A Forging Method for Deformed Short T-shape Blank

A blank and rough blank technology is applied in the field of forging of deformed short T-shaped blanks, which can solve the problems of difficult forming of deformed short T-shaped blanks, and achieve the effects of improving product competitiveness, reducing weight and improving overall performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

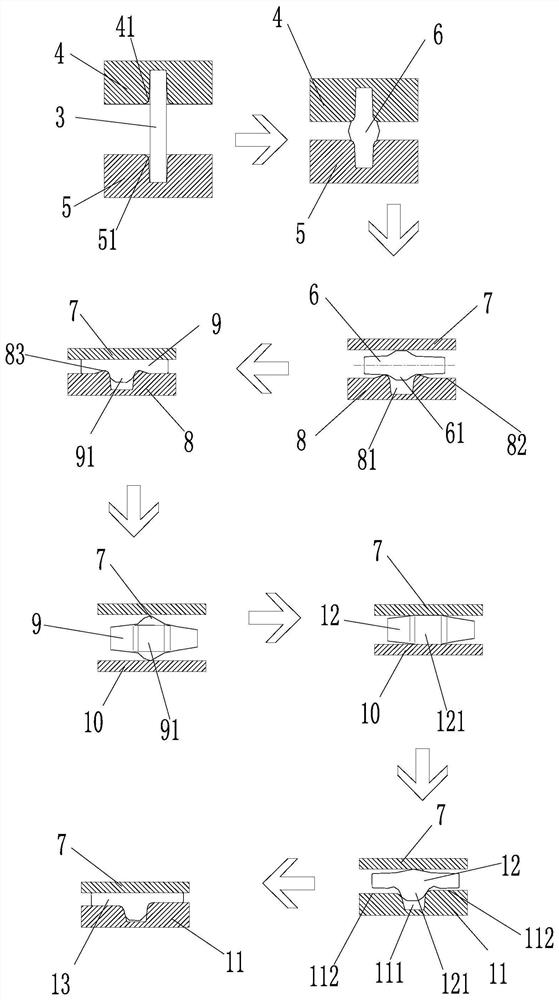

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that "up" and "bottom" and "left" and "right" in this specification indicate the relative positional relationship between the two.

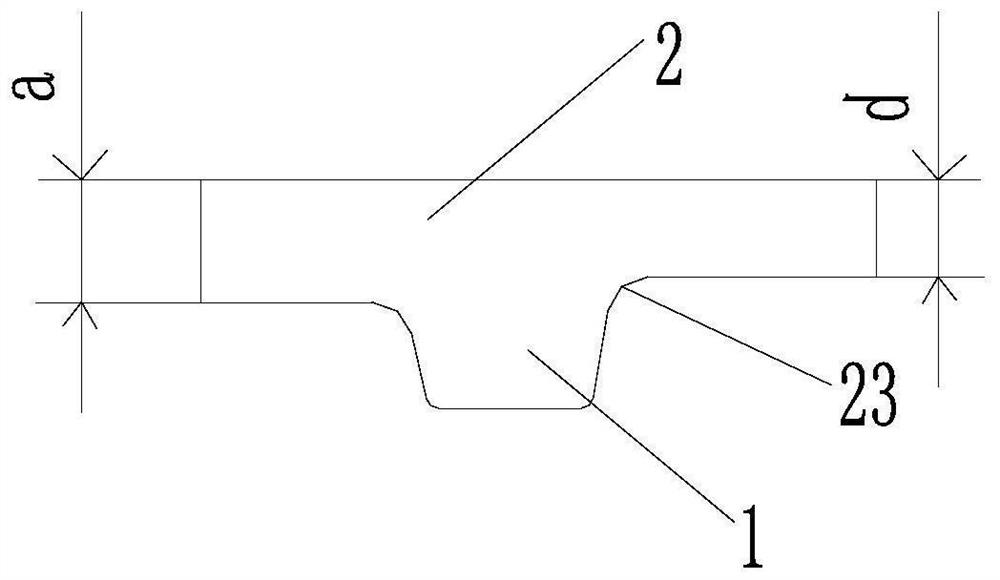

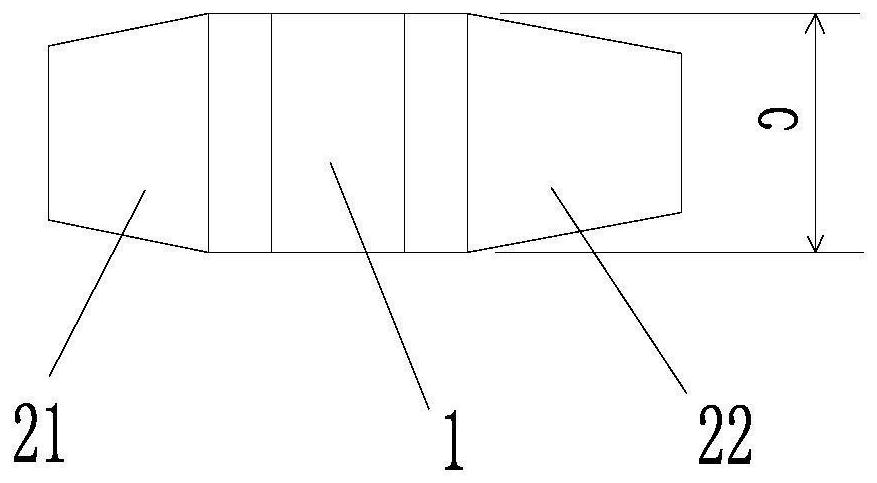

[0019] Such as image 3 , Figure 4 Shown, the forging method of a kind of deformed short T-shaped blank of the present invention, the method comprises the following steps:

[0020] In the first step, put the lower end of the rod-shaped blank 3 into the cavity of the pier thick lower die 5, put the upper end into the cavity of the pier thick upper die 4, and press the pier thick upper die 5 along the direction close to the pier thick upper die 5. Die 4, until a protrusion 61 is formed between the upper end and the lower end of the rod-shaped blank 3, thereby forming the first intermediate blank 6;

[0021] In the second step, the first intermediate blank 6 is placed flat on the flat lower mold 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com