Ceramic sintering device and ceramic sintering method

A sintering device and ceramic technology, applied in the direction of electric furnace heating, furnace type, furnace, etc., can solve the problems that are difficult to meet, pollute the sample surface, etc., and achieve the effect of easy operation, simple process flow, and lower temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] see Figure 4 , the embodiment of the present invention also provides a preparation method for realizing ceramic sintering by using the ceramic sintering device 100, comprising the following steps:

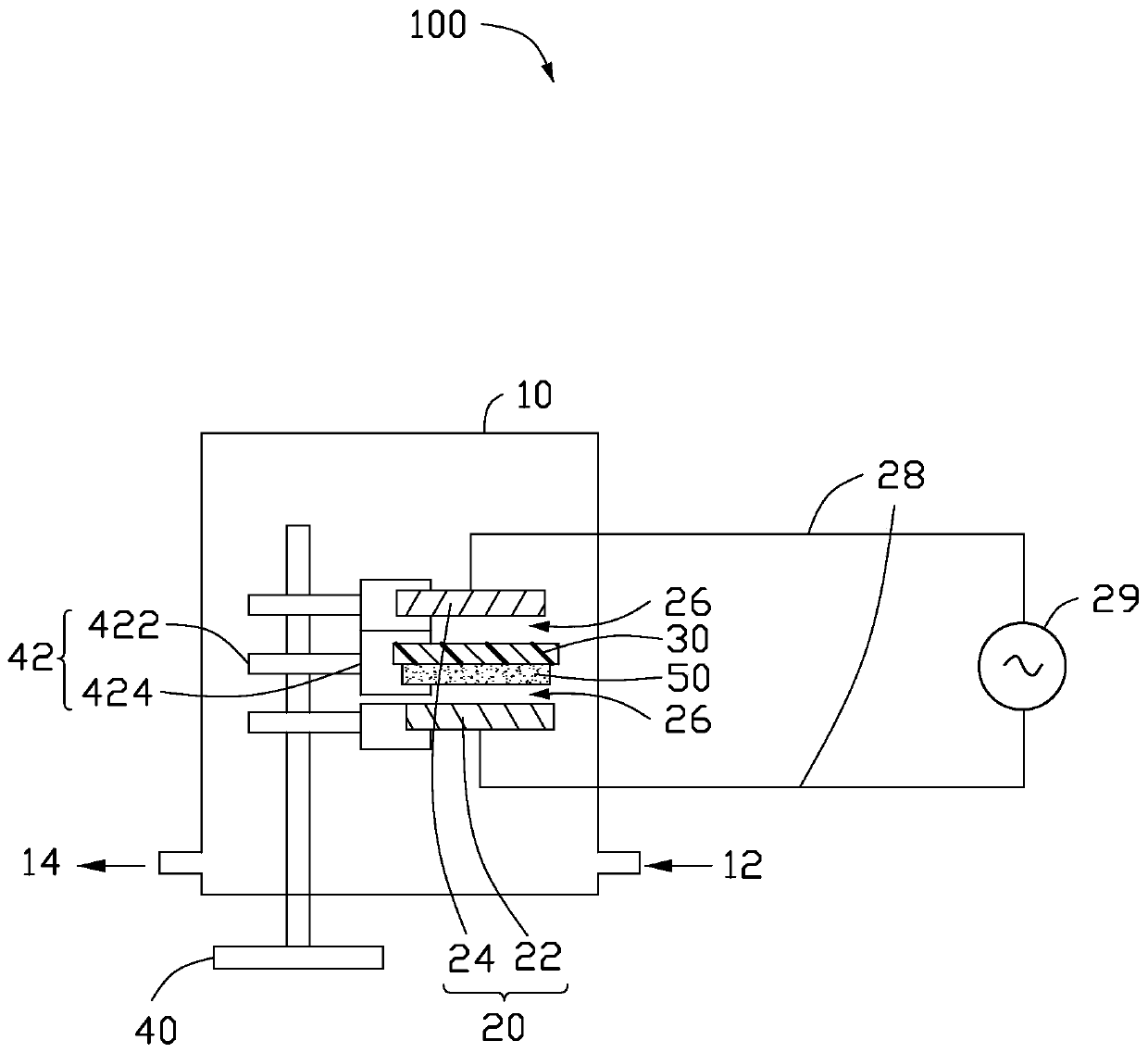

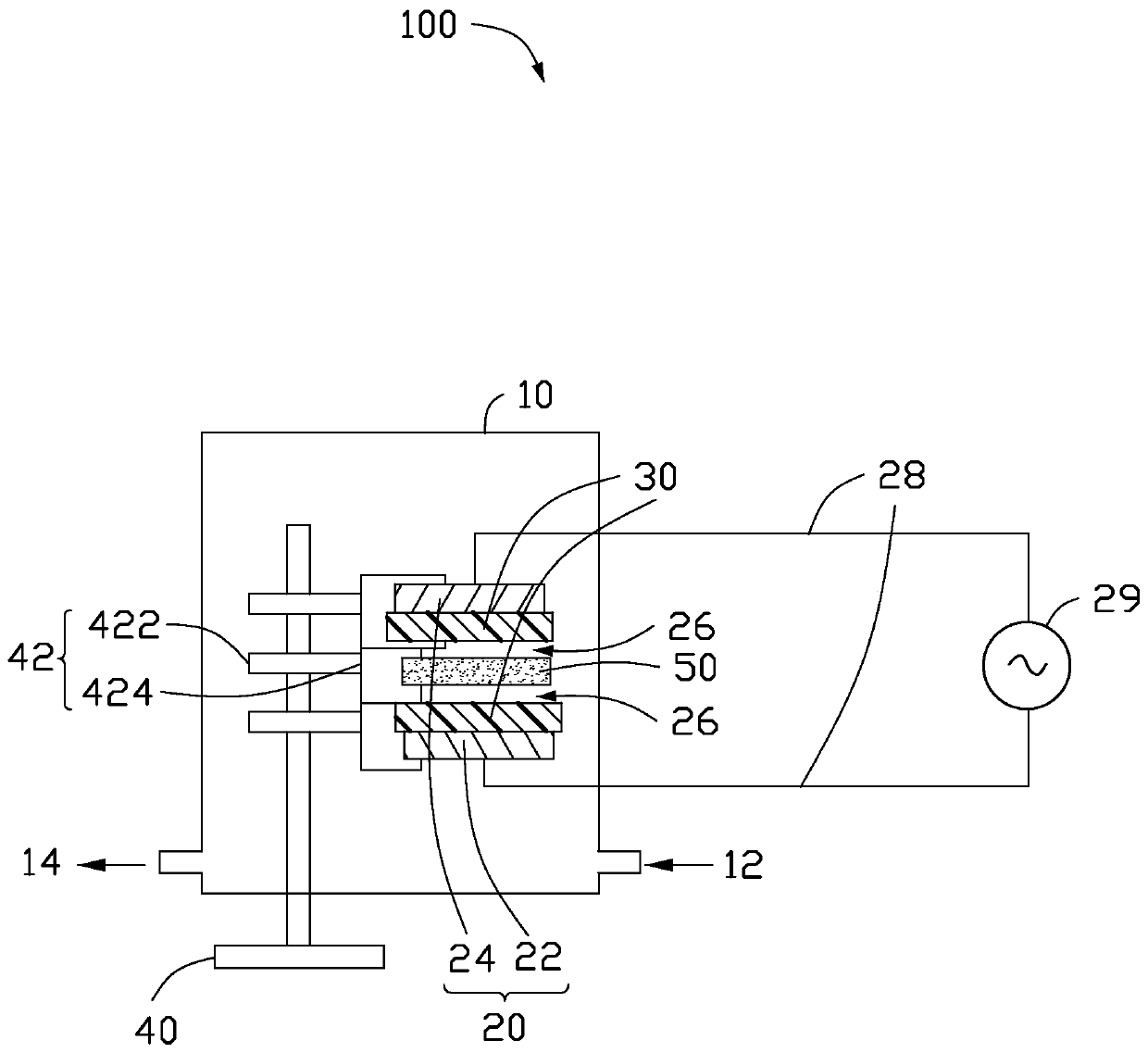

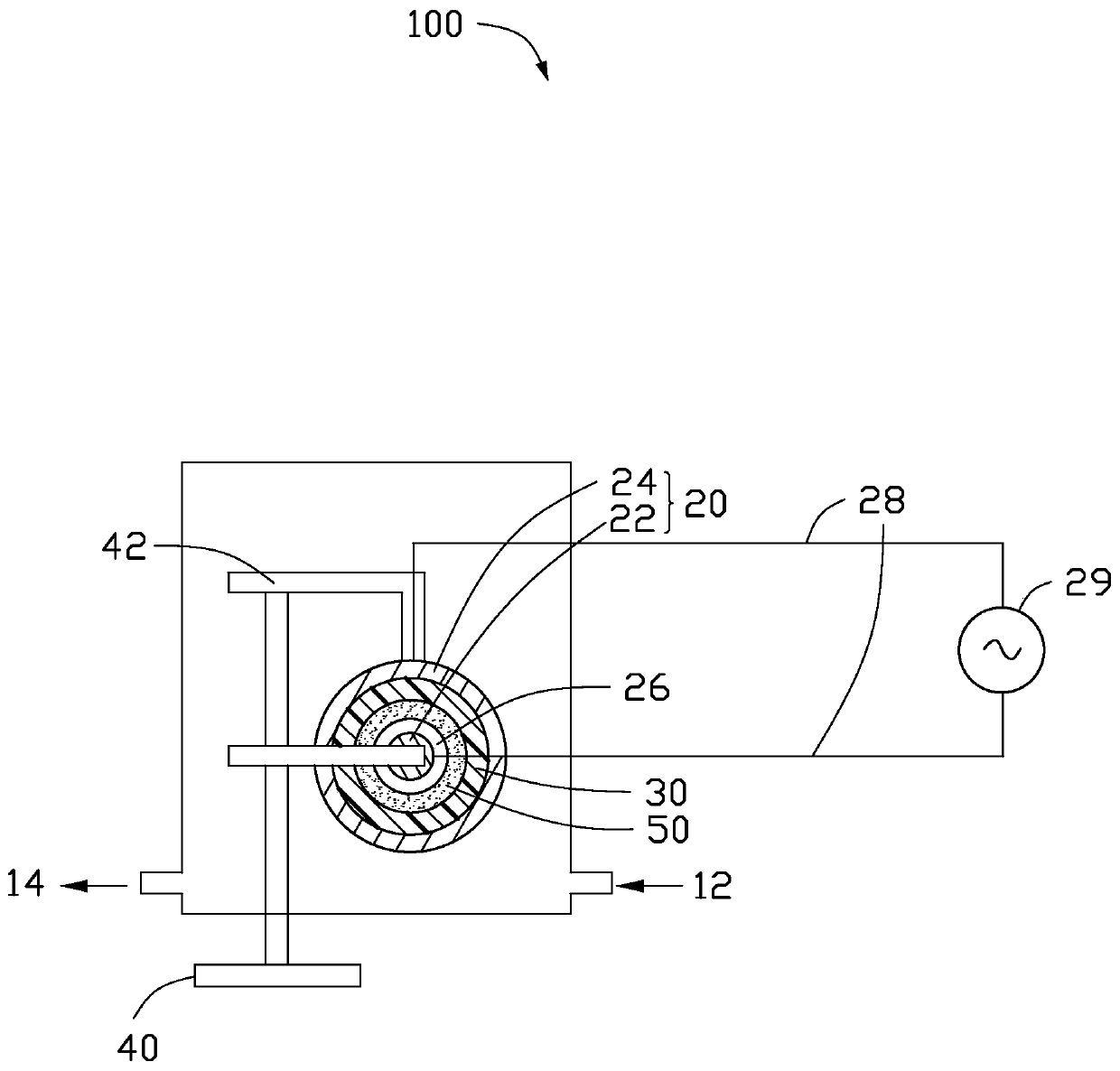

[0051] Step S1: fixing a ceramic green body 50 in the ceramic sintering device 100, the ceramic green body 50 has the same shape as the barrier medium 30 and the electrode 20, and the ceramic green body 50 and the electrode There is an air gap 26 between 20;

[0052] Step S2: passing a specific gas into the ceramic sintering device 100, so that the ceramic green body 50 is placed in the gas;

[0053] Step S3: Turn on the power supply 29, increase the amplitude of the output voltage of the power supply 29, excite the gas in the air gap 26 to generate discharge, and cut off the power supply 29 after maintaining for a certain period of time to obtain ceramics sintered by gas discharge.

Embodiment 1

[0064] A disc-shaped zinc oxide ceramic green body 50 is fixed on figure 1 On the support in the ceramic sintering device 100 shown, wherein, the thickness of the ceramic green body 50 is 1 mm, and the diameter is 10 mm; the first electrode 22 and the second electrode 24 in the ceramic sintering device 100 are circular plates of the same size, The diameter of the electrode 20 is 10 mm; the blocking medium 30 is a square aluminum oxide ceramic sheet, the thickness of the blocking medium 30 is 1 mm, and the side length is 50 mm. The ceramic green body 50 and the barrier medium 30 are tightly bonded without leaving an air gap 26, and an air gap 26 with a thickness of 0.5 mm is left between the barrier medium 30 and the first electrode 22, and the ceramic green body 50 and the second electrode 24 leaving an air gap 26 with a thickness of 0.5 mm. Adopt the AC power supply 29, connect the power supply 29, set the frequency of the voltage to 5kHz, gradually increase the amplitude of...

Embodiment 2

[0066] The difference from Embodiment 1 is that the barrier medium 30 is closely attached to the first electrode 22 and the second electrode 24 without leaving an air gap 26, and the gap between the ceramic green body 50 and the barrier medium 30 is respectively An air gap 26 with a thickness of 0.5 mm is provided. The power supply 29 is a nanosecond pulse power supply, the frequency of the voltage is set to 1kHz, and the pulse width is set to 50ns.

[0067] Others are the same as in Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com