Process for clearing metal grinding materials for derusting by using special steel wires for steel wire rope

A metal abrasive and wire rope technology, applied in metal processing equipment, abrasives, manufacturing tools, etc., can solve the problems of unstable surface cleaning quality of metal workpieces, large surface roughness of metal workpieces, and increased cost investment, etc. The cleaning quality is stable and the effect of preventing dust pollution of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

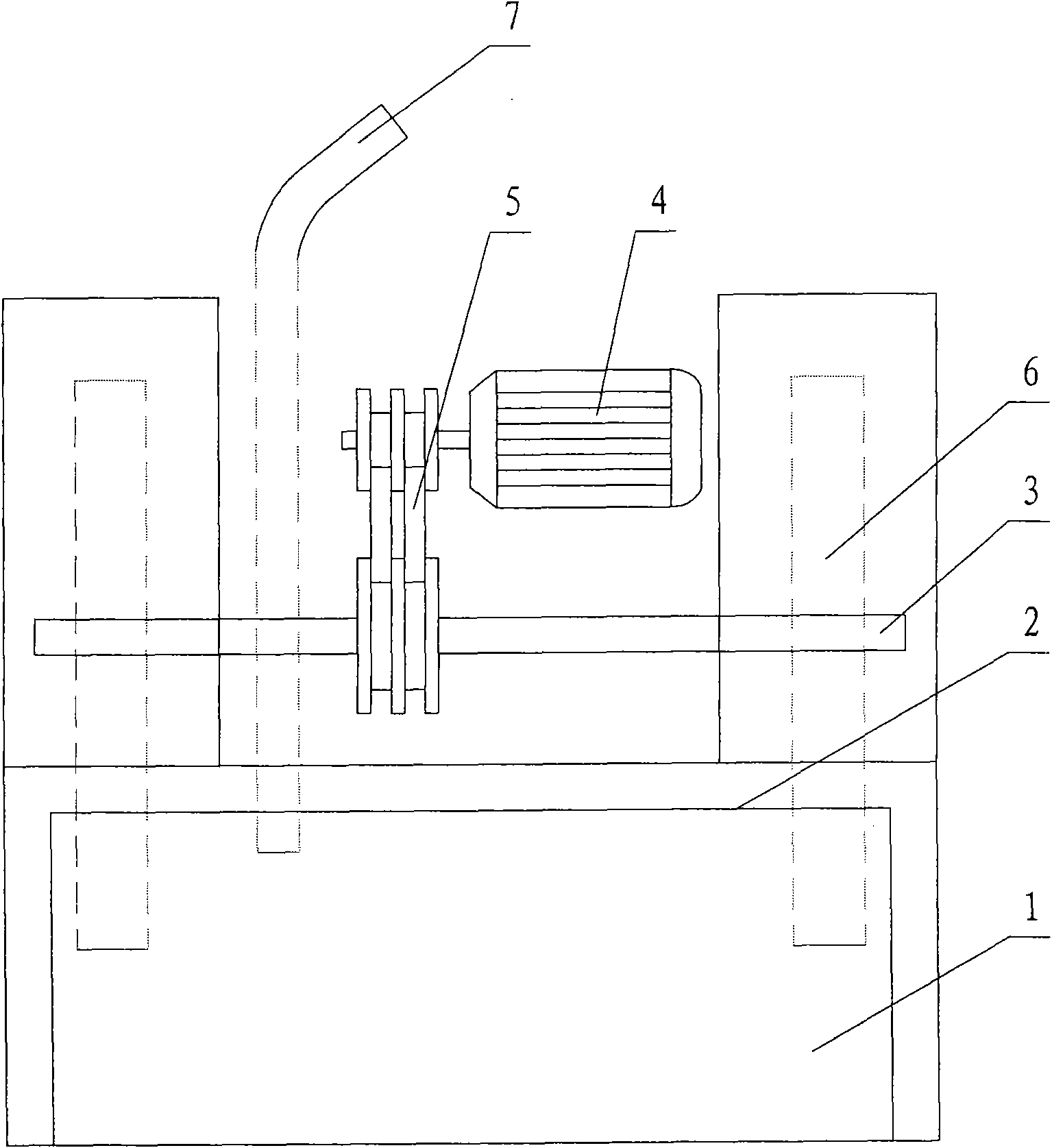

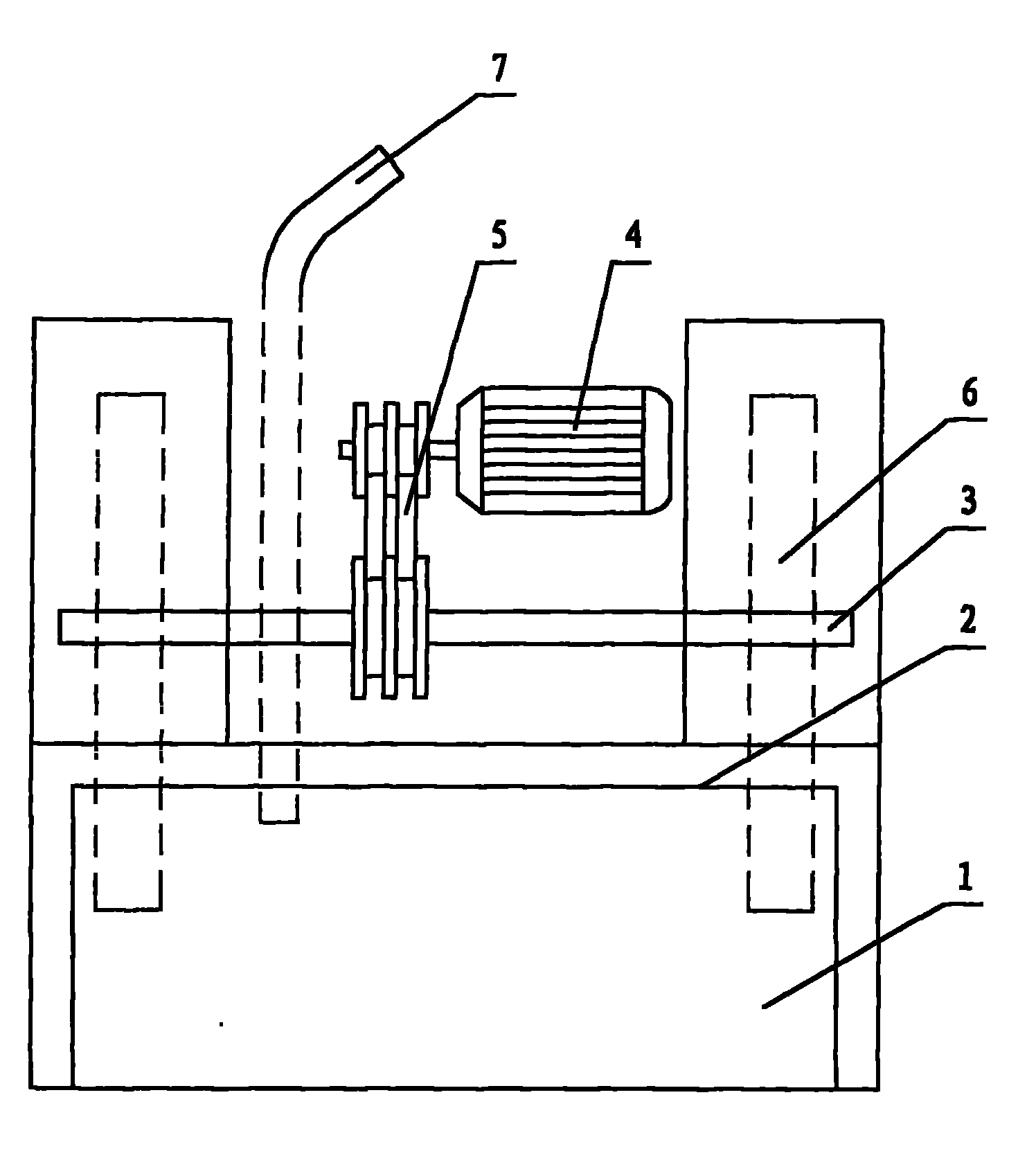

Embodiment Construction

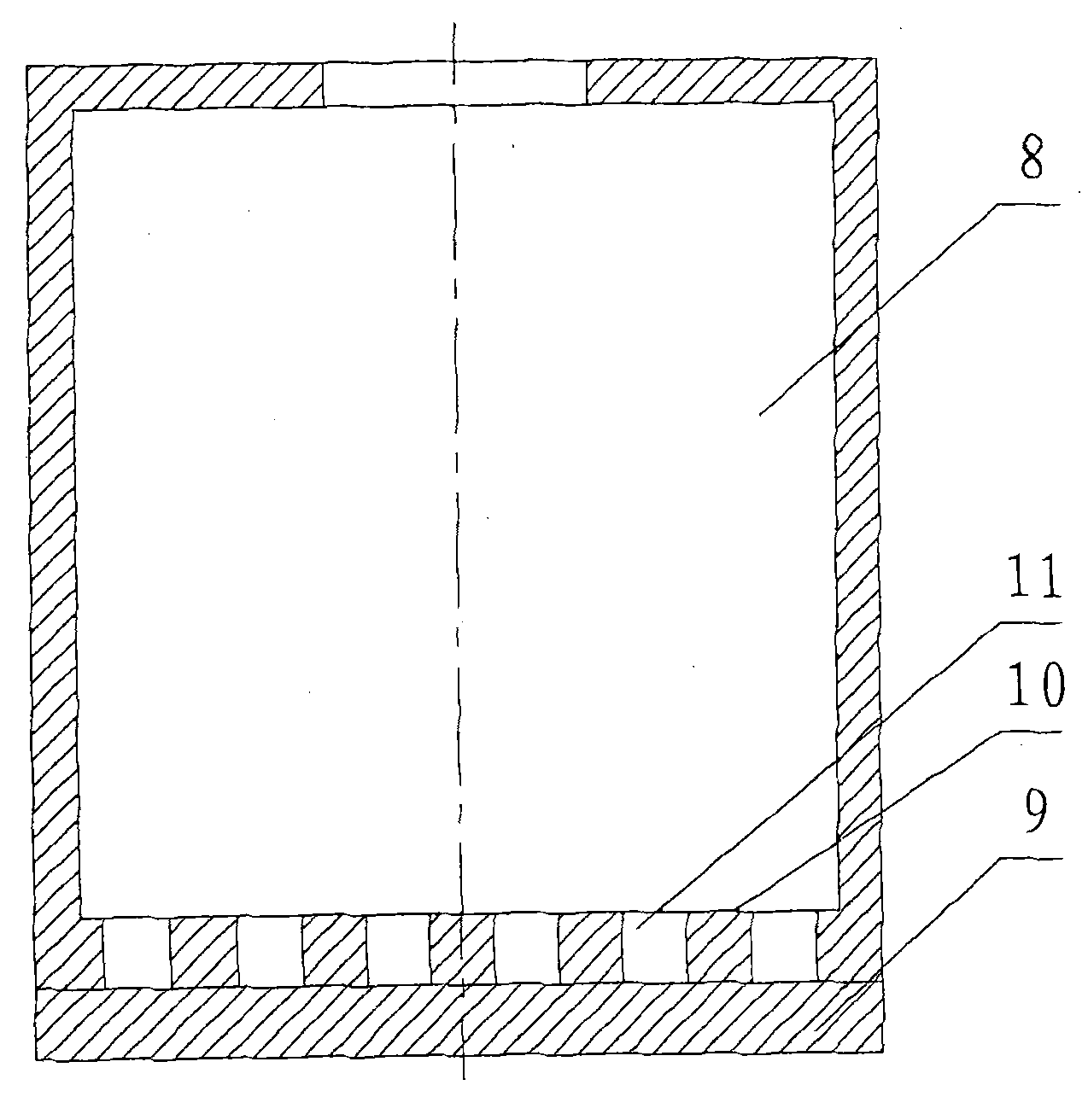

[0021] A process for making metal abrasives for cleaning and derusting with special steel wires for steel wire ropes, which is carried out in accordance with the following steps: ① disassemble the steel wire ropes into single strands of steel wires, and classify them according to diameter; ② cut the above steel wires into cylindrical steel wires by a steel wire cutting machine Cut into sections, the length of which is 1-2 times the diameter; ③Put the above-mentioned cylindrical steel wire cut sections into the rounding machine, and throw them repeatedly at a speed of 75 m / s for 30-100 minutes to remove the acute angle until it becomes Round to form a steel shot; ④ Select the steel shot in the round selector to remove unqualified products such as inclined planes, fishhooks, overlong, burrs; ⑤ Use the steel shot screened by the round selector A sieve with a diameter of 0.2 mm is used to remove debris; ⑥Packing and storage.

[0022] The above steel wire is made of 65 manganese sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com