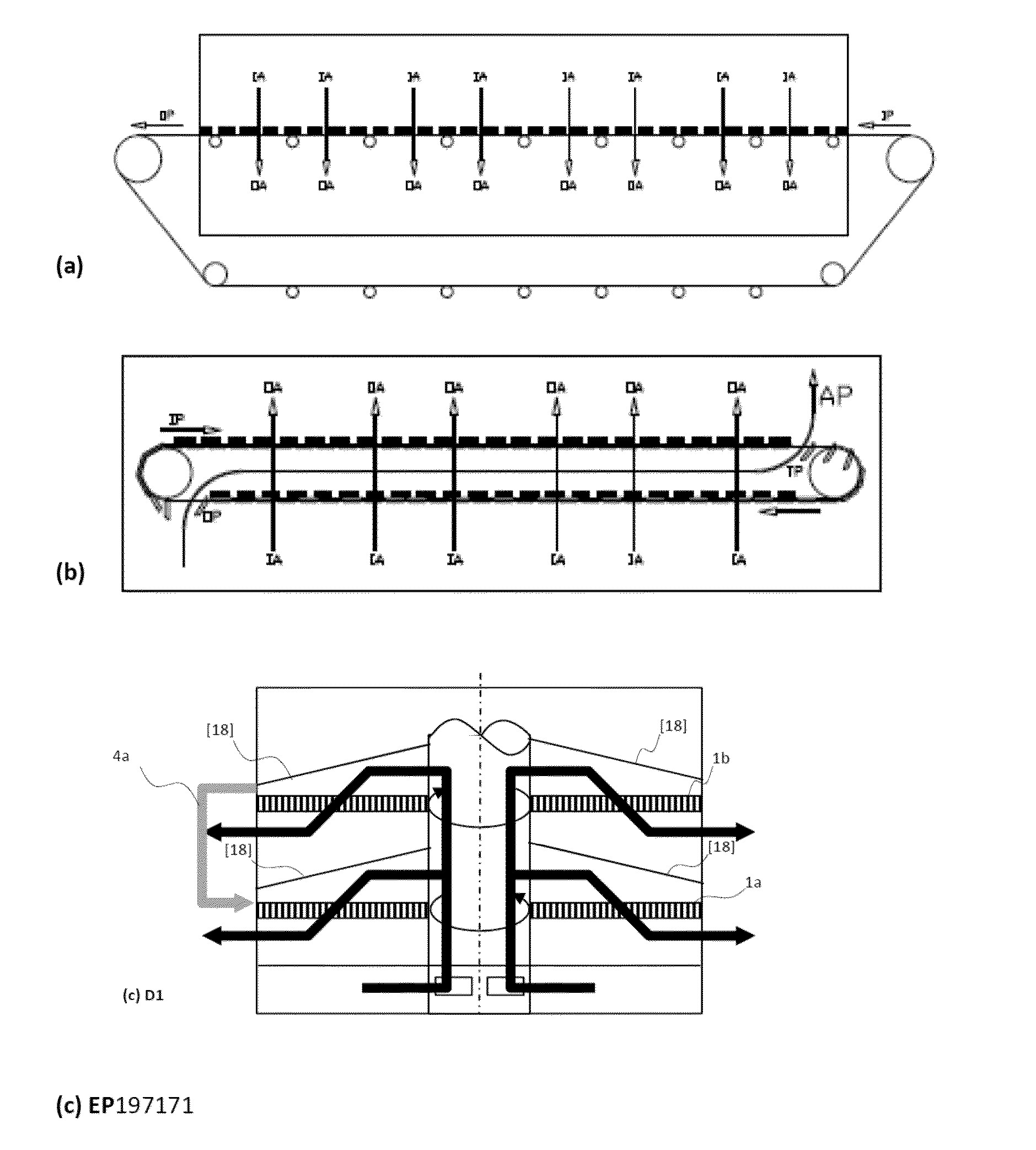

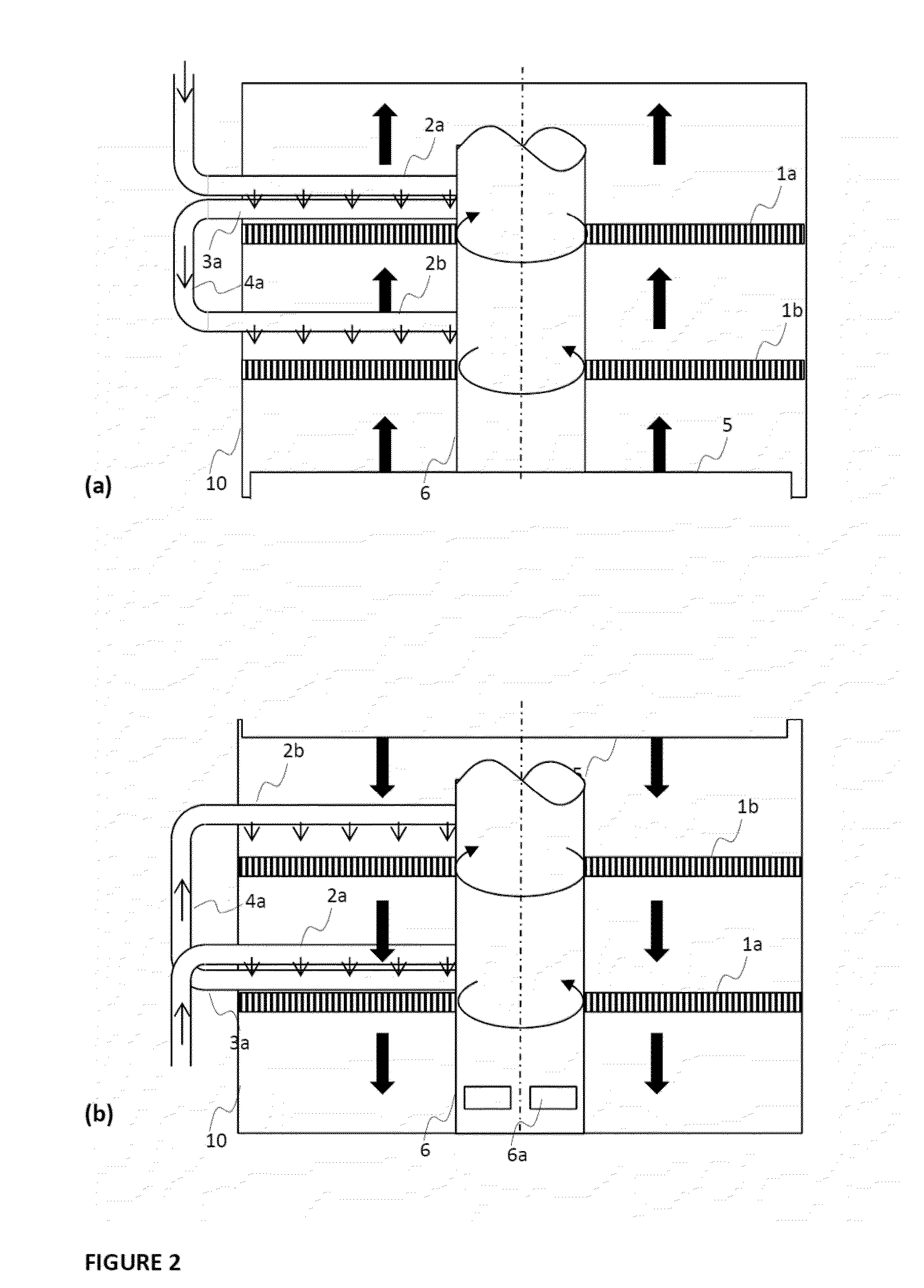

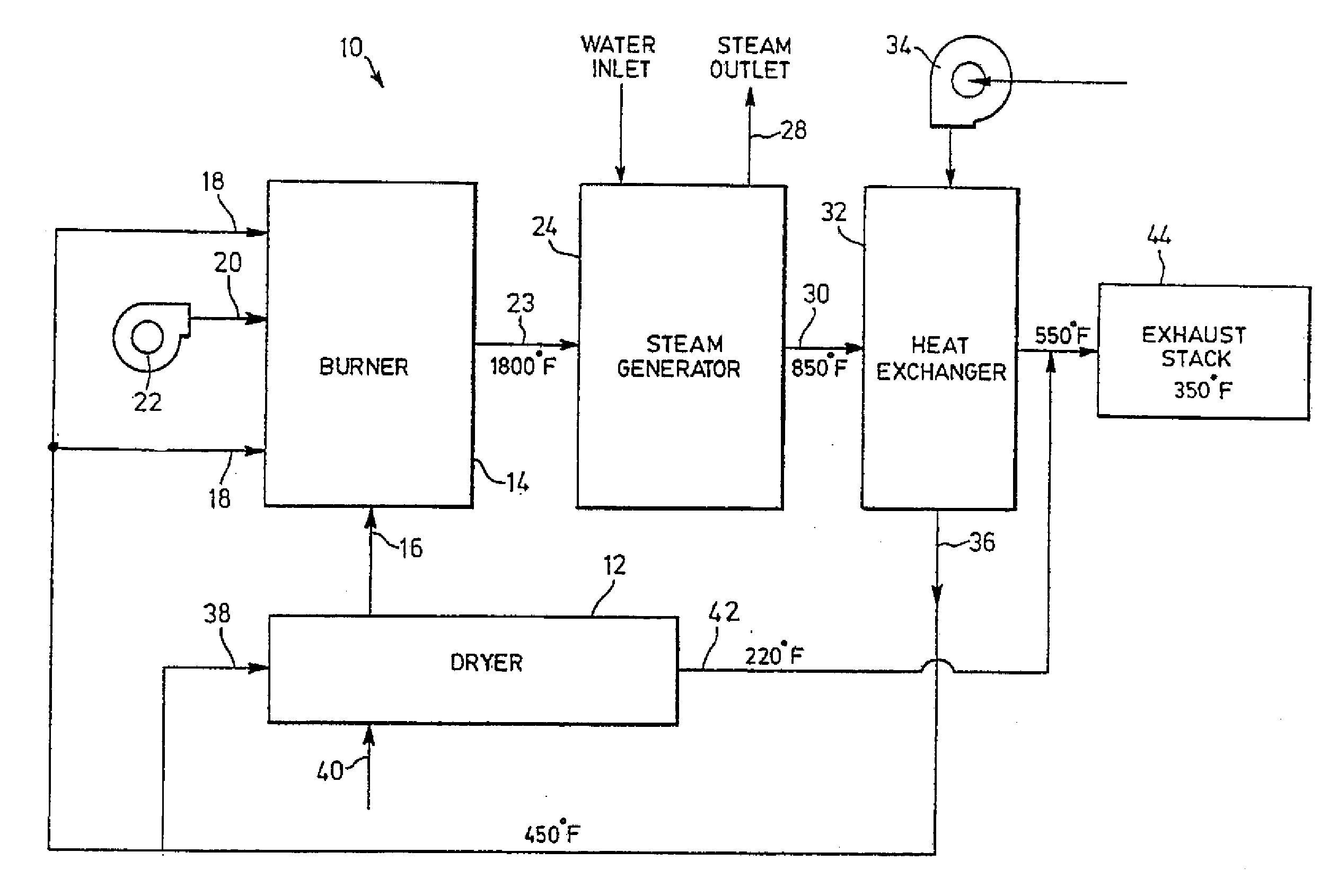

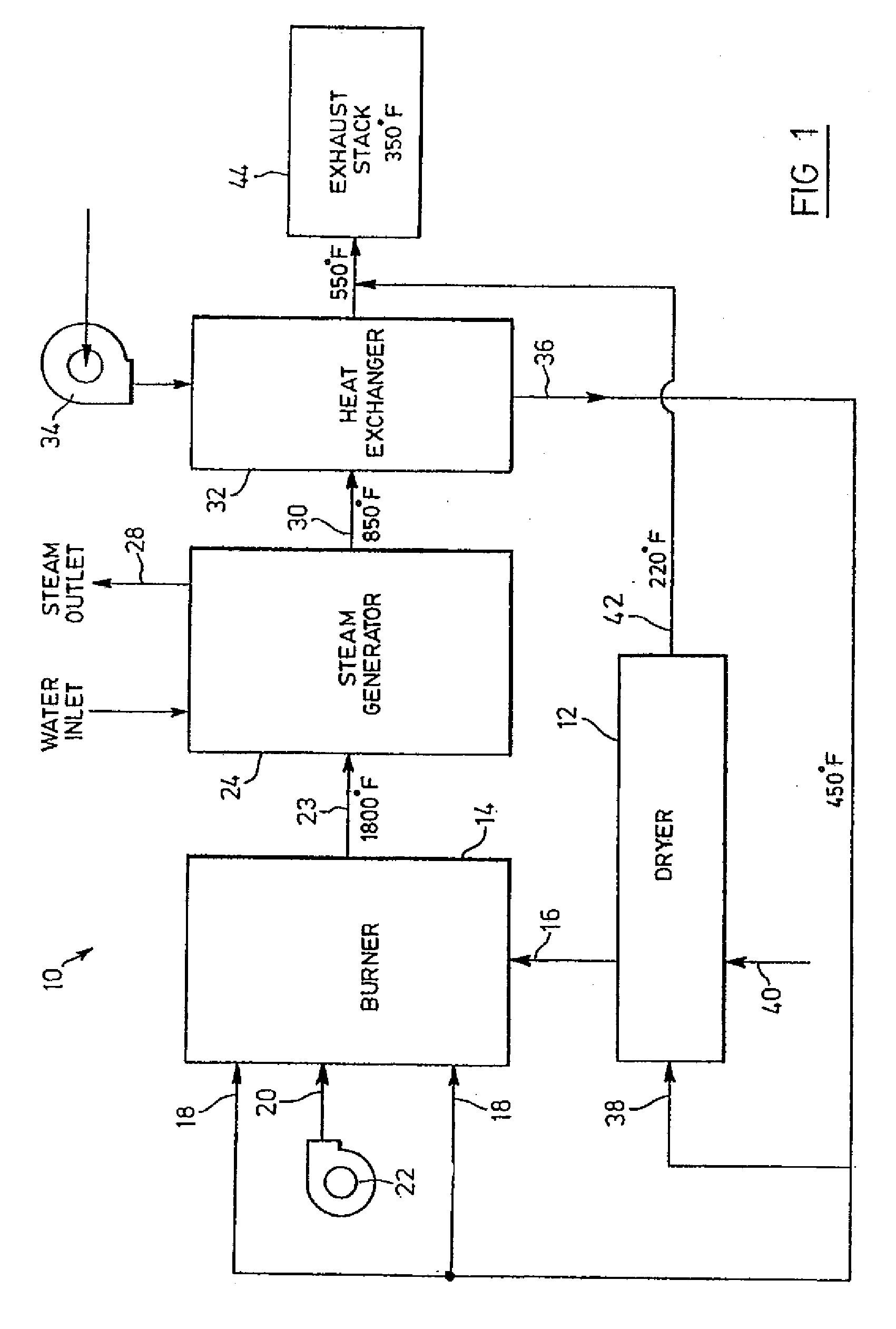

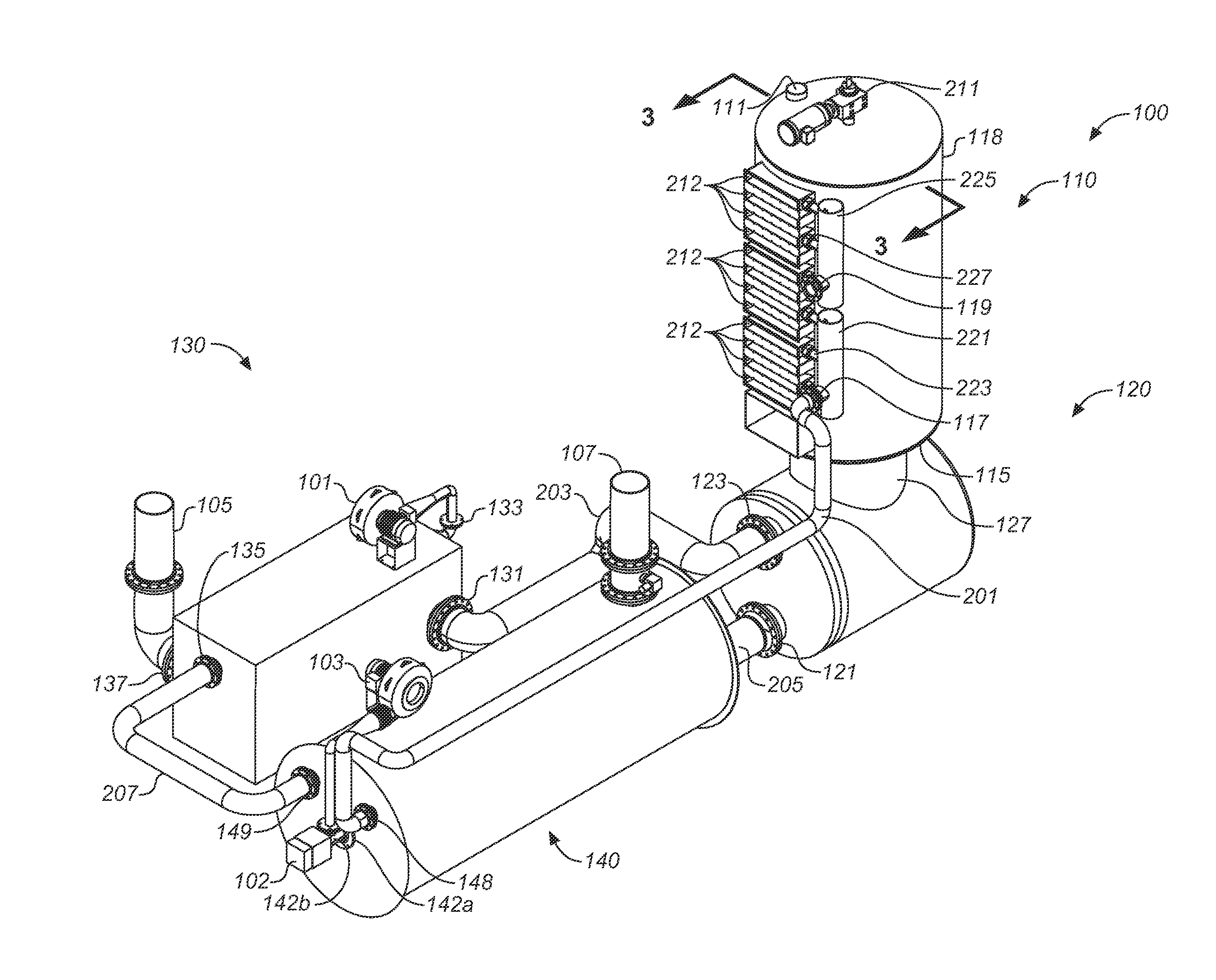

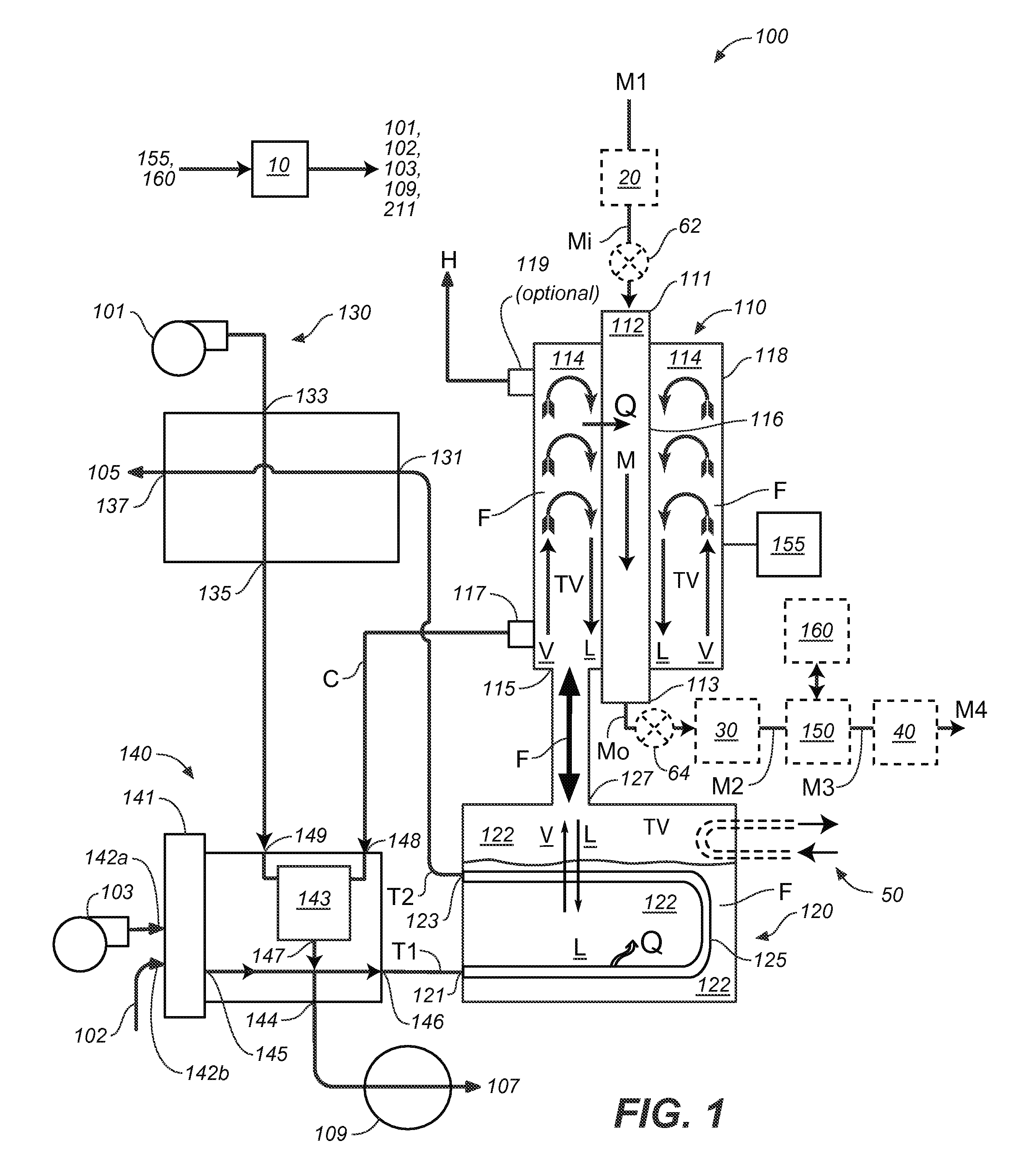

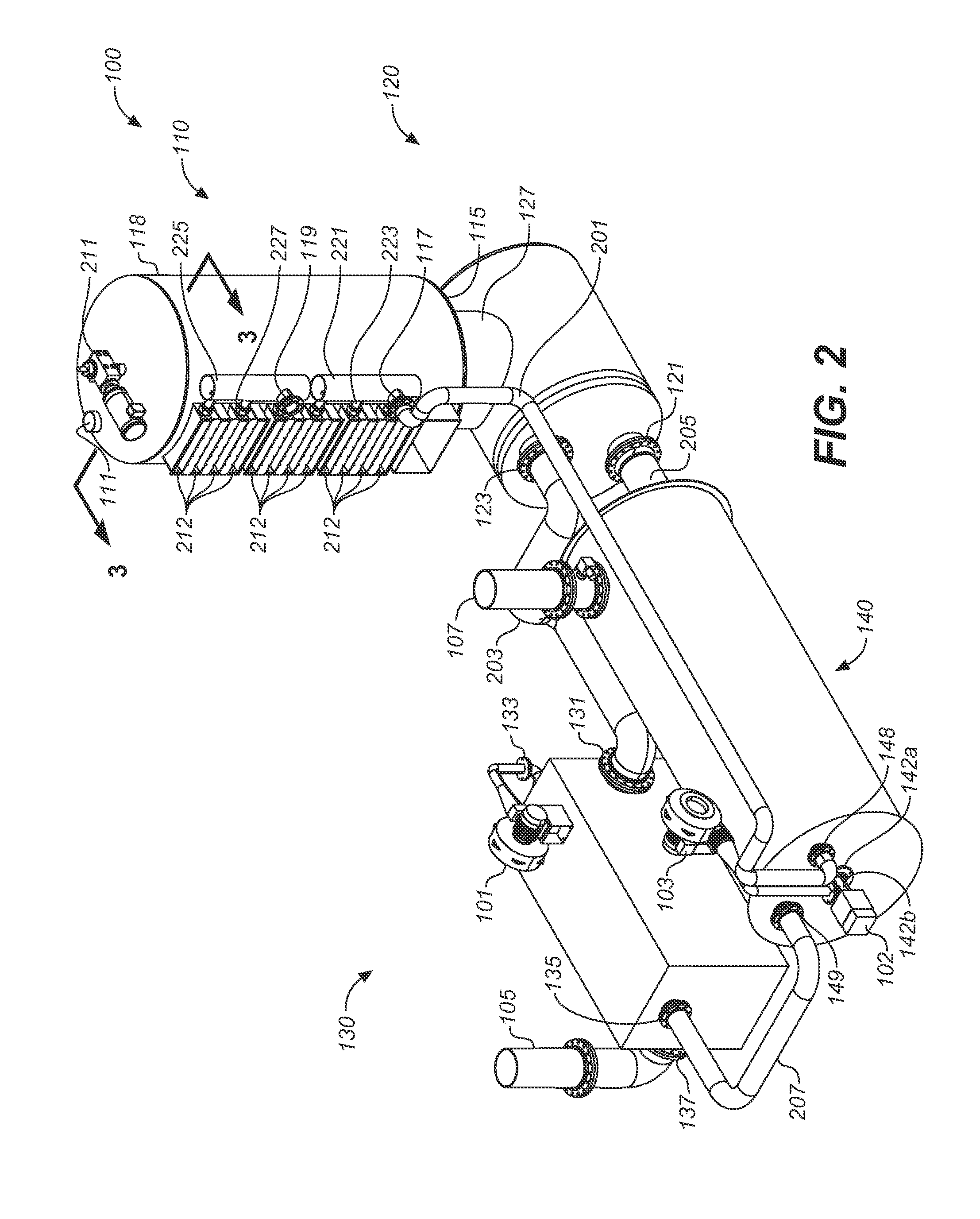

Heating media regenerators for high efficiency driers

InactiveUS20110232124A1Drying using combination processesDrying solid materials with heatClosed loopEngineering

A drier apparatus for removing water from various materials includes a mixer, drying chamber, separator and regenerator and a method for use of the apparatus. The material to be dried is mixed with a heated media to form a mixture which then passes through the chamber. While passing through the chamber, a comparatively cool fluid is passed generally counter current through the mixture so that the mixture becomes cooler and drier and the fluid becomes hotter and more saturated with moisture. The mixture is then separated into drier material and media. The media is transferred to the regenerator and heated therein by the hot fluid from the chamber and supplemental heat is supplied to bring the media to a preselected temperature for mixing with incoming material to be dried. In a closed loop embodiment of the apparatus, the fluid exiting the regenerator is also recycled from the regenerator to the chamber and a chiller is utilized to reduce the temperature of the fluid to a preselected temperature and / or a preselected dew point temperature.

Owner:SHIVVERS GRP INC THE AN IOWA

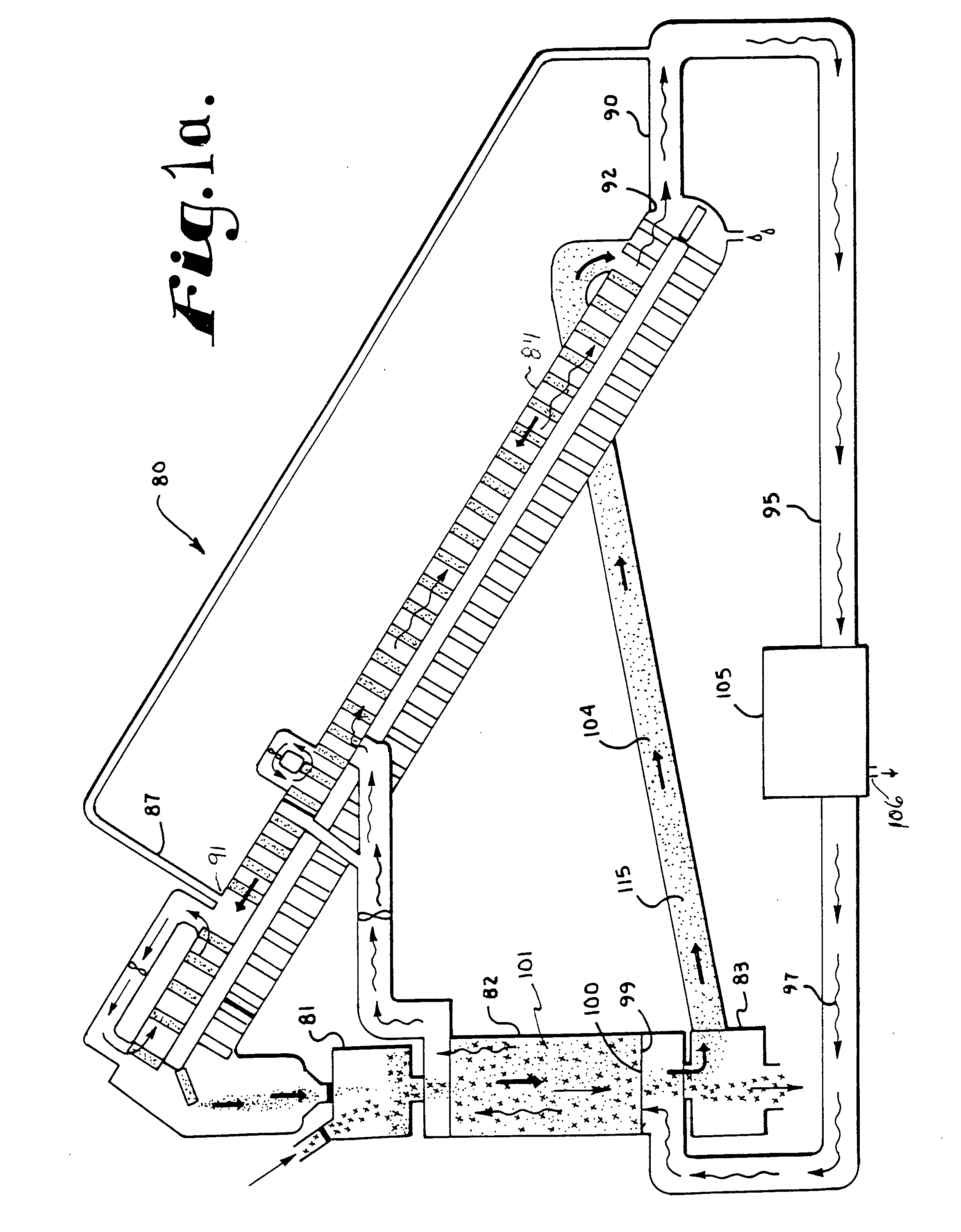

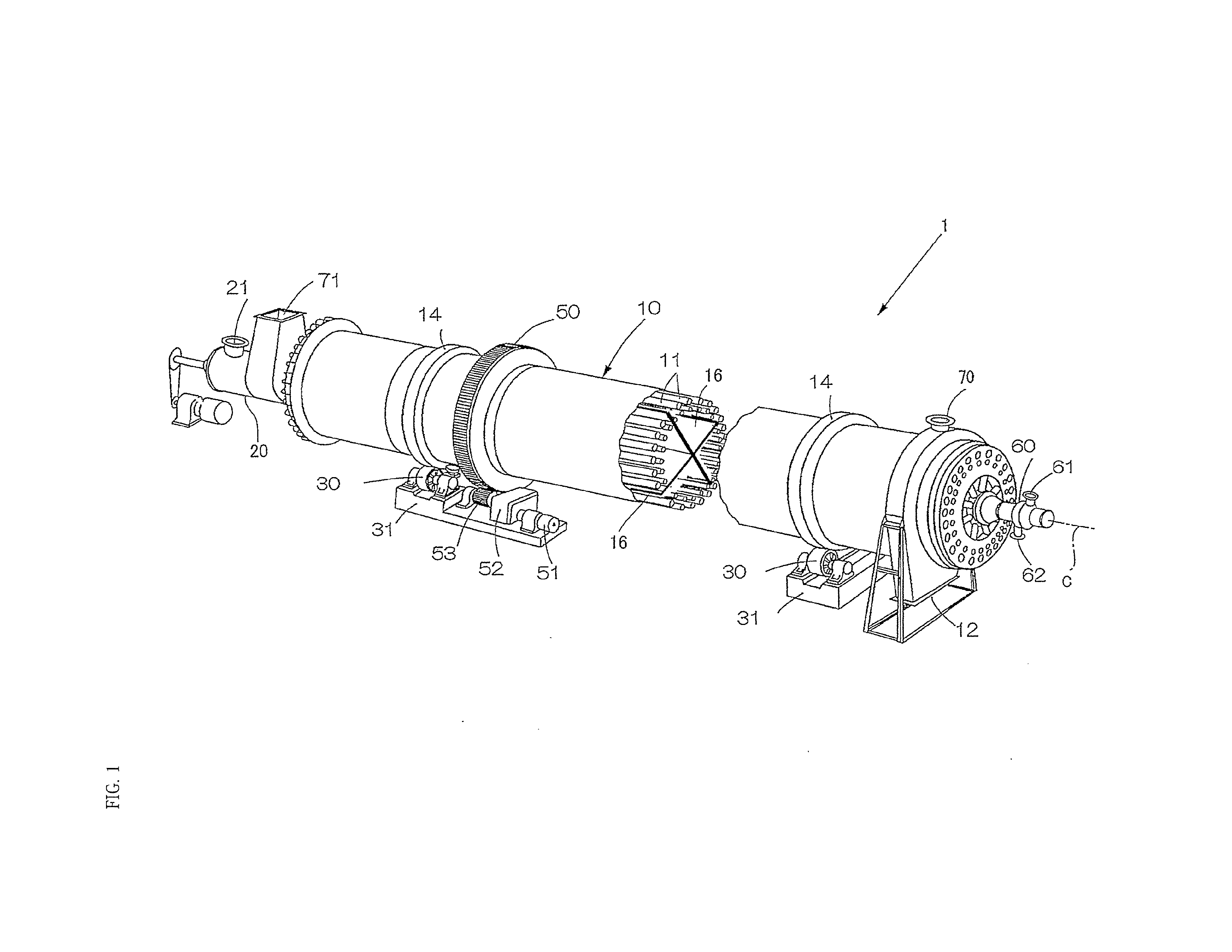

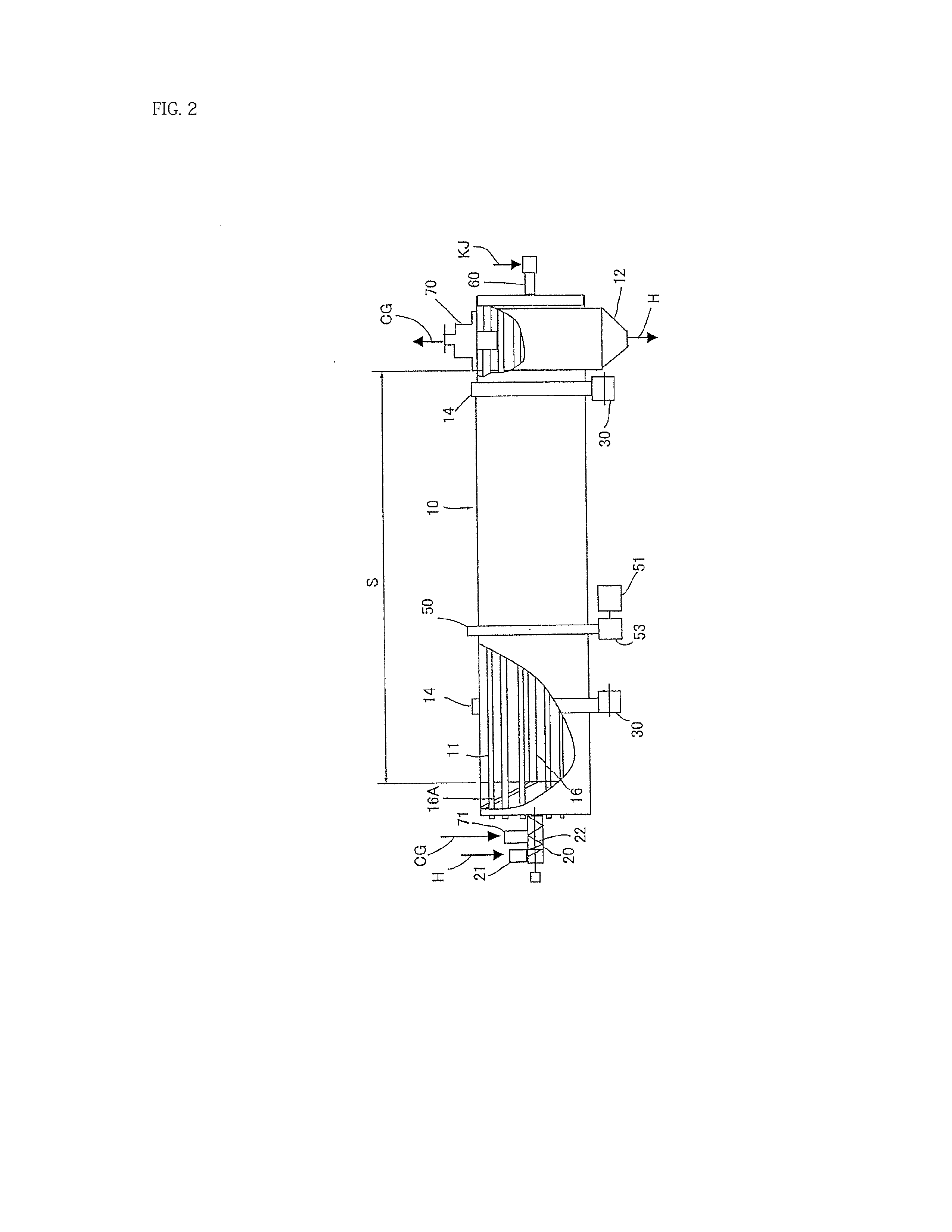

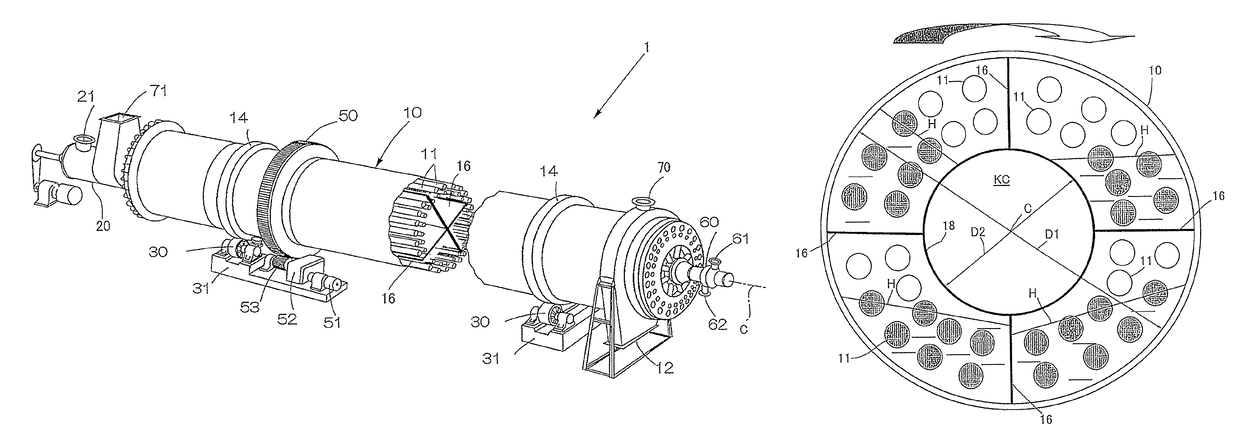

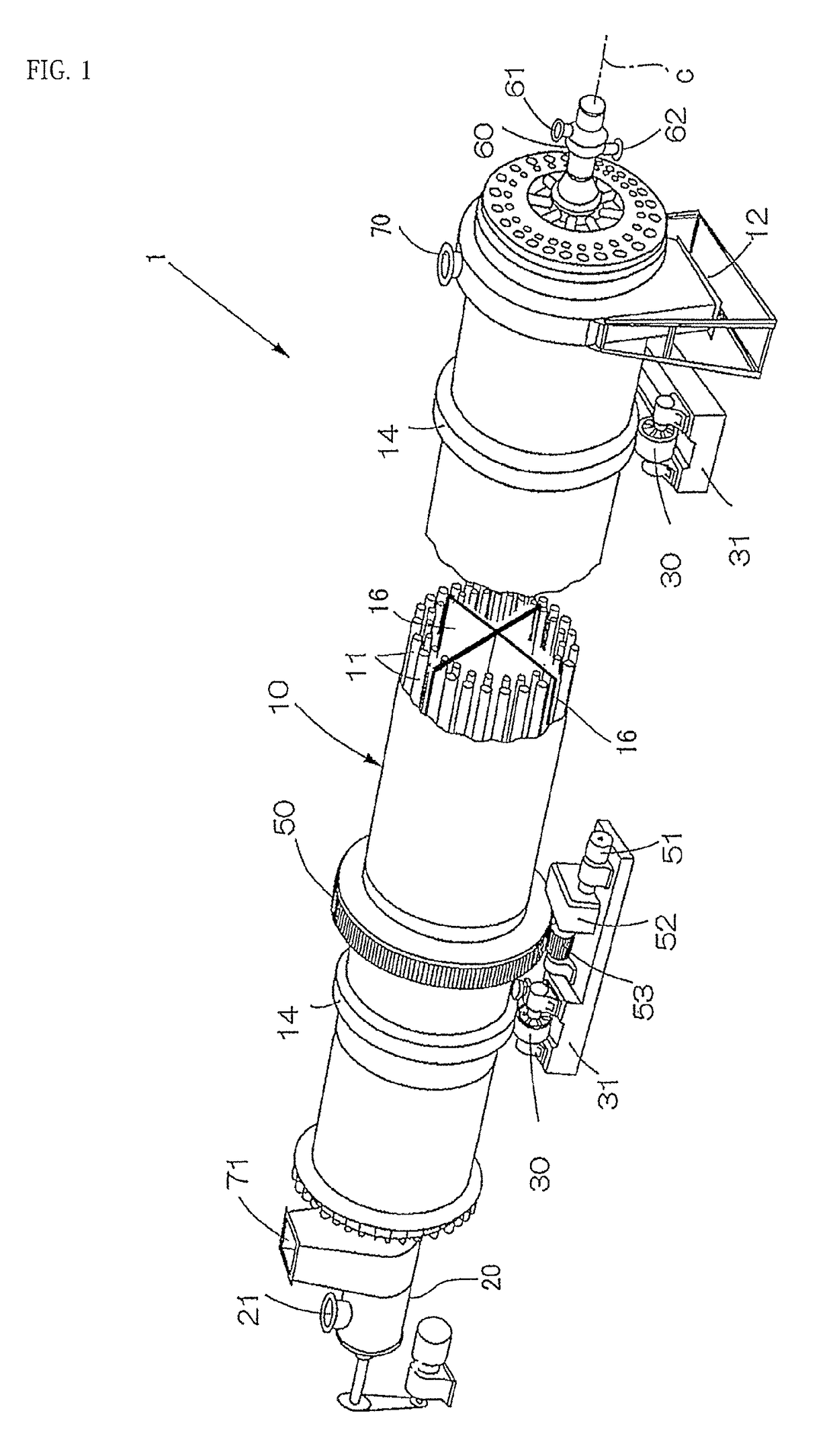

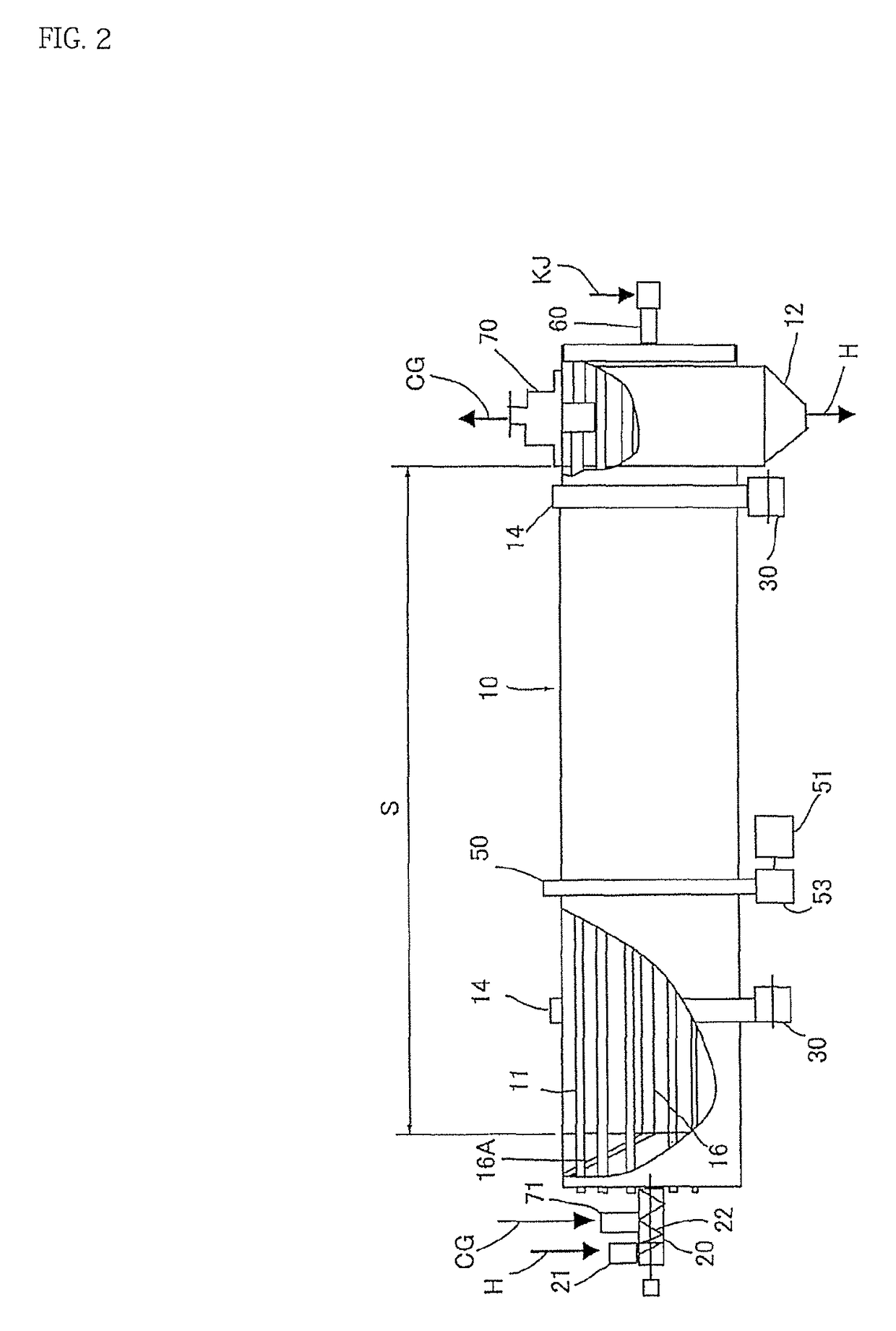

Indirectly heating rotary dryer

ActiveUS20130174436A1Good energy saving effectReduce heatDrying machines with non-progressive movementsWood particle dryingEngineeringMechanical engineering

Owner:TSUKISHIMA KIKAI CO LTD

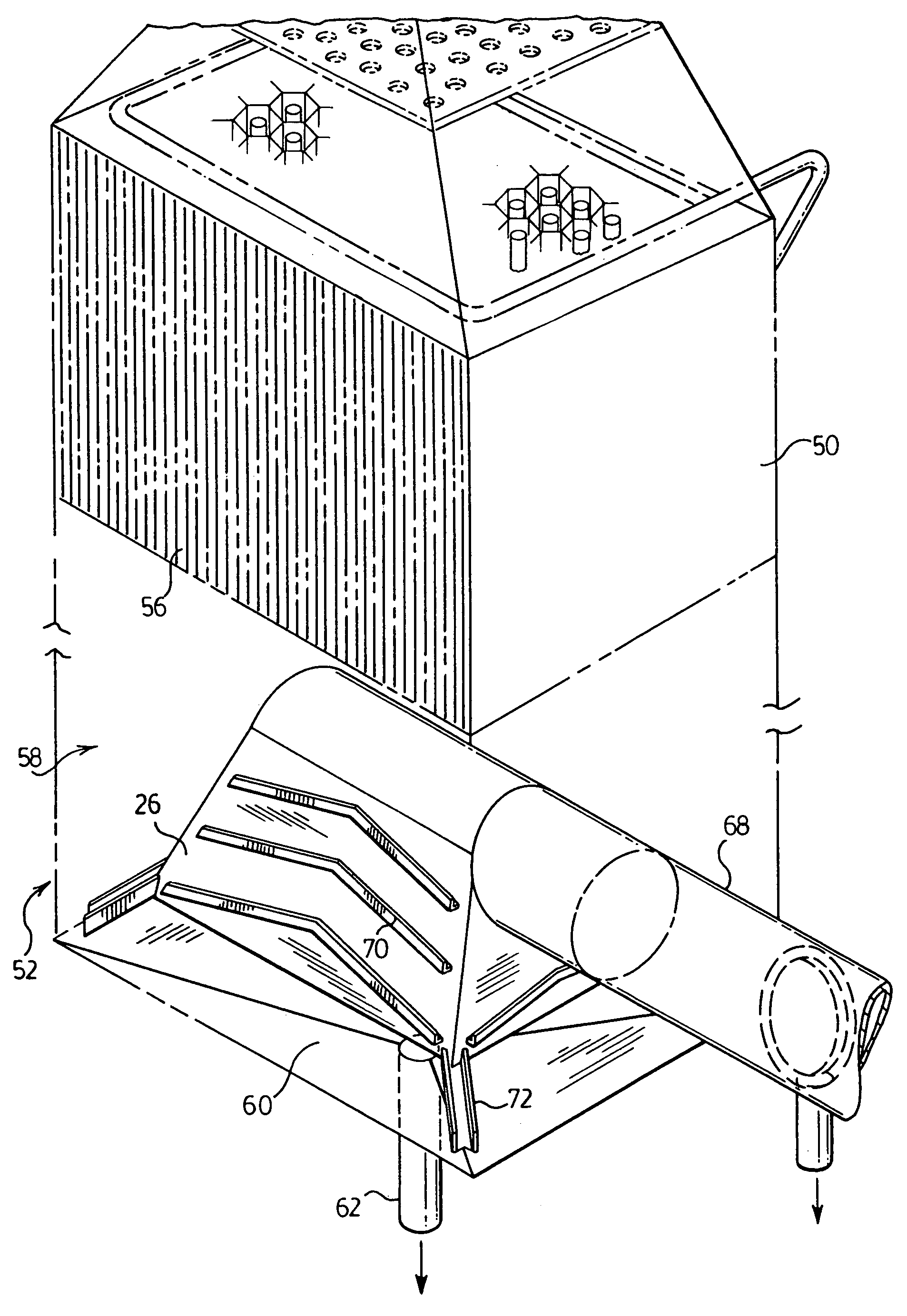

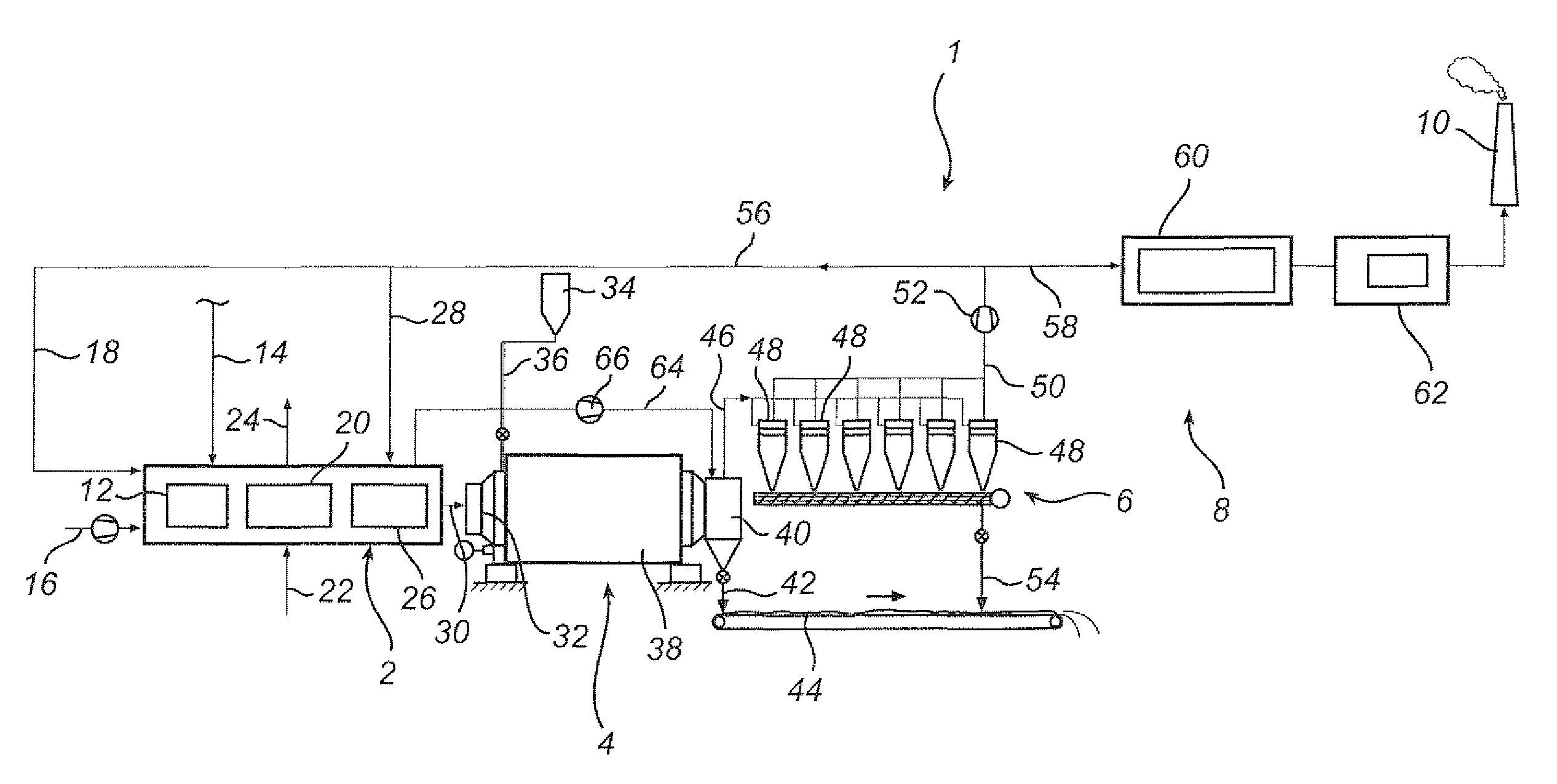

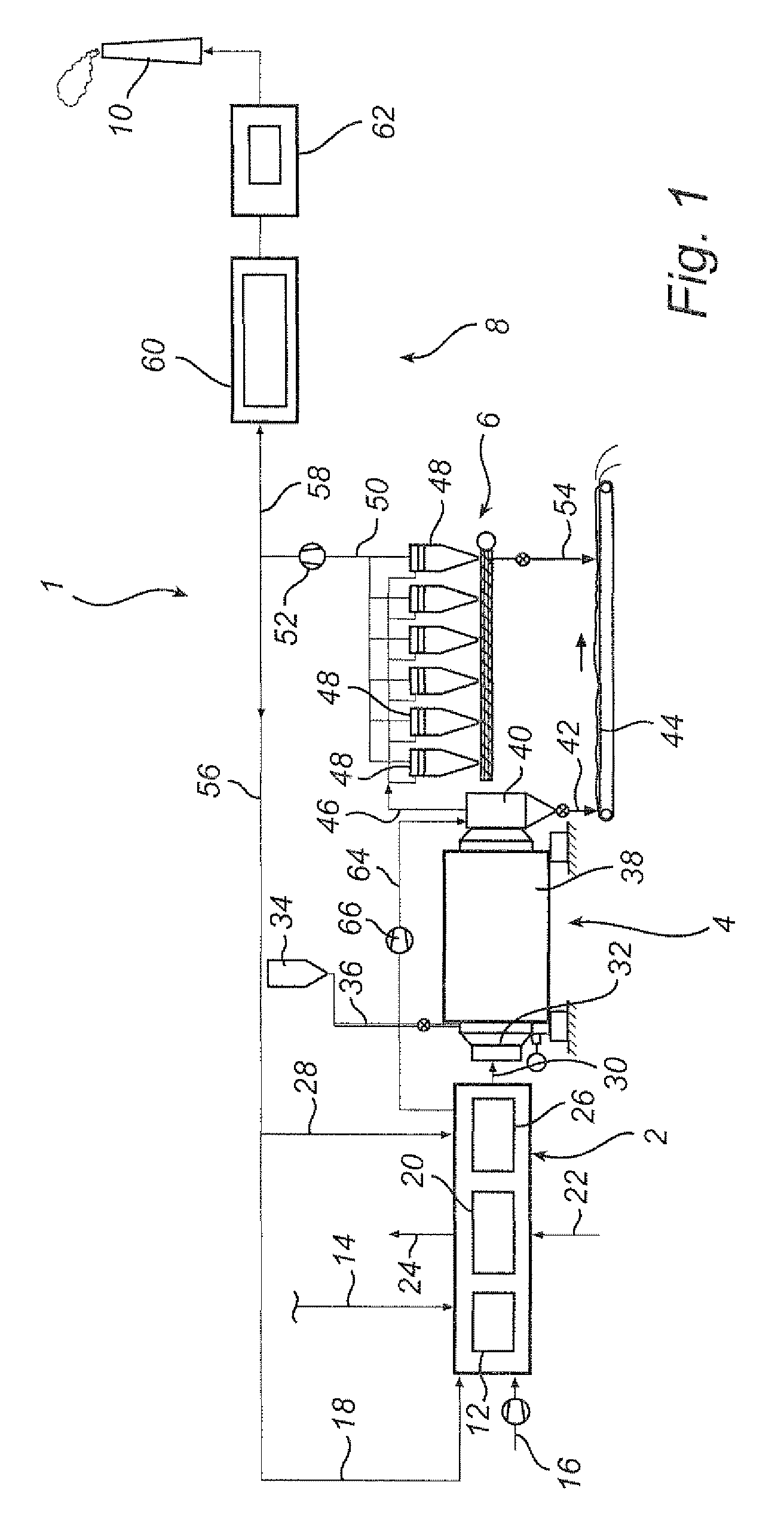

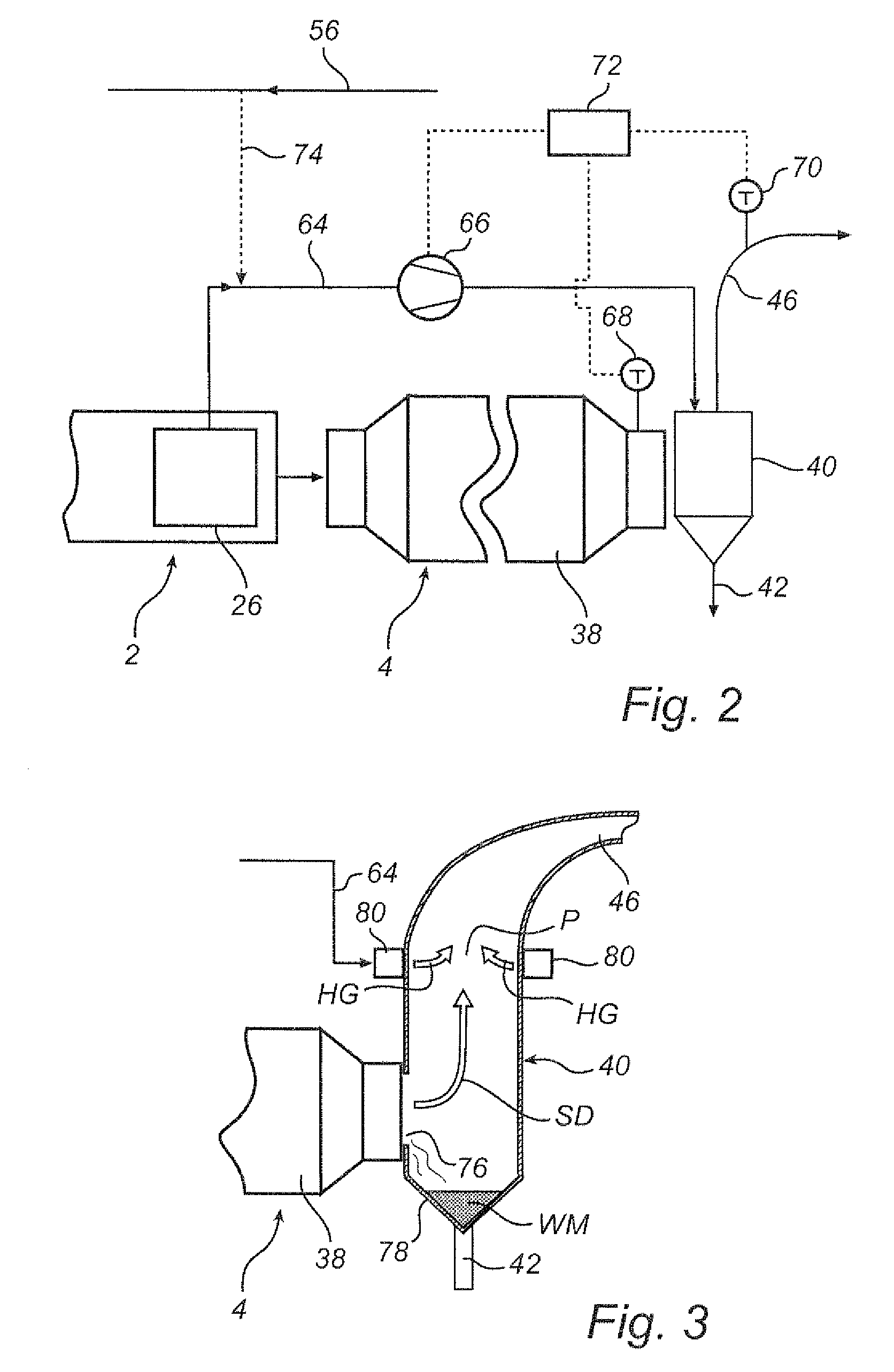

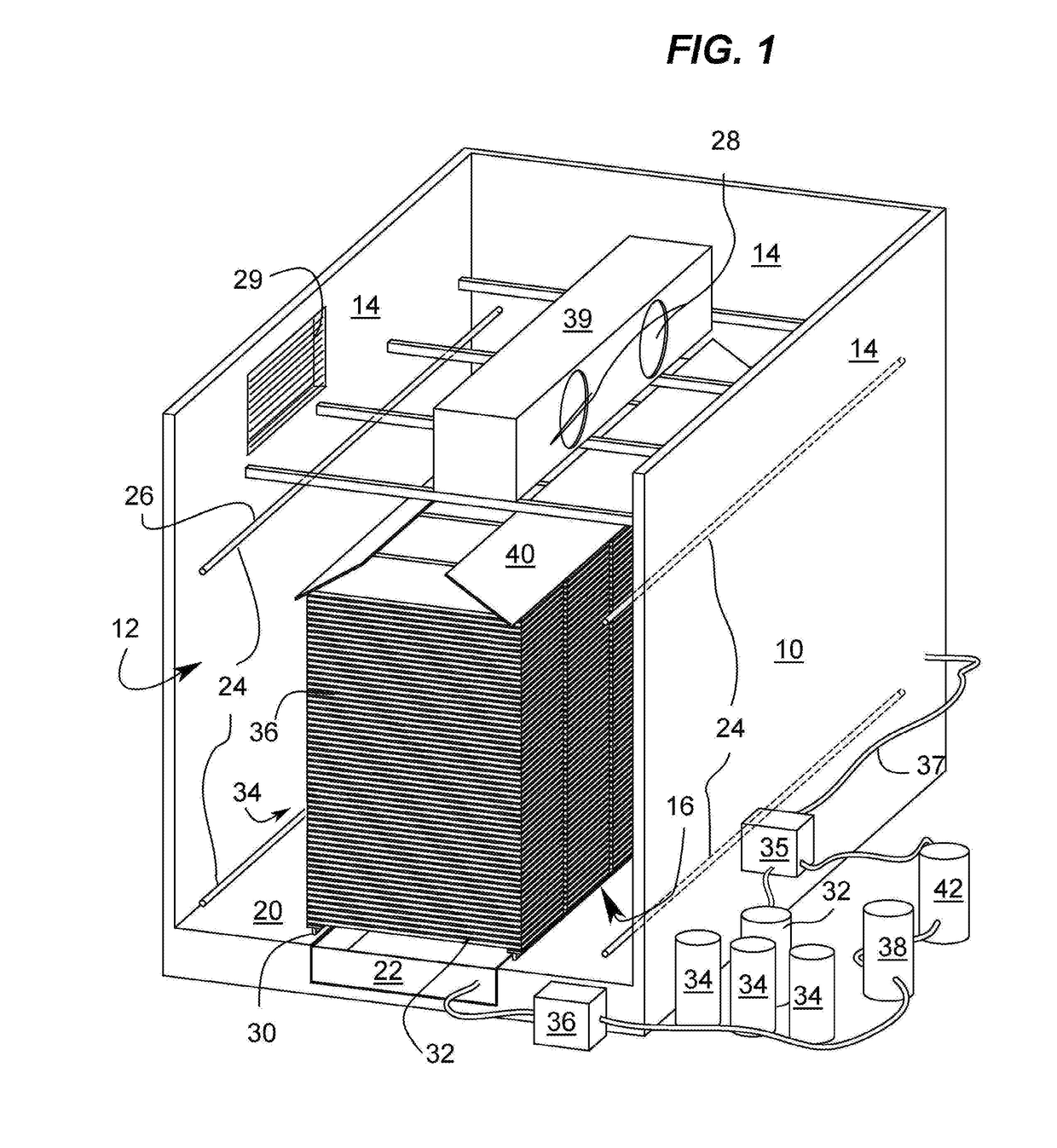

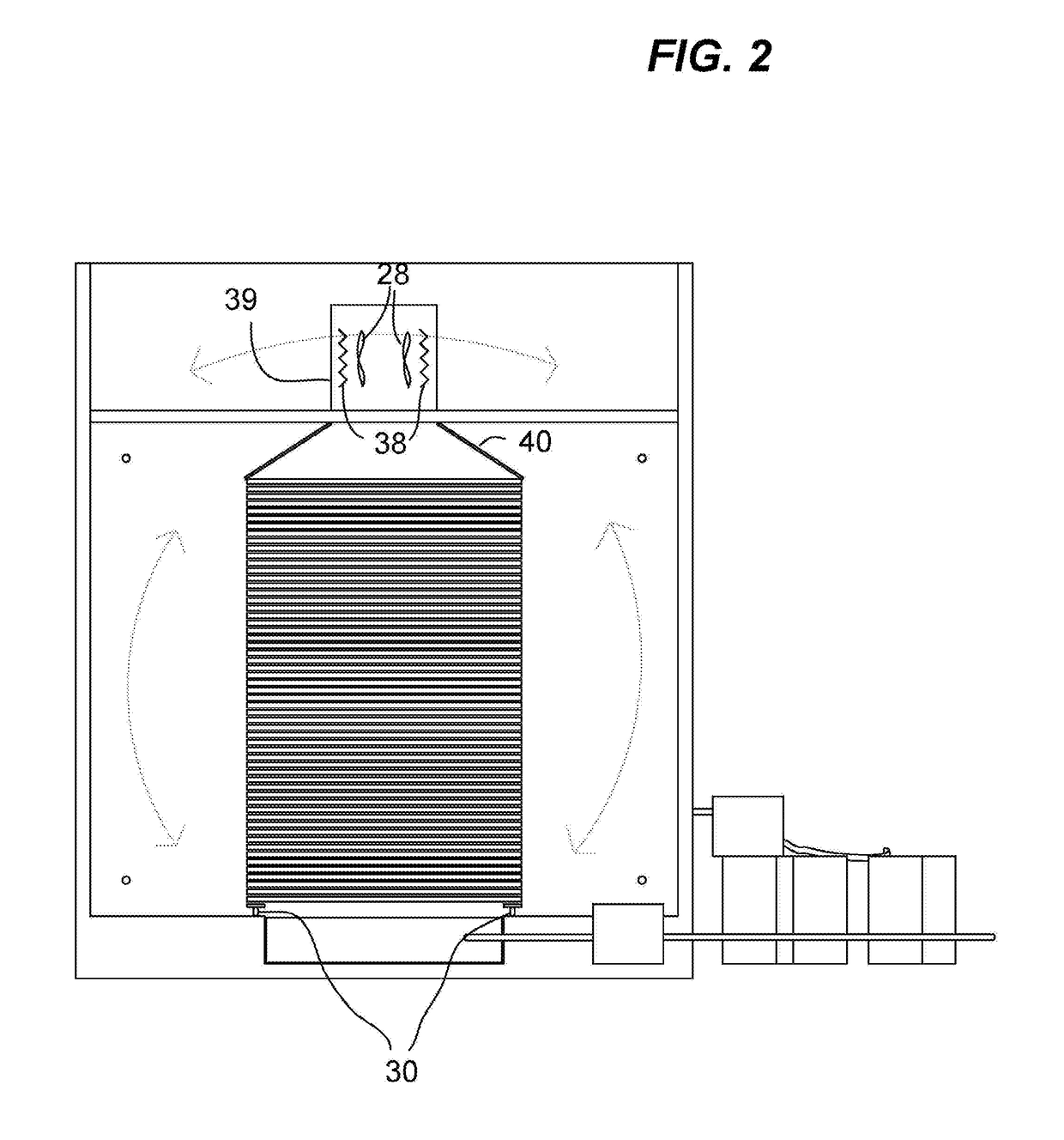

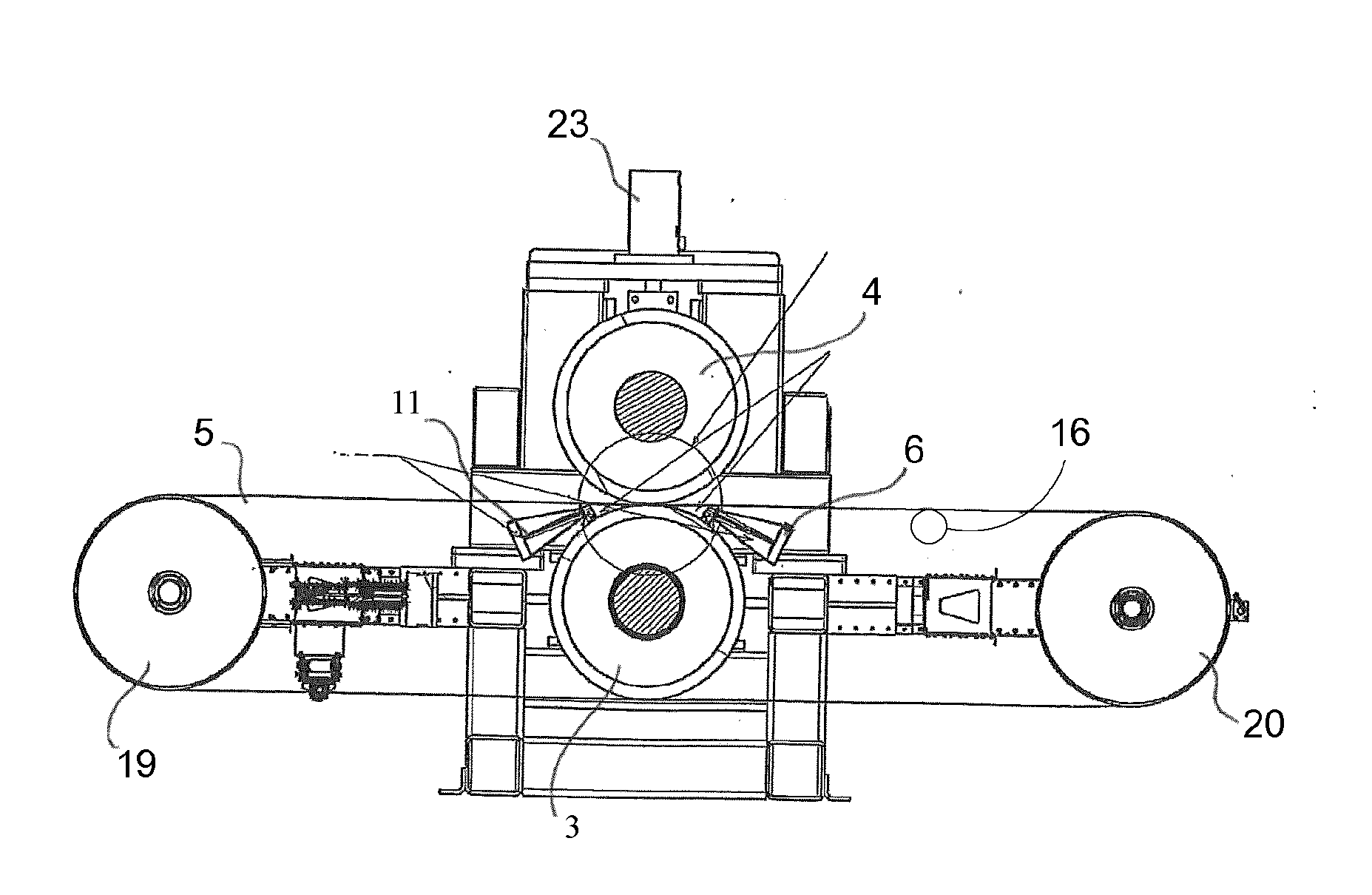

Wood material drying plant comprising a rotary dryer

InactiveUS20110056090A1Reduce stepsEfficient energy consumptionDrying solid materials with heatDispersed particle separationProcess engineeringRotating drum

A wood material drying plant including a heater for generating a hot drying gas, a rotary dryer for bringing the hot drying gas into contact with the wood material to be dried, a wood particle separating unit being operative for separating entrained wood particles from the spent drying gas, and a gas cleaning system for removing pollutants from the spent drying gas. The wood material drying plant is provided with a heating gas duct which is operative for forwarding a gas portion to a mixing position located between the rotating drum of the rotary dryer and the wood particle separating unit, said gas portion having a higher temperature than the spent drying gas, and for mixing said gas portion with said spent drying gas, such that the temperature of the spent drying gas is increased.

Owner:ANDRITZ TECH & ASSET MANAGEMENT

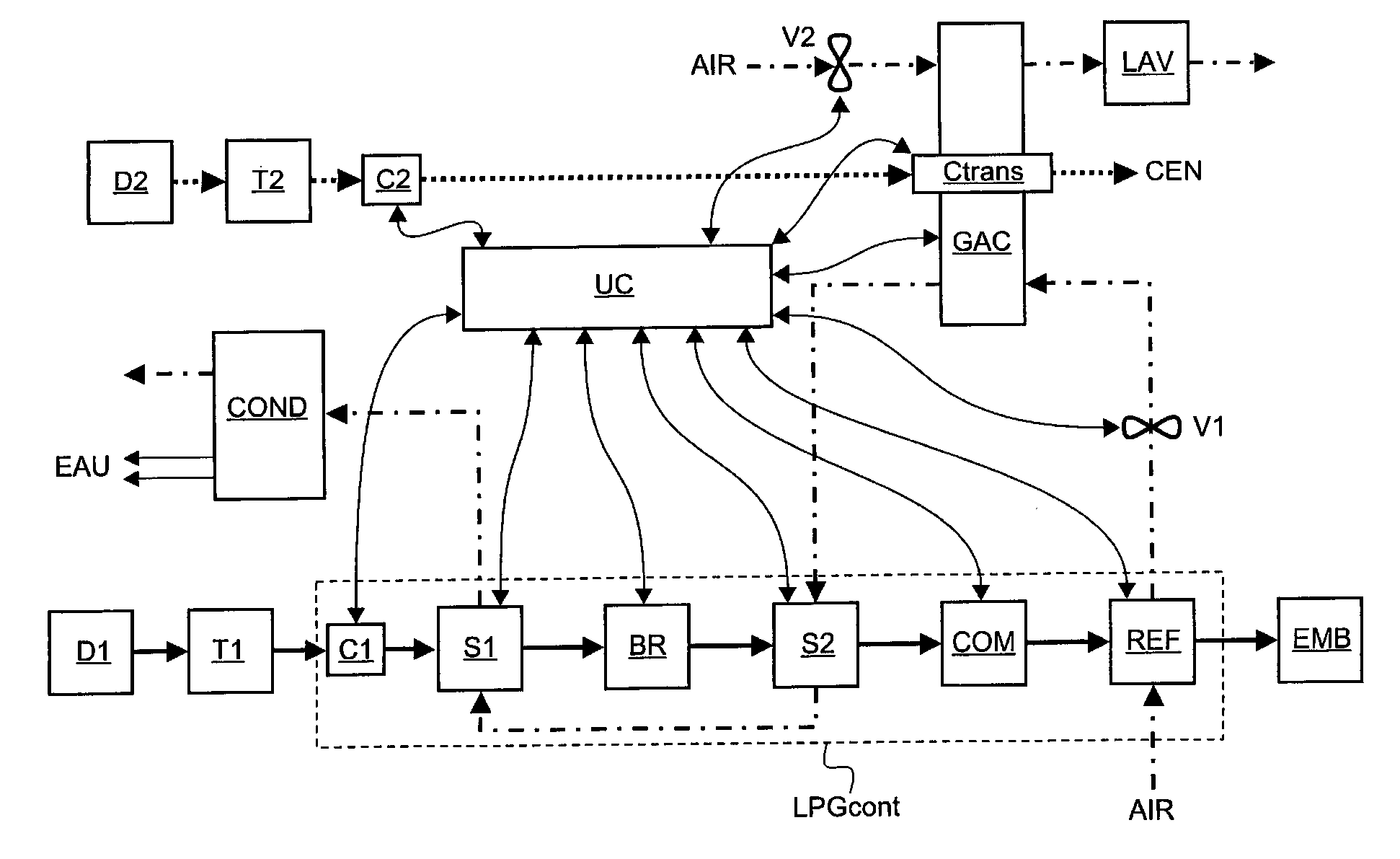

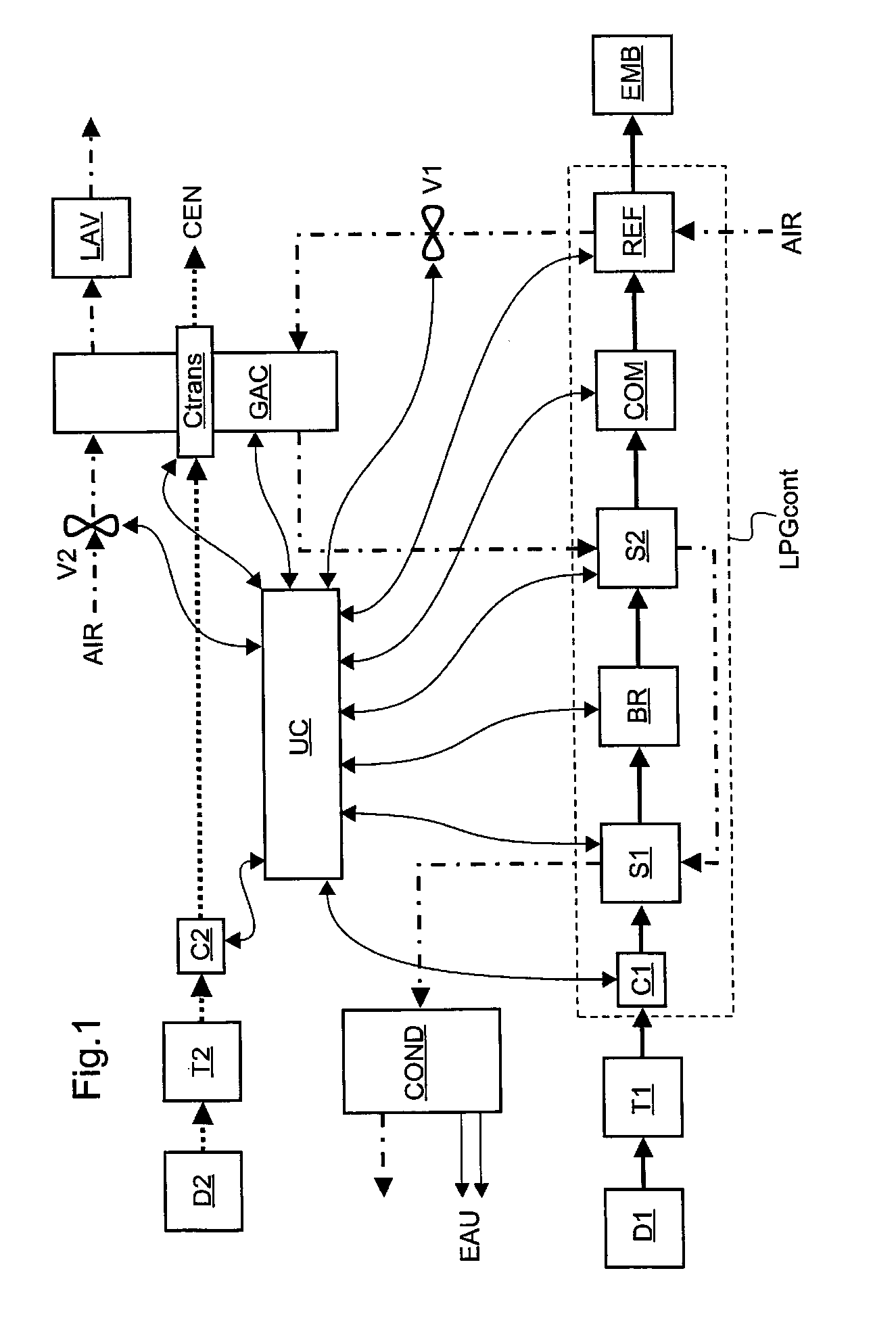

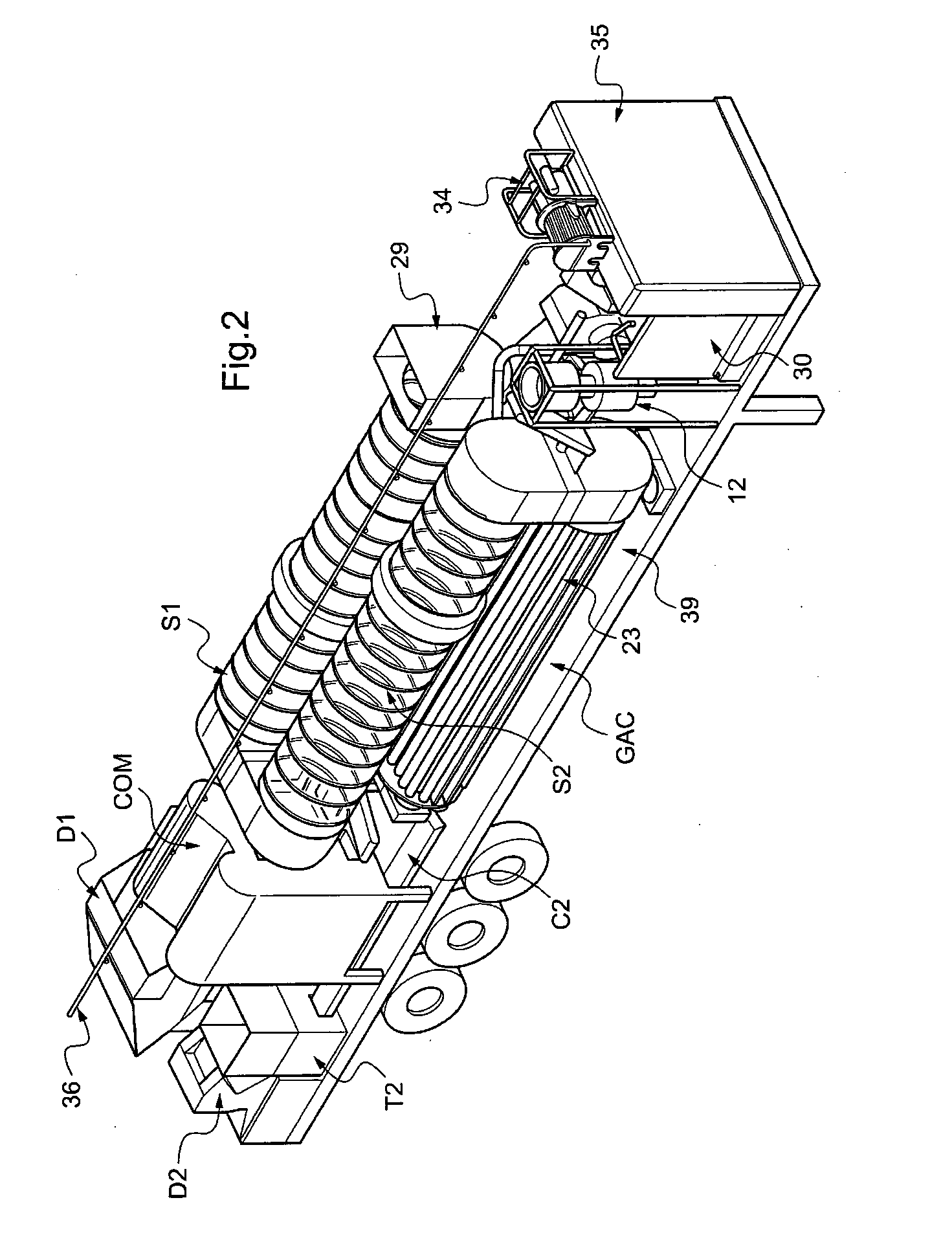

Equipment for producing granules from plants

ActiveUS20110168816A1Easy and efficient processingGas current separationWood working apparatusProduction unitWaste management

Equipment for producing granules from a ligneous material includes a unit (LPGcont) for the continuous production of agglomerated plant particles, a unit (GAC) for the production of hot air from plants, the hot air being used for the production of the agglomerated particles, and also at least one mobile load-bearing structure to which the two production units are attached.

Owner:LEJOSNE ALAIN

Indirectly heated rotary dryer

ActiveUS9683779B2Good energy saving effectReduce heatDrying machines with non-progressive movementsWood particle dryingInterior spaceEngineering

Owner:TSUKISHIMA KIKAI CO LTD

Integrated unit for treatment and drying lignocellulosic material

InactiveUS20170320090A1Allow useLow costDrying solid materials with heatSpraying apparatusCelluloseHigh humidity

An integrated boiler-dryer consisting in a sealable vessel capable of sustaining high humidity and variable gas pressures and into which is placed a lignocellulosic material, and a compound in mist form. The sealable vessel provides dry heat so as to dry the lignocellulosic material while the compound is impregnated within the lignocellulosic material.

Owner:ROY JACQUES

Process and device for fluidized bed torrefaction and grinding of a biomass feed for subsequent gasification or combustion

ActiveUS8900415B2Drying using combination processesCombustible gas coke oven heatingCombustionEngineering

Owner:INST FR DU PETROLE

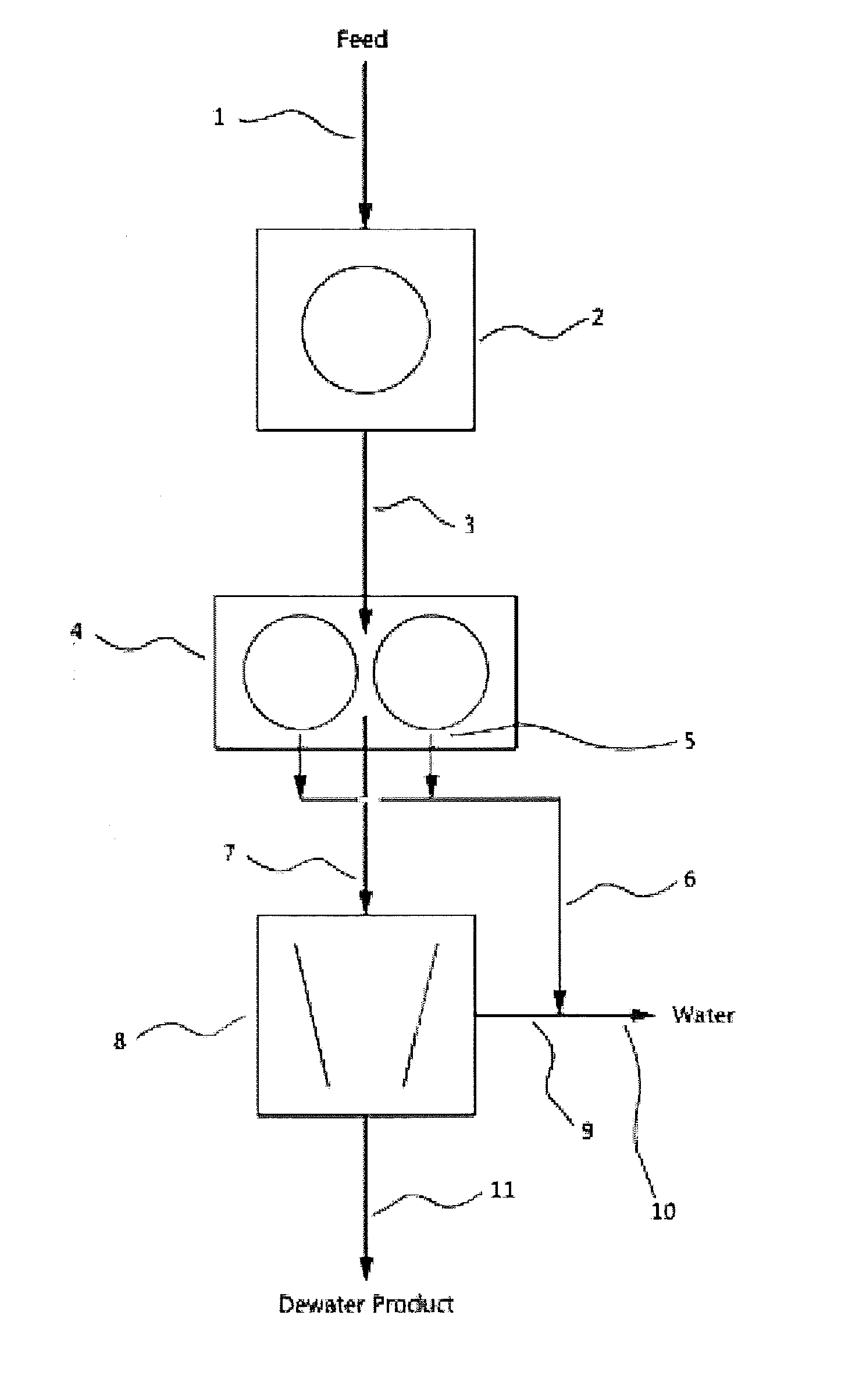

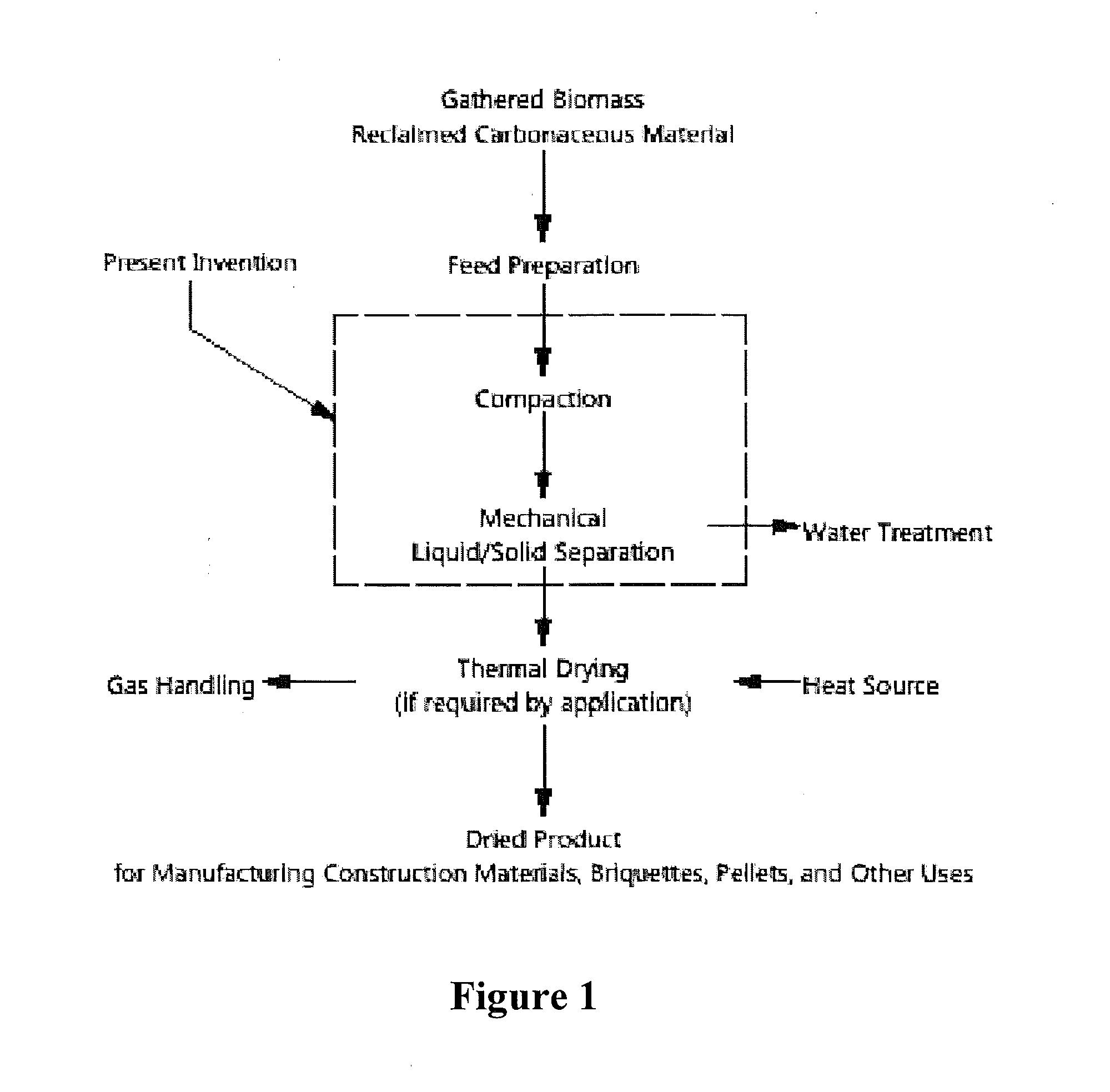

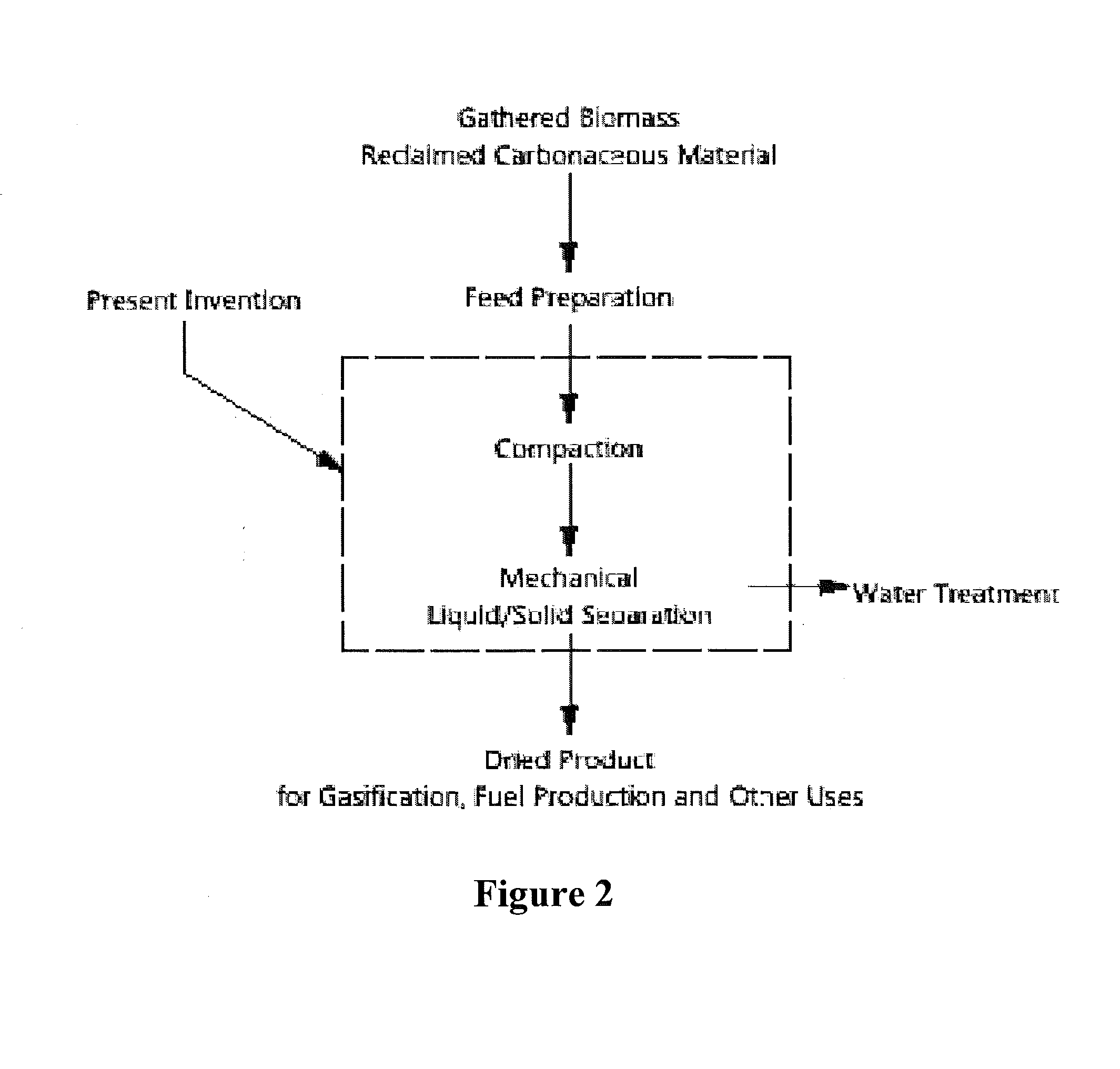

Methods of drying biomass and carbonaceous materials

InactiveUS20130326938A1Low costWeaken energyDrying solid materials without heatBiofuelsEngineeringMoisture

The invention provides methods of reducing the energy required to remove moisture from biomass, carbonaceous materials and mixtures of the same. The method significantly reduces the energy requirements by removing moisture as a liquid and by transferring the moisture to the surface of the material where it is more easily and efficiently evaporated.

Owner:GTL ENERGY LTD

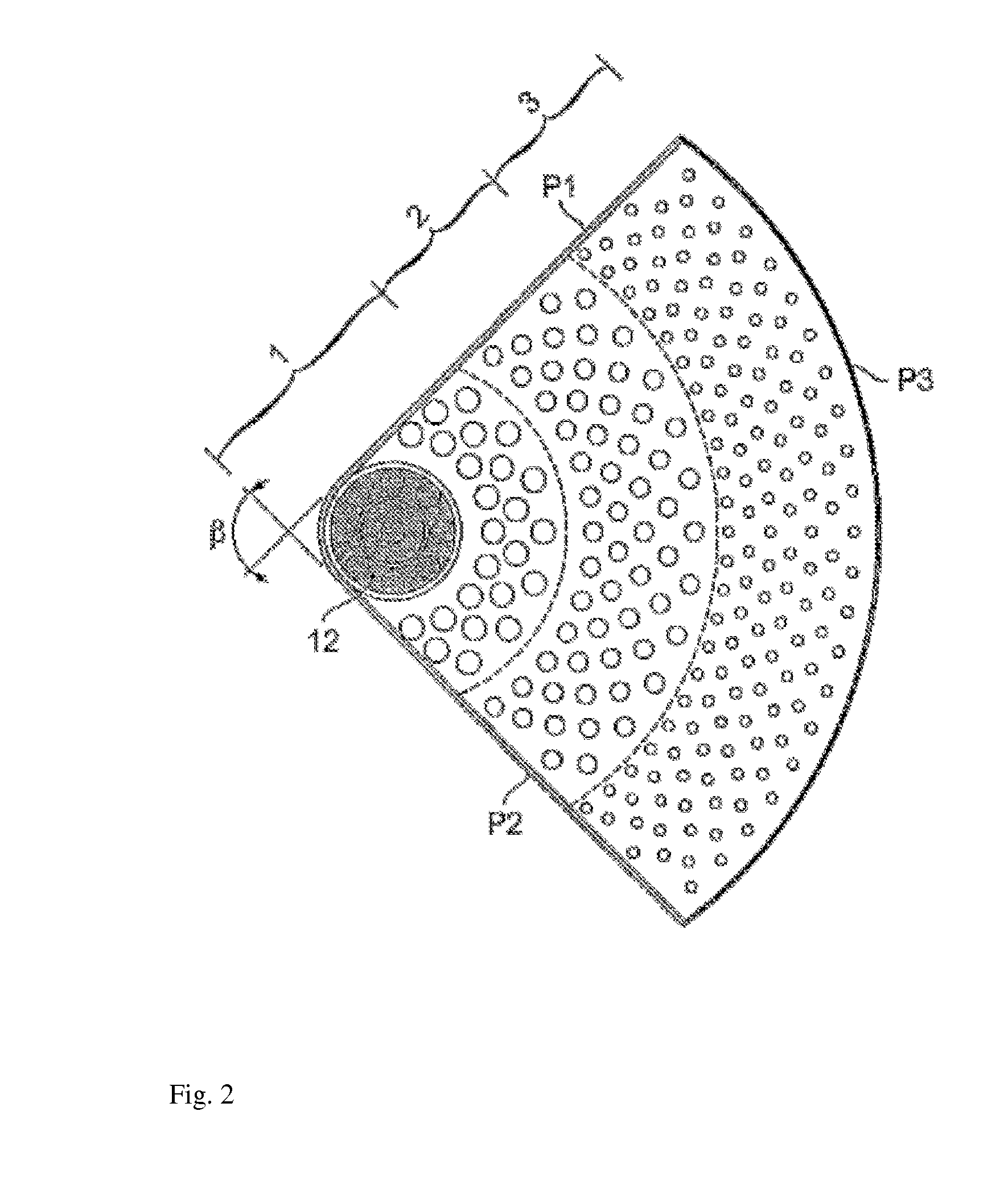

Apparatus and a method for dewatering wood chips

ActiveUS20150217530A1Counteract cloggingRemove debrisDrying solid materials with heatDrying solid materials without heatPulp and paper industry

Owner:COPOLIA COMPANY

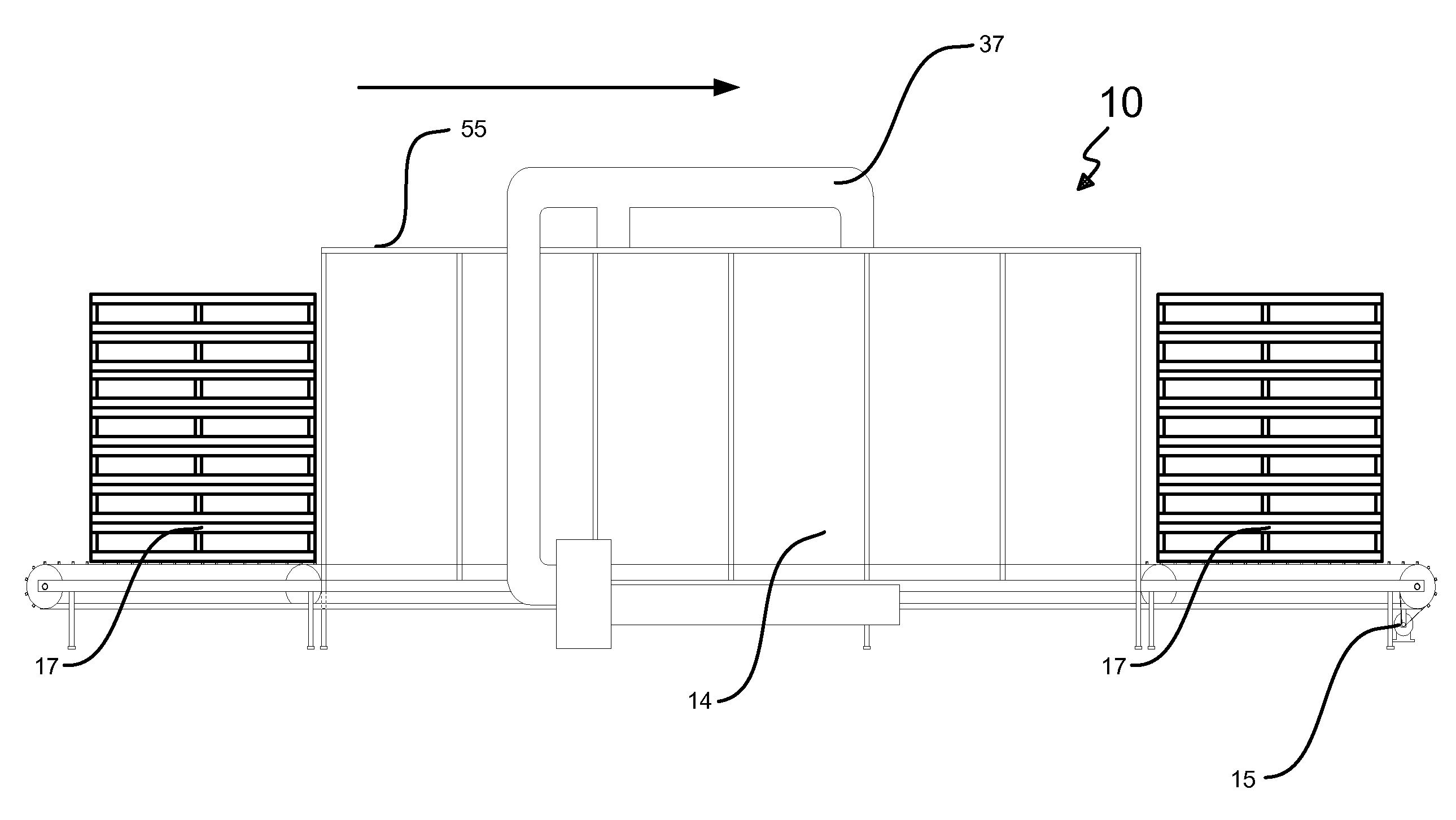

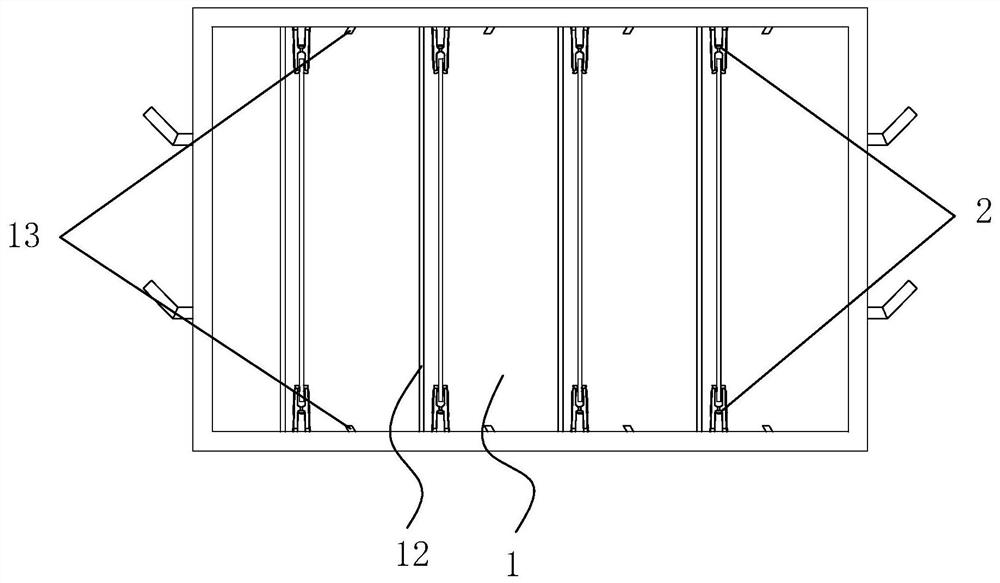

Device and process for eradicating pests in wood

A device and process for heating wood for the purpose of eradicating burrowed pests such as gypsy moths and emerald ash borer beetles are disclosed. The device is used for treating firewood and pallets made of wood to insure that burrowed pests are killed before transporting the wood across state lines in following of state regulations. The device comprises a conveyor adapted for transporting firewood or pallets an insulated and heated chamber. The wood core temperature of the wood is monitored using wireless temperature sensors. Conveyor speed is adjusted according to temperature readings in order to achieve a threshold wood core temperature and in order to maintain the threshold wood core temperature for the minimum required period of time.

Owner:THE INFERNO

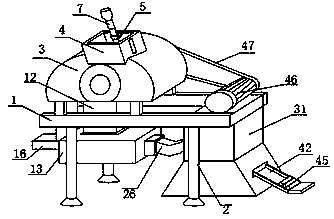

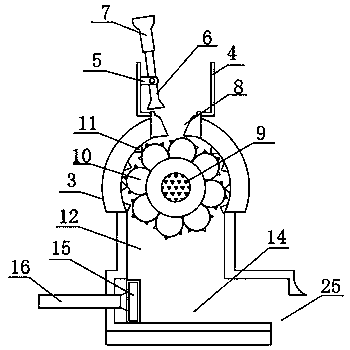

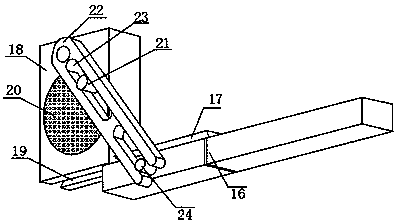

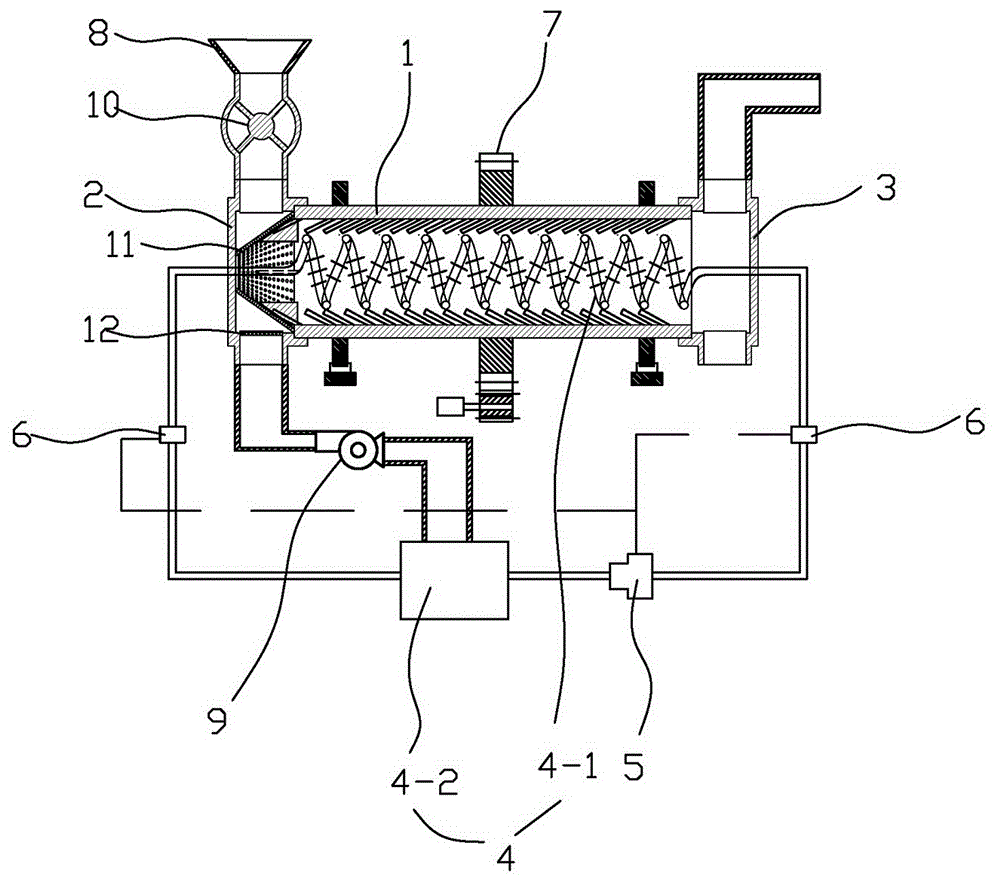

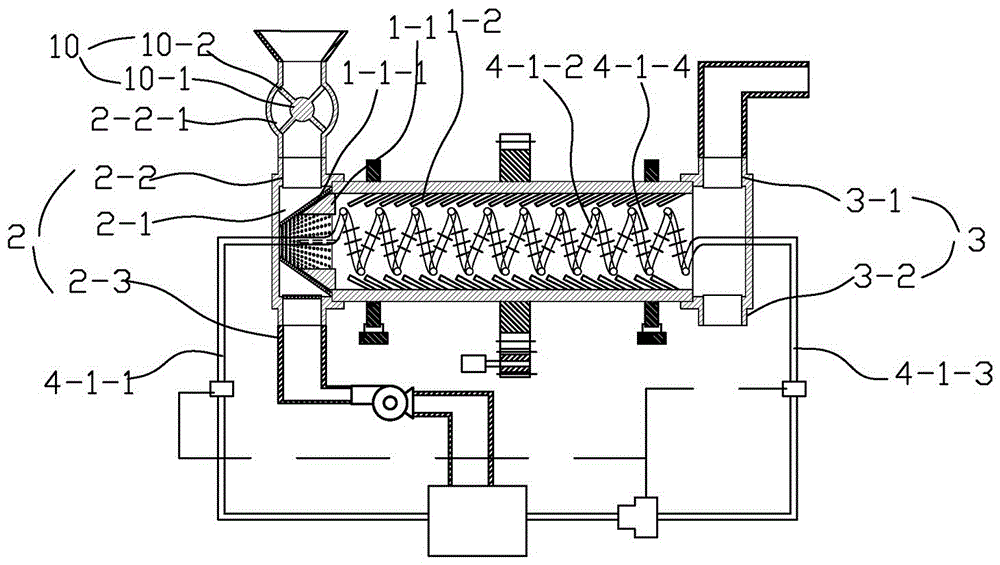

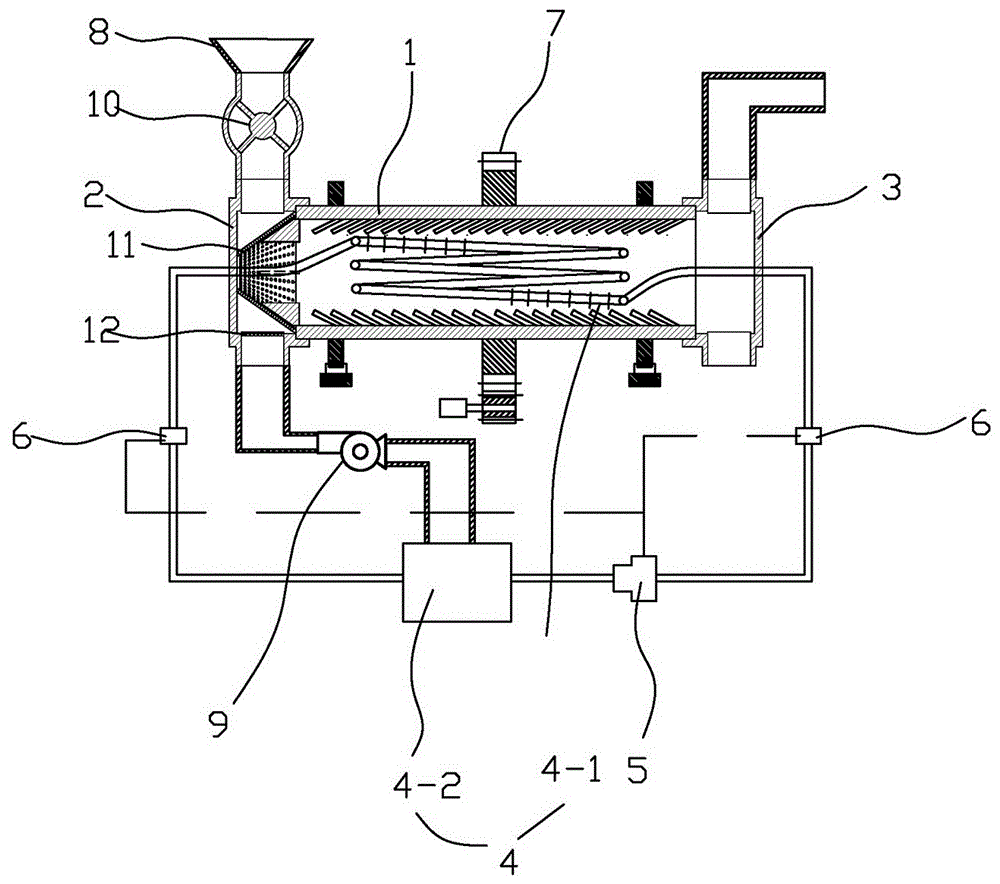

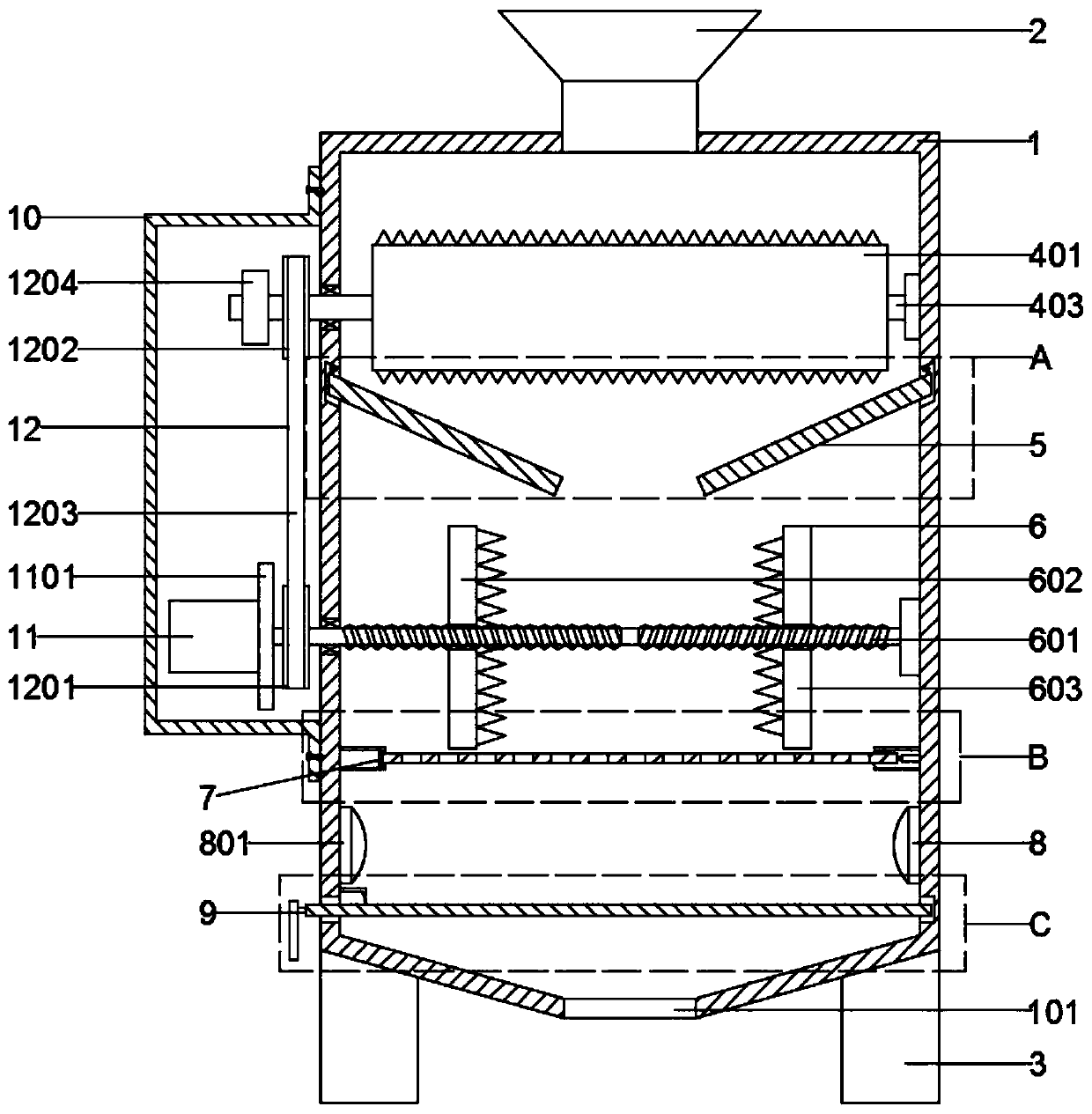

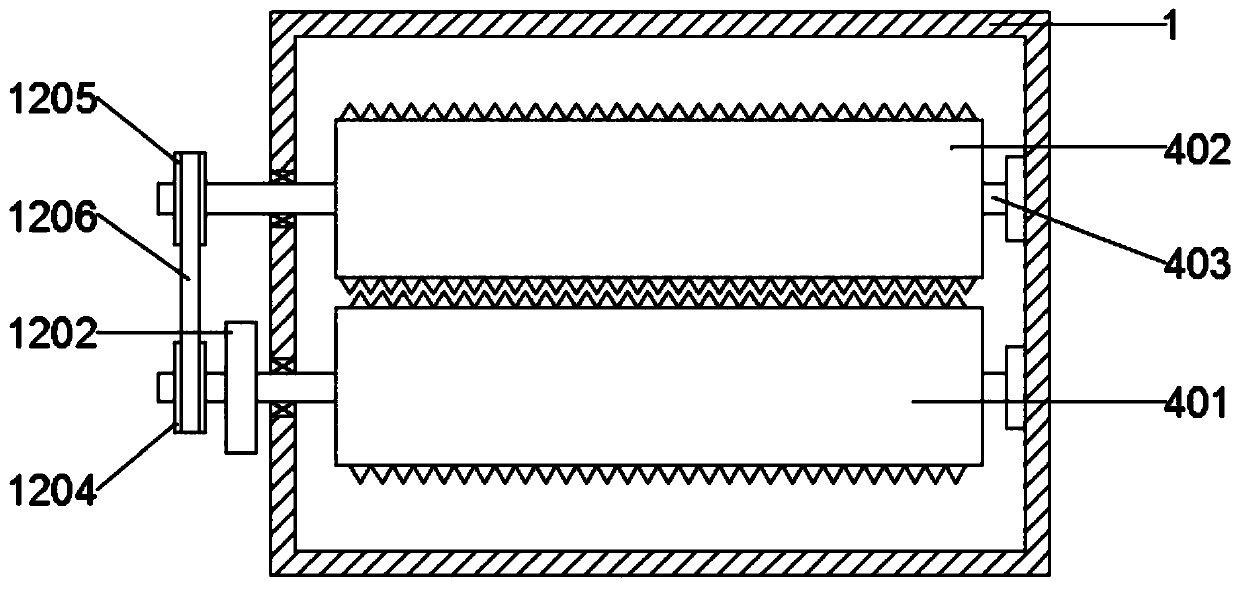

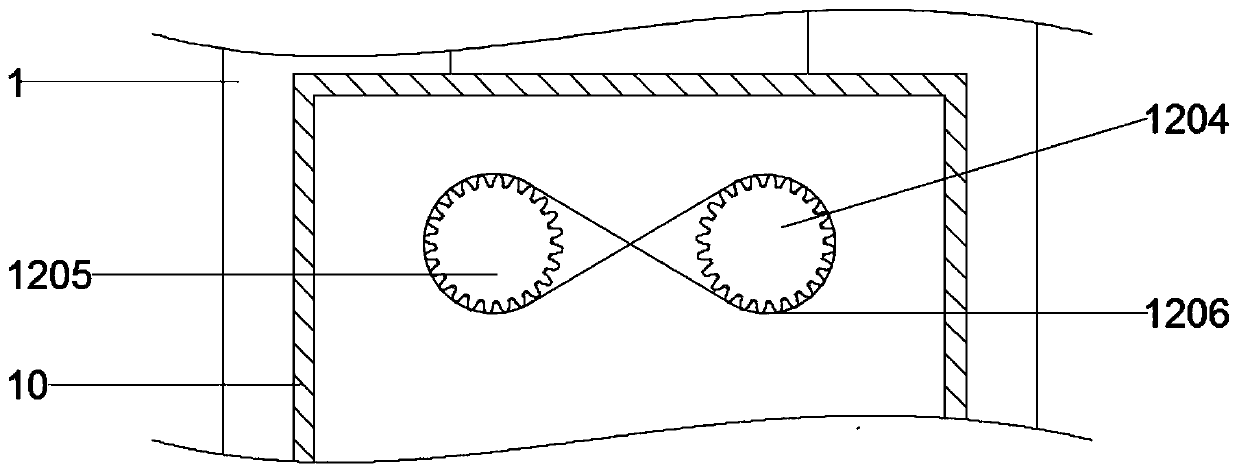

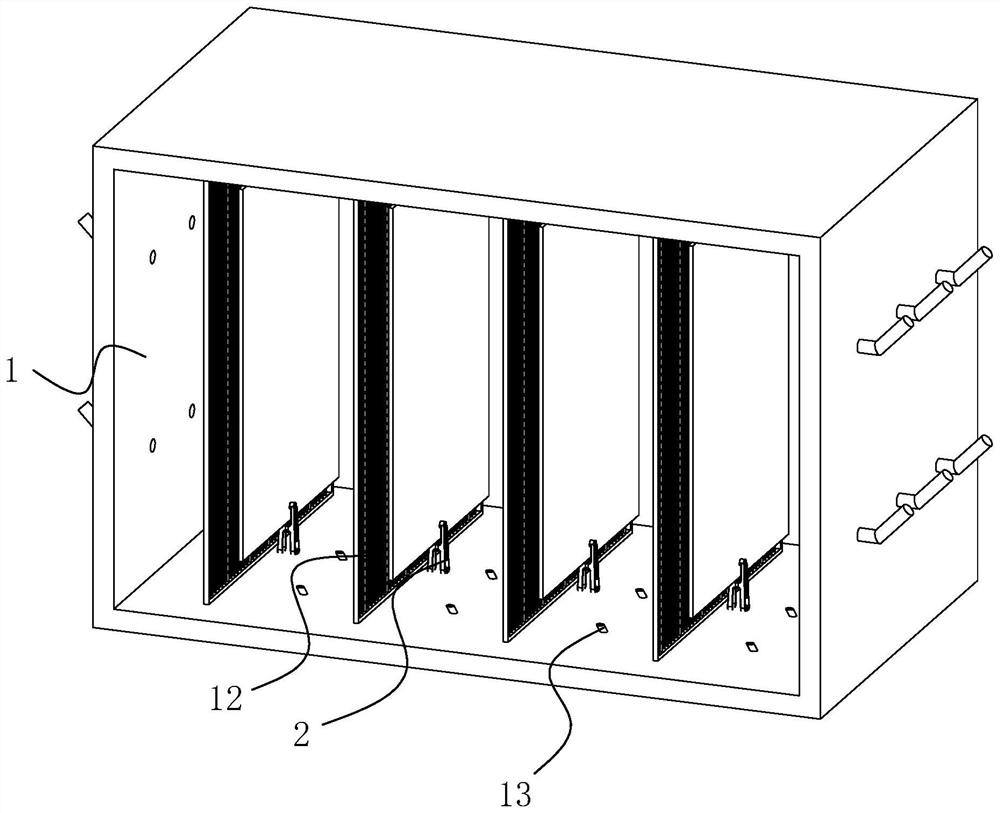

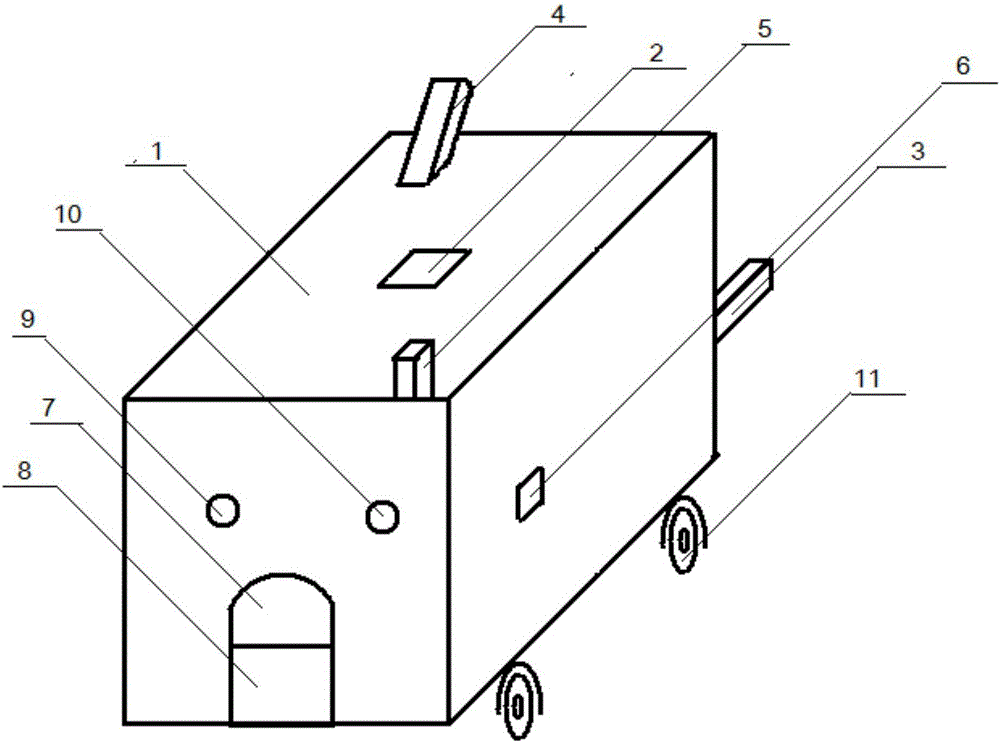

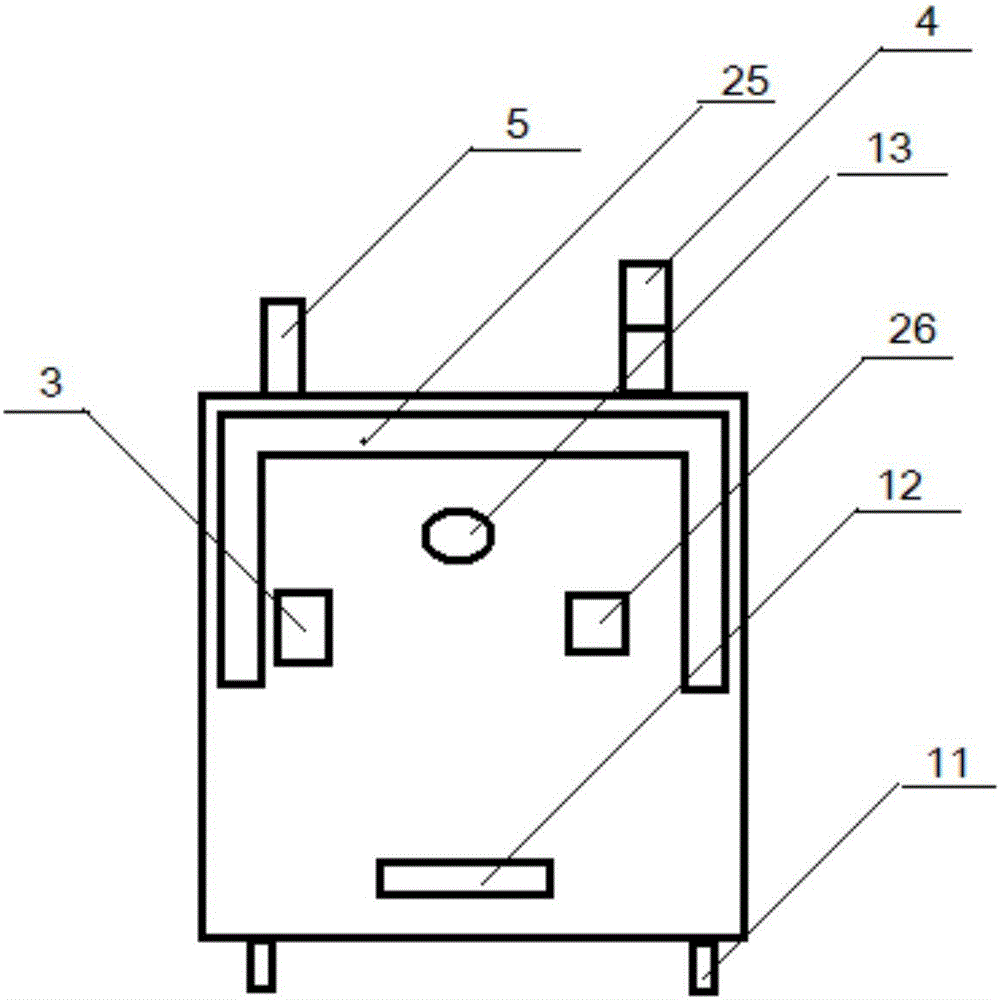

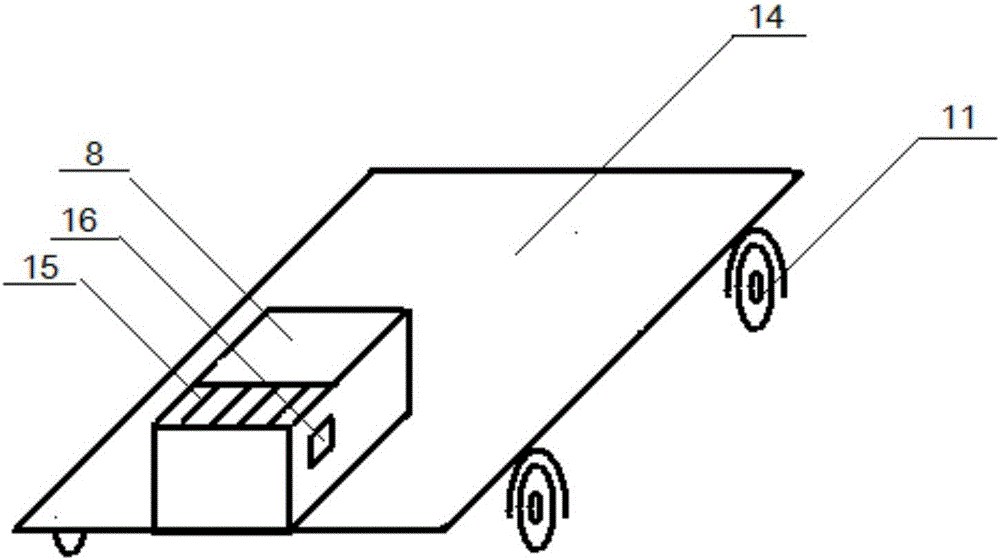

Device and method for processing wood chips of furniture factory

InactiveCN110948631AFlexible moving processAvoid cloggingDrying solid materials with heatWood working apparatusAgricultural engineeringTruck

The invention discloses a device and method for processing wood chips of a furniture factory. The processing device includes a bracket and a support leg, wherein a crushing box is fixedly arranged onan upper end surface of the bracket; a feeding hopper is riveted on the upper end surface of the crushing box; a plug rod is movably disposed on the inner wall of the feeding hopper by a hinged part;a handle is welded to the upper end of the plug rod; the bottom of the feeding hopper is provided with a first feed port; a first rotating shaft is rotatably disposed at the internal middle position of the crushing box; and a group of crushing rollers are evenly distributed outside the first rotating shaft. The device and method for processing wood chips of a furniture factory according to the present invention are fine in design and convenient to operate, integrate the crushing, conveying, drying, compressing and wrapping processes of the wood chips to form a mechanized production line, reduce production costs, improve work efficiency, facilitate truck transportation, have an effect of use better than that of a traditional method, are suitable for different working conditions and bring better prospects for use.

Owner:利辛县爱侣家俱加工有限公司

Continuous particle drying apparatus

ActiveUS9347705B2Reduce dust generationEasy transferDrying solid materials with heatDrying gas arrangementsEngineeringMechanical engineering

Owner:CROSSET LEON

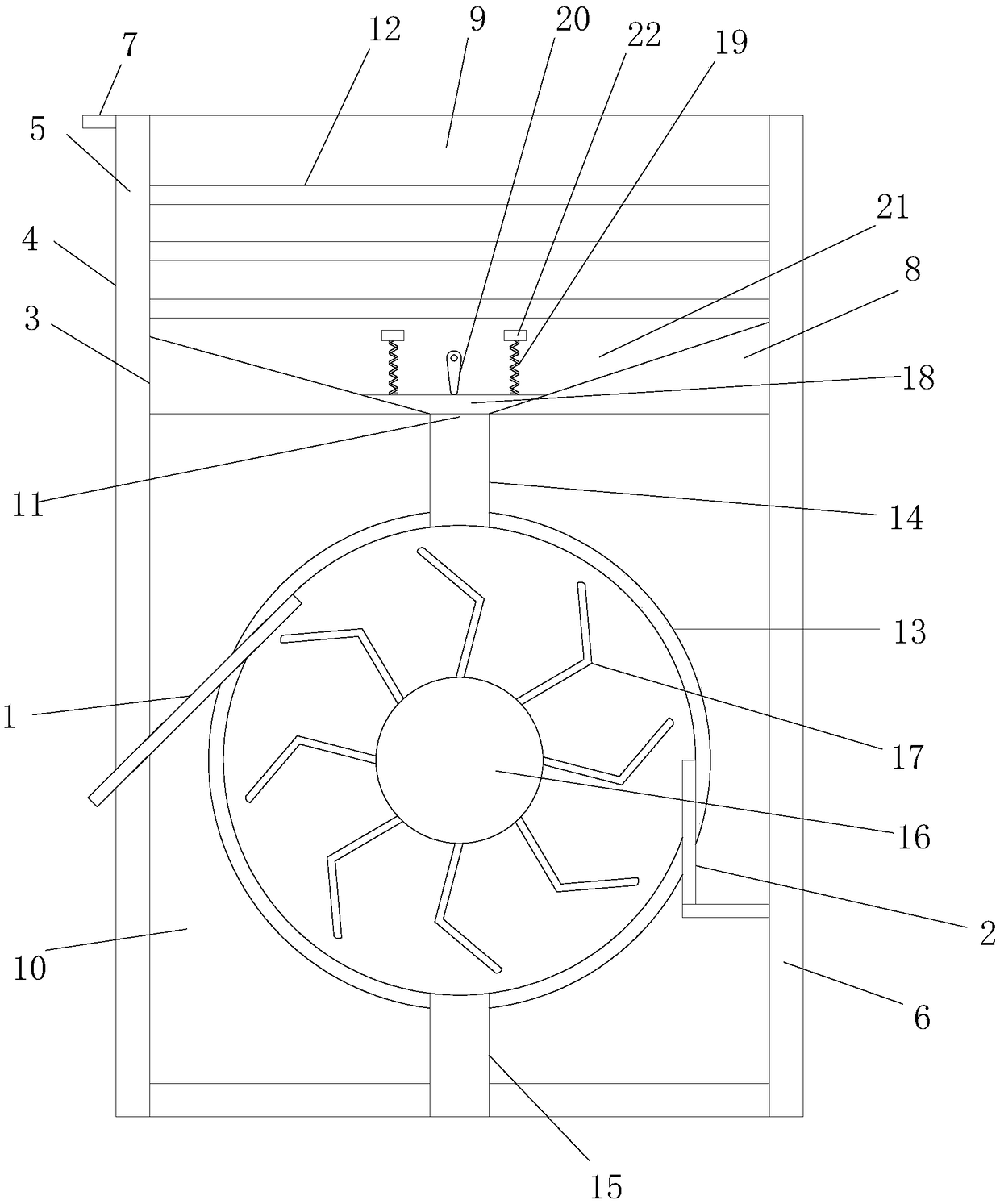

Novel wood chip dryer

ActiveCN106440708AUniform drying temperatureControllable drying temperatureDrying gas arrangementsDrying solid materialsHeat conductingPulp and paper industry

Owner:庄德恩

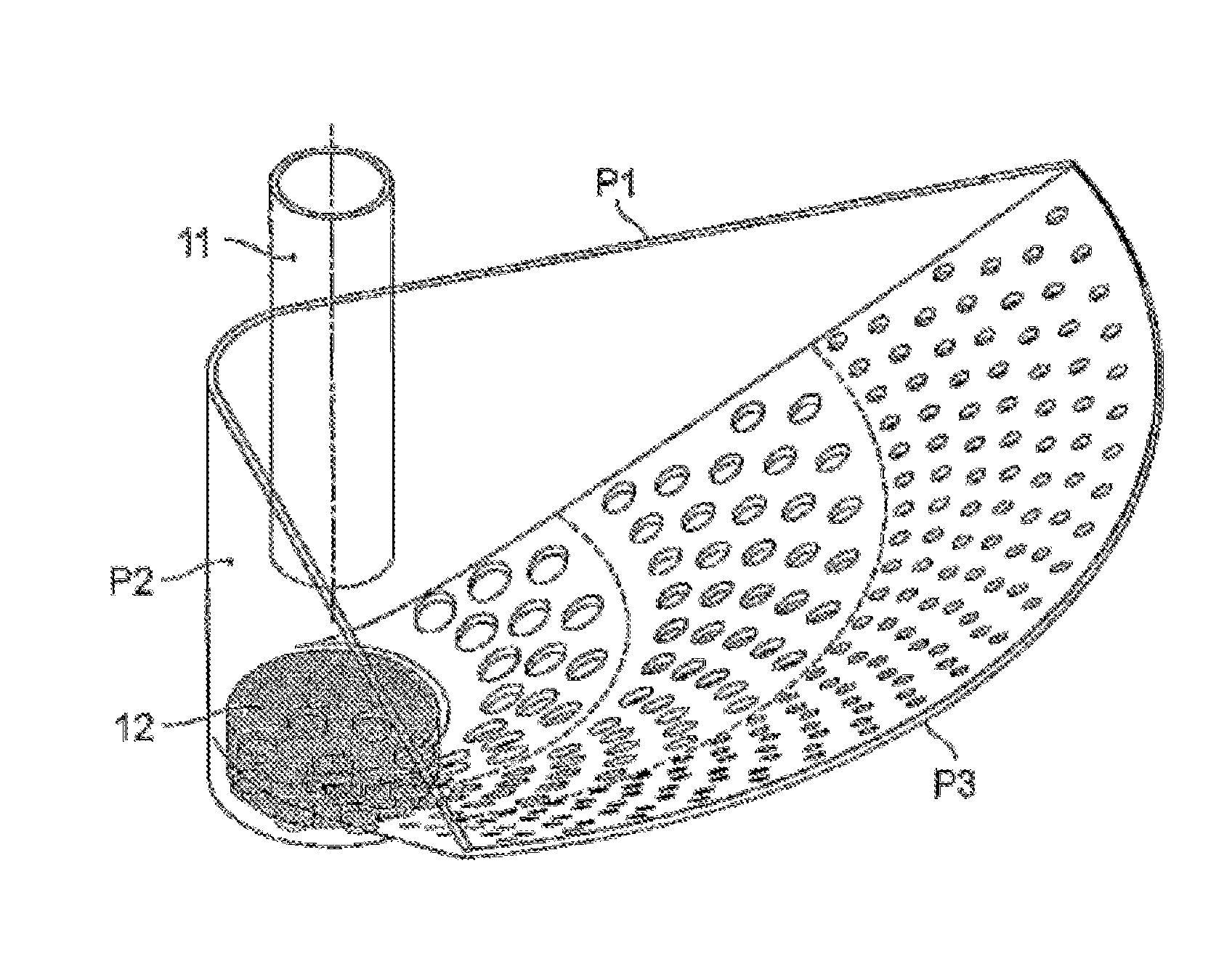

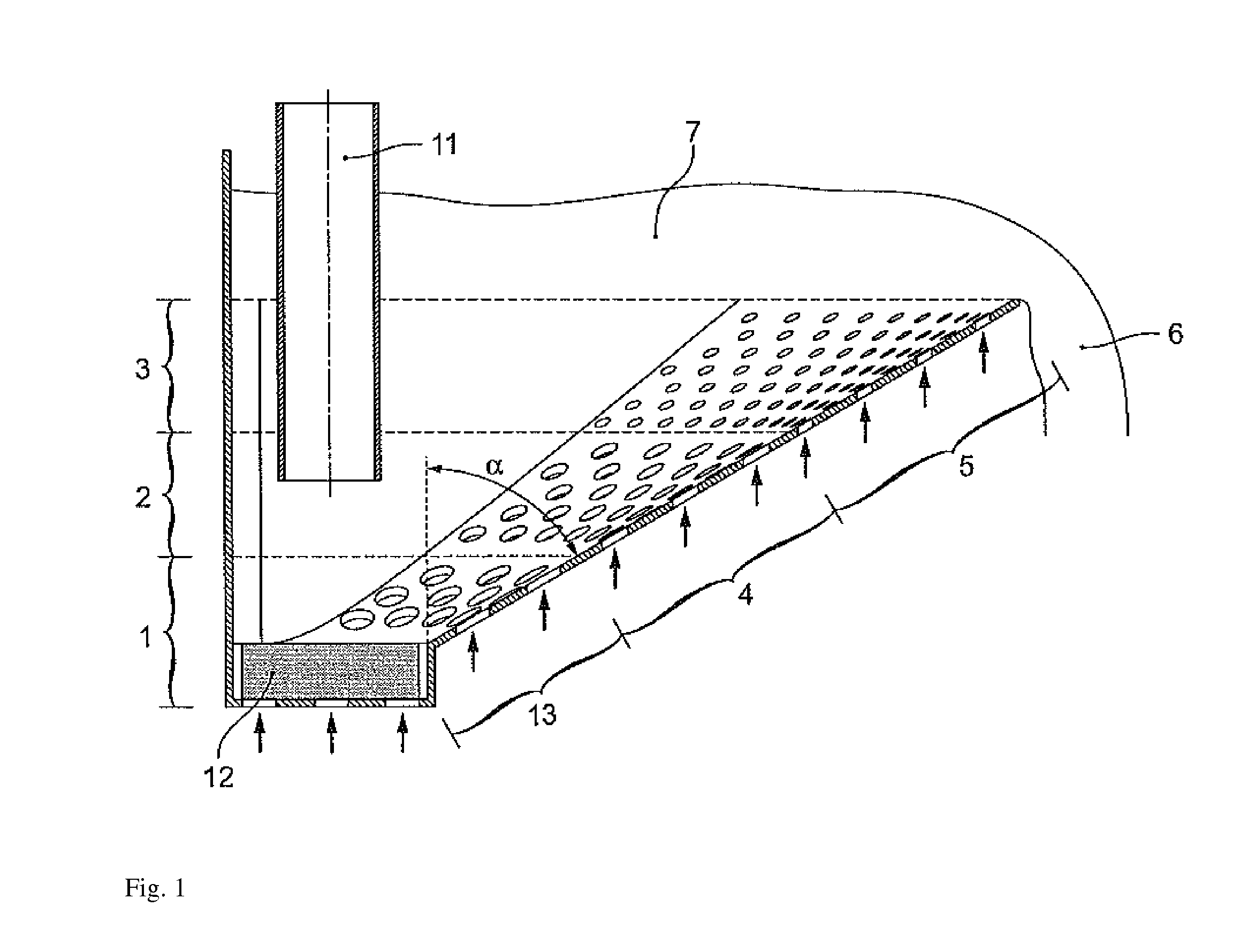

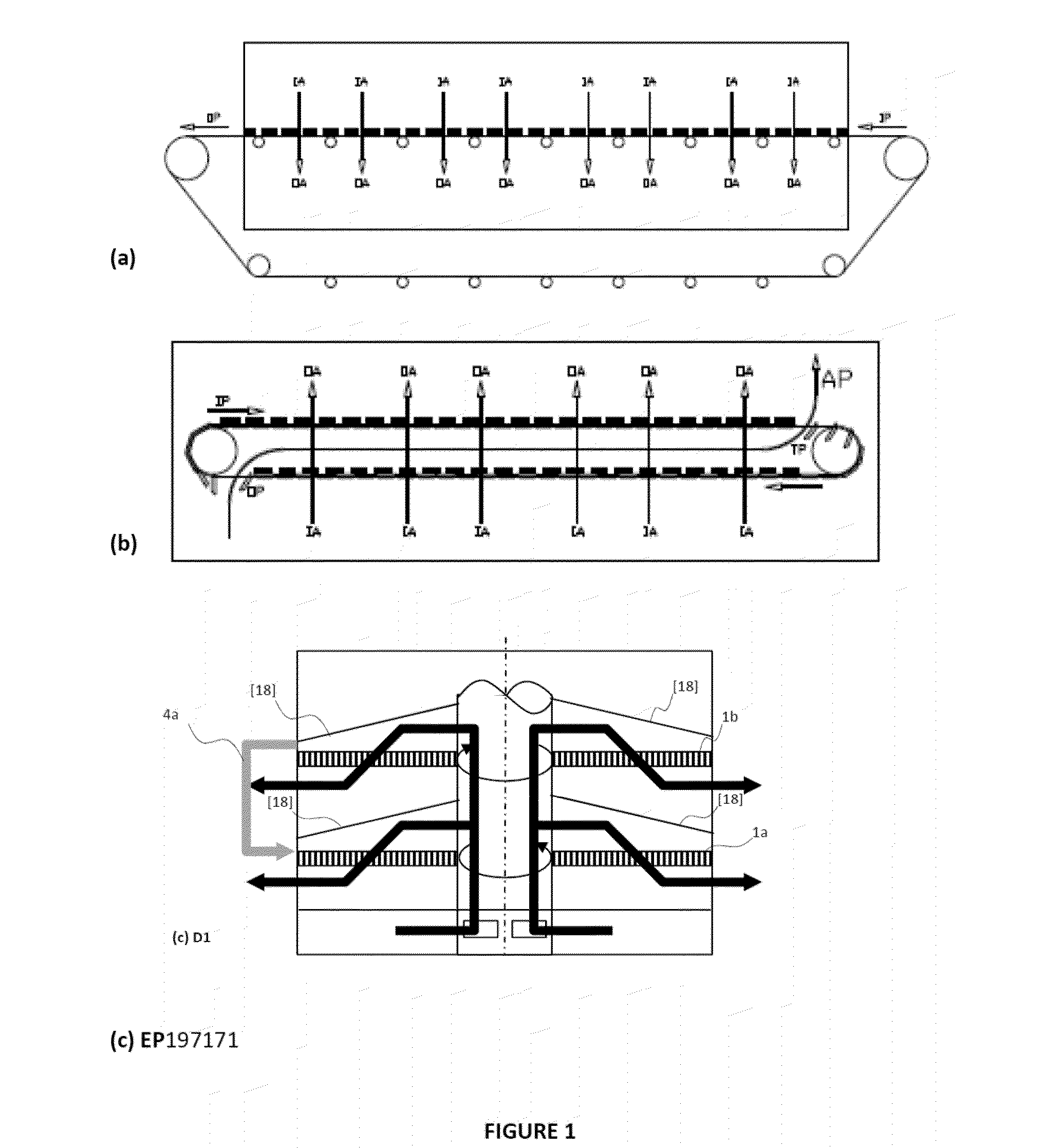

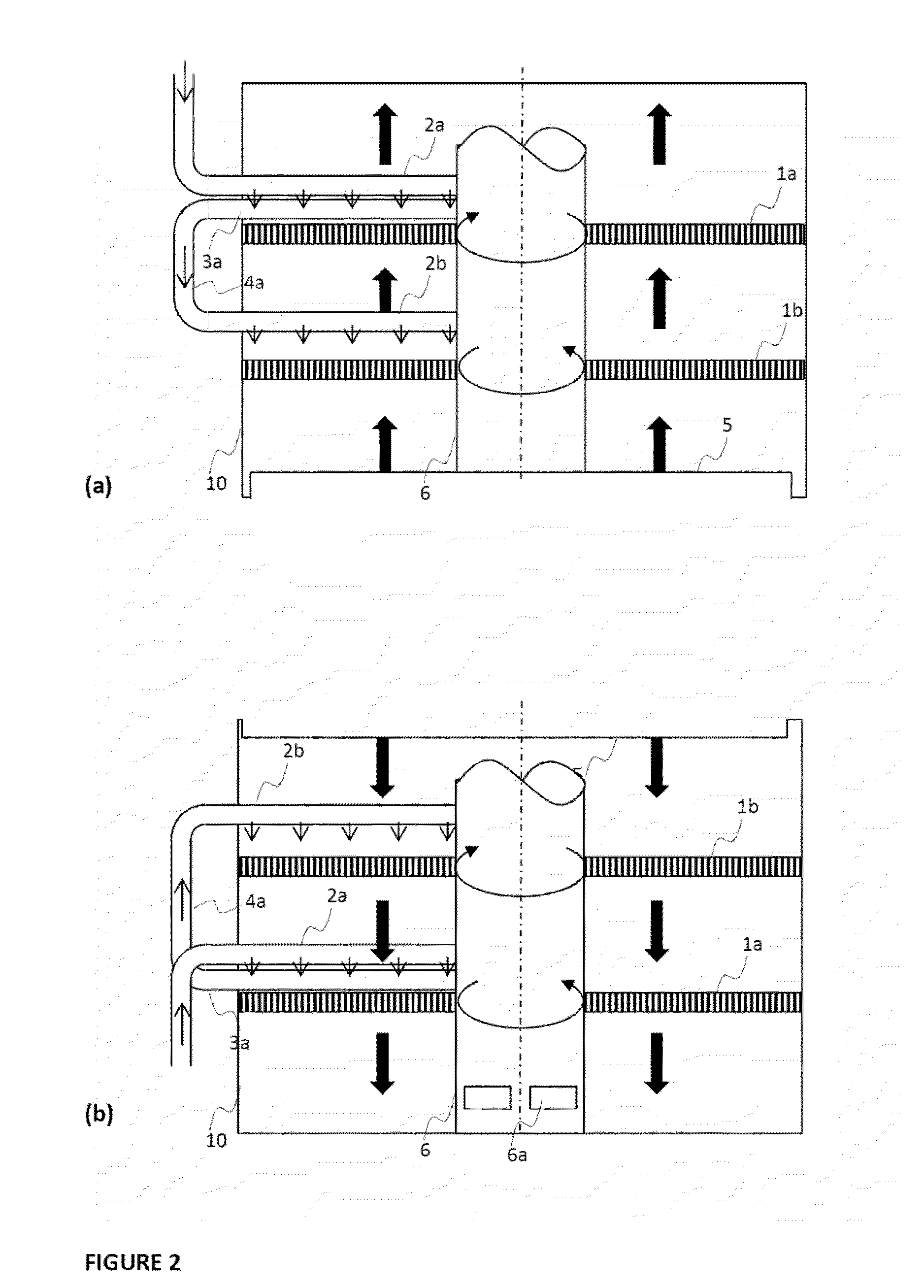

Continuous particle drying apparatus

ActiveUS20150013179A1Easy transferPromote reductionDrying solid materials with heatDrying chambers/containersEngineeringMechanical engineering

A dryer dries particles, wherein the dryer comprises two circular decks mounted substantially horizontally and rotating in opposite directions relative to one another about a same vertical axis, Z, the surface of said decks being perforated and permeable to air, steam and water, a means for blowing hot gas in a flow substantially parallel to the axis Z, passing through the second deck before passing through the first deck, means for distributing said particles to be dried on the first and second decks and means for recovering the particles after a rotation of each deck, and a means for transferring the particles collected from the first deck by the recovery means to a second distribution means suitable for distributing said particles along a radius of the second deck.

Owner:CROSSET LEON

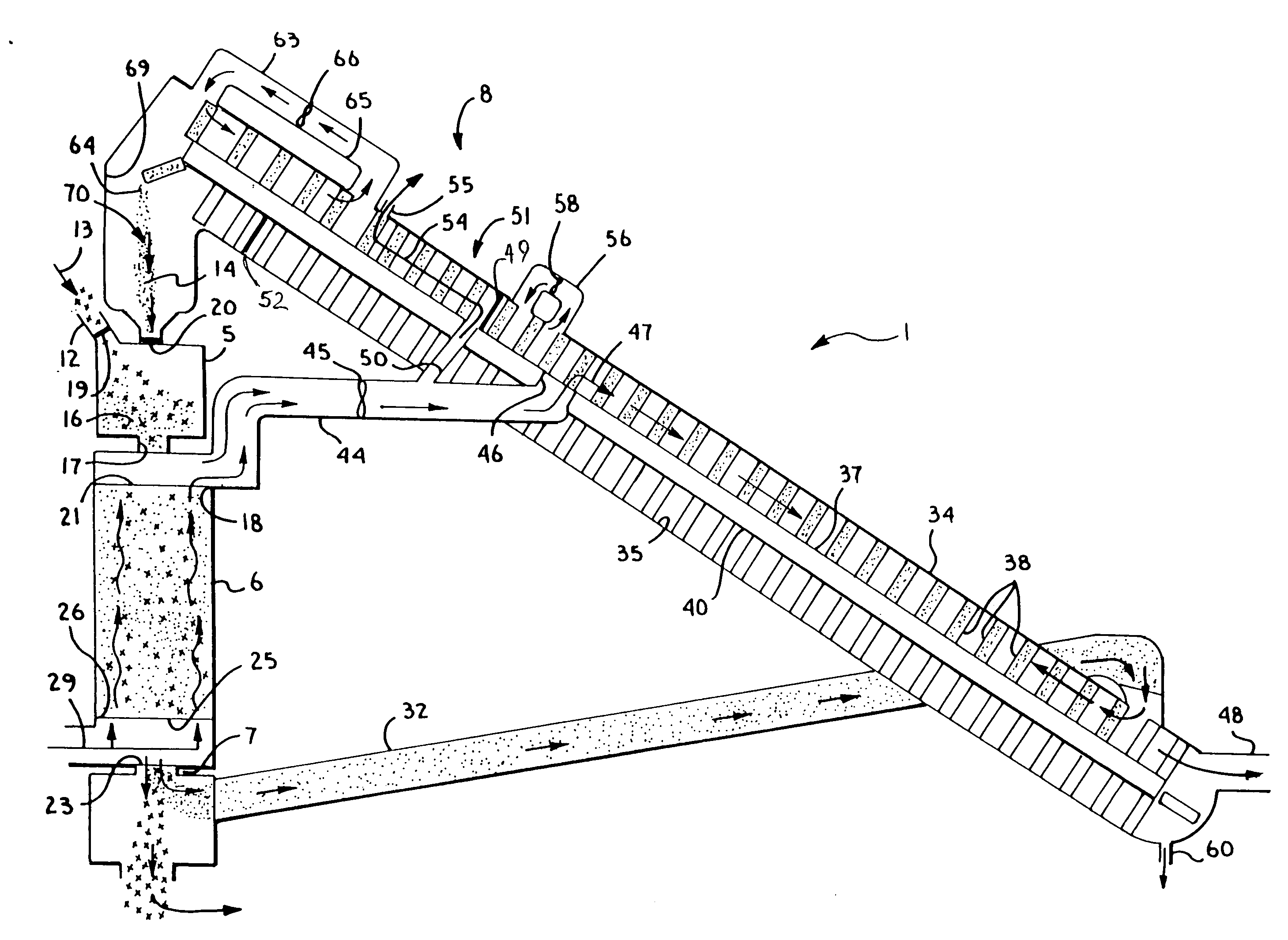

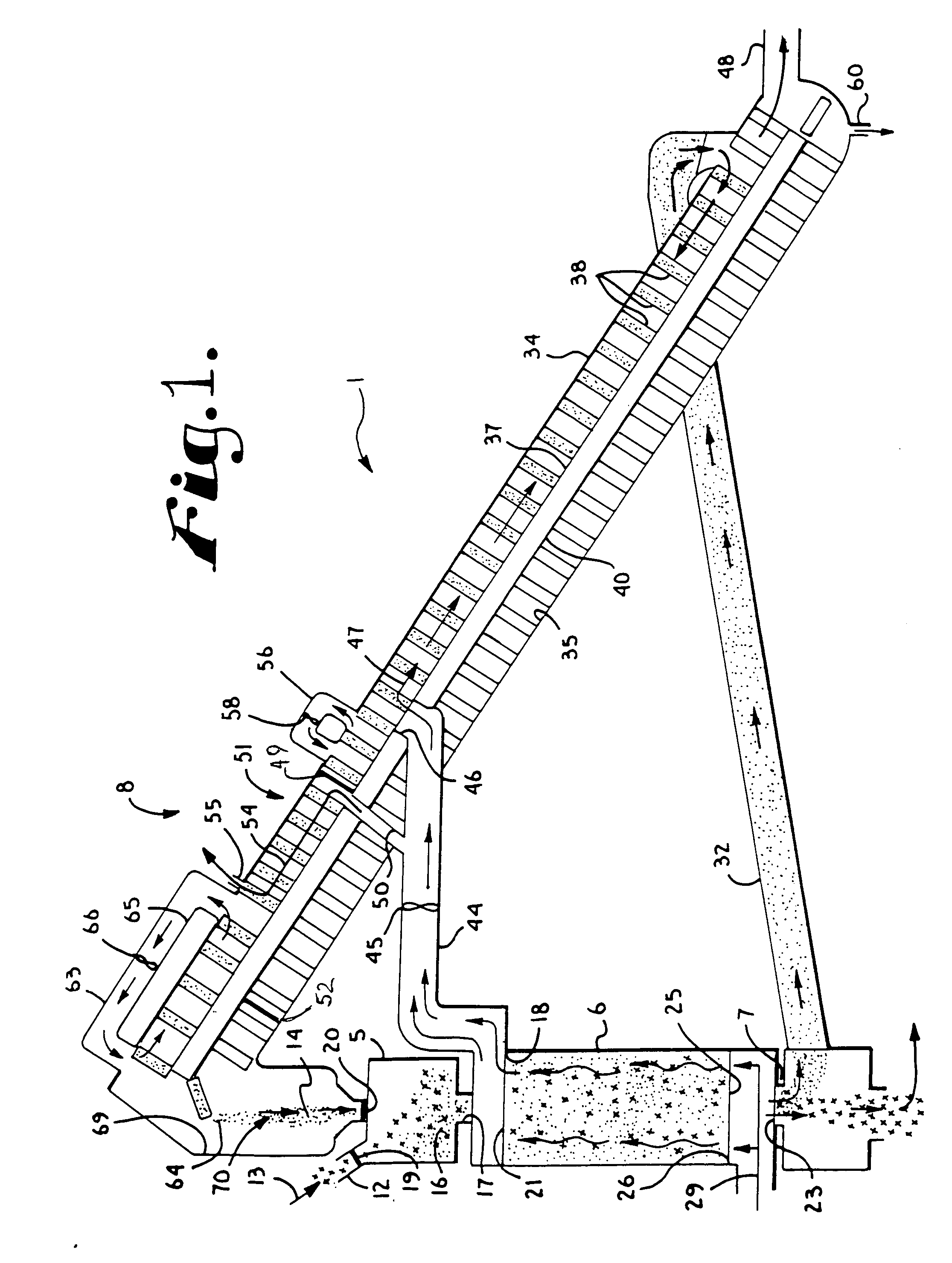

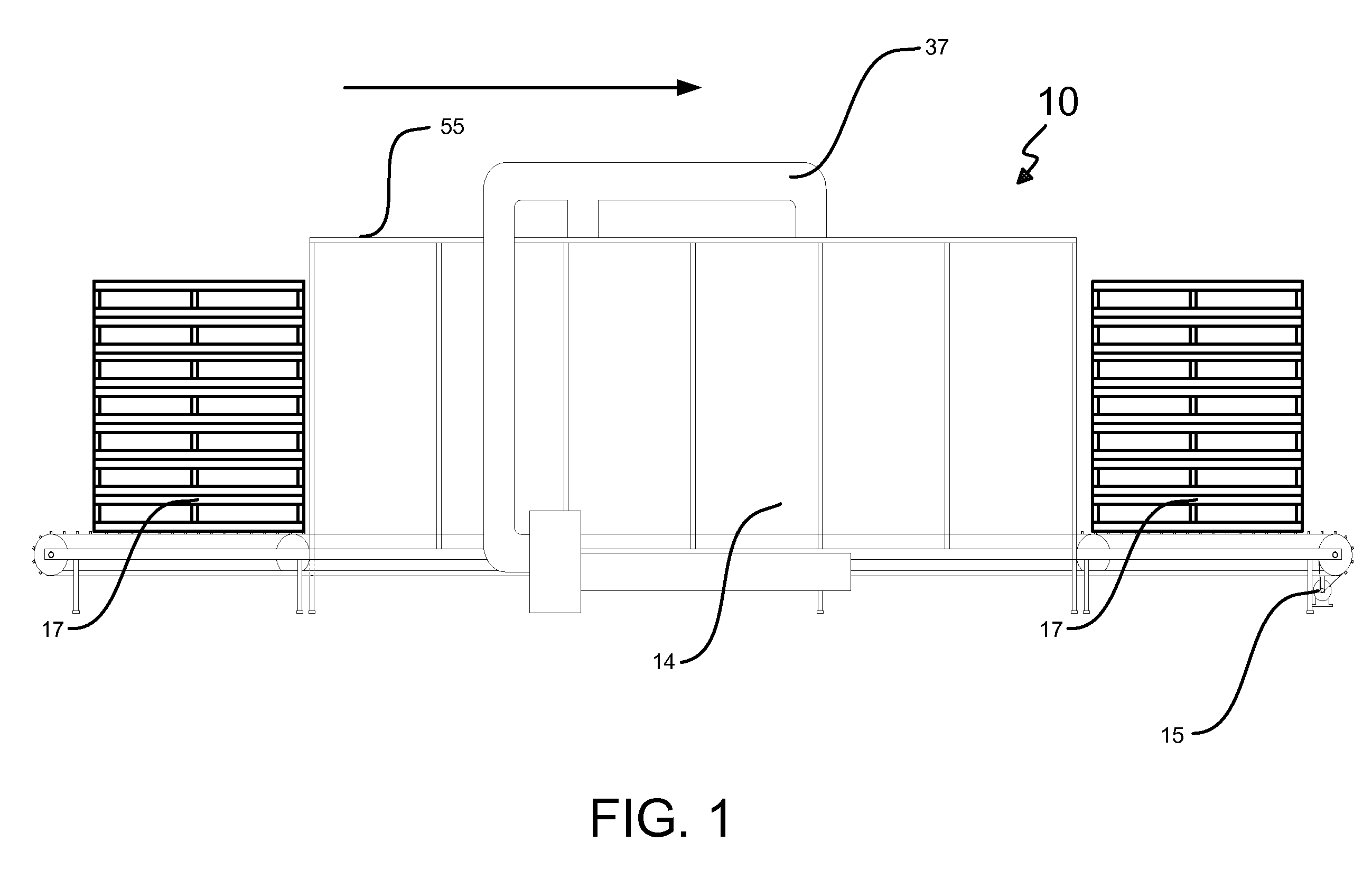

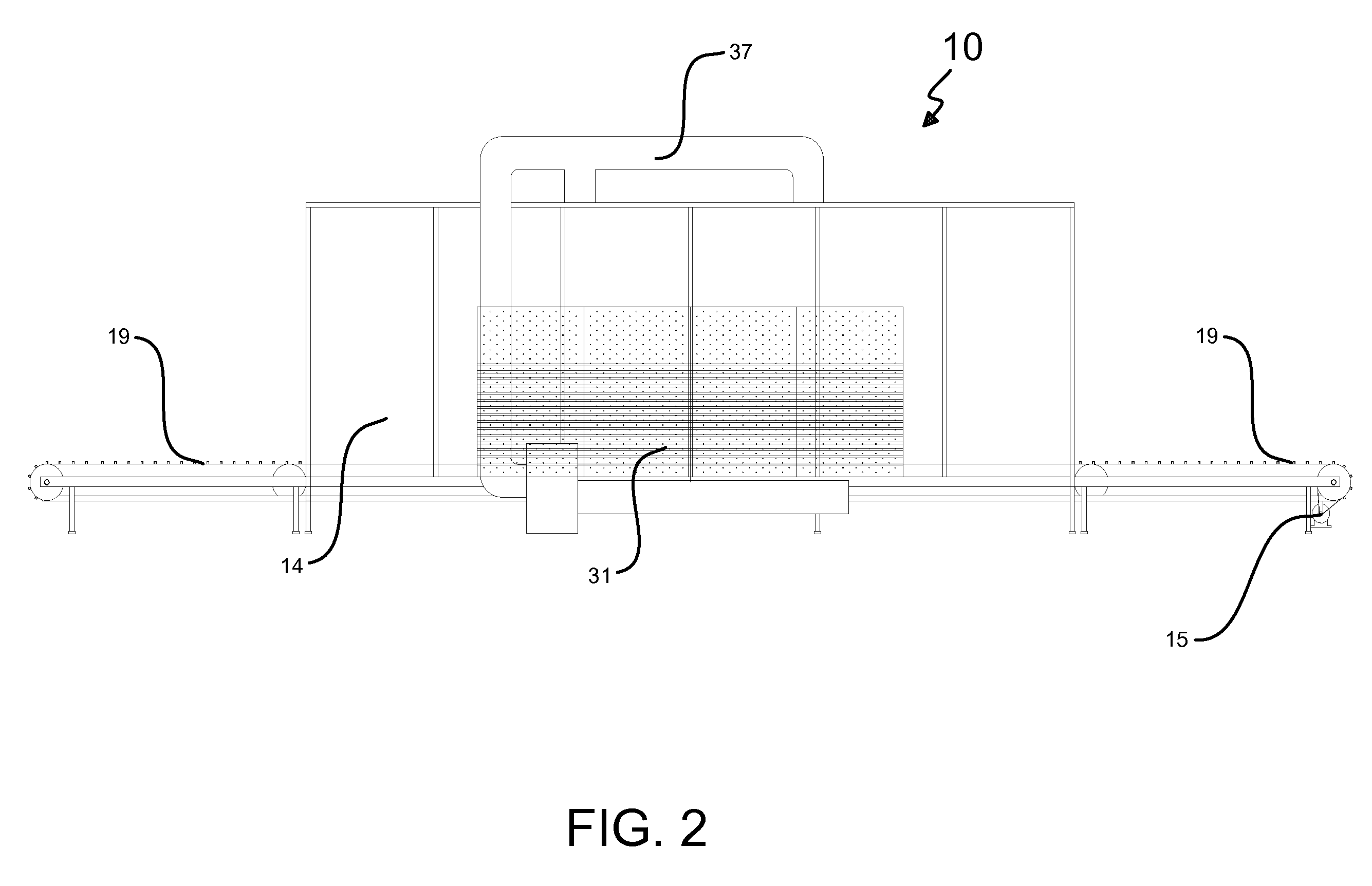

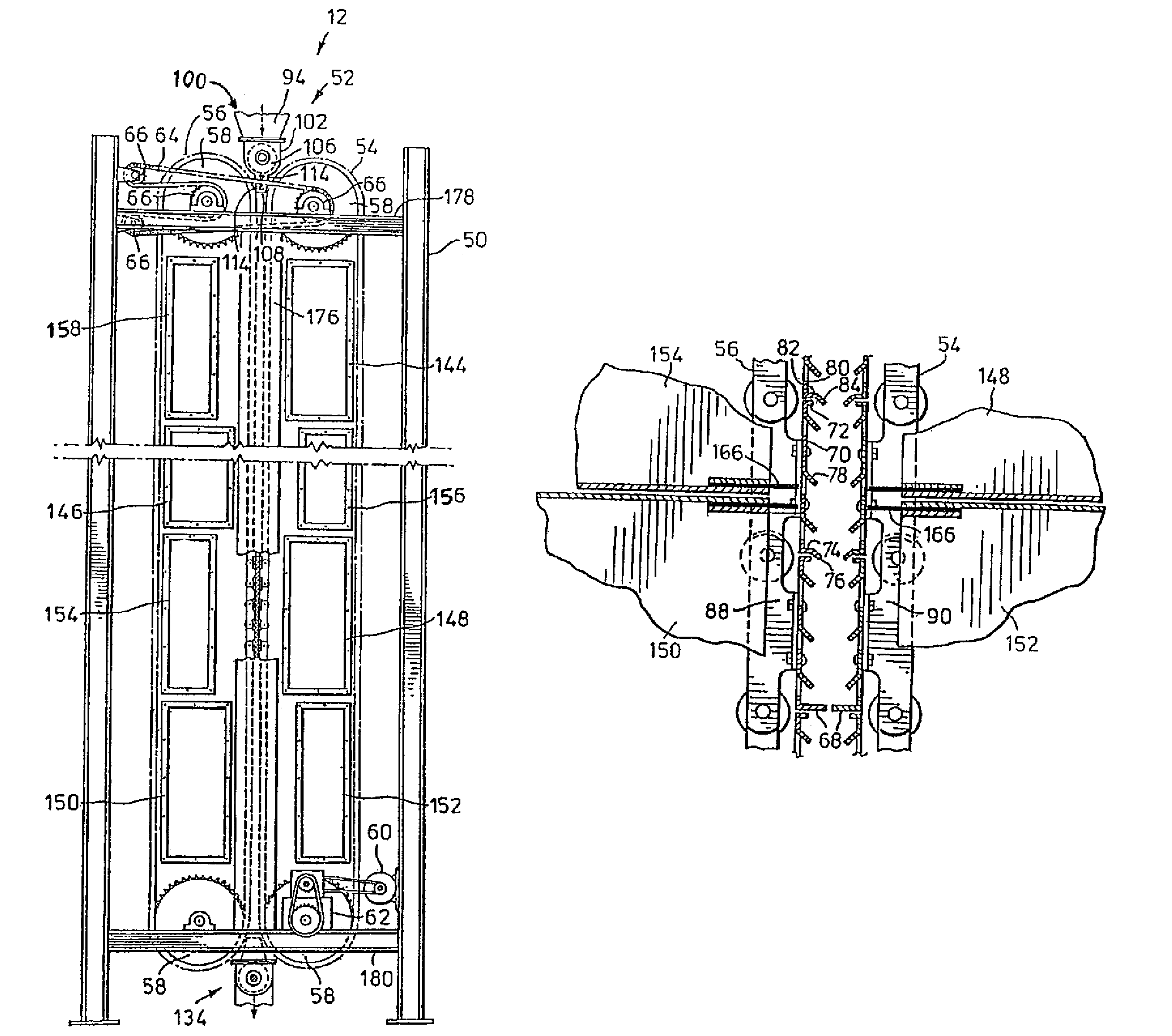

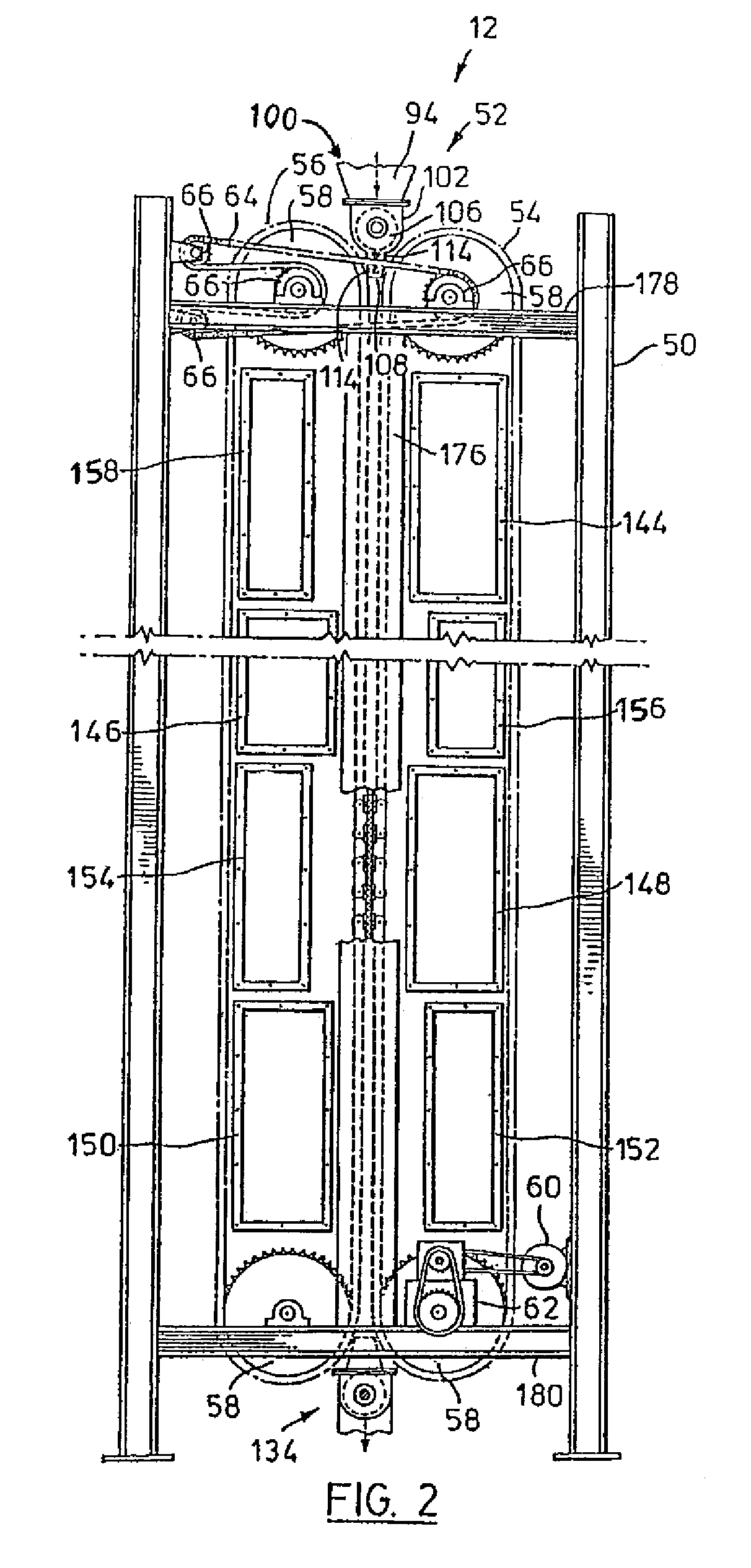

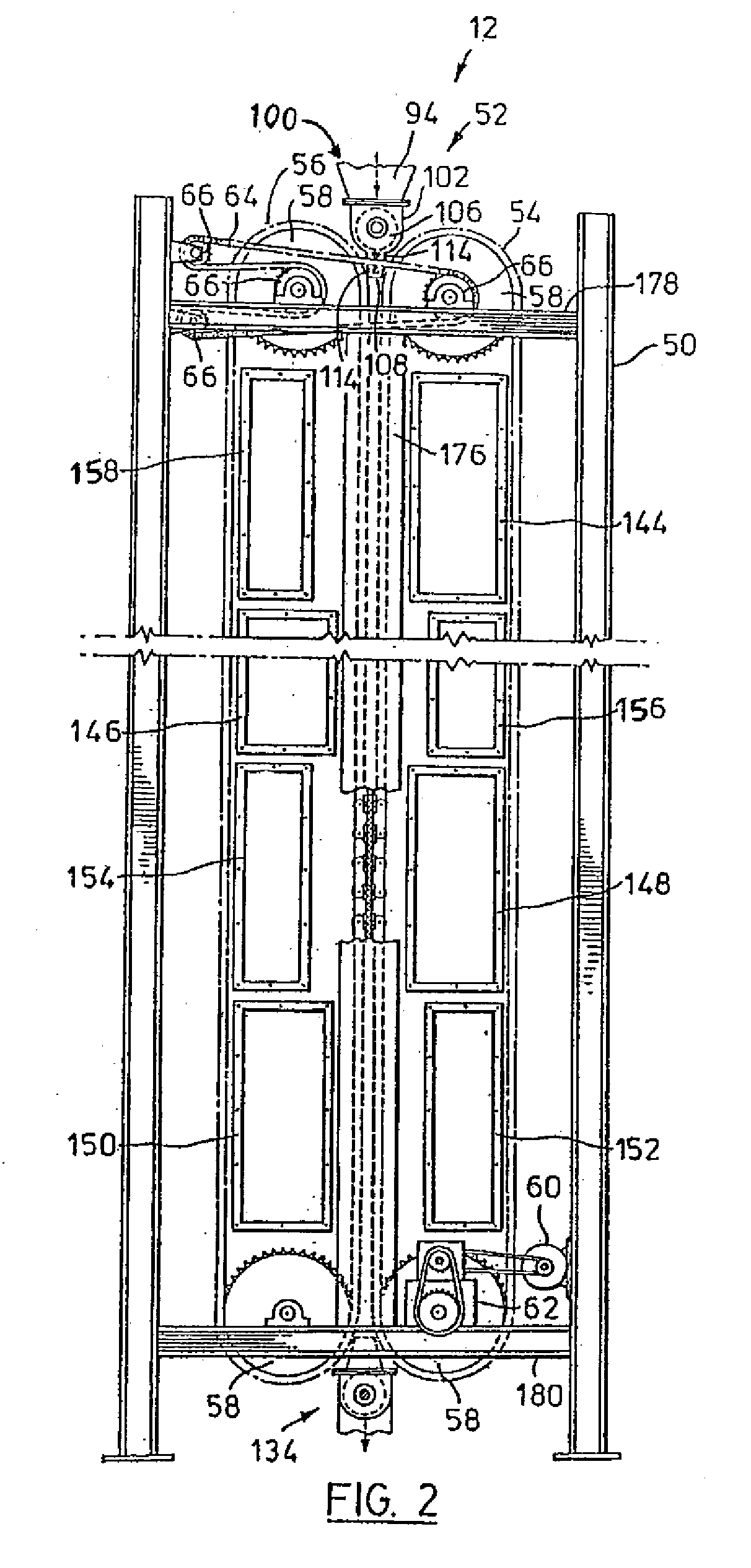

Dryer for fuel material

The invention relates to a dryer for drying fuel materials such as wood bark, wood chips, sludge, garbage, peat moss or the like. In a preferred embodiment the dryer comprises a conveyor, consisting of twin endless belts, which carries the material to be dried along a vertical path defined between parallel runs of the endless belts, and ductwork which serves to direct heated air (received from any appropriate source) across the vertical path to remove moisture from the material as it is being conveyed. The ductwork includes at least one feed duct for use in delivering the heated air to one side of the vertical path, and at least one exhaust duct for use in withdrawing moisture-laden air on another side of the vertical path. Suction is applied at the exhaust ducts to draw drying air through the ductwork, and the feed and exhaust ducts are made to seal against the conveyor to reduce the introduction of ambient air into the dryer ductwork under the suction applied.

Owner:ALTENTECH POWER

Waste wood treatment equipment for processing solid wood furniture

InactiveCN110978188AEffective cutting and crushingImprove crushing efficiencySievingScreeningSolid woodWood splinter

The invention relates to the technical field of furniture processing, in particular to waste wood treatment equipment for processing solid wood furniture. According to the equipment, waste wood is primarily crushed through a coarse crushing mechanism, through rotation of a dual-direction thread rod, a first crushing plate and a second crushing plate move oppositely, the coarsely-crushed wood is crushed secondarily, and the crushing efficiency is improved. A screening layer is arranged below a fine crushing mechanism and provided with a screening plate, when the diameter of the crushed wood issmaller than that of a through hole of the screening plate, the wood can fall down, otherwise, the wood is repeatedly cut by the fine crushing mechanism until the wood can pass through the screening plate, the diameter of the crushed wood is controlled, it is guaranteed that the wood can be recycled, and the operation of reprocessing is omitted. The saw dust of the wood meeting the recycling condition falls on a drying layer through the screening plate, heating lamps of the drying layer irradiate and heat the saw dust of the wood, so that the saw dust of the wood is sufficiently dried, it is guaranteed that the discharged saw dust of the wood can be directly recycled, and the re-drying process is not needed.

Owner:安徽嘉禾整木家居有限公司

Dryer for fuel material

The invention relates to a dryer for drying fuel materials such as wood bark, wood chips, sludge, garbage, peat moss or the like. In a preferred embodiment the dryer comprises a conveyor, consisting of twin endless belts, which carries the material to be dried along a vertical path defined between parallel runs of the endless belts, and ductwork which serves to direct heated air (received from any appropriate source) across the vertical path to remove moisture from the material as it is being conveyed. The ductwork includes at least one feed duct for use in delivering the heated air to one side of the vertical path, and at least one exhaust duct for use in withdrawing moisture-laden air on another side of the vertical path. Suction is applied at the exhaust ducts to draw drying air through the ductwork, and the feed and exhaust ducts are made to seal against the conveyor to reduce the introduction of ambient air into the dryer ductwork under the suction applied.

Owner:ALTENTECH POWER

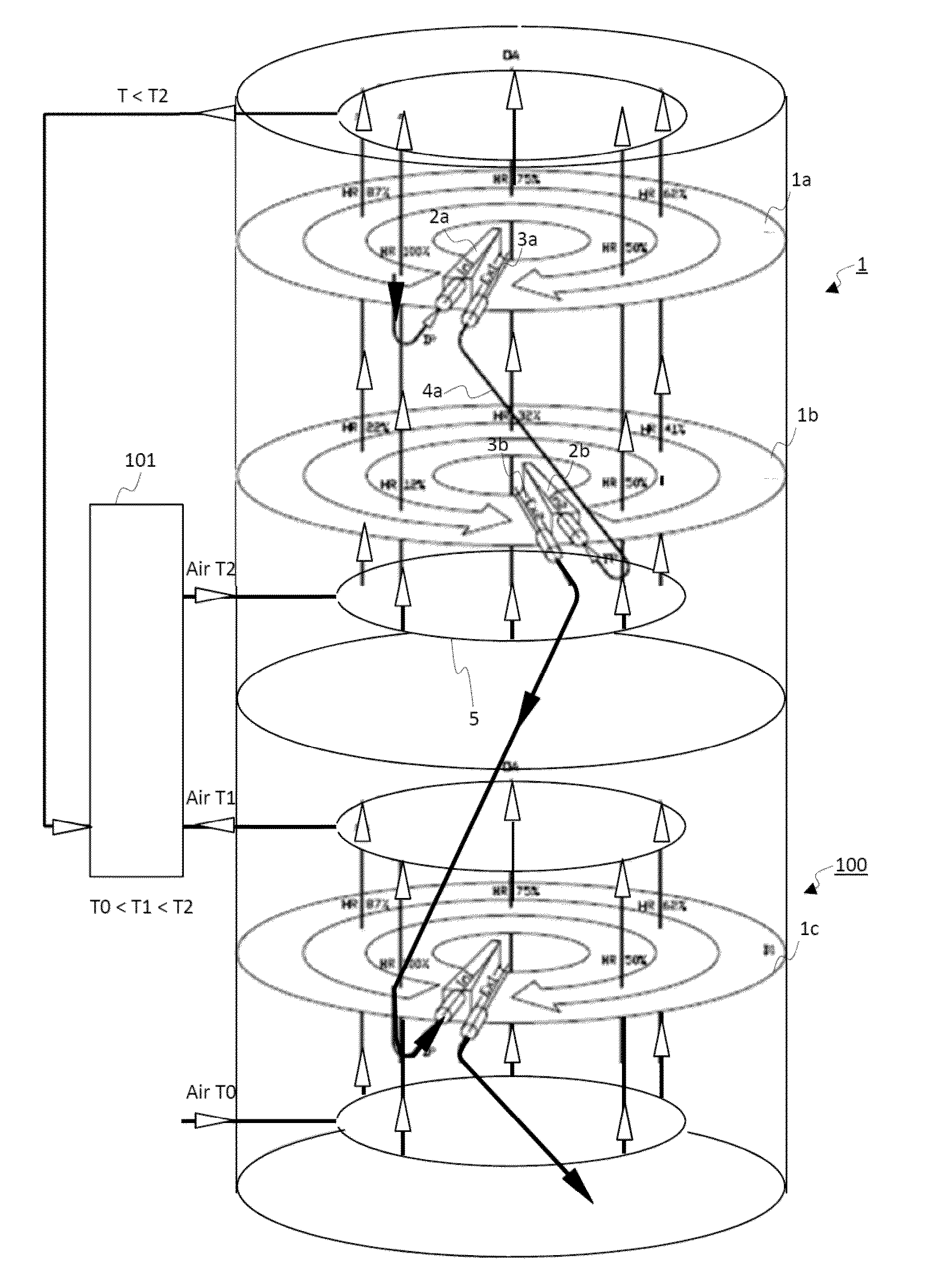

Method for continuously drying bulk goods, in particular wood fibers and/or wood chips

ActiveUS10690409B2Emit energyPositive to qualityDrying gas arrangementsDrying machines with non-progressive movementsWood fibreDrum drying

A method for drying bulk goods, in particular wood fibers and / or wood chips, wherein the bulk goods is continuously dried in a dryer (1), in particular a drum dryer. The vapor-gas mixture flows through the drum dryer (1) in a dryer circuit and is indirectly heated via at least one heat exchanger (4) by a burner waste gas that is heated in at least one burner (5). The drying vapors are supplied to the at least one heat exchanger (4). Upstream, downstream and / or within the at least one heat exchanger (4), at least a partial flow of the drying vapors are branched off to be conducted into the burner (5). The remaining partial flow is conducted to the dryer (1) again. The partial flow of drying vapors to the burner (5) is driven by at least one regulable partial vapor fan (10).

Owner:KRONOPLUS LTD

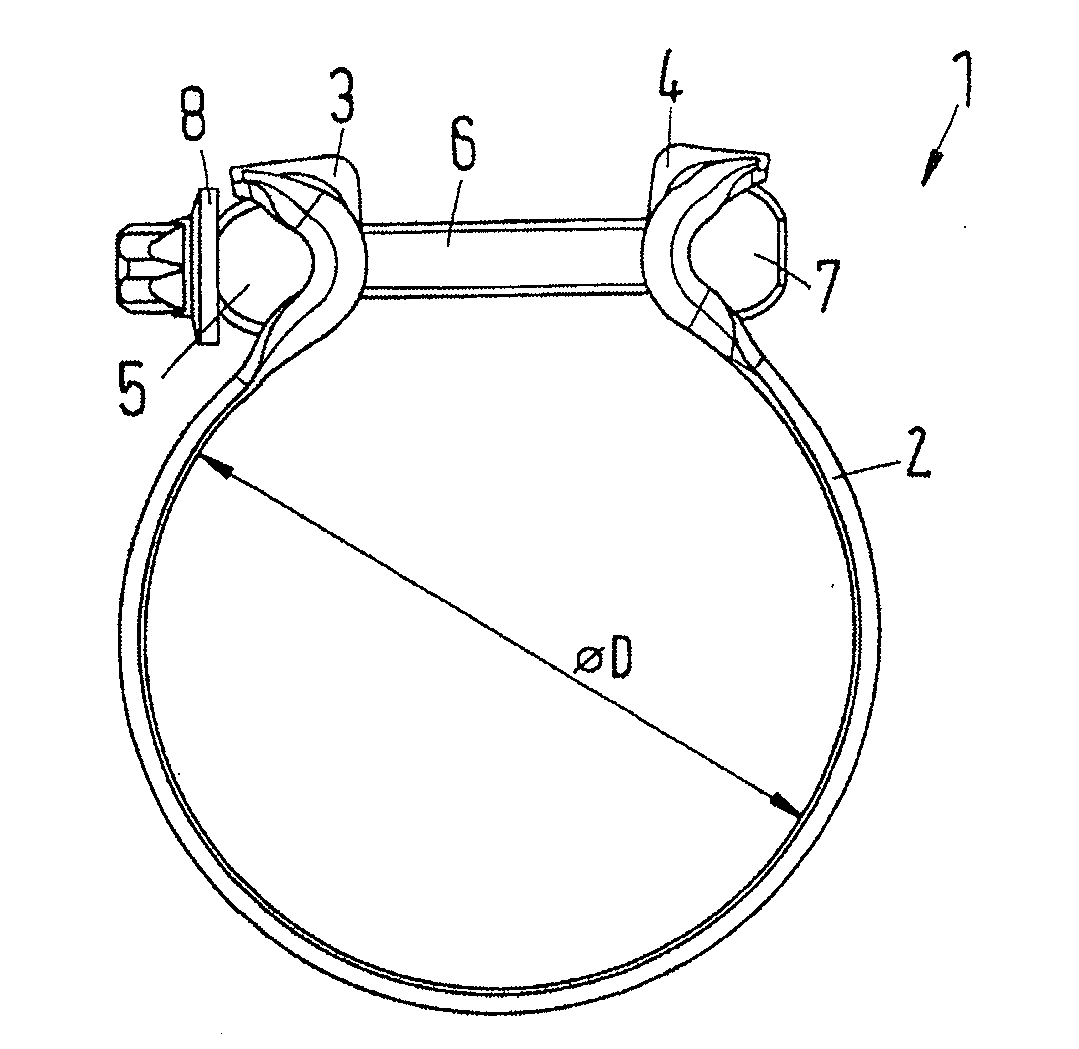

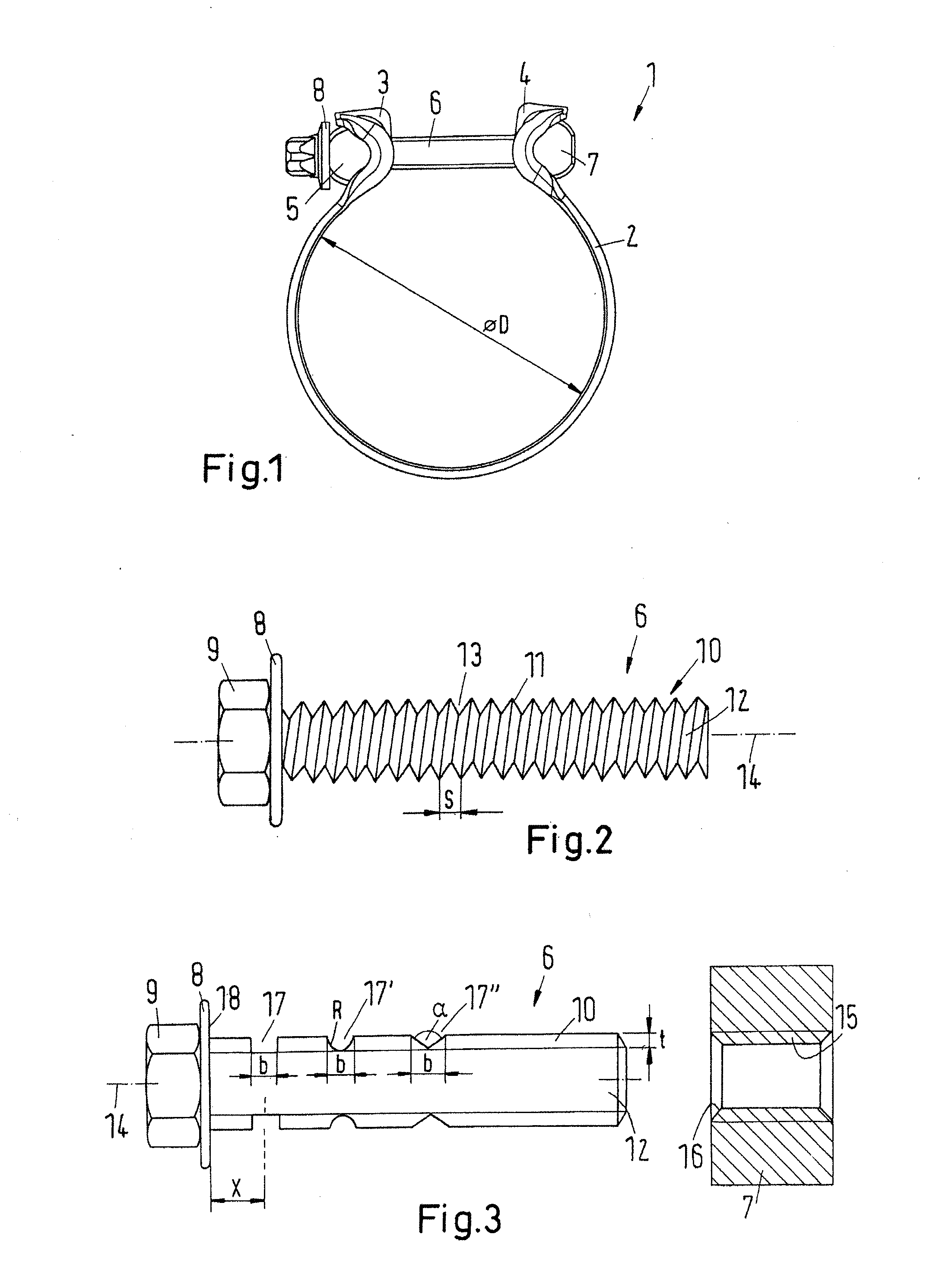

Screw connection, in particular for a clamp, and clamp

Screw connection, in particular, a tension clamp, and method of forming the screw connection. The screw connection includes a screw having a screw head and an external thread with a thread turn profile and a thread axis, and a mating thread element having an internal thread, matched to the external thread, with at least one thread groove bordered by thread flanks to screwably receive the screw. A geometrically defined deformation of the external thread is arranged at a predetermined distance from the screw head to collide with at least one thread flank during the screwing of the screw into the mating thread element.

Owner:NORMA GERMANY GMBH

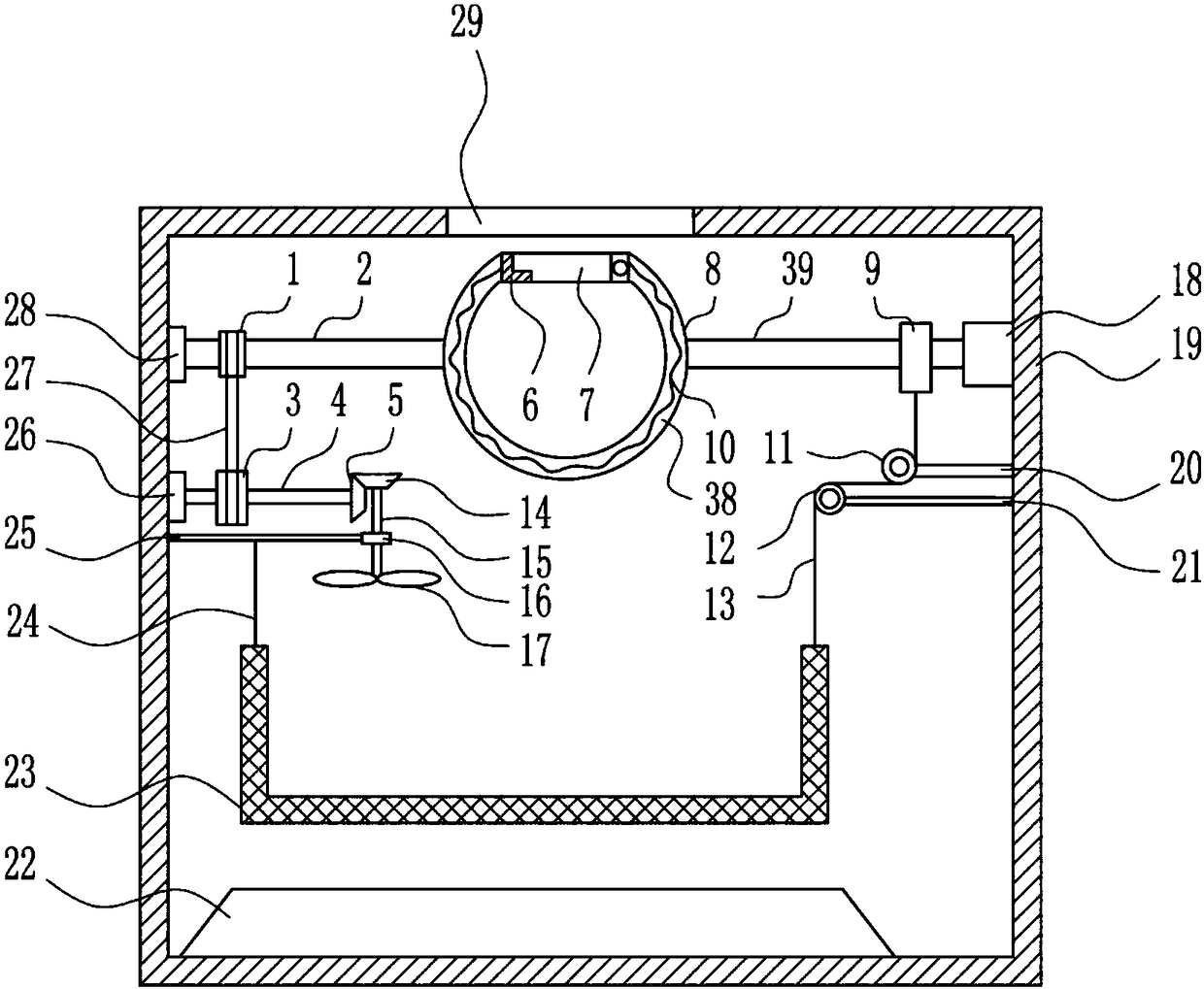

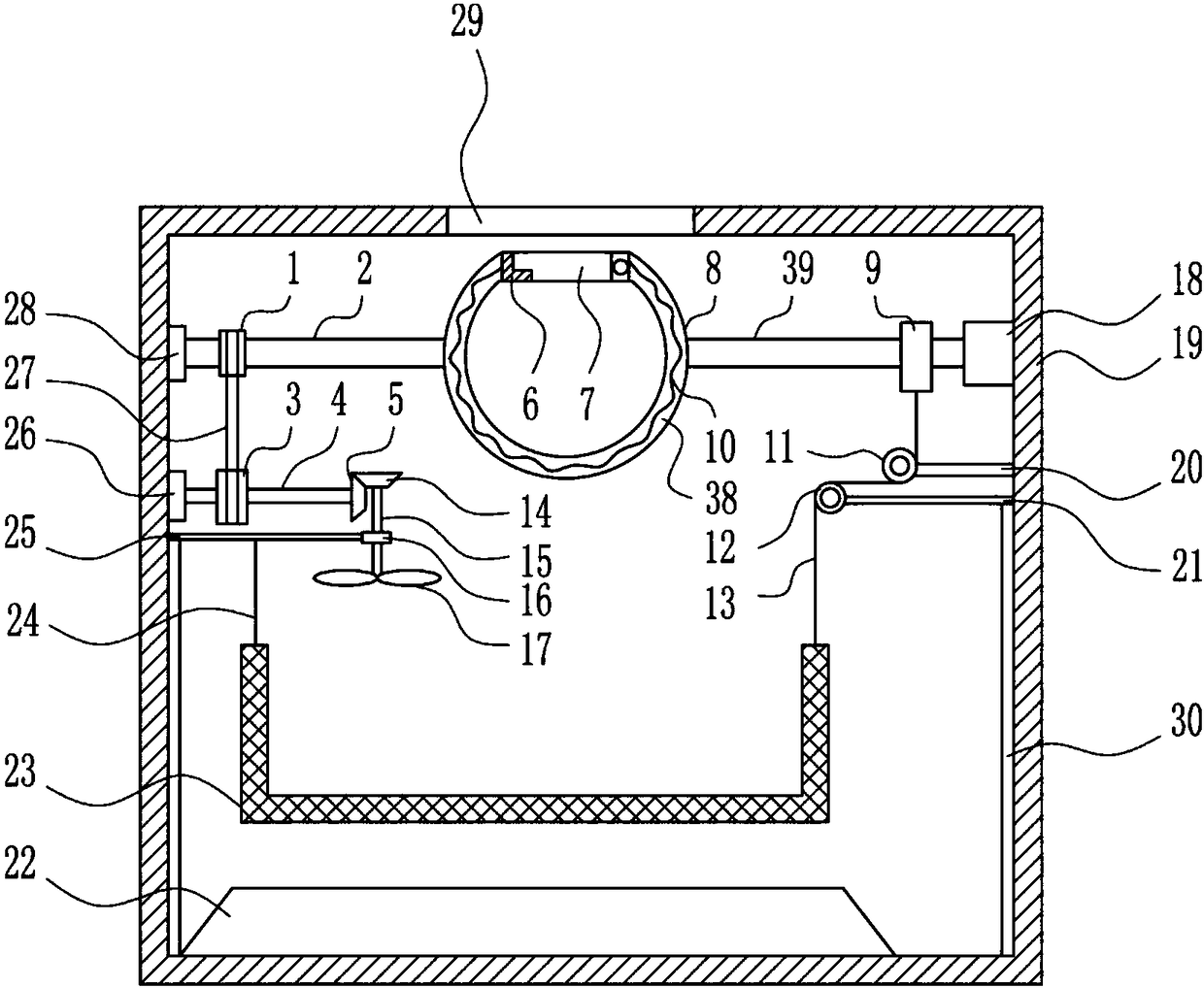

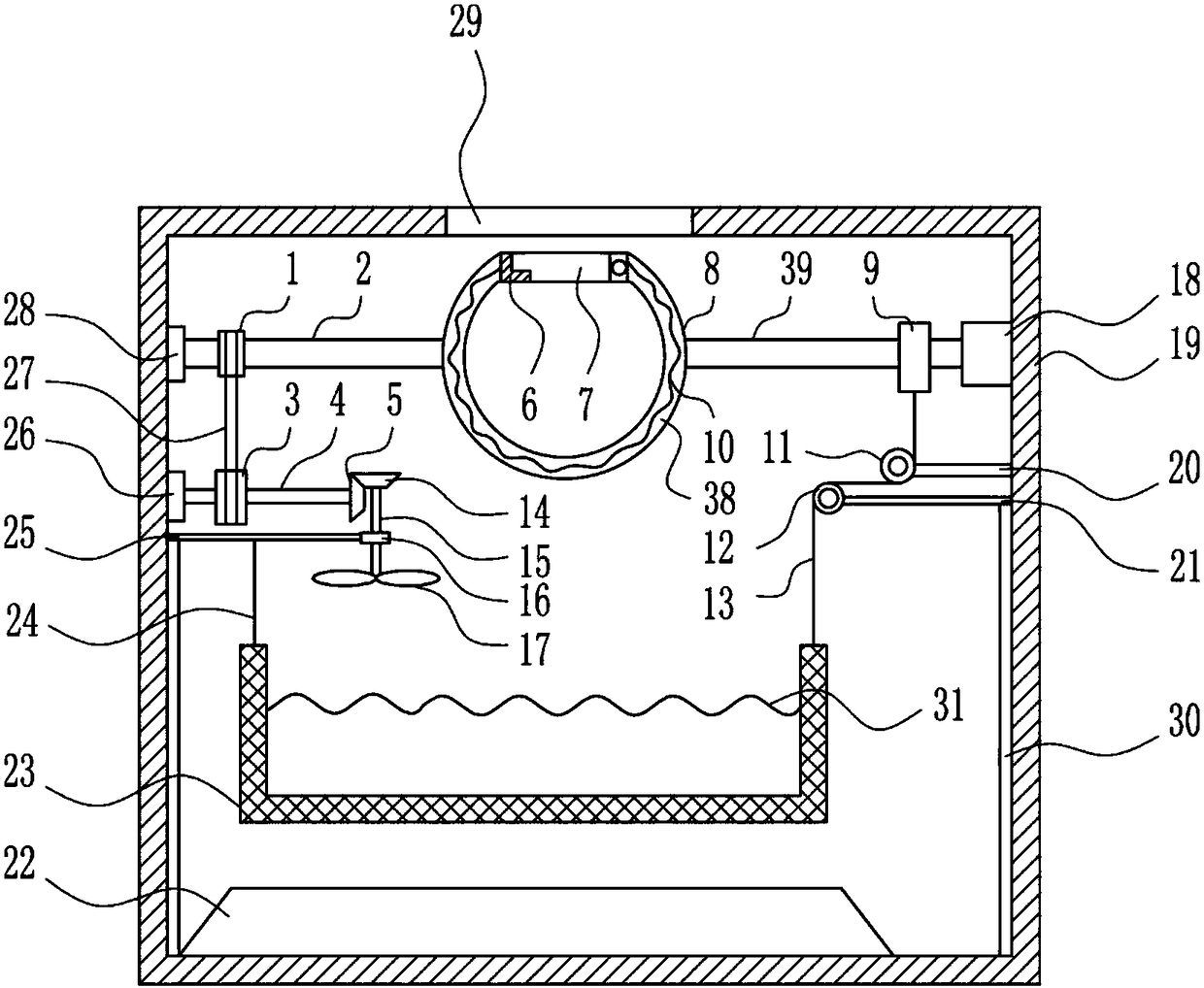

Secondary drying device of sawdust

PendingCN109405521AEfficient dryingImprove drying efficiencyDrying machine combinationsDrying gas arrangementsEngineeringSawdust

The invention provides a secondary drying device of sawdust. The secondary drying device comprises a drying box, a hot air inflow pipe, a hot air outflow pipe and a hot air generator. A horizontally-arranged partition is arranged in the drying box, the interior of the drying box is divided into a primary drying chamber and a secondary drying chamber which are vertically arranged by the partition,a quantitative discharge port communicating with the primary drying chamber and the secondary drying chamber is formed in the partition, and a quantitative discharge part capable of blocking the quantitative discharge port is arranged in the primary drying chamber. Multiple preheating pipes are arranged in the primary drying chamber at intervals in the vertical direction. A drying barrel is arranged in the secondary drying chamber, the central axis of the drying barrel is horizontally arranged, a feed pipe communicating with the quantitative discharge port is arranged at the top end of the drying barrel, and a discharge pipe stretching out of the drying box is arranged at the bottom end of the drying barrel. One end of the hot air inflow pipe penetrates through an outer shell and an innershell and stretches into the drying barrel, the other end of the hot air inflow pipe is connected with the hot air generator, one end of the hot air outflow pipe stretches into the drying barrel, andthe other end of the hot air outflow pipe stretches into a second air chamber. The drying speed is high, the one-time drying amount is large, and the large-scale production requirements can be met.

Owner:铜陵启汇新型能源有限公司

Wood shaving drying equipment for shaving board manufacturing

InactiveCN108870898ADry thoroughlyEvenly heatedDrying chambers/containersDrying solid materialsWood shavingsPulp and paper industry

The invention relates to drying equipment, in particular to wood shaving drying equipment for shaving board manufacturing. The wood shaving drying equipment for shaving board manufacturing performs the drying in batches, and is uniform in drying. The wood shaving drying equipment for shaving board manufacturing comprises a small belt wheel, a first rotating shaft, a large belt wheel, a second rotating shaft, a first bevel gear, an electromagnet, an iron cover, a drying groove, a wire winding wheel, a heating wire, a first pulley and the like; an inlet is formed in middle of the top of a dryingbox; a servo motor, a first support rod and a second support rod are connected to the right wall in the drying box in sequence from top to bottom in a bolt connecting mode; and a fourth rotating shaft is arranged on the left side of the servo motor. The wood shaving drying equipment for shaving board manufacturing achieves the effects of dryness of wood shavings in batches, more complete and thorough dryness of the wood shavings and convenience for subsequent procedure treatment.

Owner:严晓凤

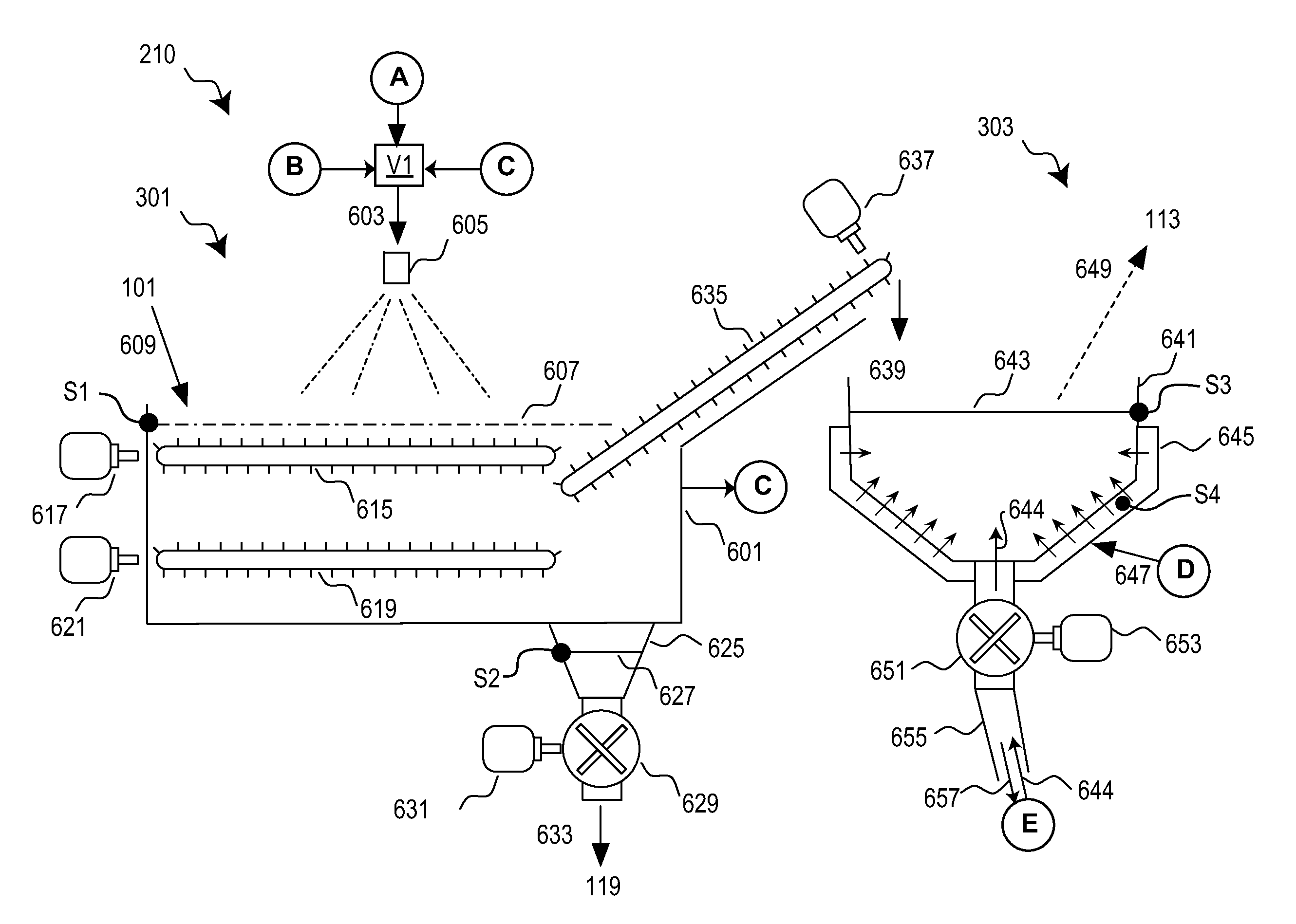

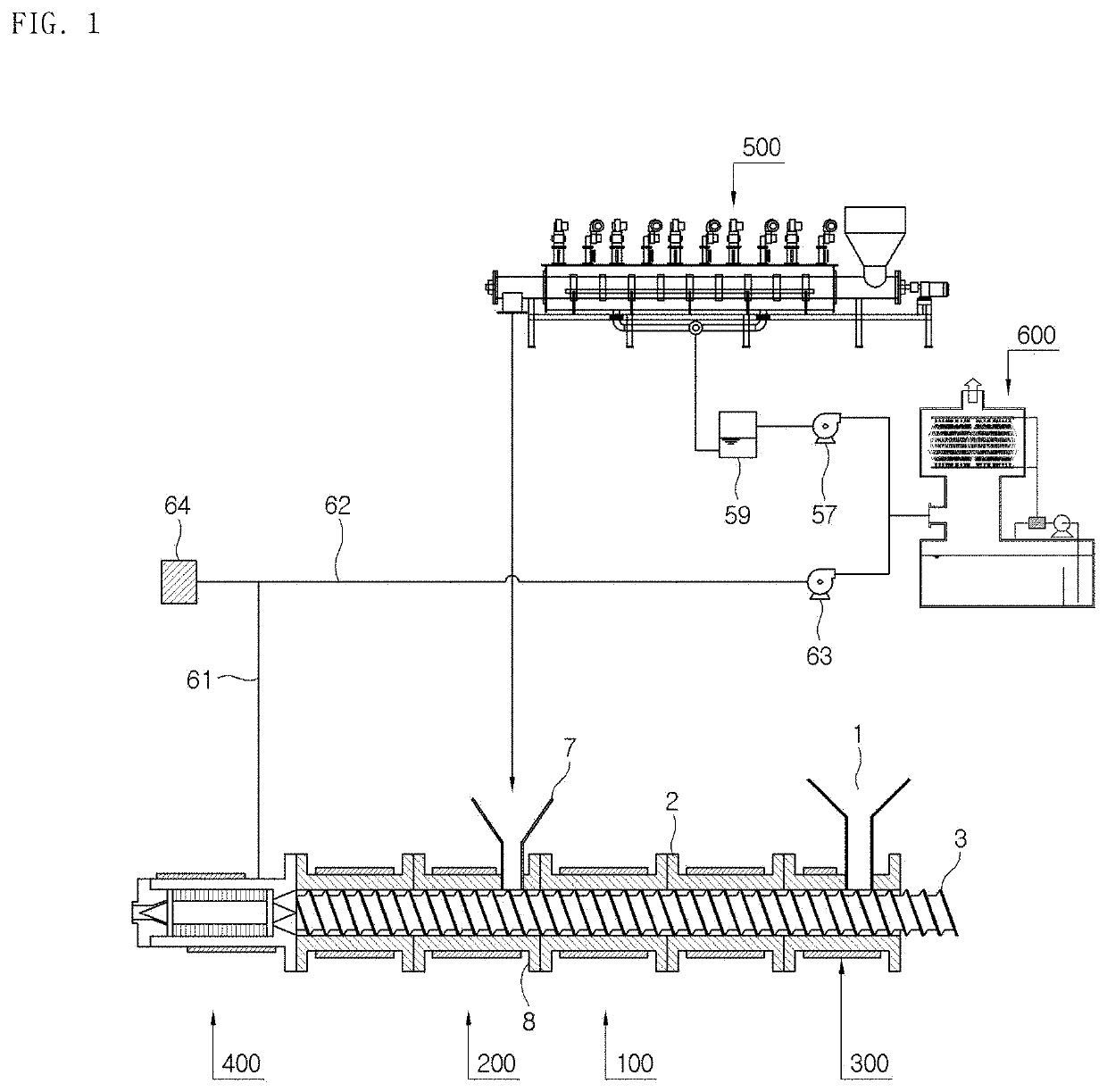

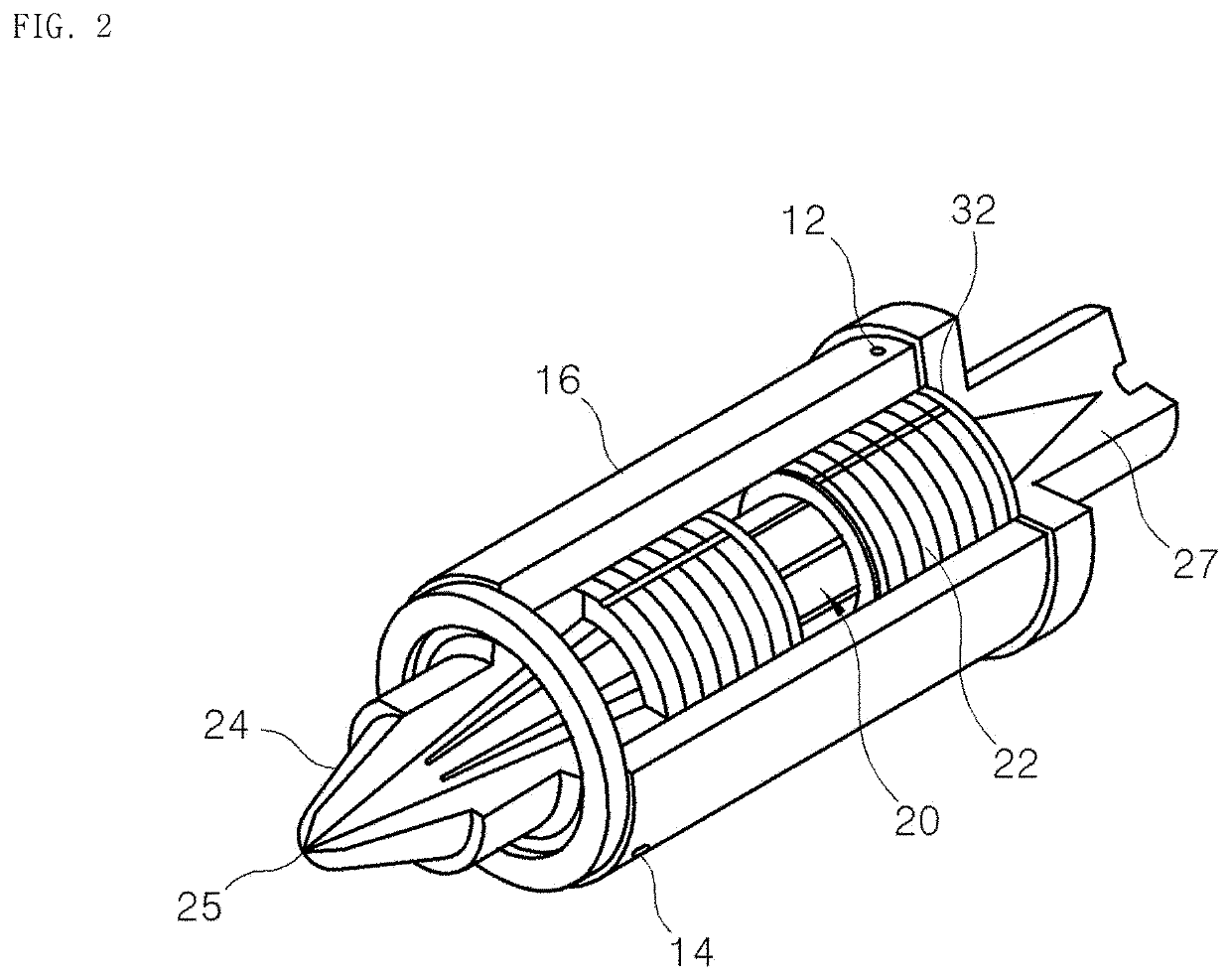

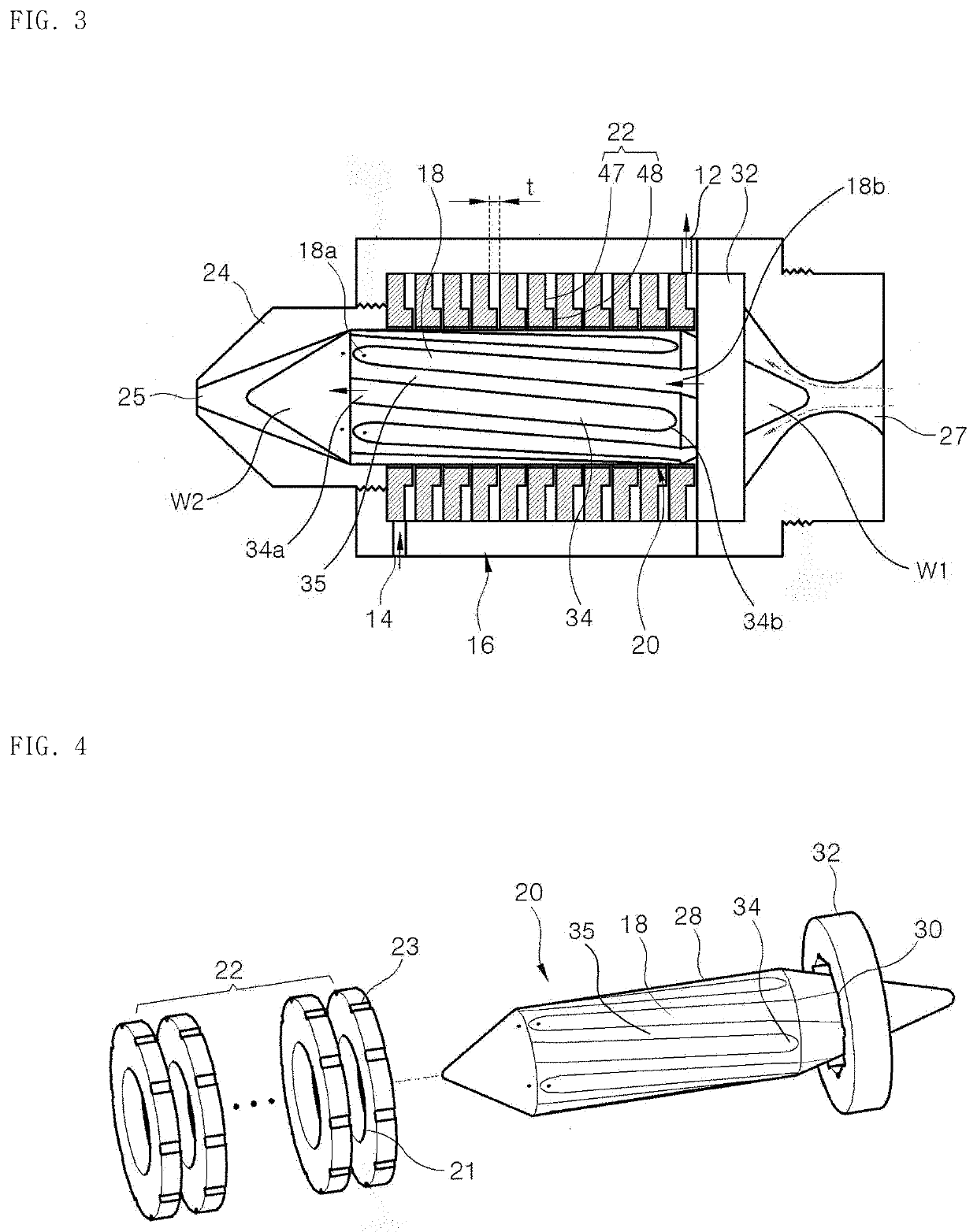

Facility for forming wood plastic composite with microwave and degassing device

ActiveUS20210318064A1Efficient removalEnhanced couplingDrying solid materials with heatWood particle dryingPolymer resinPlastic compounding

The present disclosure relates to a facility for forming a wood plastic composite by mixing and extruding wood powder and a polymer resin. According to a facility of the present disclosure, in a process of forming a wood plastic composite, gas and water vapor contained in wood powder and polymer resin are efficiently removed, and thus, a coupling force between wood powder and polymer resin increases, and also, wood powder is uniformly dispersed inside polymer resin, and thus, physical properties of a wood plastic composite to be formed is not degraded, and in addition, since there is no stagnant section while molten liquid of wood powder and polymer resin passes through each apparatus in the facility, wood powder is prevented from carbonizing or polymer resin is prevented from solidifying, and thus, physical properties of the wood plastic composite to be formed are maintained constant.

Owner:NEXT GEN GRAPHENE POLYMERS CO LTD +1

Device and method for controlling the conversion of biomass to biofuel

InactiveUS9005400B2Drying solid materials without heatDirect heating destructive distillationControl systemSolid fuel

Owner:RENEWABLE FUEL TECH

Plywood production process, waste drying chamber and laminating feeder

InactiveCN112248142AIncrease profitHigh strengthRadiation/waves wood treatmentDrying solid materials with heatSurface layerAdhesive

The invention relates to a plywood production process, a waste drying chamber and a laminating feeder. The plywood production process comprises the following steps: performing rotary cutting on a woodsection to obtain a surface layer plate meeting requirements, and placing the surface layer plate in a wood plate drying chamber for drying treatment; collecting sawdust waste, placing the sawdust waste in the waste drying chamber for drying treatment, mixing the dried waste, an asphalt material and cullet to obtain a mixture, adding an adhesive into the mixture, and pressing the mixture througha hot press to form a core veneer; coating one surface of the surface layer plate with an adhesive, and sequentially attaching the surface, with the adhesive, of the surface layer plate to the top surface and the bottom surface of the core veneer; and placing the composite plate in a hot press for hot pressing, thereby obtaining finished plywood. The utilization rate of wood can be improved.

Owner:漳州市桥头木业有限公司

Furnace including multiple trays and phase-change heat transfer

InactiveUS20140144042A1Drying solid materials with heatDrying gas arrangementsEngineeringVapor phase

A method and apparatus for heating materials is described. The apparatus is a furnace that includes multiple gravity-feed trays and a heat transfer fluid that heats material by the heat evolved during phase change. The apparatus also includes moving paddles that urge the material through each tray. The method provides for the torrefying of the material using a phase-change heat-transfer fluid by providing the material sequentially to at least two trays, where the at least two trays are substantially horizontal and disposed at different vertical heights; condensing the vapor phase at a temperature; and providing heat from the condensing the vapor phase to the material, where the temperature is sufficient to torrefy the material.

Owner:WECHSLER MARK +3

Saw dust baking device

PendingCN106123546AClear in timeReduce wearDrying solid materialsWood particle dryingEngineeringThermal efficiency

The invention relates to a saw dust baking device. The saw dust baking device is characterized in that a baking device body (1) is a rectangular quadrangle. A layer with an ash residue bin (8) and a bottom bin (17) is arranged on a bottom plate (14) of the baking device body (1); a burning and baking layer is arranged at the upper part of the layer with the ash residue bin (8) and the bottom bin (17); double jackets formed by a shell (18), a second layer of plates (19), a third layer of plates (20) and an inner layer of plates (21) are arranged in the burning and baking layer of the baking device body (1). Through the saw dust baking device, the heat energy is fully utilized; the double jackets are arranged in a burning furnace and are used for utilizing the heat; the raw material is heated and dewatered in two times; the heat efficiency is high; the fuel is reduced.

Owner:胡启志

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com