Light metal surface laser impact micronano particle injection reinforcing method

A technology of micro-nano particles and laser shock, which is applied in the field of surface modification of light metal materials, can solve the problems of limiting the application range of light metal materials, poor surface hardness and wear resistance, and burning of light alloy elements, so as to improve surface hardness and improve performance , the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

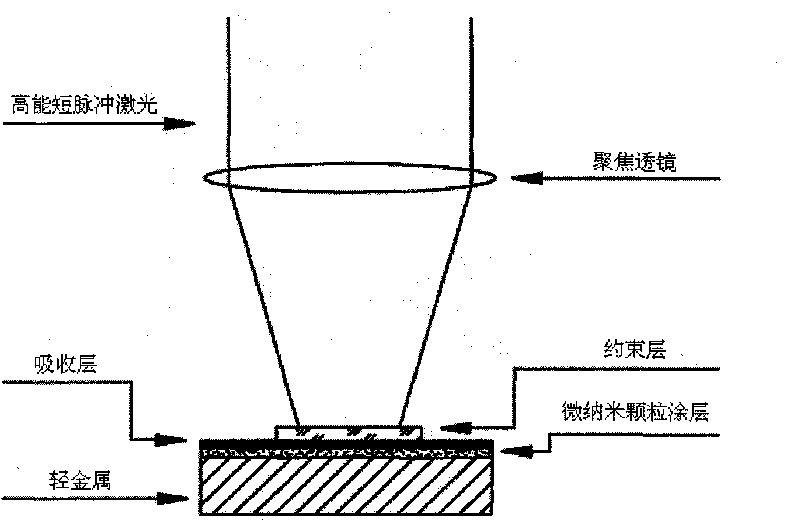

[0027] Example 1: Laser Shock Nanoparticle Implantation Strengthening Method on Aluminum Alloy Surface

[0028] Aluminum alloys are widely used, but common melting strengthening methods may cause defects such as light element burning and cracks. The method of the present invention is implemented on the surface of aluminum alloys for laser shock nanoparticle injection strengthening, which includes the following steps:

[0029] (1) First remove the oxide layer on the surface of the aluminum alloy by mechanical grinding, then polish it with 800# metallographic sandpaper, and finally clean the surface of the aluminum alloy with acetone;

[0030] (2) Pre-coat WC particles with a particle size of 100 nanometers on the surface of the aluminum alloy with an inorganic binder. The thickness of the nano-WC particle coating is 0.1 mm. The thickness of the layer is 0.2mm, dry naturally;

[0031] (3) Use high-energy short-pulse Nd:YAG laser to shock the above-mentioned absorbing layer and ...

Embodiment 2

[0035] Example 2: Laser Shock Micron Particle Implantation Strengthening Method on Magnesium Alloy Surface

[0036] Magnesium alloys have a very wide range of applications, but common melting strengthening methods may cause defects such as light element burning, pores and cracks. The method of the present invention is implemented on the surface of magnesium alloys for laser shock micron particle injection strengthening, which includes the following steps:

[0037] (1) First remove the oxide layer on the surface of the magnesium alloy by chemical etching, then polish it with 900# metallographic sandpaper, and finally clean the surface of the magnesium alloy with alcohol;

[0038] (2) Pre-coat SiC particles with a particle size of 100 microns on the surface of the magnesium alloy with an inorganic binder. The coating thickness of the micron SiC particles is 0.5 mm. The thickness of the layer is 0.5mm, dry naturally;

[0039] (3) Use high-energy short-pulse Nd:YAG laser to shock t...

Embodiment 3

[0042] Example 3: Laser Shock Nanoparticle Implantation Strengthening Method on Titanium Alloy Surface

[0043] Titanium alloy has a very wide range of applications, but the common melting strengthening method may cause defects such as light element burning, pores and cracks. The method of the present invention is implemented on the surface of titanium alloy by laser shock nanoparticle implantation strengthening, which includes the following steps:

[0044] (1) First remove the oxide layer on the surface of the titanium alloy by mechanical grinding, then polish it with 1000# metallographic sandpaper, and finally clean the surface of the titanium alloy with acetone;

[0045] (2) Use an inorganic binder to pre-coat TiC particles with a particle size of 1 nanometer on the surface of the titanium alloy. The thickness of the nano-TiC particle coating is 1 mm. After drying, apply a layer of black paint as an absorbing layer for laser shock. The thickness is 1mm, dry naturally;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com