Preparation method of interlayer frequency selective surface composite material

A frequency-selective surface and composite material technology, applied to antennas, radiation unit covers, electrical components and other directions suitable for movable objects, can solve the problems of affecting the electromagnetic characteristics of the test piece, poor environmental adaptability, and poor maintenance performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

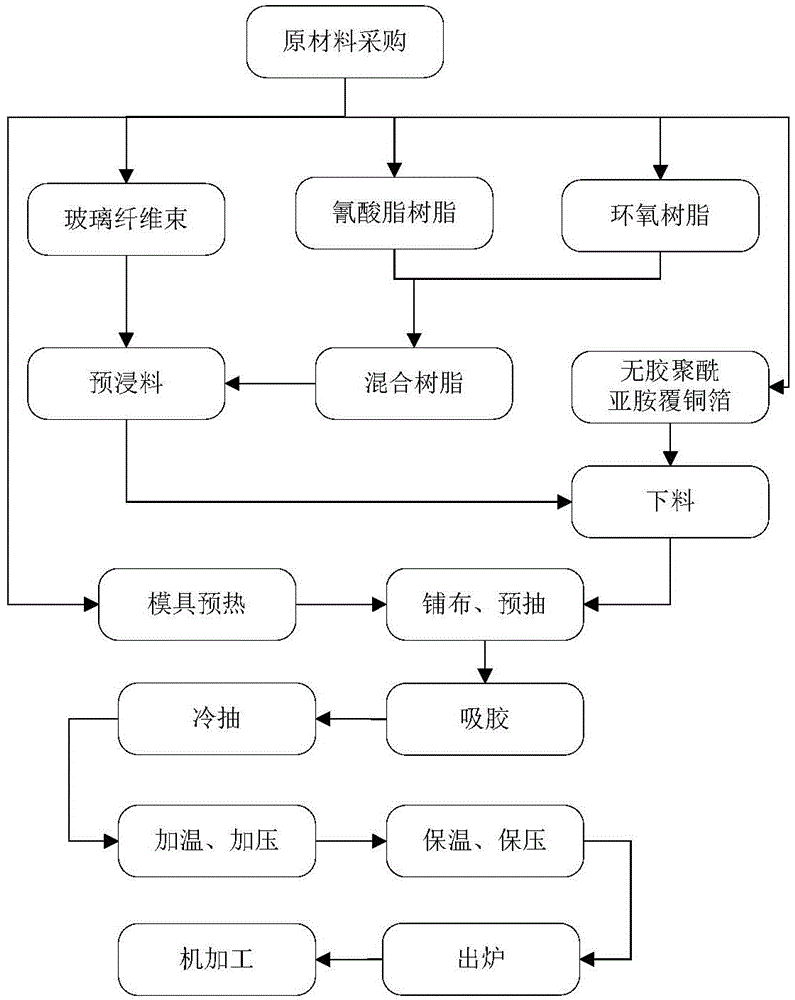

[0036] See figure 1 — Figure 9 , a method for preparing an interlayer frequency selective surface composite material of the present invention, the specific steps of the method are as follows:

[0037] 1. Select cyanate resin and epoxy resin to prepare mixed resin;

[0038] 2. Put the mixed resin prepared in step 1 into the dipping tank to prepare a 0.1mm thick glass fiber prepreg for later use;

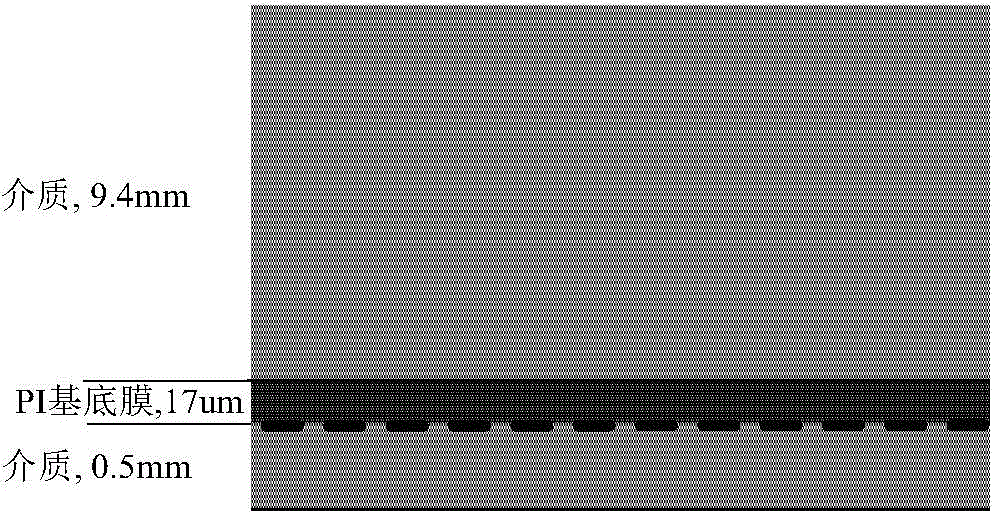

[0039] 3. Choose 500×500 adhesive-free polyimide copper-clad foil, and use printed circuit board technology to etch frequency-selective surface gap units on the copper foil, and the unit form is a ring unit;

[0040] 4. Select the prepreg prepared in step 2 and cut it into 500×500;

[0041] 5. Clean the surface of the mold, and then put it in an oven for preheating, the temperature is controlled at 38°C;

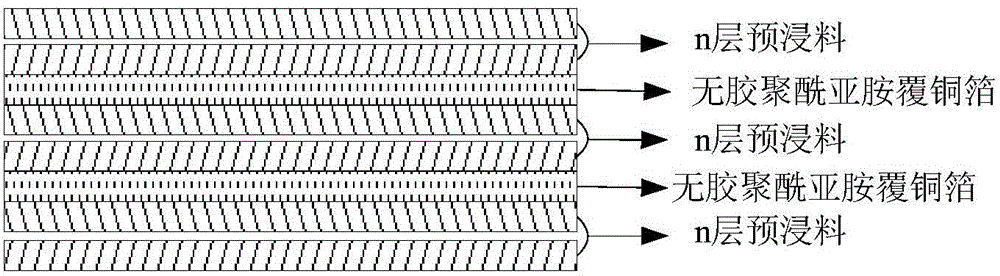

[0042] 6. Press image 3 Lay the good prepreg and adhesive-free polyimide copper clad foil in step 3 and step 4;

[0043] 7. Vacuumize the prepreg laid in step 6 and the adhe...

Embodiment 2

[0053] 1. Select cyanate resin and epoxy resin to prepare mixed resin;

[0054] 2. Put the mixed resin prepared in step 1 into the dipping tank to prepare a 0.1mm thick glass fiber prepreg for later use;

[0055] 3. Choose 1000×1000 adhesive-free polyimide copper-clad foil, and use printed circuit board technology to etch the frequency-selective surface gap unit on the copper foil, and the unit form is a ring unit;

[0056] 4. Select the prepreg prepared in step 2, the copper foil prepared in step 3 and the 8mm dielectric honeycomb board to cut into a sector with a radius of 0.7m and a central angle of 123°;

[0057] 5. Clean the surface of the mold, and then put it in an oven for preheating, the temperature is controlled at 38°C;

[0058] 6. Press Figure 7 Lay the prepreg, copper foil and honeycomb panels prepared in step 4;

[0059] 7. Vacuumize the prepreg, copper foil and honeycomb panel laid in step 6, and the vacuum degree is 1×10 -1 MPa;

[0060] 8. Prepare the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com