Modified biological asphalt material, preparation method thereof and application of material

A bio-asphalt and modified technology, applied in building insulation materials, building structures, building components, etc., can solve the problems of general bearing capacity and limited high temperature rutting resistance, achieve good bearing capacity, improve high temperature stability, and improve Effects of softening point and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

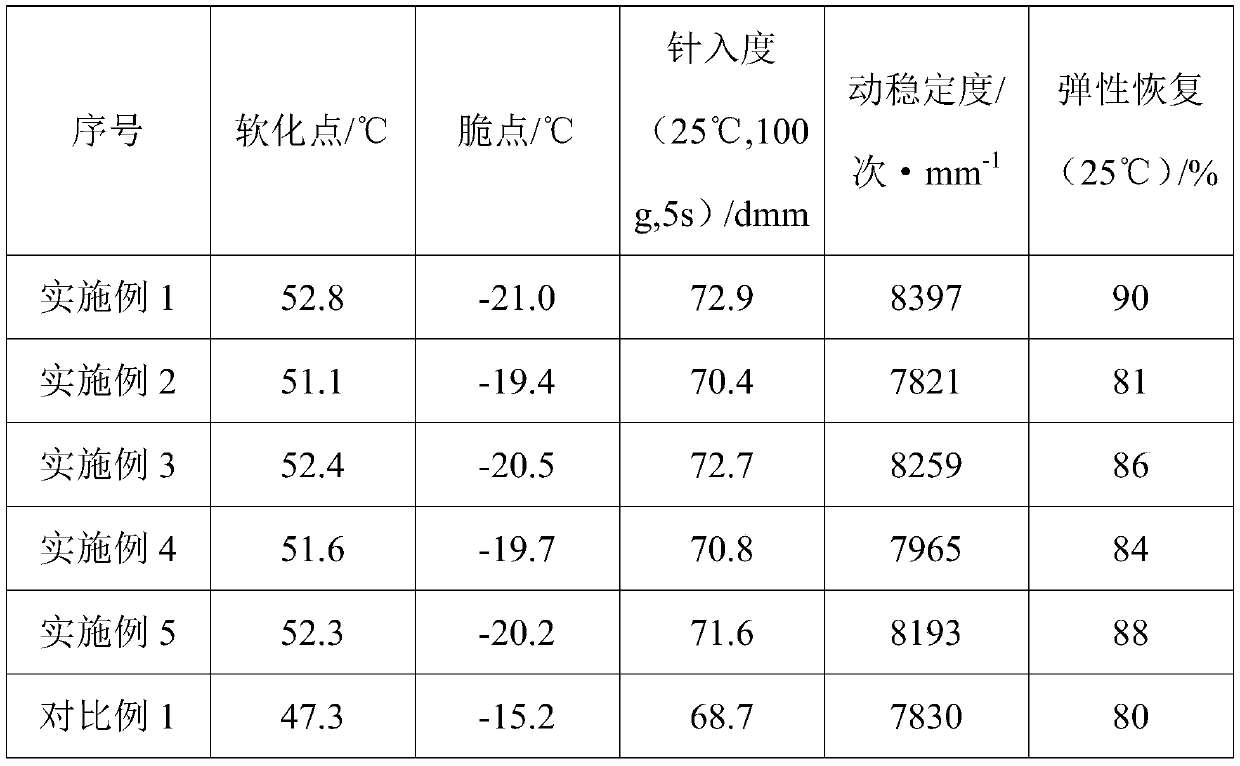

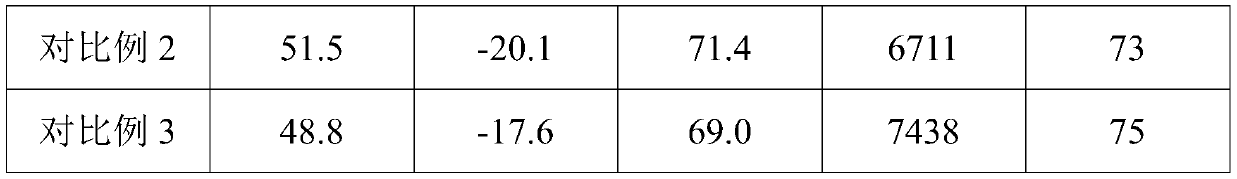

Examples

Embodiment 1

[0028] This embodiment provides a modified asphalt material, including: 58g of bio-asphalt, 12g of 70-mesh rubber, 2g of sulfur, 18g of glycerin, and 0.4g of chopped mineral fiber. The method for preparing the modified asphalt material by using the above-mentioned raw materials comprises the following steps:

[0029] (1) Grind and stir 58g of bio-asphalt and 12g of 70-mesh rubber at 110°C for 15 minutes to obtain mixture A 1 ;

[0030] (2) the mixture A 1 Mix with 2g of sulfur and 18g of glycerin at 160°C for 15 minutes, then add 0.4g of chopped mineral fiber and stir for 8 minutes to obtain mixture B 1 ;

[0031] (3) mix mixture B 1 Stirring at 160° C. for 70 minutes at a stirring speed of 500 r / min.

[0032] The chopped mineral fibers used in this example are basalt fibers with a length of 6 mm.

Embodiment 2

[0034] This embodiment provides a modified asphalt material, including: 30g of bio-asphalt, 10g of 100-mesh resin, 3g of polyvinyl alcohol, 25g of rubber oil, and 0.6g of mineral wool fiber.

[0035] The method for preparing the modified asphalt material by using the above-mentioned raw materials comprises the following steps:

[0036] (1) Grind and stir 30g of bio-asphalt and 10g of 100-mesh resin at 120°C for 10 minutes to obtain mixture A 2 ;

[0037] (2) the mixture A 2 Mix with 3g of polyvinyl alcohol and 25g of rubber oil at 180°C for 10 minutes, then add 0.6g of mineral wool fiber and stir for 10 minutes to obtain mixture B 2 ;

[0038] (3) mix mixture B 2 Stirring at 140° C. for 80 minutes at a stirring speed of 600 r / min to obtain the obtained product.

[0039] The mineral wool fibers used in this embodiment are basalt fibers with a length of 4-8 mm.

Embodiment 3

[0041] This embodiment provides a modified asphalt material, including: 78g of bio-asphalt, 15g of 40-mesh thermoplastic elastomer, 1g of polyvinyl alcohol, 10g of pine oil, and 0.2g of chopped mineral fiber.

[0042] The method for preparing the modified asphalt material by using the above-mentioned raw materials comprises the following steps:

[0043] (1) Grind and stir 78g of bio-asphalt and 15g of 40-mesh thermoplastic elastomer at 100°C for 20 minutes to obtain mixture A 3 ;

[0044] (2) the mixture A 3 Mix with 1g of polyvinyl alcohol and 10g of pine oil at 140°C for 20 minutes, then add 0.2g of chopped mineral fiber and stir for 5 minutes to obtain mixture B3 ;

[0045] (3) mix mixture B 3 Stirring at 180° C. for 60 minutes at a stirring speed of 400 r / min.

[0046] The chopped mineral fibers used in this example are carbon fibers with a length of 3 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com