Efficient nitrogen and phosphorus fire retardant for epoxy resin and preparation method of efficient nitrogen and phosphorus fire retardant

A technology for nitrogen-phosphorus flame retardants and epoxy resins, applied in the field of high-efficiency nitrogen-phosphorus flame retardants, to achieve the effects of simplified process steps, high char formation rate and glass transition temperature, and improved flame retardant and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

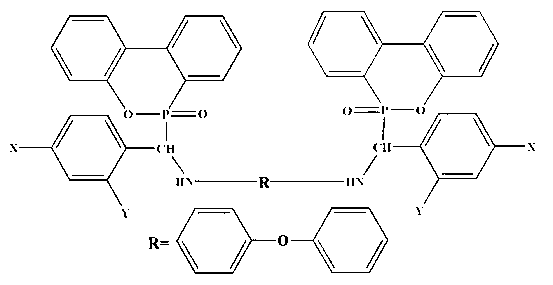

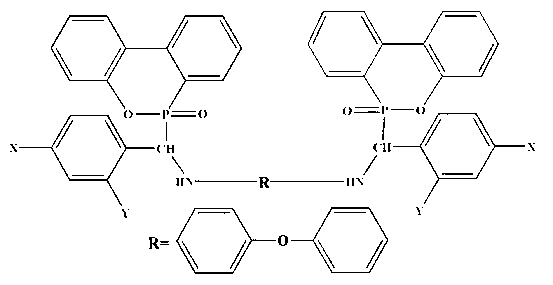

Image

Examples

Embodiment 1

[0024] flame retardant ( 1 ) The synthetic steps are as follows:

[0025] Add 10.01 g of DDE, 10.61 g of benzaldehyde and 412 g of absolute ethanol into a three-necked flask with a stirring device, and under stirring, the reaction temperature is 0°C for 2-4 h until the end of the reaction;

[0026] Then, 21.62g DOPO was added to the reaction mixture in the three-necked flask, and under stirring, the reaction temperature was 0°C for 18 hours. After the reaction, the final mixture was suction-filtered, washed, and dried in a vacuum oven at 60°C. Dry 8h, obtain required flame retardant ( 1 ).

[0027] flame retardant ( 1 ) test analysis results are as follows:

[0028] 1 H HMR (ppm, DMSO-d 6 ), δ=4.96-5.10 (H), 5.45-5.57 (H), 6.10 (NH), 6.40-6.51 (2H), 6.55 (NH), 6.57-6.68 (2H), 7.05 (H), 7.20 (H ), 7.25-7.35 (6H), 7.35-7.43 (2H), 7.43-7.50 (3H), 7.55 (H), 7.70-7.80 (2H), 7.95-8.05 (2H), 8.15-8.25 (4H).

[0029] 13 C NMR (ppm, DMSO-d 6 ), Δ = 55.3, 56.5, 56.9, 57.7, 115...

Embodiment 2

[0034] flame retardant ( 2 ) The synthetic steps are as follows:

[0035] Add 10.01 g of DDE, 12.21 g of 4-hydroxybenzaldehyde and 200 g of absolute ethanol into a three-necked flask with a stirring device. Under stirring, the reaction temperature is 30 ° C for 2-4 h until the end of the reaction;

[0036] Then, 21.62g DOPO was added to the reaction mixture in the three-necked flask, and under stirring, the reaction temperature was 30°C for 18 hours. After the reaction, the final mixture was suction filtered, washed, and dried in a vacuum oven for 60 ℃ drying for 8 h to obtain the required flame retardant ( 2 ).

[0037] flame retardant ( 2 ) test analysis results are as follows:

[0038] 1 H HMR (ppm, DMSO-d 6 ), δ=4.80-4.91 (H), 5.20-5.33 (H), 5.98 (NH), 6.40 (NH), 6.45-6.70 (8H), 7.05 (H20), 7.15-7.23 (3H), 7.40-7.50 (H), 7.55 (H), 7.70-7.80 (2H), 7.95-8.05 (2H), 8.15-8.25 (4H), 9.36 (H), 9.40 (H).

[0039] 13 C NMR (ppm, DMSO-d6), δ=55.1, 55.8, 56.5, 57.0, 115.0, 11...

Embodiment 3

[0044] flame retardant ( 3 ) The synthetic steps are as follows:

[0045] Add 10.01g of DDE, 12.21g of 2-hydroxybenzaldehyde and 89g of ethyl acetate into a three-necked flask with a stirring device, and under stirring, the reaction temperature is 60°C for 2-4 hours;

[0046] Then, 21.62g DOPO was added to the reaction mixture in the three-necked flask, and under stirring, the reaction temperature was 60°C for 18 hours. After the reaction, the final mixture was suction-filtered, washed, and dried in a vacuum oven for 60 ℃ drying for 8 h to obtain the required flame retardant ( 3 ),

[0047] flame retardant ( 3 ) test analysis results are as follows:

[0048] 1 H HMR (ppm, DMSO-d 6 ), δ=5.20 (H), 5.35(H), 6.12 (NH), 6.40-6.60 (7H), 6.70-6.80 (4H), 7.02 (2H), 7.09 (H), 7.13(H), 7, 25-7.45 (4H), 7.50 (H), 7.58 (H), 7.65-7.80 (2H), 8.00-8.10 (2H), 8.15-8.25 (4H), 9.40 (H), 9.54 (H).

[0049] 13 C NMR (ppm, DMSO-d 6 ), Δ = 48.4, 49.5, 49.7, 50.7, 115.0, 119.5, 120.5, 121....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com