Fire retardant used for polylactic acid, antiflaming polylactic acid material and preparation method of fire retardant

A polylactic acid material and polylactic acid technology, applied in the field of polymer materials, can solve problems such as poor compatibility, flammability and heat resistance, and reduction of physical and mechanical properties of polylactic acid materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A method for preparing a flame retardant for polylactic acid according to an embodiment of the present invention includes the following steps S1-S2:

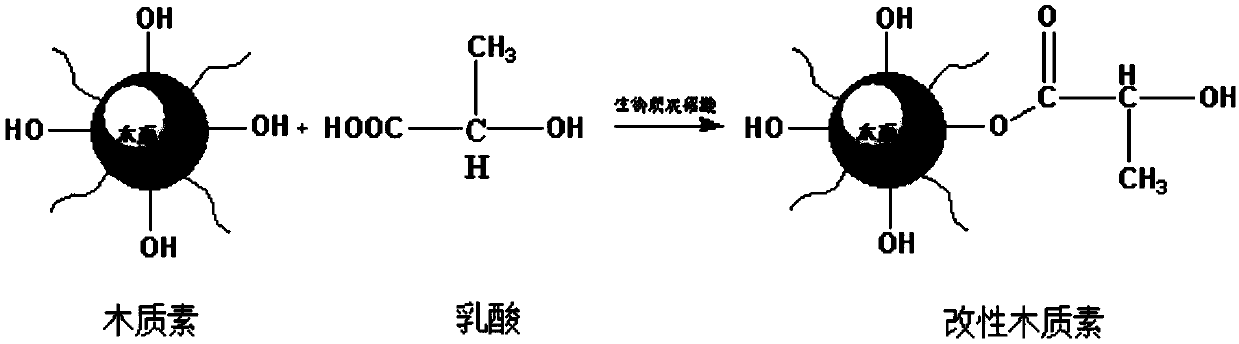

[0022] S1. Provide modified lignin. The preparation method of modified lignin includes the following steps: mixing lignin, lactic acid and biomass charcoal sulfonic acid and extruding to obtain modified lignin.

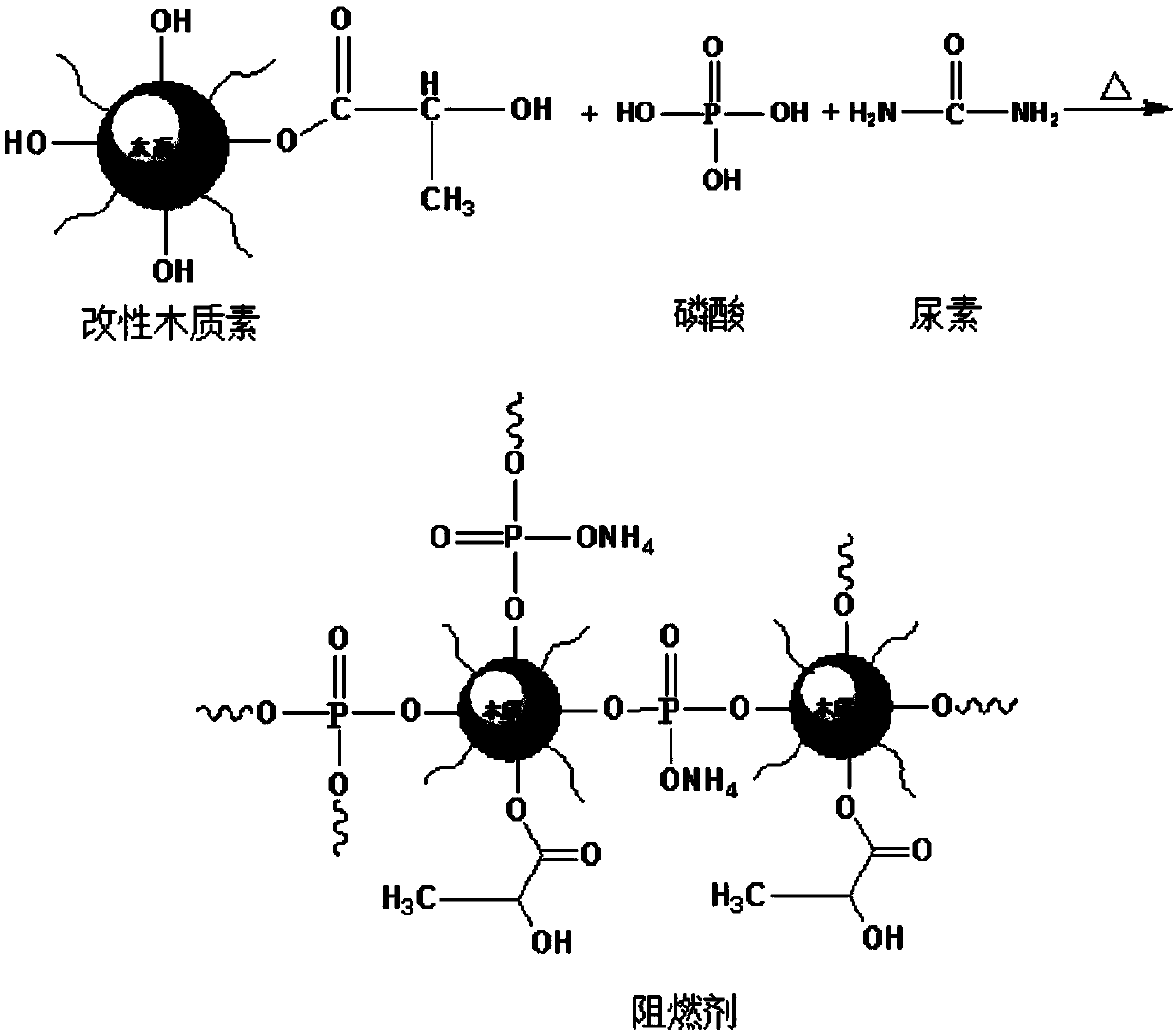

[0023] S2. Mix the first reactant with phosphoric acid and modified lignin, heat up to 90-110°C to react until bubbles are generated, and then react at 220-240°C for 1-3 hours to obtain a flame retardant for polylactic acid. One reactant is urea and / or melamine.

[0024] In this example, lactic acid is used to modify lignin under the catalysis of biomass charcoal sulfonic acid to obtain modified lignin, and then react the modified lignin with phosphoric acid, urea or melamine to generate a flame retardant for polylactic acid , the specific reaction principle is as follows Figure 1~2 shown. Since the flame reta...

Embodiment 1

[0035] Mix 100 parts by mass of acid lignin, 25 parts by mass of lactic acid and 0.5 part by mass of biomass charcoal sulfonic acid in a high mixer to obtain a precursor. The precursor is reactively extruded through a twin-screw extruder to obtain modified lignin. The extrusion temperature is 85°C, 95°C, 105°C, 115°C, 115°C, 115°C, and 115°C in sequence from the feeding section to the machine head. , screw speed 15rpm.

[0036] Add 10 parts by mass of urea, 10 parts by mass of phosphoric acid and 6 parts by mass of modified lignin into the reactor, heat up to 100°C at a rate of 20°C / min while stirring, and then continue stirring until the reaction system A large number of bubbles were generated to obtain a prepolymer. Pour the prepolymer into a porcelain container, place it in a constant temperature furnace at 230°C and continue to react for 2 hours to obtain a flame retardant for polylactic acid.

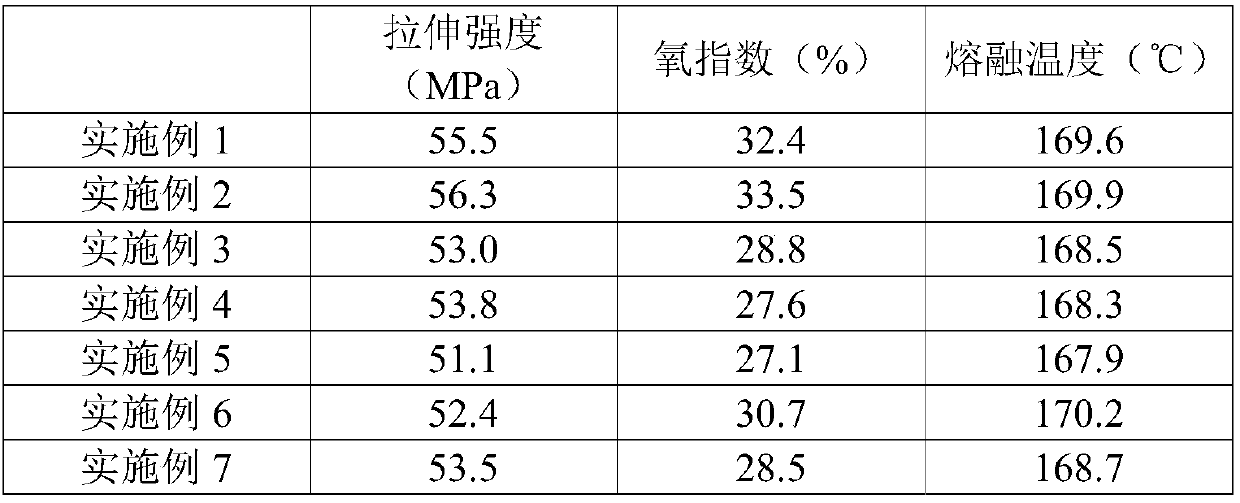

[0037] 100 parts by mass of polylactic acid and 20 parts by mass of a flame ...

Embodiment 2

[0039] Mix 100 parts by mass of acid lignin, 25 parts by mass of lactic acid and 0.5 part by mass of biomass charcoal sulfonic acid in a high mixer to obtain a precursor. The precursor is reactively extruded through a twin-screw extruder to obtain modified lignin. The extrusion temperature is 85°C, 95°C, 105°C, 115°C, 115°C, 115°C, and 115°C in sequence from the feeding section to the machine head. , screw speed 15rpm.

[0040]Add 10 parts by mass of melamine, 10 parts by mass of phosphoric acid and 6 parts by mass of modified lignin into the reactor, heat up to 110°C at a rate of 20°C / min while stirring, and then continue stirring until the reaction system A large number of bubbles were generated to obtain a prepolymer. Pour the prepolymer into a porcelain container, place it in a constant temperature furnace at 230°C and continue to react for 3 hours to obtain a flame retardant for polylactic acid.

[0041] 100 parts by mass of polylactic acid and 20 parts by mass of a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com