Method for treating connection strength of reinforced composite material and metal through ultrafast laser

A technology for enhancing composite materials and ultra-fast lasers, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problem of unstable joint interface bonding effect of heterostructure joints, difficult to control mechanical treatment, and pollute the environment. Gas and other problems, to achieve the effect of improving pretreatment efficiency, stable removal effect, and small heat affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with specific examples, but the present invention is not limited to the following examples.

[0030] This embodiment provides a FRP / metal material connection joint strengthening method, including the following steps:

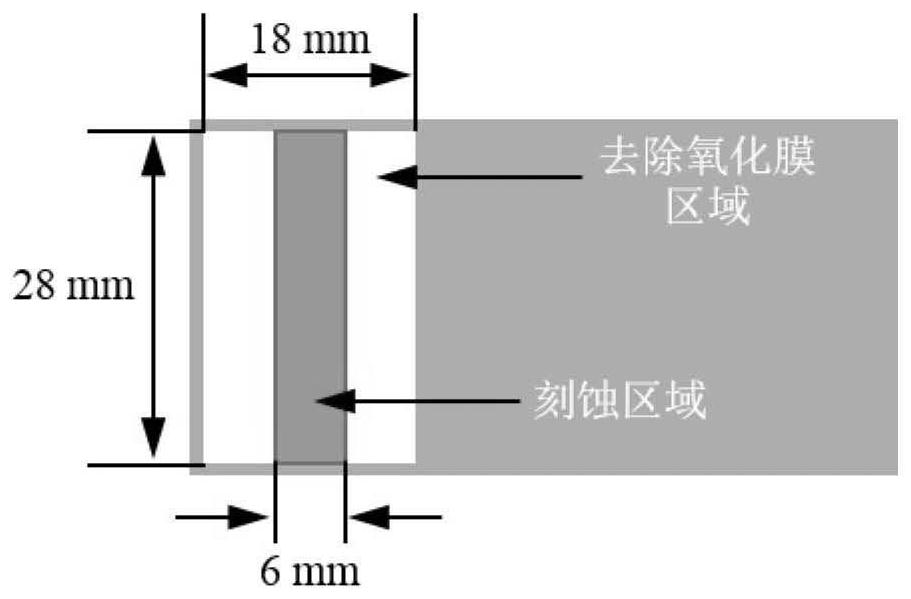

[0031] Step S1, using an ultrafast laser to remove the thin oxide film at the connection interface of the metal material.

[0032] As an advanced processing technology, ultrafast laser has an ultrashort pulse width that can effectively suppress thermal diffusion and realize "cold processing". Therefore, ultrafast lasers have unique advantages in removing metal oxide films.

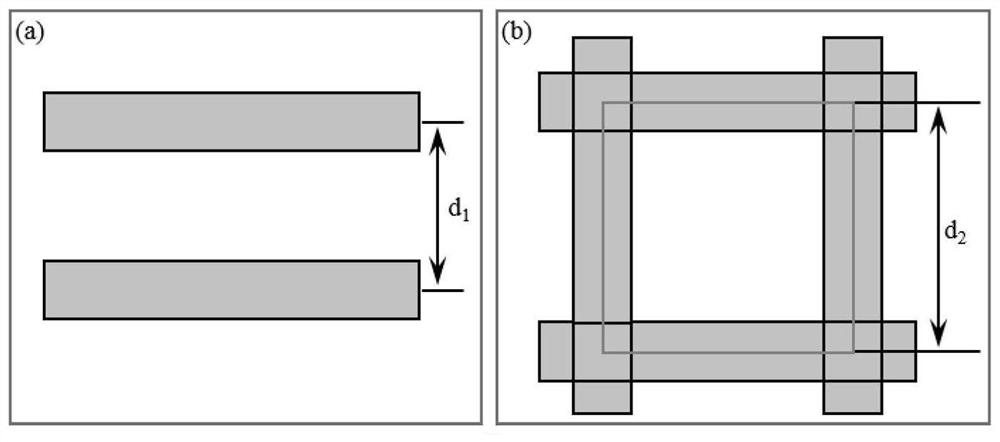

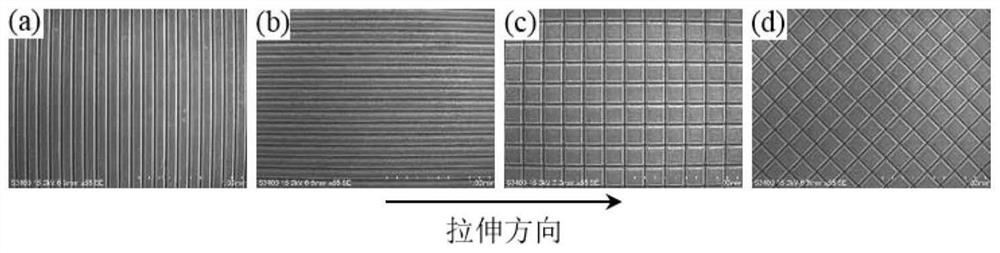

[0033] Step S2, using an ultrafast laser to etch a microstructure on the surface of the metal material after the oxide film has been removed.

[0034] The laser pre-etching treatment and the mechanical bonding enhancement process in the prior art, including sandpaper grinding, shot blasting, etc., are all...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com