Porous lithium ion battery separator with interpenetrating polymer network structure, and preparation method and application for porous lithium ion battery separator

An interpenetrating network structure, lithium-ion battery technology, applied in the direction of batteries, secondary batteries, structural parts, etc., to achieve good compatibility, improve thermal stability, and ensure the effect of ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

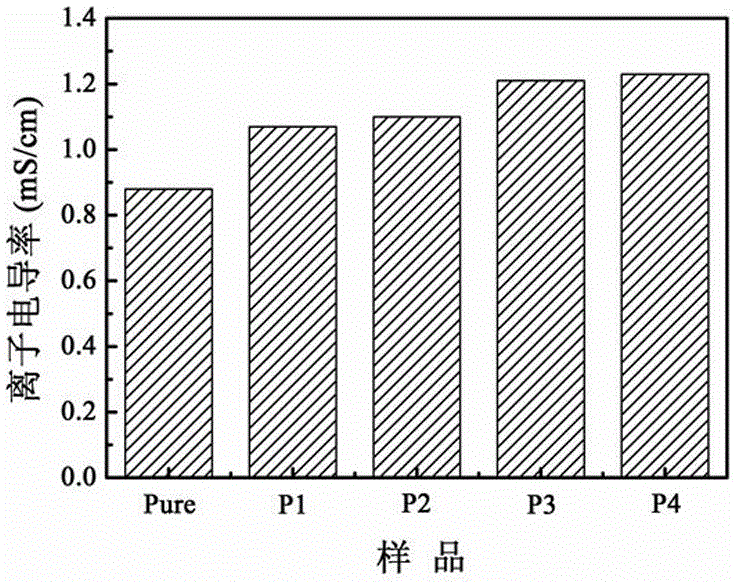

[0047] Example 1: Preparation of a porous lithium-ion battery separator with an interpenetrating network structure using PEG400 as a porogen

[0048] 1.2 g PVDF-HFP and 0.105 g OV-POSS were weighed, put into a mixed solvent of 4.5 g DMF and 3 g THF, and stirred at room temperature for 2 h to form a homogeneous solution. Add 0.8 g PEGMEMA, according to the theoretical mass of PEG400 accounted for the gel film, add PEG400, continue to stir for 1 h. Finally, 0.010 g DMPA was added and stirred for 10 min until it was completely dissolved. After standing for defoaming, use an adjustable film applicator to evenly coat the solution on a clean and flat polyethylene plate; finally, place the polyethylene plate coated with the solution under an ultraviolet lamp to initiate polymerization, and place it in a 70°C refrigerator after the end. Dry in a vacuum oven for 18 h to remove the solvent. The diaphragm was taken out and soaked in deionized water at 60°C for 40 h to wash away the por...

Embodiment 2

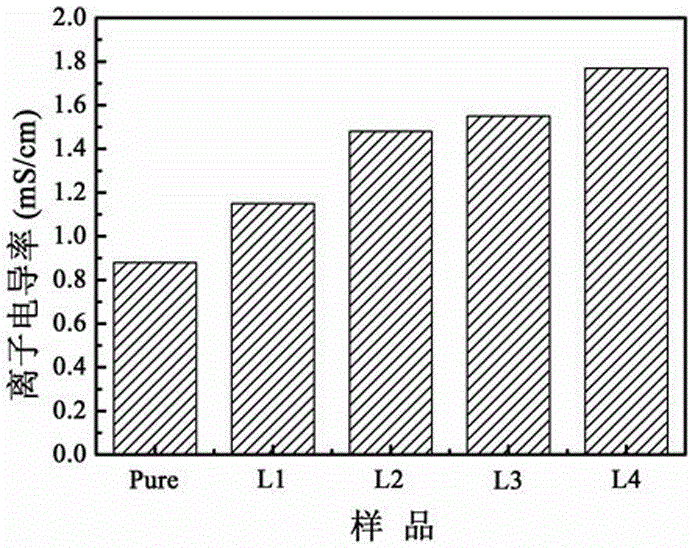

[0049] Example 2: Preparation of a porous lithium-ion battery separator with an interpenetrating network structure using PVP as a porogen

[0050]Preparation of porous lithium-ion battery separator with interpenetrating network structure: 1.2 g PVDF-HFP and 0.105 g POSS were weighed, dissolved in 4.5 g DMF and 3 g THF, and stirred at room temperature for 2 h to form a uniform solution. Add 0.8 g PEGMEMA, according to the theoretical mass of PVP in the gel film, add PVP, continue stirring for 1 h, finally add 0.020 g DMPA, stir for 10 min until completely dissolved. After standing for defoaming, use an adjustable film applicator to evenly coat the solution on a clean and flat polyethylene plate; finally put the solution-coated polyethylene plate under a UV lamp to initiate polymerization. The diaphragm was taken out and soaked in deionized water at 50°C for 48 h to wash away the porogen and unreacted monomers. Finally, dry in a vacuum oven at 60°C for 24 h to obtain porous lit...

Embodiment 3

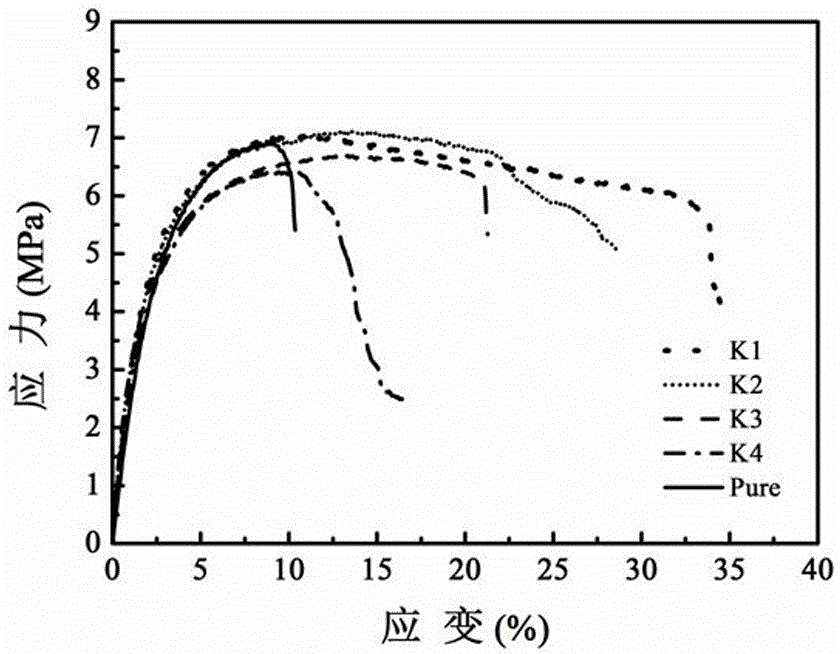

[0051] Example 3: Preparation of a porous lithium-ion battery separator with an interpenetrating network structure using lithium chloride inorganic salt as a porogen

[0052] Preparation of porous lithium-ion battery separator with interpenetrating network structure: weigh 1.2 g PVDF-HFP, 0.105 g POSS, dissolve in 4.5 g DMF and 3 g THF, stir at room temperature for 2 h until completely dissolved, then add 0.8 g PEGMEMA, according to the theoretical mass of inorganic salts in the gel film, add lithium chloride, continue stirring for 1 h, and finally add 0.030 g DMPA, stir for 10 min until completely dissolved. After standing for defoaming, use an adjustable film applicator to evenly coat the solution on a clean and flat polyethylene plate; finally put the solution-coated polyethylene plate under a UV lamp to initiate polymerization. The diaphragm was taken out and soaked in deionized water at 60°C for 40 h to wash away the porogen and unreacted monomers. Finally, put it in a v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ionic conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com