Biomedical Mg-Sn-Mn series magnesium alloy and plate rolling process thereof

A mg-sn-mn, biomedical technology, applied in the field of alloys, can solve the problems of poor plasticity at room temperature and unclear biological effects, and achieve the effect of improving plasticity and strength at room temperature and improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

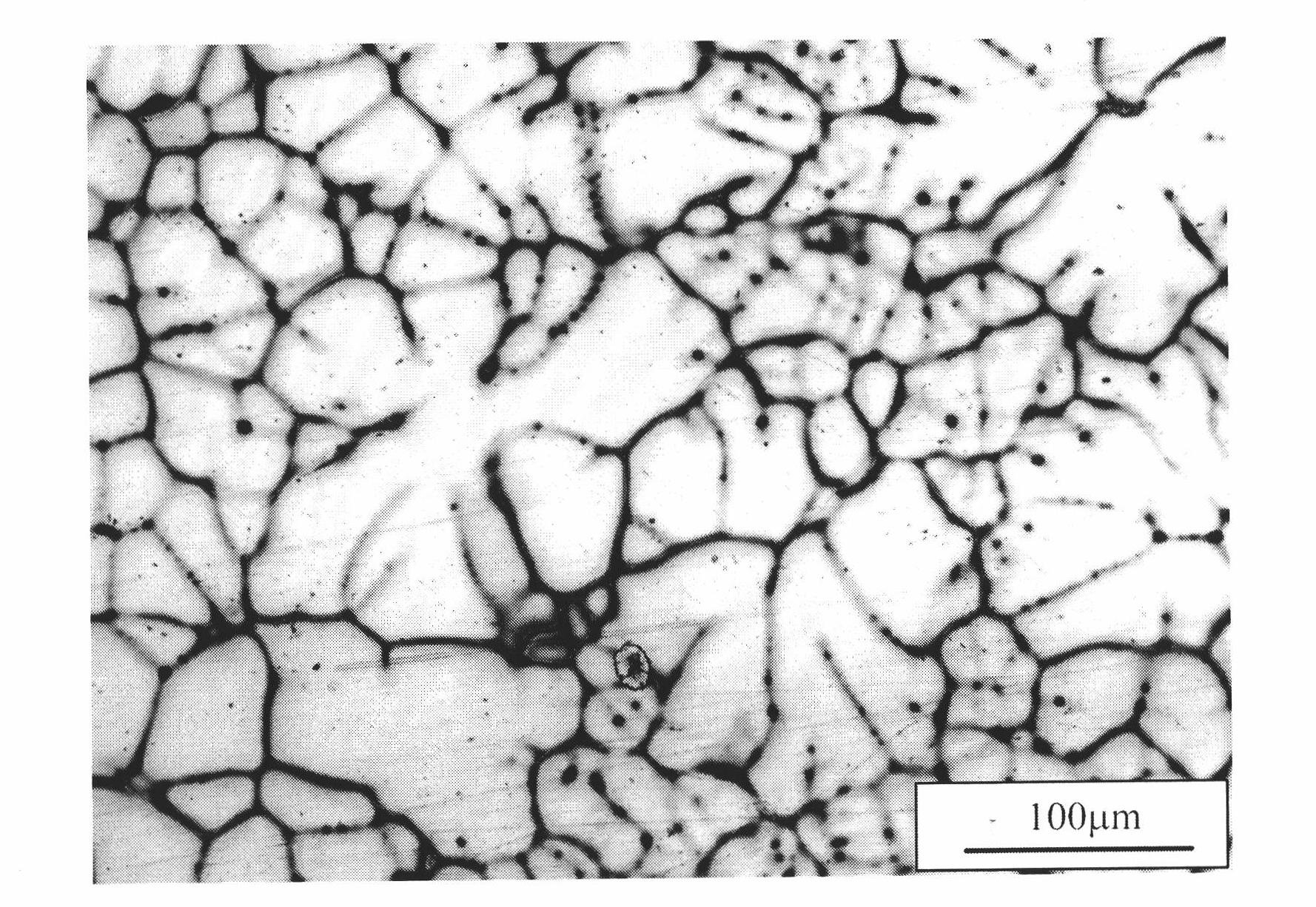

[0028] Using pure magnesium ingot (purity 99.95%), pure tin ingot (purity 99.9%) and Mg-9.7% Mn master alloy, according to Mg-3Sn-0.5Mn alloy composition (nominal composition: Sn 3%, Mn 0.5%, impurity elements Fe6 / CO 2 Under the protection of mixed gas, it is poured into a metal mold for gravity casting. The as-cast Mg-3Sn-0.5Mn alloy metallographic structure obtained by the present invention is as figure 1 Shown.

Embodiment 2

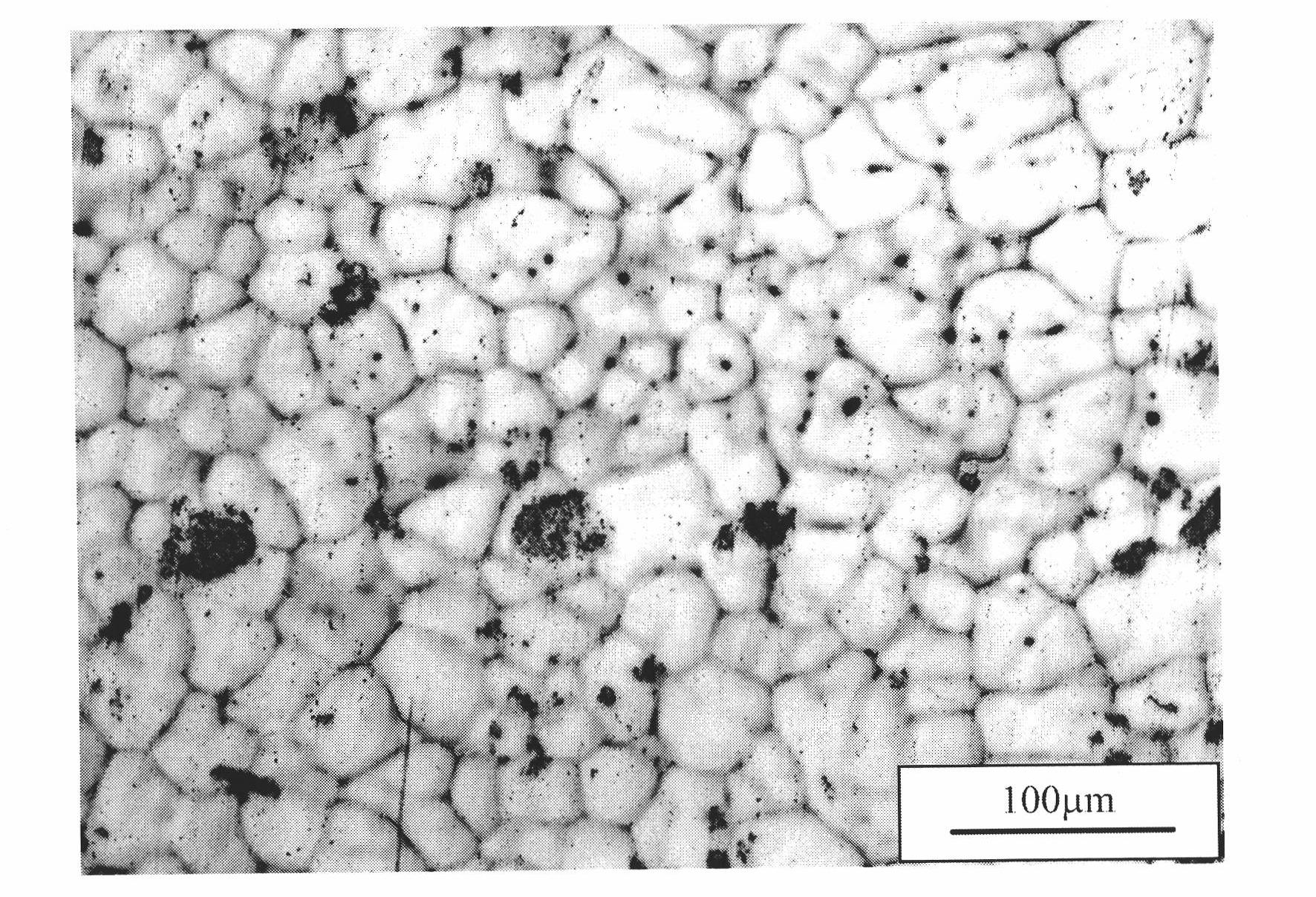

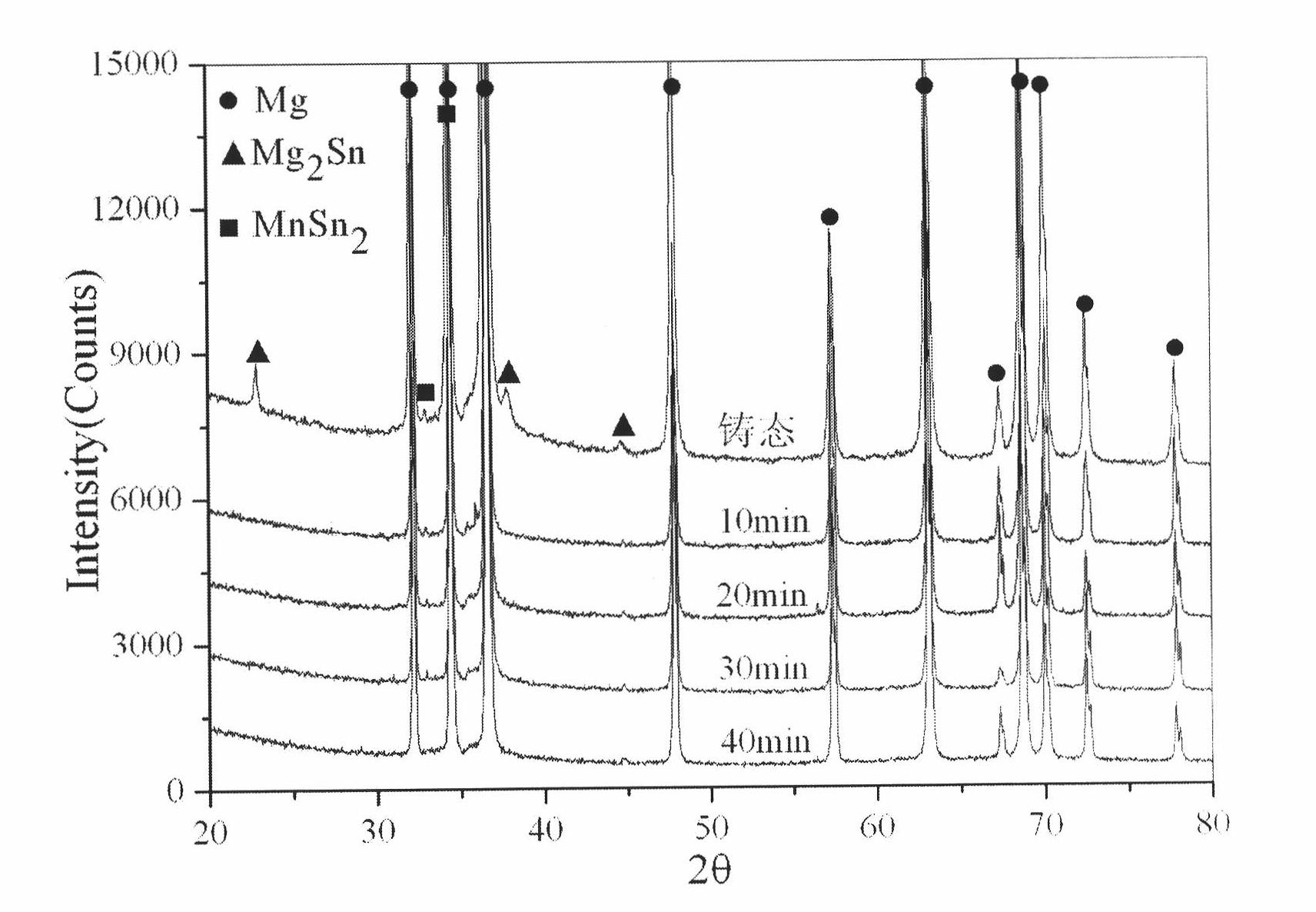

[0030] Using pure magnesium ingot (purity 99.95%), pure tin ingot (purity 99.9%) and Mg-9.7%Mn master alloy, according to Mg-3Sn-1Mn alloy composition (nominal composition: Sn 3%, Mn 1%, impurity element Fe 6 / CO 2 Under the protection of mixed gas, it is poured into a metal mold for gravity casting. The as-cast Mg-3Sn-1Mn alloy metallographic structure obtained by the present invention is as figure 2 Shown. The above-mentioned as-cast Mg-3Sn-1Mn alloy is subjected to high temperature and short-term solution treatment (solution treatment temperature is 555℃, holding time is 10-40min), and its phase composition, namely X-ray diffraction (XRD) pattern, is as follows image 3 Shown.

Embodiment 3

[0032] Before rolling the Mg-3Sn-0.5Mn alloy ingots described in Example 1, two homogenization heat treatment processes were used, which were a combination of traditional solution treatment and high-temperature short-time solution treatment combined with traditional solution treatment, to obtain rolled Mg -3Sn-0.5Mn alloy phase composition, namely X-ray diffraction (XRD) pattern as shown in Figure 4 The rolling state 1 and rolling state 2 are shown. Rolling deformation after homogenization heat treatment: rough rolling billet temperature is 400~450℃, pass reduction is 10-15%; middle rolling temperature is 350~400℃, pass reduction can reach 50-60% ; The finishing temperature is 260~350℃, and the reduction of pass is 5-10%. With the above-mentioned rolling process, the rolling reduction exceeds 90% without cracks. The resulting rolled Mg-3Sn-0.5Mn alloy metallographic structure is as follows Figure 5 As shown, it can be seen from the figure that the grains of the magnesium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com