Process and device for fluidized bed torrefaction and grinding of a biomass feed for subsequent gasification or combustion

a technology of fluidized bed and biomass feed, which is applied in the direction of wood particle drying, wood particle drying, and solid material drying, etc., can solve the problems of not finding a prior art process for torrefaction and grinding, and no information available regarding the technology used for torrefaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

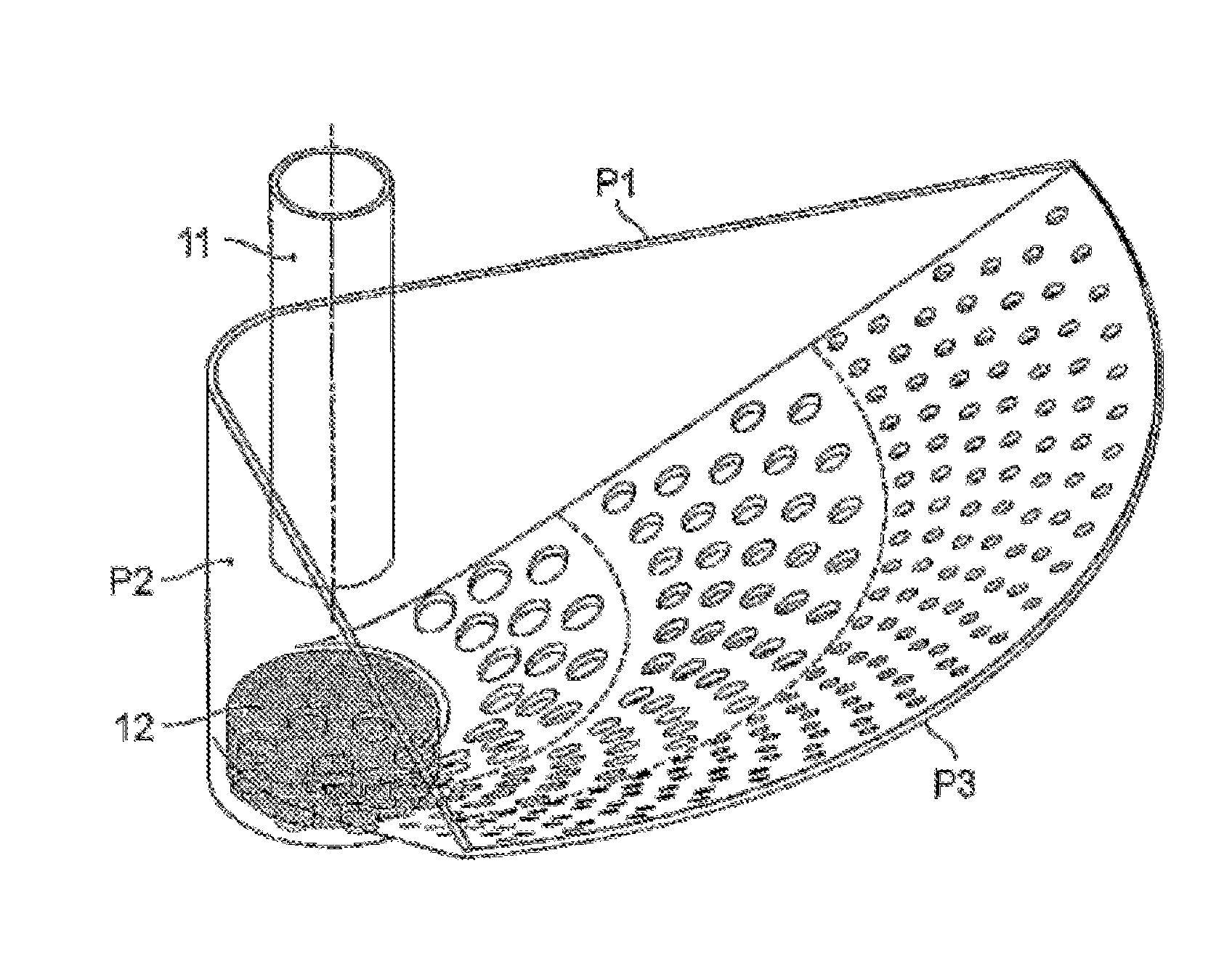

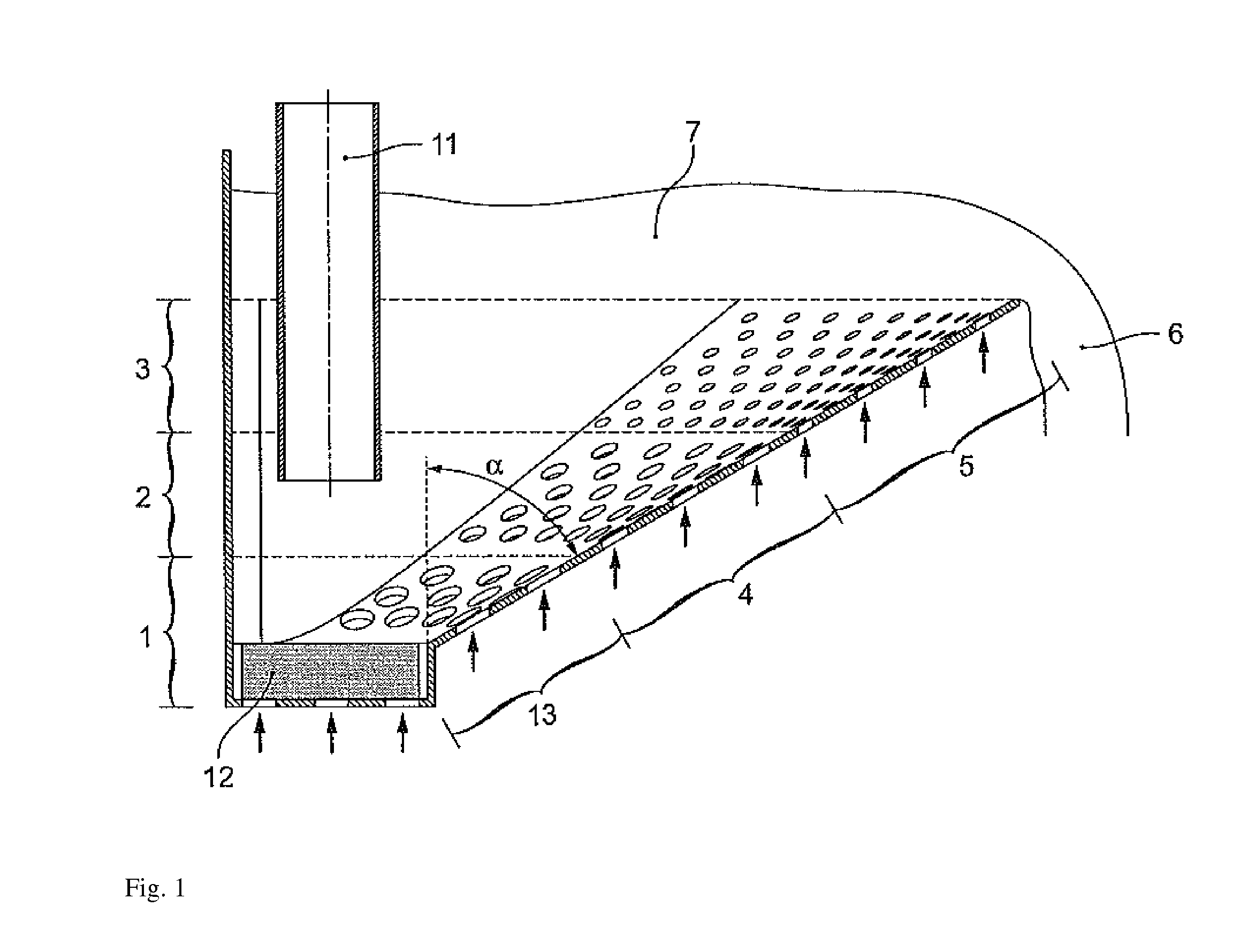

[0089]The first example concerns a unit in accordance with the invention operating at atmospheric pressure and treating particles of biomass in the form of wood pellets with dimensions of 2 cm×3 cm×5 cm with a water content of 35% by weight with a view to obtaining particles less than 500 microns in size and with a water content of less than 5% by weight.

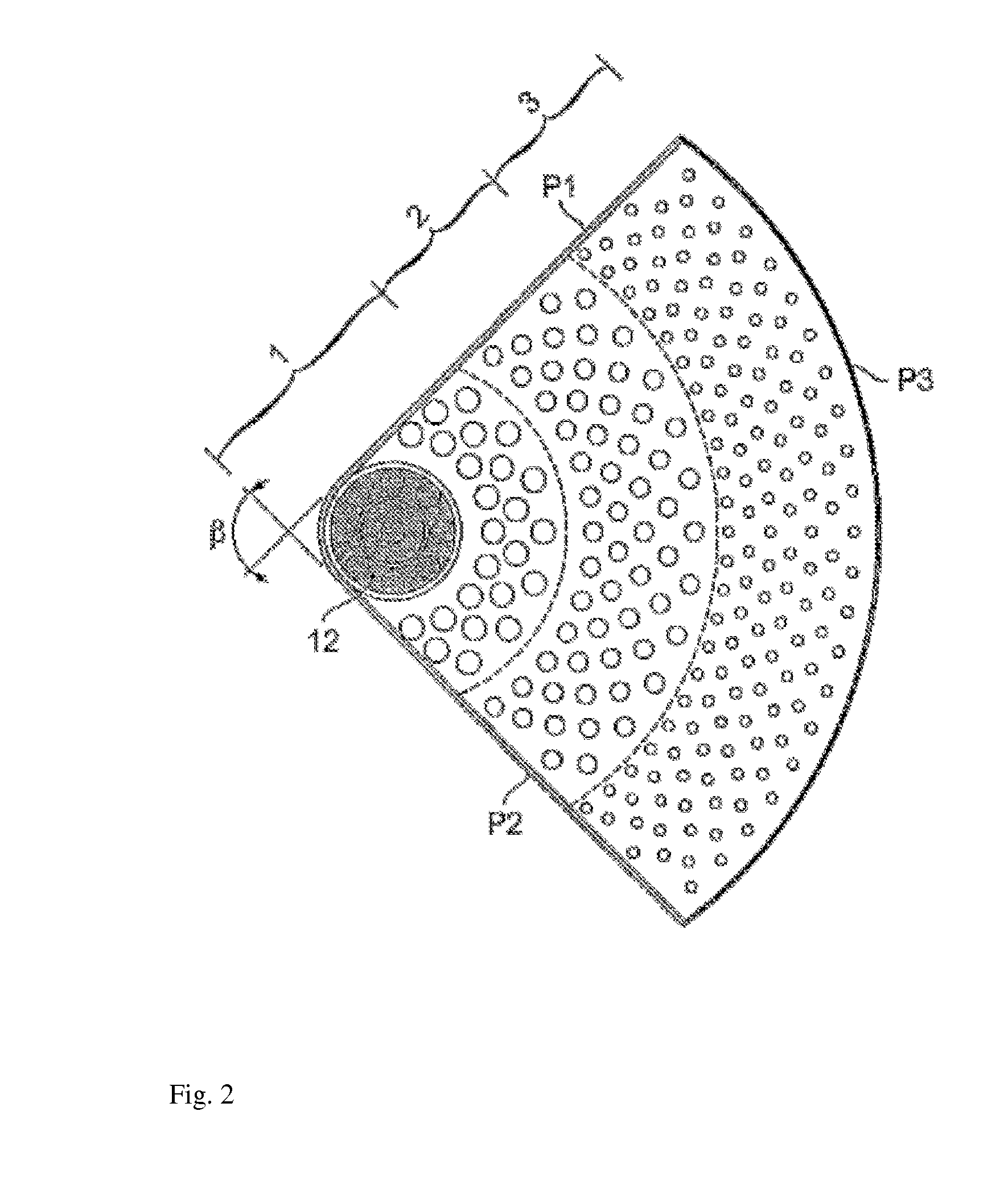

[0090]The feed flow velocity of the biomass to be treated is: 20000 tones / year, i.e. 2.31 tones / hour. The torrefaction and grinding unit of the invention corresponded to a conical sector with a peak angle β of 90° and had the following dimensions:

[0091]Total height: 2.5 m

[0092]Maximum diameter (at upper zone): 4.6 m

[0093]Diameter of grinder (lower zone): 0.5 m

[0094]Intermediate zone diameter: 0.5 to 3.6 m

[0095]Upper zone diameter: 3.6 to 4.6 m

[0096]Angle (α) of inclined wall to vertical: 43°

[0097]Velocity of fluidization in zone 1 and 2: 27.3 cm / s

[0098]Velocity of fluidization in zone 3: 6.3 cm / s

[0099]Mean void fraction of fluidized...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com