Saw dust baking device

A baking device and sawdust technology, applied in heating devices, drying, drying machines, etc., can solve the problems of low thermal efficiency, affecting the profit of the charcoal industry, slow drying speed, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

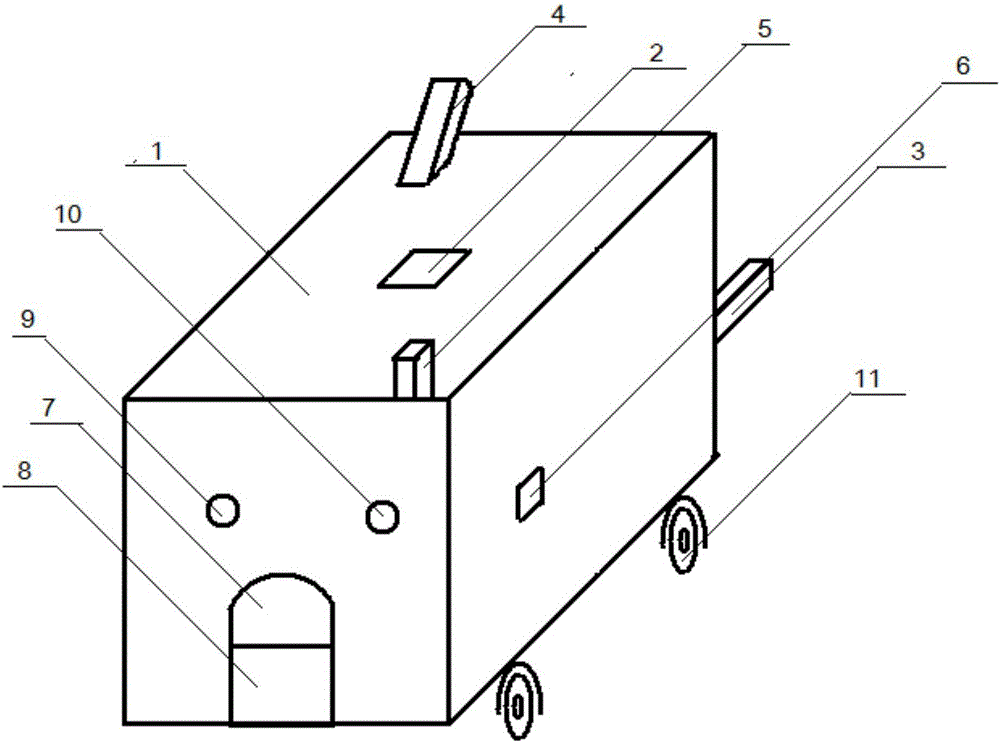

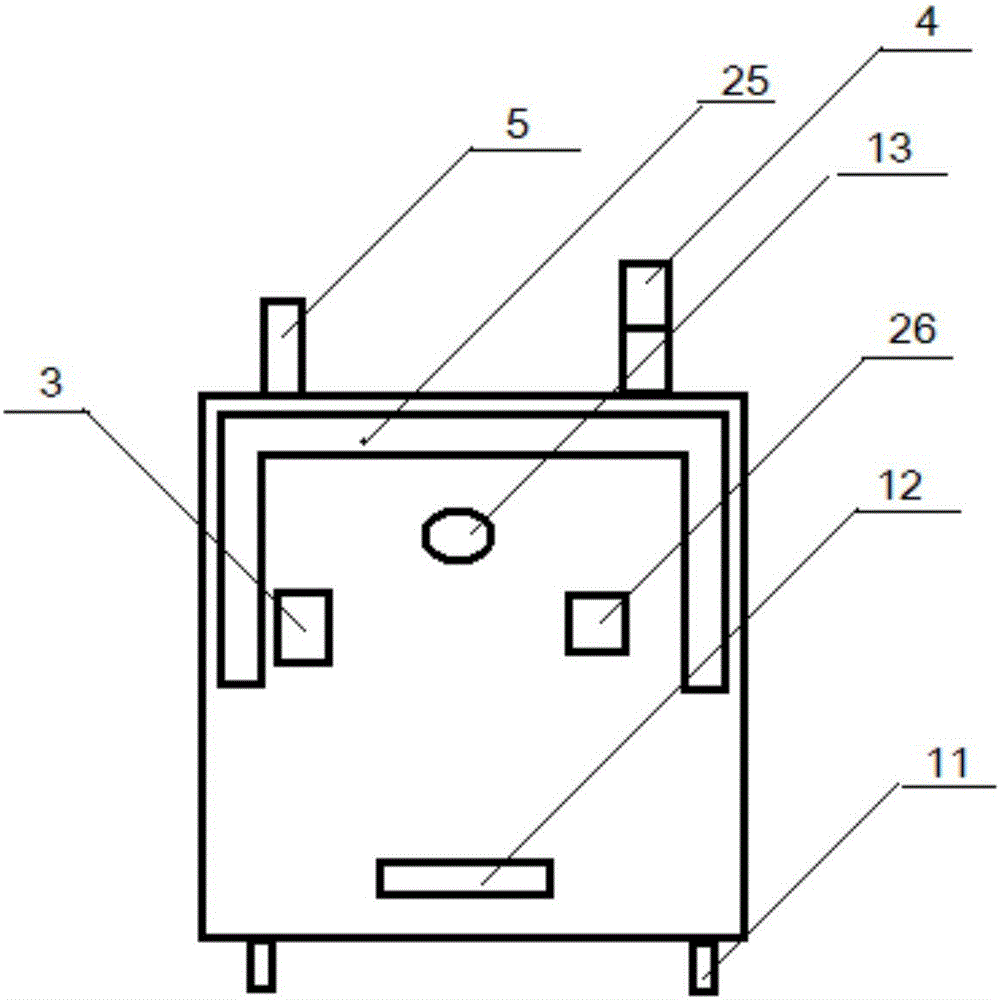

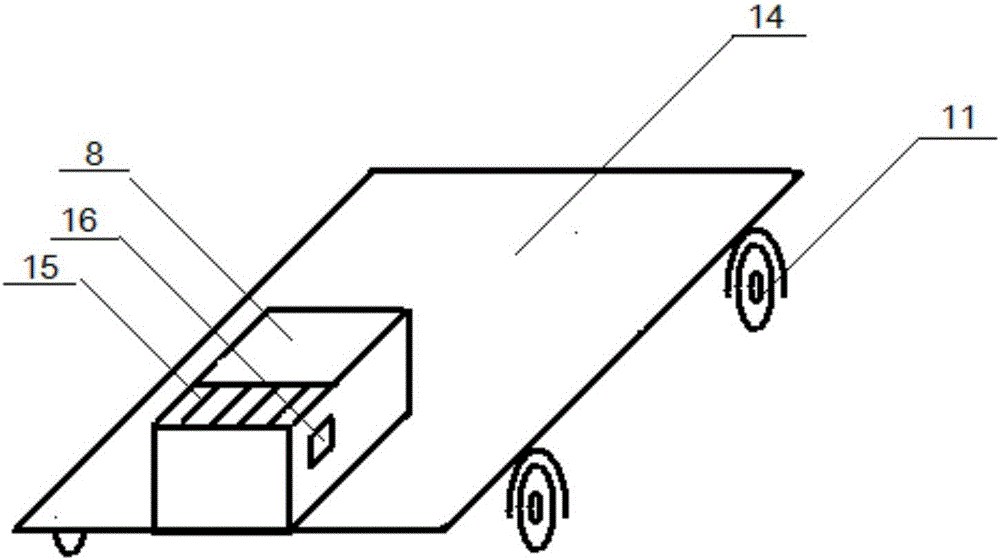

[0041] Embodiment 1: A sawdust roasting device of the present invention, the roasting device body 1 is a rectangular square, the bottom plate 14 of the roasting device body 1 is provided with an ash bin 8 and a bottom bin 17 layers, and the bottom bin 17 is a hollow layer , the ash bin 8 is in the center of the front part of the bottom bin 17, the top front end of the ash bin 8 is provided with a furnace bridge 15, and the bottom of the furnace bridge 15 in the ash bin 8 is provided with an oxygen inlet hole 16 communicating with the bottom bin 17. The back bottom bin 17 of the baking device body 1 is provided with an oxygen inlet 12, and the air enters the bottom bin 17 from the oxygen inlet 12, then enters the ash bin 8 from the bottom bin 17 through the oxygen inlet hole 16, and then enters the ash bin 8 from the ash slag. The furnace bridge 15 on the top of the bin 8 enters the combustion area and combusts with the combustion gas entering from the gas inlet 6; There is a d...

Embodiment 2

[0042] Embodiment 2: A sawdust roasting device of the present invention, the roasting device body 1 is a rectangular square, the bottom plate 14 of the roasting device body 1 is provided with ash bin 8 and bottom bin 17 layers, and the bottom bin 17 is a hollow layer , the ash bin 8 is in the center of the front part of the bottom bin 17, the top front end of the ash bin 8 is provided with a furnace bridge 15, and the bottom of the furnace bridge 15 in the ash bin 8 is provided with an oxygen inlet hole 16 communicating with the bottom bin 17. The back bottom bin 17 of the baking device body 1 is provided with an oxygen inlet 12, and the air enters the bottom bin 17 from the oxygen inlet 12, then enters the ash bin 8 from the bottom bin 17 through the oxygen inlet hole 16, and then enters the ash bin 8 from the ash slag. The furnace bridge 15 on the top of the bin 8 enters the combustion area and combusts with the combustion gas entering from the gas inlet 6; There is a double...

Embodiment 3

[0043] Embodiment 3: A sawdust roasting device of the present invention, the roasting device body 1 is a rectangular square, the bottom plate 14 of the roasting device body 1 is provided with an ash bin 8 and a bottom bin 17 layers, and the bottom bin 17 is a hollow layer , the ash bin 8 is in the center of the front part of the bottom bin 17, the top front end of the ash bin 8 is provided with a furnace bridge 15, and the bottom of the furnace bridge 15 in the ash bin 8 is provided with an oxygen inlet hole 16 communicating with the bottom bin 17. The back bottom bin 17 of the baking device body 1 is provided with an oxygen inlet 12, and the air enters the bottom bin 17 from the oxygen inlet 12, then enters the ash bin 8 from the bottom bin 17 through the oxygen inlet hole 16, and then enters the ash bin 8 from the ash slag. The furnace bridge 15 on the top of the bin 8 enters the combustion area and combusts with the combustion gas entering from the gas inlet 6; There is a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com