Methods of drying biomass and carbonaceous materials

a technology of carbonaceous materials and biomass, which is applied in the direction of drying, waste based fuel, lighting and heating apparatus, etc., can solve the problems of degrading biomass materials, increasing energy prices outpacing the efficiency of these drying processes, and affecting the economic and technical benefits of power generation, so as to reduce thermal energy and cost, and uniform chemical and physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

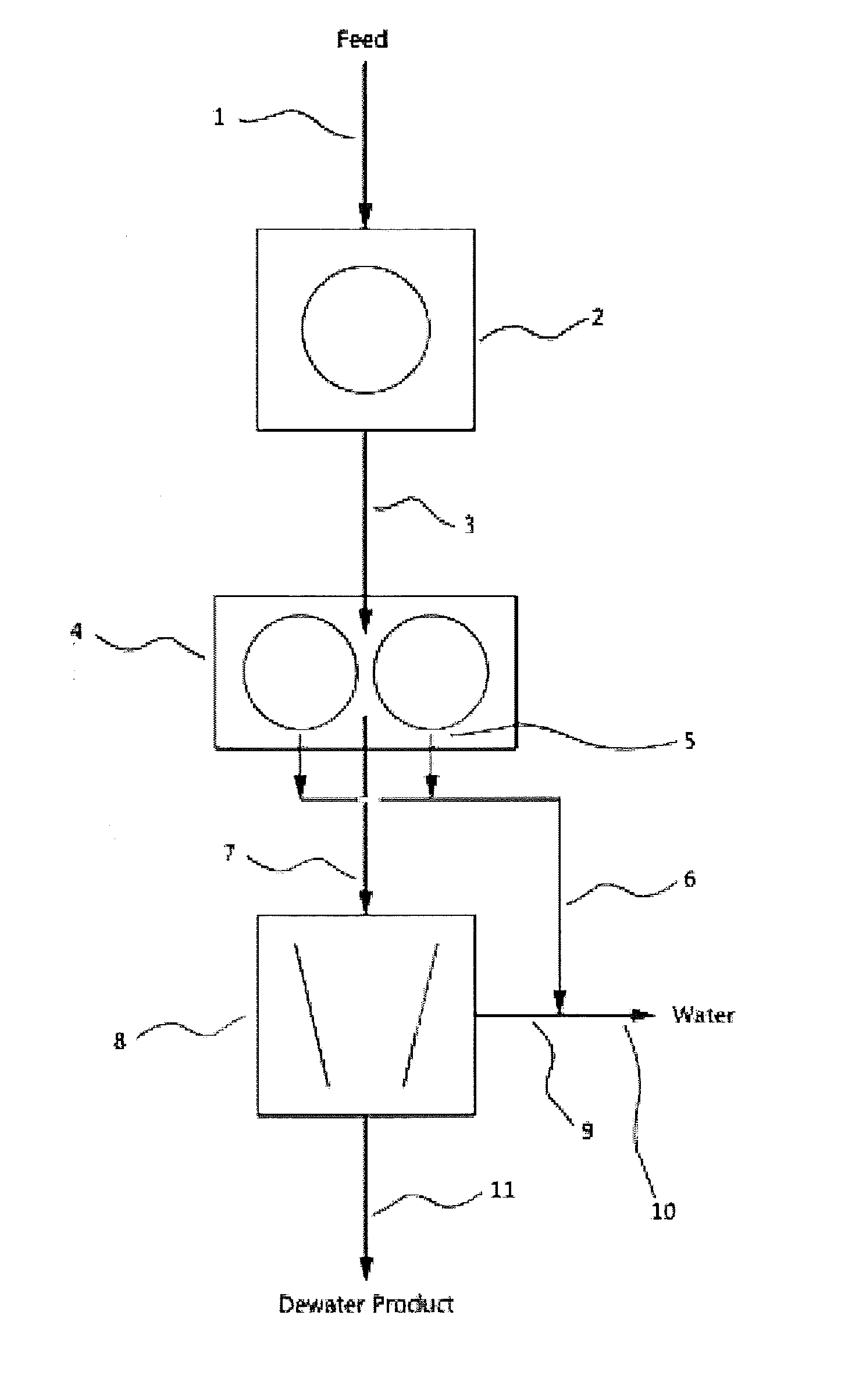

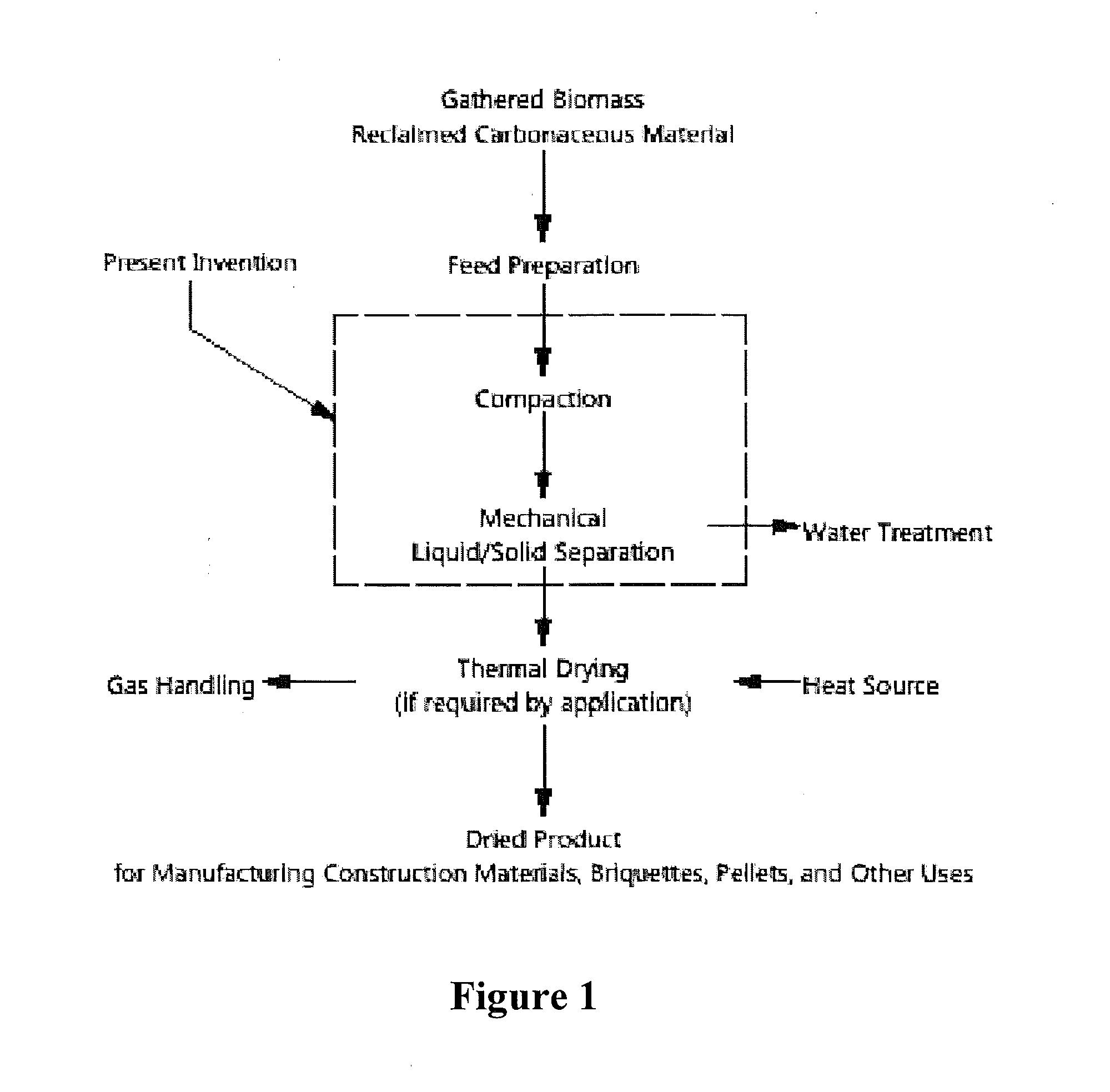

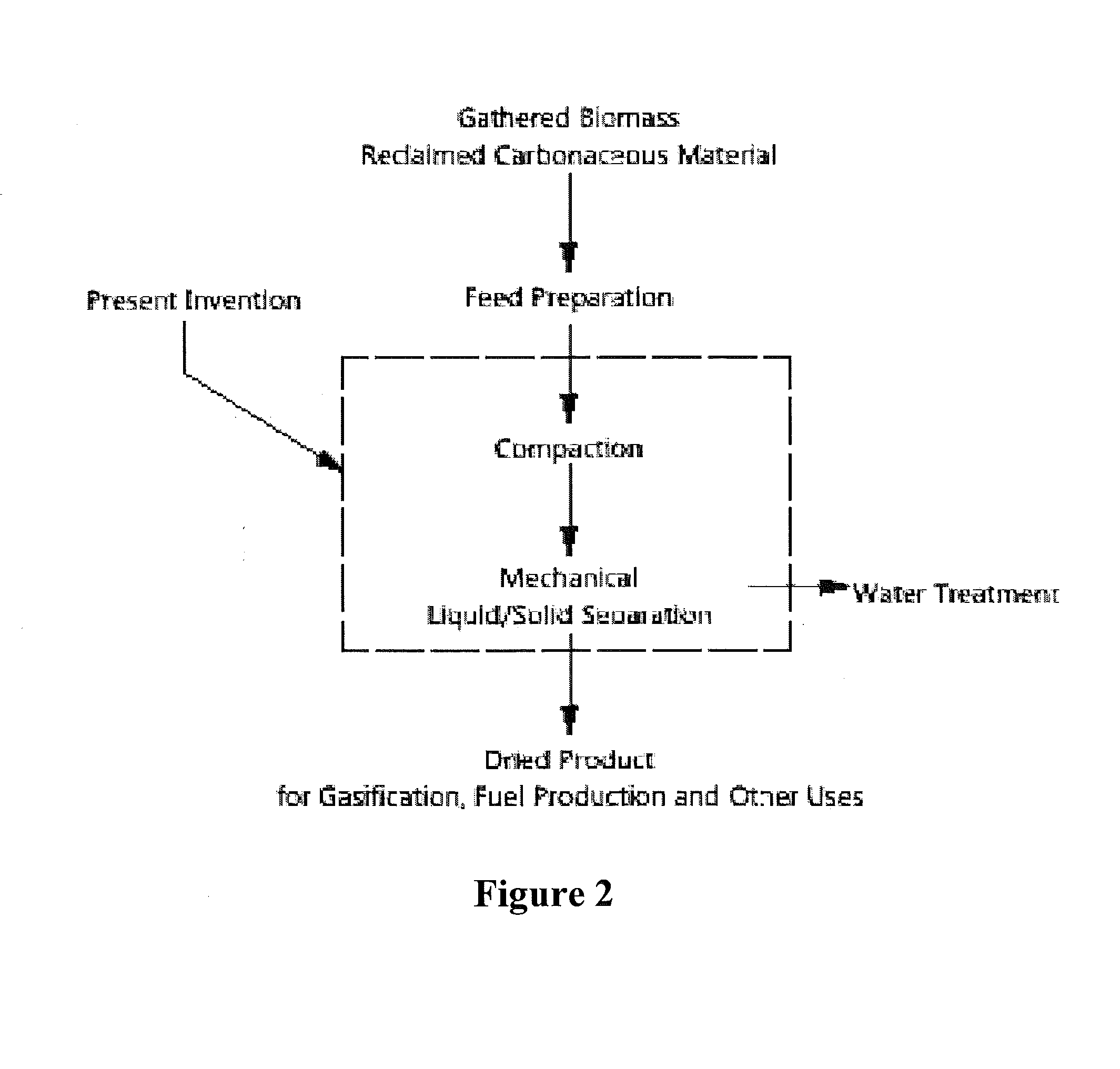

Method used

Image

Examples

example 1

[0082]Samples of pine, red oak and PRB coal, and Brown Coal (coal from LaTrobe Valley, Australia) were processed to confirm the efficiency and performance of mechanical compaction to remove liquid water. The samples were prepared to sizes and shapes believed to be advantageous for compaction. Each material, including a mixture of pine and PRB coal, were subjected to up to 40,000 lb / in2 pressure. Expressed water was collected. All materials were weighed and assayed for moisture content. All compaction tasks were conducted at ambient temperature.

[0083]Raw materials (unprocessed material) and compacted products were dried at about 104° F. on a laboratory moisture determination device to ascertain the relative drying rates of each sample. Results are summarized in Table 1, and plotted in FIGS. 4-9. Graphics were added to FIG. 4 that show the moisture removed by compaction and the reduction in drying time required to achieve an equal moisture content. In this case, compaction removed abo...

example 2

[0093]Industry requires briquettes to resist breakage during handling and storage. Sometimes briquettes made exclusively from low-rank coal are brittle or lack strength to satisfy industry's requirements. In this example, a mixture consisting of low-rank coal and pine wood was prepared and processed by the present invention. Results confirm that the physical properties of briquettes made from this mixture were superior to those made exclusively from low-rank coal.

[0094]The first series of tests measured the compressive strength of briquettes that contained various proportions of low-rank coal and pine wood (biomass). Both materials were milled to pass about a 2.4 mm screen opening. Table 3 demonstrates that increasing the proportion of biomass increases compressive strength, a measure of the ability to bear weight without breaking. Observations have concluded that biomass provides additional strength by making the briquette slightly flexible, thus able to bend with the load without ...

example 3

[0097]There is an incentive to reduce greenhouse gas (GHG) emissions created by burning fossil fuels, especially low-rank coal. Government agencies including the United States EPA, publishes the carbon dioxide emission factor for low-rank coal (lignite) is 4,600 lb / st lignite fired. The emission factor for wood, the type of biomass used in the examples presented for the present invention, is 3,400 lb / st wood fired. The carbon dioxide produced by combusting wood, a renewable resource, is not considered a GHG. Briquettes formed from a mixture of low-rank coal and biomass therefore has the advantage of producing less GHG for any given amount of energy produced by combustion. Carbon dioxide emissions are reduced approximately in proportion to the amount of biomass included in the briquette. For example, a briquette formed as described in these Examples, containing about 20 wt % biomass, will reduce GHG emissions by approximately 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| compaction energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com