Method for reducing flow resistance of interlayer cooling structure of 3D printing thrust chamber

A cooling structure and 3D printing technology, applied in the field of 3D printing, can solve problems such as interlayer channel flow resistance, achieve the effects of reducing flow resistance, improving flow resistance efficiency, and reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0027] The present invention provides a method for reducing the flow resistance of the interlayer cooling structure of the 3D printing thrust chamber, which is specifically implemented according to the following steps:

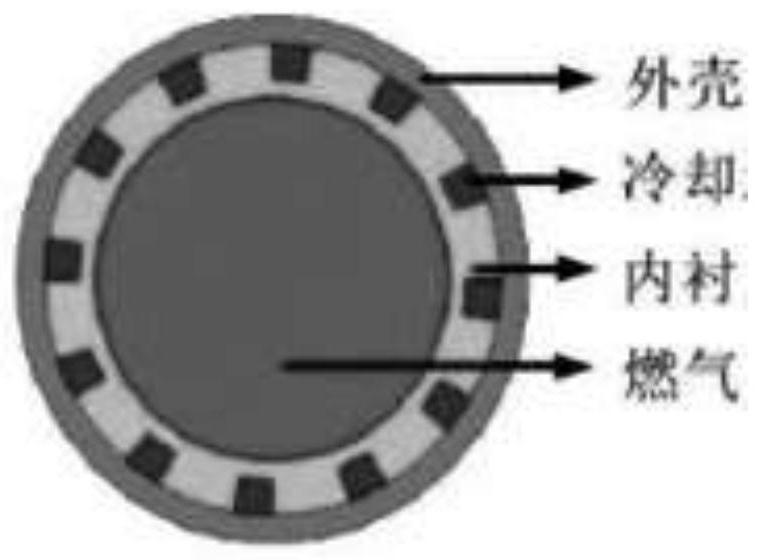

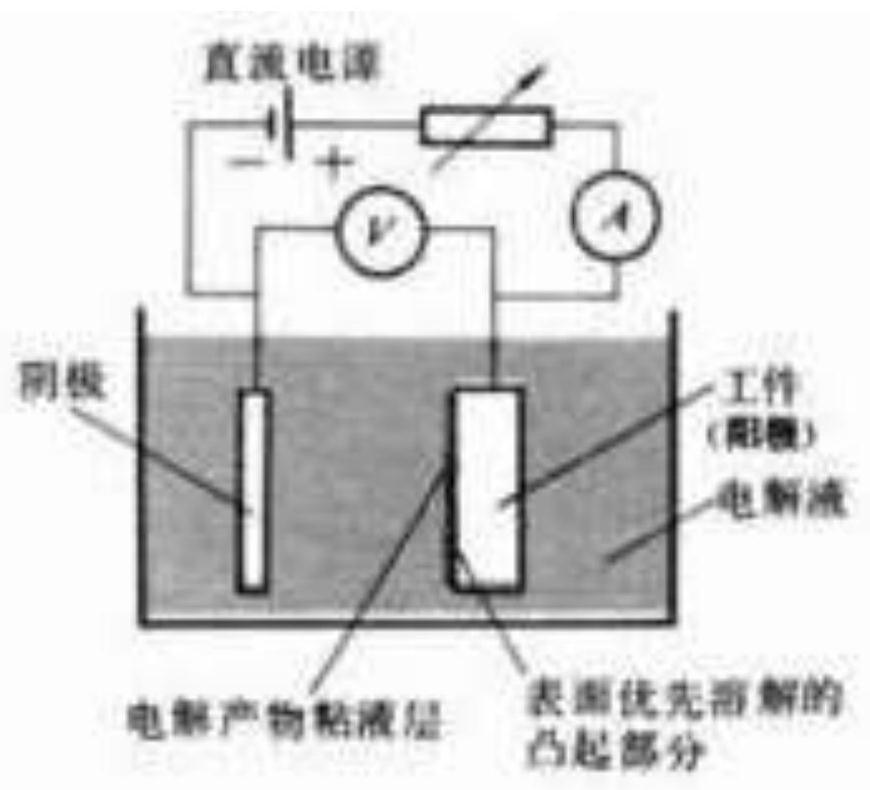

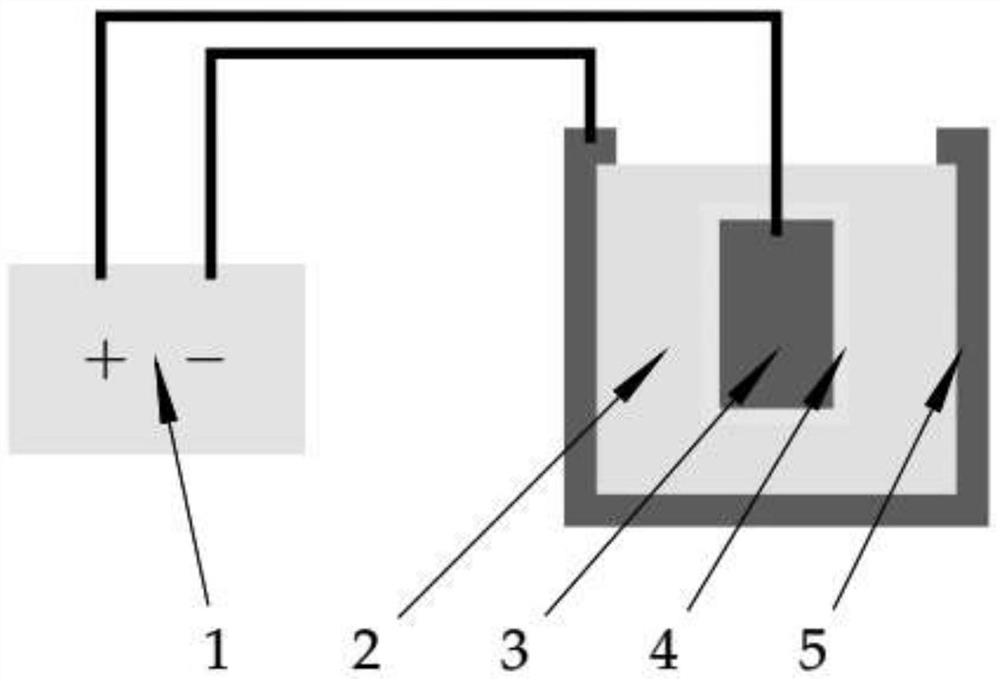

[0028] Step 1. First, construct and design the interlayer cooling structure of the thrust chamber. The interlayer structure includes an inner layer and an outer layer. The coolant inlet and outlet should be set at both ends. The middle of the interlayer structure is divided into multiple cooling channels by several axial ribs. , including the inflow channel and the outflow channel, the two channels should be arranged adjacent to each other in turn, and a plurality of lattice protrusions should be arranged at intervals in the circulation channel to further improve the cooling capacity of the interlayer. Then use Solidworks sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com