Quasi pressure adjusting casting machine and casting method thereof

A casting machine and pressure regulating technology, applied in the field of casting forming process and equipment, can solve the problems of low production efficiency, reduced aluminum alloy gas content, expensive equipment cost, etc., and achieve high production efficiency, improved casting strength, and low equipment cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

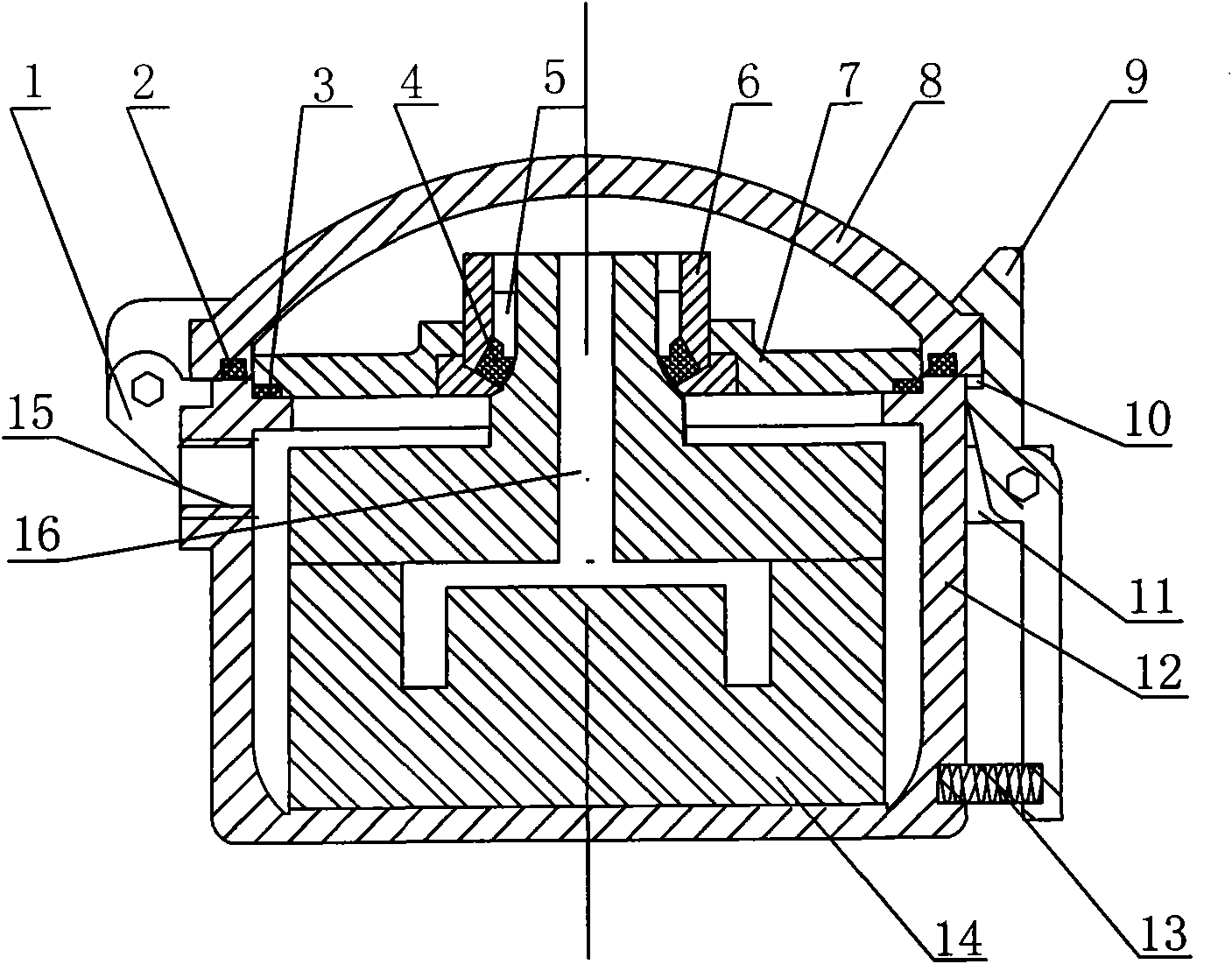

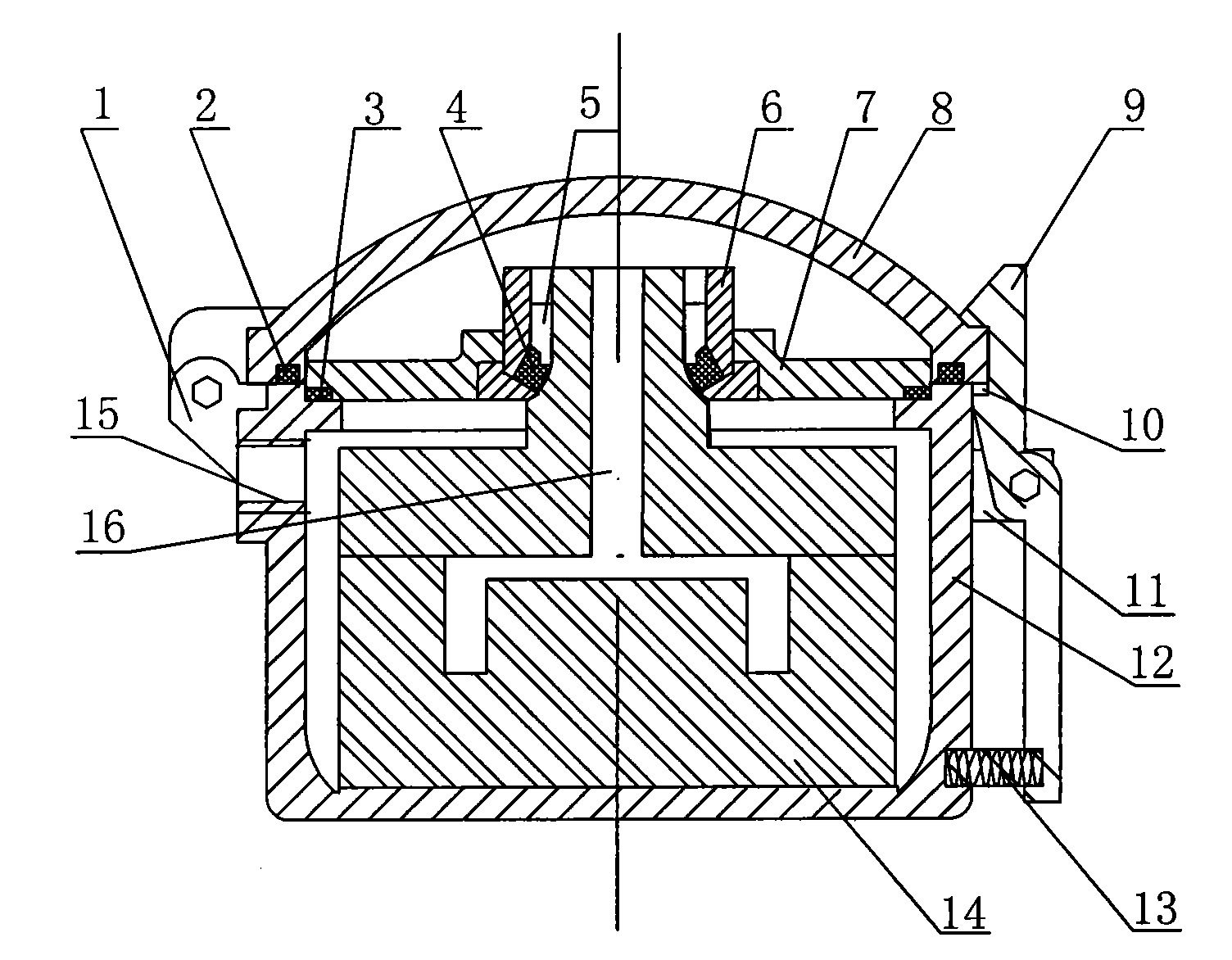

[0022] The quasi-pressure regulating casting machine includes a pouring kettle 12, a vacuum partition 7, an upper cover 8, a quick locking mechanism 9, a sealing cone 5 and a right-angle sealing ring 6. The upper cover 8 is hinged with the upper cover hinge ear 1 provided on one side of the pouring kettle 12, and the quick locking mechanism 9 is hinged with the locking mechanism hinge ear 11 provided on the other side of the pouring kettle 12 in the middle, and the quick lock The upper end of the tightening mechanism 9 is provided with a groove 10 locked with the upper cover 8, and the lower end is provided with a tension spring 13 connected to the pouring kettle 12, and the two ends of the tension spring 13 are respectively fixed on the pouring kettle 12 and the quick locking mechanism. 9, the vacuum partition 7 is equipped with a right-angle sealing ring 6 and the cover is installed on the top opening of the pouring kettle 12, and the sealing cone 5 is sleeved in the right-an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com