Casting-rolling method for aluminum matrix composite reinforced by in-situ generated TiB2 particles

A particle-reinforced aluminum and composite material technology, applied in metal rolling and other directions, can solve the problems of uneven preparation process production efficiency, high cost, large particle dispersion, etc., to improve the comprehensive performance of products, improve poor wettability, and improve particle The effect of dispersion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

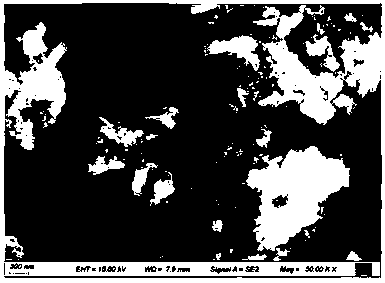

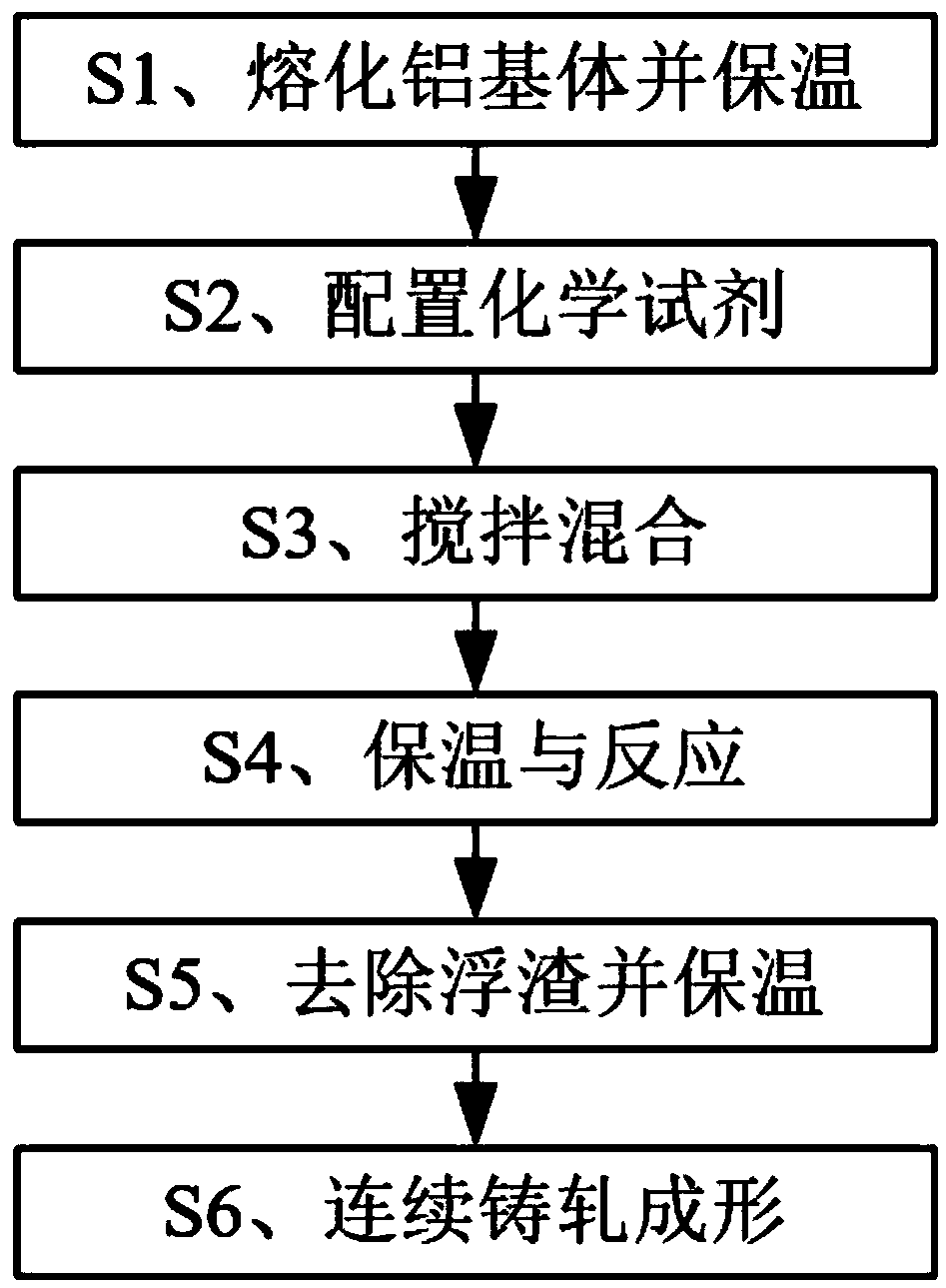

[0052] The aluminum matrix is 6061 aluminum alloy, and TiB with a particle content of 5%wt is prepared 2 The steps of particle reinforced 6061 aluminum-based composite board are as follows:

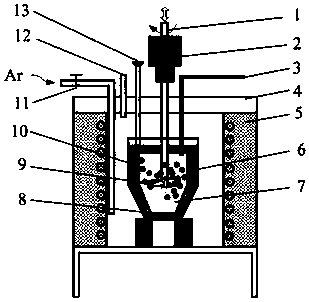

[0053] S1. Melt the aluminum substrate and keep it warm: Put the 6061 aluminum ingot into the crucible 6, put it in the protective atmosphere 11 and use the heating furnace 5 to heat it to the specified temperature of 830°C. After the 6061 aluminum ingot is melted into 6061 aluminum liquid, the holding time is 20 minutes.

[0054] S2, configuration of chemical reagents: KBF with Ti / B=1:2 stoichiometric ratio 4 (194.2g) and K 2 TiF 6 (185g) and catalyst MgF 2 (20g) and AlF 6 Na 3 (40g) Mix well, and use a heating furnace to dry at the specified temperature of 200°C for 30 minutes.

[0055] S3. Adding chemical reagents: stir with graphite stirring paddle 9, and evenly disperse the dried chemical reagents into 6061 aluminum liquid through the adding channel 13 to prepare a mixed melt, with a stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com