Preparation method for high-purity high-density MAX phase coating

A coating and densification technology, which is applied in the field of preparation of high-purity, strong and dense MAX phase coatings, can solve the problems of reducing the application economy of MAX phase coatings, difficulty in making targets for MAX phase composite targets, and unfavorable application of MAX phase coatings. It is easy to uniformize deposition in a large area, which is beneficial to industrial application and has the effect of low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Put the cleaned and dried substrate into the vacuum cavity.

[0038] (2) Introduce 40 sccm of argon gas into the vacuum chamber, set the current of the linear anode ion source to 0.2A, and the substrate negative bias voltage to -150V, and use the ionized argon ions to etch the substrate for 20 minutes.

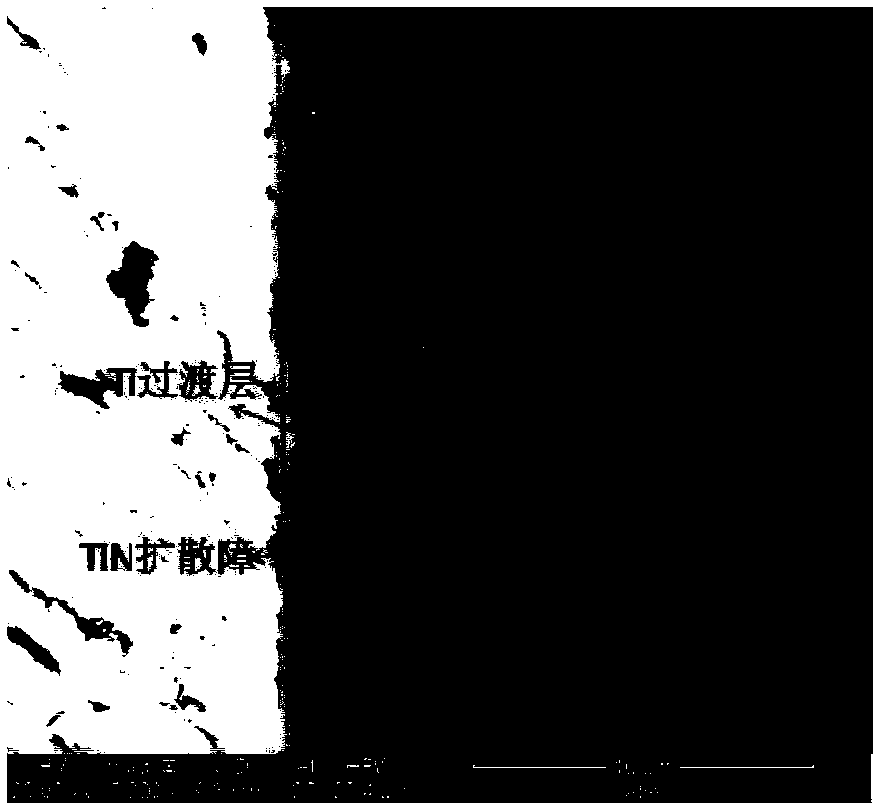

[0039](3) The Ti transition layer was deposited by arc ion plating technology, the sputtering current was 60A, the Ar flow rate was 200sccm, the gas pressure was 1.0Pa, and the deposition thickness was 350nm.

[0040] (4) The TiN diffusion barrier was deposited by arc ion plating technology, the sputtering current was 60A, N 2 The flow rate is 500 sccm, the gas pressure is 5.0 Pa, and the deposition thickness is 500 nm.

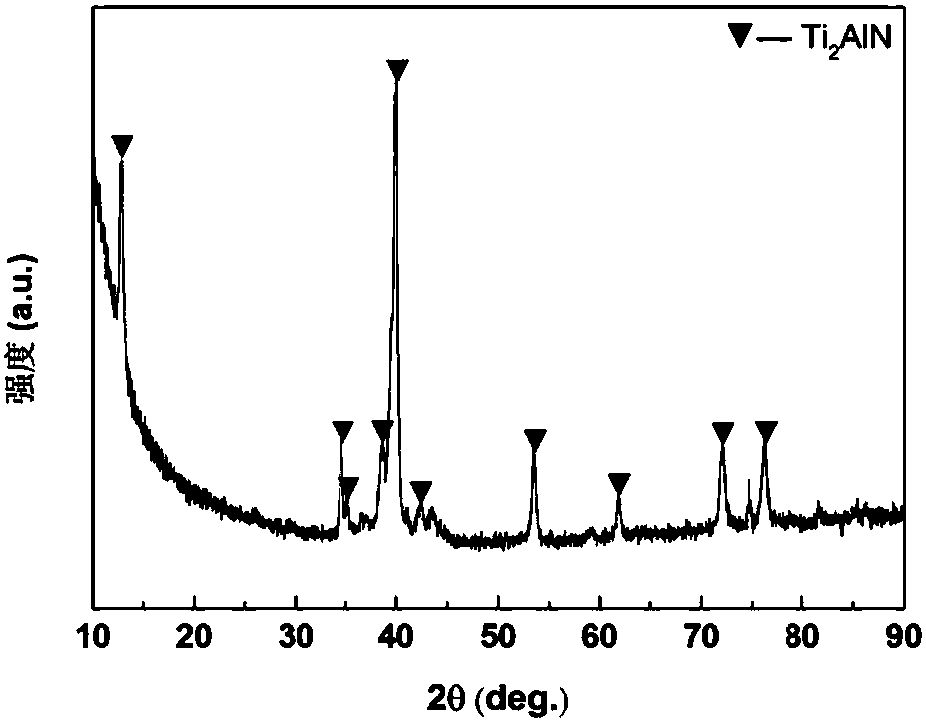

[0041] (5) The Ti-Al-N coating is deposited by arc composite magnetron sputtering technology, the arc target is Ti target, the magnetron sputtering target is Al target, the substrate is placed between the arc and the magnetron sputtering target, a...

Embodiment 2

[0058] (1) Put the cleaned and dried substrate into the vacuum cavity.

[0059] (2) Introduce 40 sccm of argon gas into the vacuum chamber, set the current of the linear anode ion source to 0.2A, and the substrate negative bias voltage to -150V, and use the ionized argon ions to etch the substrate for 20 minutes.

[0060] (3) The Cr transition layer was deposited by arc ion plating technology, the sputtering current was 60A, the Ar flow rate was 200sccm, the gas pressure was 1.0Pa, and the deposition thickness was 350nm.

[0061] (4) The CrN diffusion barrier was deposited by arc ion plating technology, the sputtering current was 60A, N 2 The flow rate is 500 sccm, the gas pressure is 5.0 Pa, and the deposition thickness is 500 nm.

[0062] (5) The Cr-Al-C coating is deposited by arc composite magnetron sputtering technology, the arc target is Ti target, the magnetron sputtering target is Al target, the substrate is placed directly in front of the magnetron sputtering target,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com