Preparation method and application of fixed bed framework metal catalyst

A framework metal and catalyst technology, which is applied in the field of hydrogenation of organic unsaturated compounds, can solve the problems of unfavorable alloy activation and catalyst activity improvement, catalyst strength is difficult to guarantee, and is not suitable for hydrogenation reaction, etc., to achieve excellent flame retardancy Sexuality and chemical inertness, saving active metal resources, solving the effect of high calcination temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

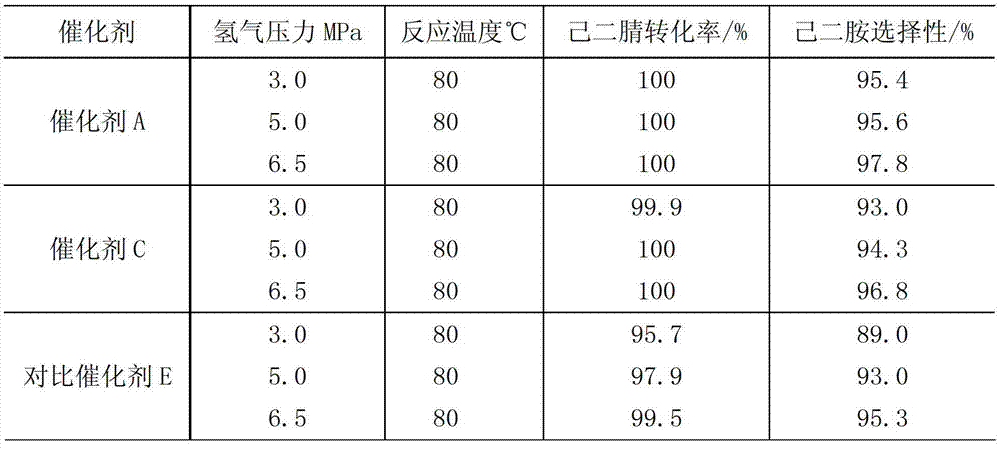

[0017] Embodiment 1: preparation of catalyst A

[0018] Weigh 16.7g of polytetrafluoroethylene concentrate and 2g of polyacrylamide to prepare a slurry, then add 90g of nickel-aluminum alloy powder with a particle size of 200-240 mesh (mass content: nickel 47.3%, aluminum 48.2%, iron and other elements 4.5%), fully kneaded, extruded into a cylindrical strip with a diameter of 1.8mm, dried under an infrared lamp, dried at 120°C for 3h, and then heat-treated at 250°C for 3h under an argon atmosphere. The activation conditions are: put 50g of the above particles into 250ml of NaOH solution with a mass percentage concentration of 20%, raise the temperature to 70°C for 2h, wash with deoxygenated deionized water until the pH value is 7-8, and then wash with absolute ethanol Replace deionized water to prepare catalyst A, which is stored in absolute ethanol.

Embodiment 2

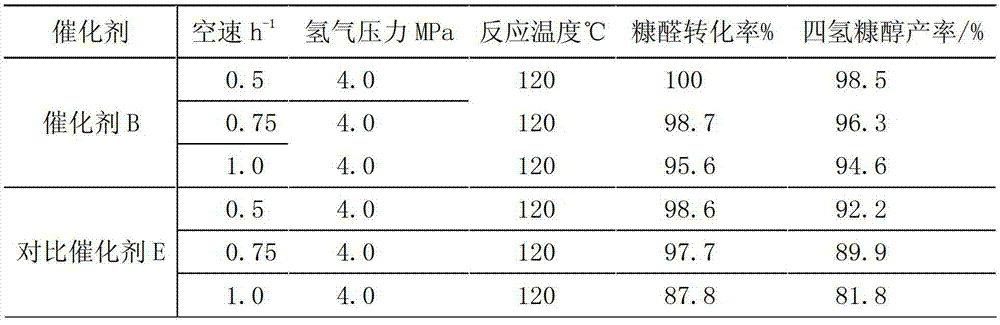

[0019] Embodiment 2: preparation of catalyst B

[0020] Weigh 12.5g of polytetrafluoroethylene concentrate and 2.5g of carboxymethyl cellulose to prepare a slurry, then add 90g of nickel-aluminum alloy powder with a particle size of 200-240 mesh (mass content: nickel 52.1%, aluminum 43.8%, molybdenum and other elements 4.1%), fully ground and evaporated to dryness, pressed into a cylindrical sheet with a diameter of 3.0mm and a height of 2.0mm, dried at 120°C for 3h, and then heat-treated at 300°C for 2h under an argon atmosphere. The activation conditions are: put 50g of the above particles into 350ml of a solution with a mass percent concentration of 15% NaOH, raise the temperature to 80°C for 2 hours, wash with deoxygenated and deionized water until the pH value is 7-9, and then wash with absolute ethanol Replace deionized water to prepare catalyst B, which is stored in absolute ethanol.

Embodiment 3

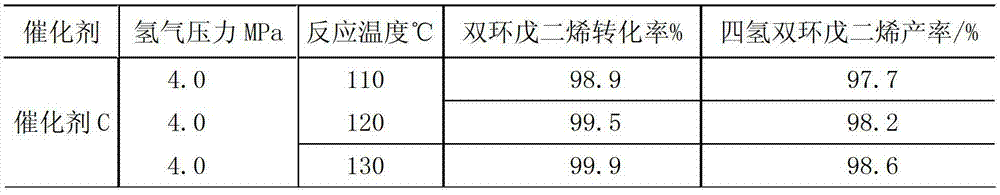

[0021] Embodiment 3: preparation of catalyst C

[0022] Prepare 50g of nickel-aluminum alloy powder with a particle size of 200-240 mesh (mass content: nickel 47.3%, aluminum 48.2%, iron and other elements 4.5%), 10g of polytetrafluoroethylene concentrate and 2.5g of carboxymethyl cellulose Slurry, and then smear the slurry on nickel foam (area density 320g / m 2 ) surface, the viscosity of the slurry should enter the interior of the nickel foam network structure. Dry at room temperature, dry at 120°C for 3 hours, then heat-treat at 250°C for 2 hours in a tube furnace under an argon atmosphere, and cut the nickel foam into 2-3mm square particles. The activation conditions are: 20g foamed nickel coated nickel-aluminum alloy particles, 30g NaOH to prepare a solution with a mass percentage of 20%, activate at 80°C for 2h, then wash with deoxygenated and deionized water until the pH value is 7-8, and then wash with absolute ethanol Replace deionized water to prepare catalyst C, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com