Antioxidation/heat insulation integrated composite coating, polyimide composite coated with composite coating and preparation method of polyimide composite

A composite coating, polyimide technology, applied in the coating, metal material coating process, melt spraying and other directions, can solve the high temperature resistance and wear resistance of resin-based composite materials can not meet the needs of practical applications and other problems , to achieve the effect of improving long-term oxidation resistance, low thermal conductivity, and improving high temperature oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

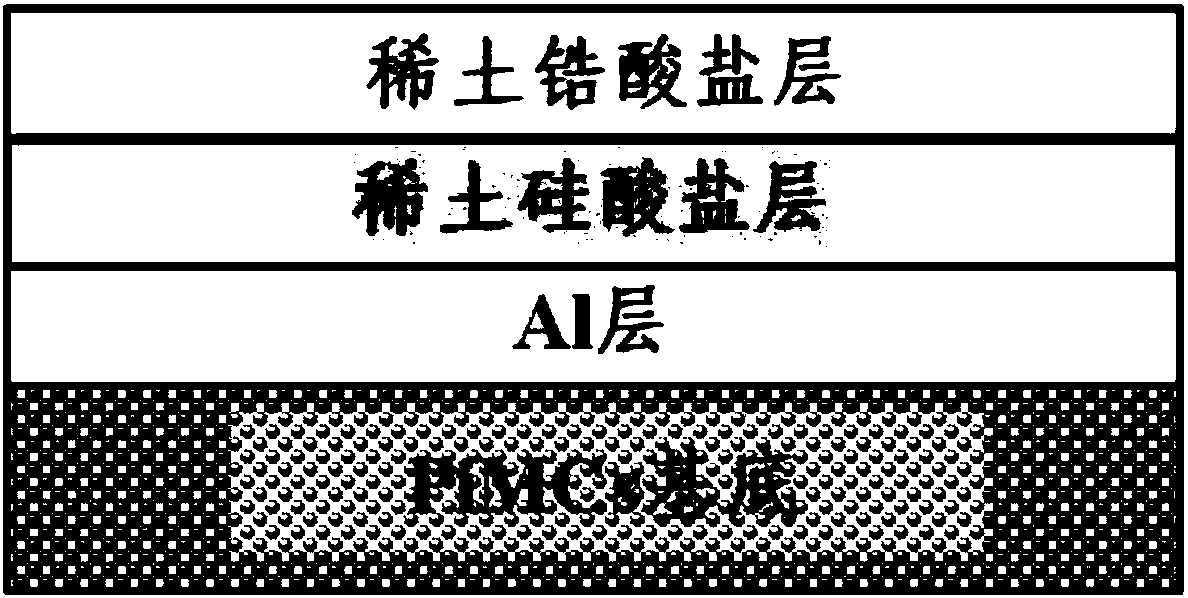

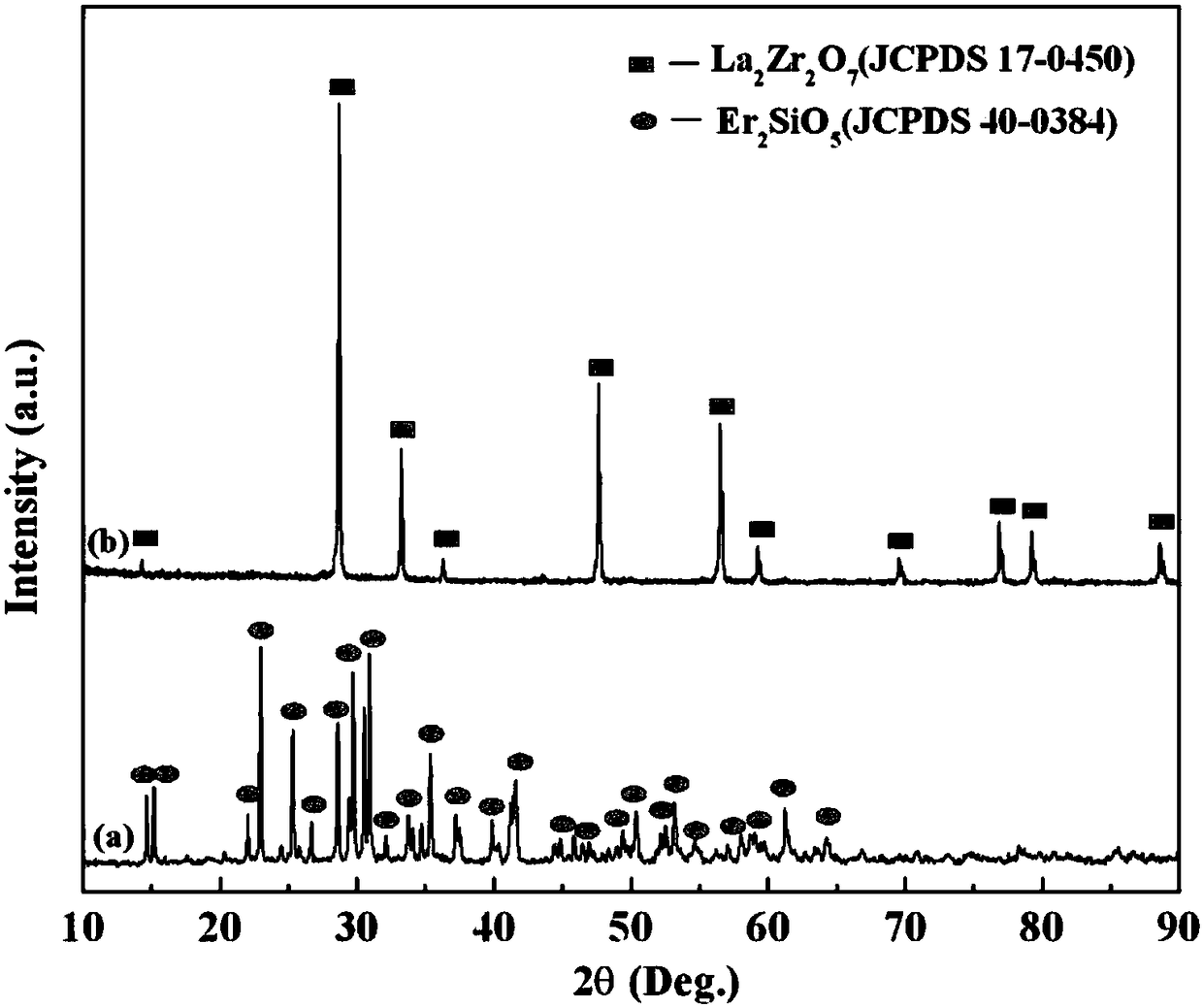

[0037] Such as figure 1 As shown, a polyimide composite material coated with a composite coating on the surface includes a polyimide composite substrate and a composite coating coated on the surface of the polyimide composite substrate. The base of the polyimide composite material is a quartz fiber reinforced polyimide resin matrix composite material, and the composite coating is an anti-oxidation / heat insulation integrated composite coating with a three-layer superimposed structure, starting from the surface of the polyimide composite material base followed by metal Al transition layer, Er 2 SiO 5 For the ceramic inner layer and La 2 Zr 2 o 7 Ceramic outer layer. Among them, the metal Al layer thickness is 31 μm, Er 2 SiO 5 70 μm thick, La 2 Zr 2 o 7 The thickness is 50 μm.

[0038] The preparation method of the polyimide composite material that surface is coated with composite coating in the present embodiment comprises the following steps:

[0039] (1) High-temp...

Embodiment 2

[0080] Such as figure 1 As shown, a polyimide composite material coated with a composite coating on the surface includes a polyimide composite substrate and a composite coating coated on the surface of the polyimide composite substrate. The base of the polyimide composite material is a quartz fiber reinforced polyimide resin matrix composite material, and the composite coating is an anti-oxidation / heat insulation integrated composite coating with a three-layer superimposed structure, starting from the surface of the polyimide composite material base followed by metal Al transition layer, Yb 2 SiO 5 For ceramic inner layer with Nd 2 Zr 2 o 7 Ceramic outer layer. Among them, the thickness of the metal Al layer is 42 μm, and the Yb 2 SiO 5 Thickness 55μm, Nd 2 Zr 2 o 7 The thickness is 120 μm.

[0081] The preparation method of the polyimide composite material that surface is coated with composite coating in the present embodiment is as follows:

[0082] (1) High-temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com