Graphene and liquid metal composite material and preparation method thereof

A technology of liquid metal and graphene, which is applied in the field of graphene and liquid metal composite materials and its preparation, can solve the problems of complex preparation process, low sample repeatability, and low plastic phase strength, and achieve broad application prospects and plasticity. Improve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

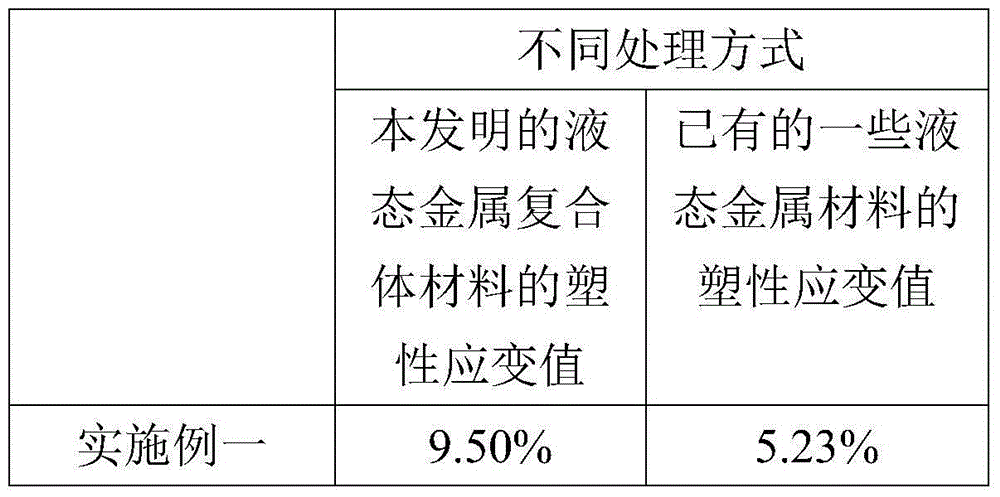

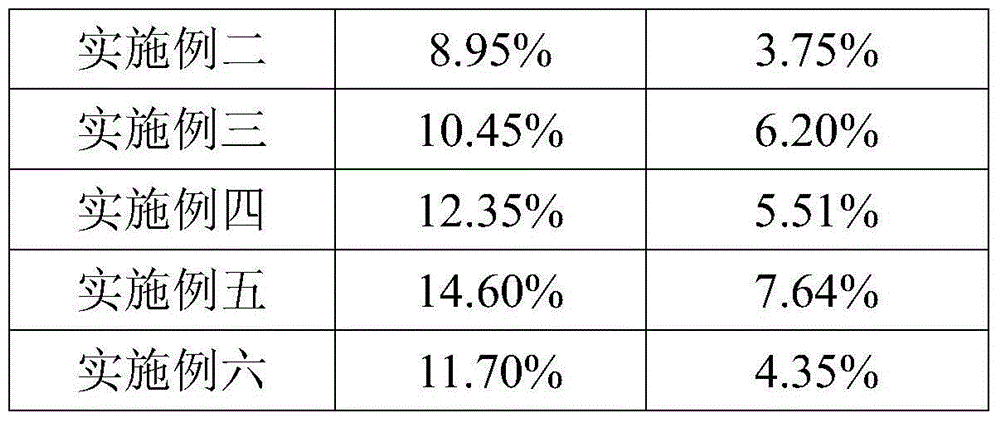

Examples

preparation example Construction

[0024] In some embodiments, the preparation method of graphene and liquid metal composite material may comprise the following steps:

[0025] 1) Provide graphene: it can be graphene prepared by various physical and chemical methods, such as single-layer graphene, double-layer graphene and multi-layer graphene with more than 3 layers; preferably, graphene is prepared with liquid metal Before the composite material is dispersed, the graphene surface can be modified and dispersed by physical or chemical methods, such as silane coupling agent surface modification, ethanol ultrasound, electrochemical modification, etc.

[0026] 2) Provide liquid metal: it can be one of zirconium-based liquid metal, magnesium-based liquid metal, copper-based liquid metal, aluminum-based liquid metal, iron-based liquid metal, nickel-based liquid metal, titanium-based liquid metal, preferably its vitrification The temperature is higher than the crystallization temperature by 18°C or more.

[0027] ...

Embodiment 1

[0031] 1) Provide single-layer graphene through pre-dispersion treatment; before graphene and liquid metal are prepared as a composite material, dispersion treatment is carried out, and modification and dispersion are carried out by a silane coupling agent.

[0032] 2) Provide liquid metal; this time, zirconium-based liquid metal is used, and the glass transition temperature is 18°C higher than the crystallization temperature.

[0033] 3) Add 5 parts of pretreated graphene to 100 parts of liquid metal, put it into a vacuum melting furnace, and first vacuum the furnace to make the vacuum degree reach 10 -3 -10 -2 Pa, start the induction heating, the heating power is 50KW, under the protection of 99.99% argon, carry out high-temperature melting, the melting temperature is 2500 ° C, and the melting time is 1 hour; the above melting process can be repeated 3 times, so that the graphene and zirconium-based liquid The metals are fully mixed with each other to form a molten body. ...

Embodiment 2

[0037] 1) Provide single-layer graphene through pre-dispersion treatment; before graphene and liquid metal are prepared as a composite material, dispersion treatment is carried out, and modification and dispersion are carried out by a silane coupling agent.

[0038] 2) Provide liquid metal; this time, magnesium-based liquid metal is used, and the glass transition temperature is 25°C higher than the crystallization temperature.

[0039] 3) Add 7.5 parts of pretreated graphene to 100 parts of liquid metal, put it into a vacuum melting furnace, and first vacuum the furnace to make the vacuum degree reach 10 -3 -10 -2 Pa, start the induction heating, the heating power is 30KW, under the protection of 99.99% argon, carry out high-temperature melting, the melting temperature is 1300 ° C, and the melting time is 1.5 hours; the above melting process can be repeated 3 times, so that graphene and magnesium-based liquid metal Mix well with each other to form a melt.

[0040] 4) Using t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com