Cold stamping process of heavy-duty off-road vehicle frame reinforcing plate

An automobile frame and reinforcing plate technology, which is applied in the field of machining, can solve the problems of easy sliding and rotation, excessive size and angle, stress concentration, etc., and achieves the effects of high production efficiency, cost saving and good product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

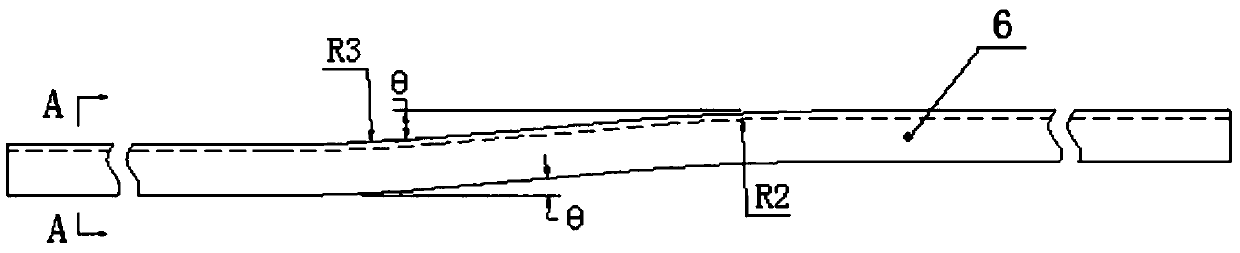

[0020] figure 1 Shown is a structural schematic view of the reinforced plate product of the present invention.

[0021] figure 2 Shown is the invention figure 1 A-A cross-sectional schematic diagram.

[0022] The present invention provides a cold stamping process for a frame reinforcement plate of a heavy-duty off-road vehicle. The reinforcement plate 6 is a symmetrical part with an L-shaped cross-section and a bending fillet radius of R1. It is bent at θ degrees, and the radius of the bending fillet is R2 and R3; the material thickness range of the material used is 8-12mm, and the yield strength range is 450MPa-600Mpa.

[0023] Preferably, the material used is a high-strength hot-rolled steel plate with a length of 6320 mm, a thickness of 10 mm, and a strength of σs≥500 MPa.

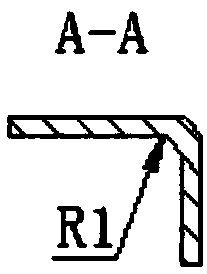

[0024] The process is: blanking→roll forming→bending→separation. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com