Method for preparing heat-fatigue-resistance wear-resistance laminated particle reinforced composite material

A technology of particle reinforcement and composite materials, which is applied in the field of metal matrix composite materials, can solve the problems of being unsuitable for large-scale industrial production, easy to form slag inclusions, poor process controllability, etc., and achieve the convenience of large-scale industrial production, stable production quality, The effect of high overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

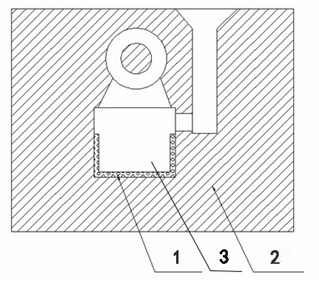

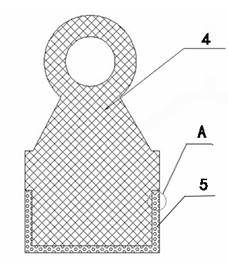

[0032] (1) Mix Ni6025WC powder with a particle size of 150 mesh with tungsten carbide particles with a particle size of -40~+60 mesh, add polyvinyl alcohol (PVA) to make a preformed block (such as figure 1 Award number 1), where the volume fraction of the nickel-based self-fluxing alloy powder in the prefabricated block is 15%; the volume fraction of the binder in the prefabricated block is 2%;

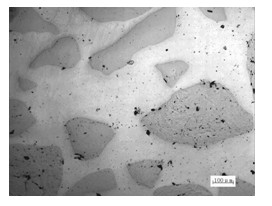

[0033] (2) Using conventional lost foam casting, using cutting methods according to the shape and structure of the wear-resistant parts, adopting a gasifiable hammer head foam model made of polystyrene (EPS), and coating the prefabricated blocks on the wear-resistant parts to withstand heat Circulate and wear surfaces, then melt alloy steel Cr15 high chromium steel to a pouring temperature of 1580°C, pour it into the cavity where the preform obtained in step (1) is placed, cool and solidify at room temperature, and clear the sand to obtain The wear-resistant layered particle reinforced co...

Embodiment 2

[0036] (1) Ni25A powder with a particle size of 180 mesh and silicon carbide and tungsten carbide particles with a particle size of 40 mesh are uniformly mixed, and polyvinyl alcohol (PVA) is added to form a prefabricated block. Among them, the nickel-based self-fluxing alloy powder accounts for the prefabricated block. The volume fraction of the prefabricated block is 10%; the volume fraction of the binder in the prefabricated block is 2%;

[0037] (2) Using conventional sand casting, pre-embed the prefabricated block in the hammer-head sand mold cavity made of resin sand according to the casting process requirements, and then smelt high carbon steel (ordinary carbon steel) to a pouring temperature of 1580 ℃, then put it Pouring into the cavity where the prefabricated block obtained in step (1) is placed, cooling and solidifying at room temperature, and after sand cleaning, a heat-resistant fatigue-resistant layered composite wear-resistant layer, metallurgical transition layer, ...

Embodiment 3

[0039] (1) Ni25B powder with a particle size of 200 meshes and silicon carbide and tungsten carbide particles with a particle size of 60 meshes are mixed uniformly, and polyvinyl alcohol (PVA) is added to form a prefabricated block. Among them, the nickel-based self-fluxing alloy powder accounts for the prefabricated block. The volume fraction of the binder is 15%; the volume fraction of the binder in the prefabricated block is 2%;

[0040] (2) Using conventional sand casting, pre-embed the prefabricated block in the hammerhead sand mold cavity made of sodium silicate sand according to the casting process requirements, and then smelt high carbon steel (ordinary carbon steel) to the pouring temperature, then pour it Put the prefabricated block obtained in step (1) into the cavity, cool and solidify at room temperature, and then clean the sand to obtain a wear-resistant layer composed of heat-resistant fatigue-resistant layered composite wear-resistant layer, metallurgical transitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com