Environment-friendly halogen-free flame retardant for glass fiber reinforced PA6 (polyamide) and preparation method thereof

A technology of flame retardant and flame retardant synergist, which is applied in the field of phosphorus and nitrogen-based environmentally friendly halogen-free flame retardants, which can solve the problems of product mechanical strength decline, secondary damage, and impact on dimensional stability, and achieve smoke emission Effect of small size, high flame retardant grade, and excellent flame retardant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

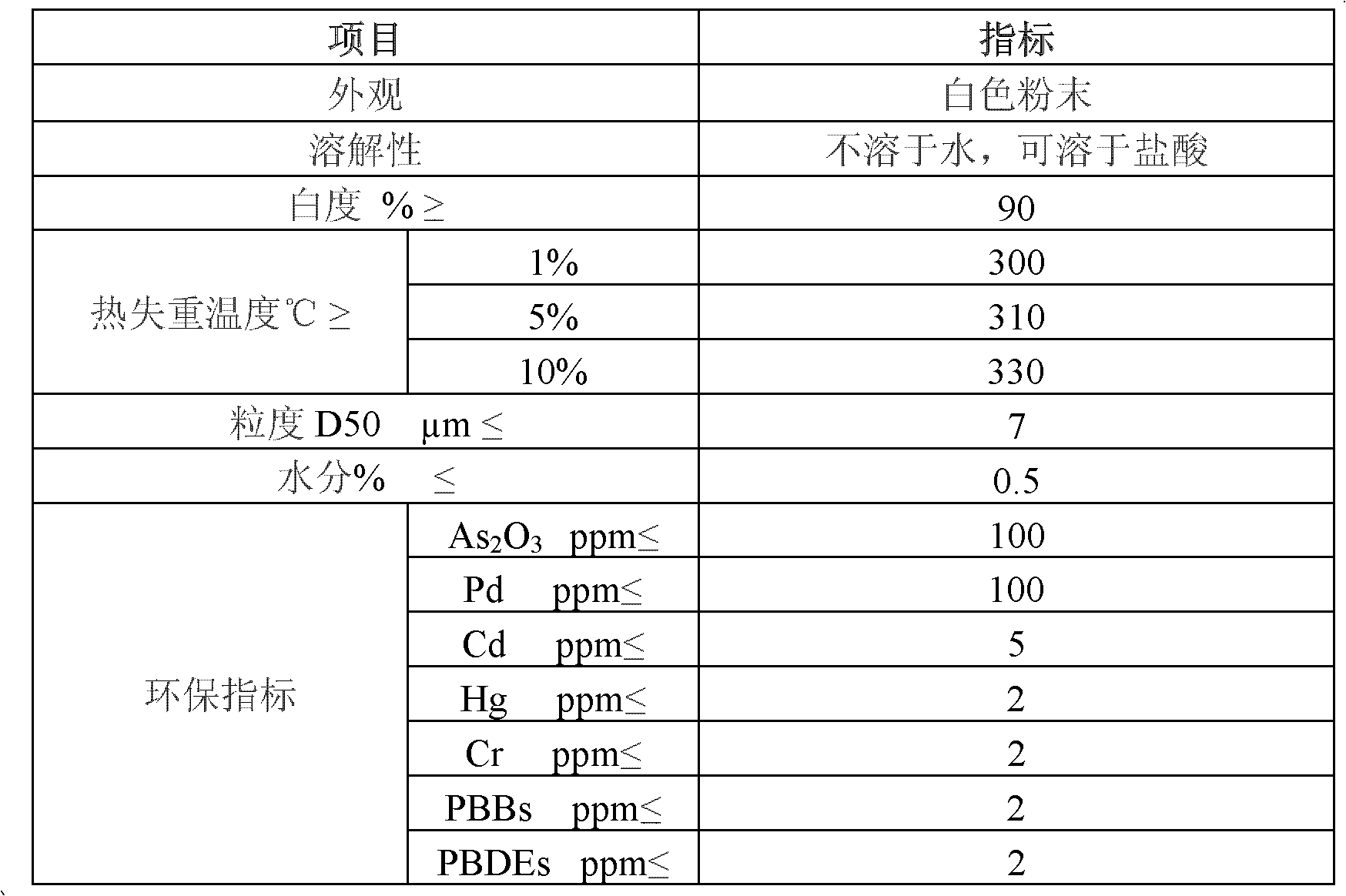

Image

Examples

Embodiment 1

[0012] Proportion (parts by weight): main flame retardant 12, melamine cyanurate 5, ammonium polyphosphate 3, synergistic charring agent (4A molecular sieve) 2, flame retardant synergist (zinc borate) 3, antioxidant 168 0.5.

[0013] Preparation method: Add phosphoric acid into the reaction kettle, then add water equivalent to 8.5 times the volume of phosphoric acid as the reaction solvent, slowly add aluminum hydroxide under the condition of mechanical stirring (the molar ratio of aluminum hydroxide and phosphoric acid is 1:1) , after reacting at a temperature of 85°C for 6.5h, the main flame retardant aluminum phosphate was obtained by centrifugation, drying, and crushing, and then the various components were kneaded and reacted at a temperature of 65°C for 3h according to the above ratio to obtain the product.

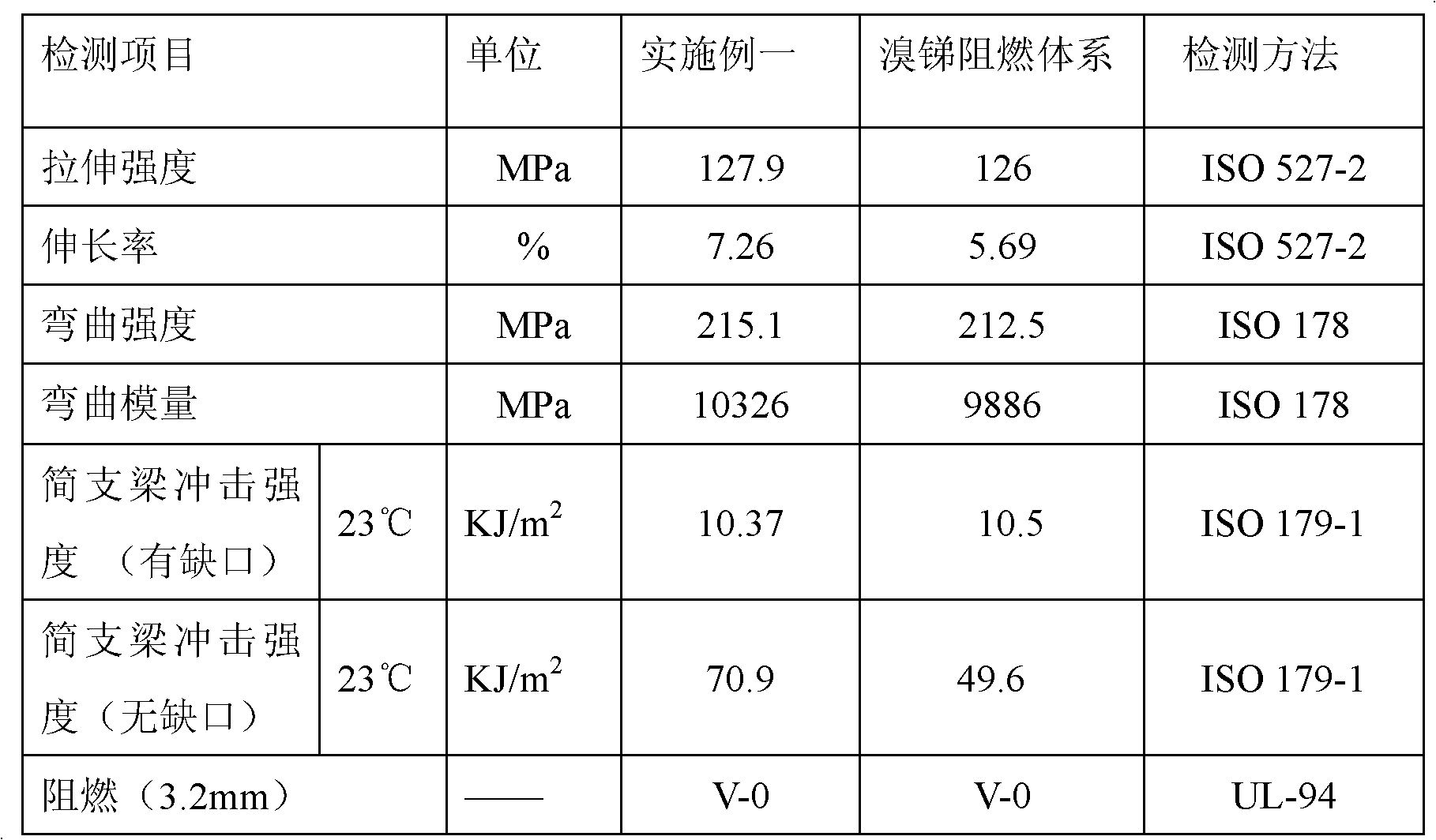

[0014] The application effect of the obtained product and traditional bromine and antimony flame retardants in glass fiber reinforced PA6 is as follows:

[0015] 1...

Embodiment 2

[0027] Proportion (parts by weight): main flame retardant 10, melamine cyanurate 5, ammonium polyphosphate 3, synergistic char forming agent (zeolite) 1.2, flame retardant synergist (zinc borate) 0.8, antioxidant 1010 0.5.

[0028] Preparation method: Add phosphoric acid into the reaction kettle, then add water equivalent to 9 times the volume of phosphoric acid as the reaction solvent, slowly add aluminum hydroxide under the condition of mechanical stirring (the molar ratio of aluminum hydroxide to phosphoric acid is 0.8:1) After reacting at 90°C for 7 hours, the main flame retardant aluminum phosphate was obtained by centrifugation, drying, and crushing, and then kneading and reacting various components at 70°C for 3.5 hours according to the above ratio to obtain the inventive product.

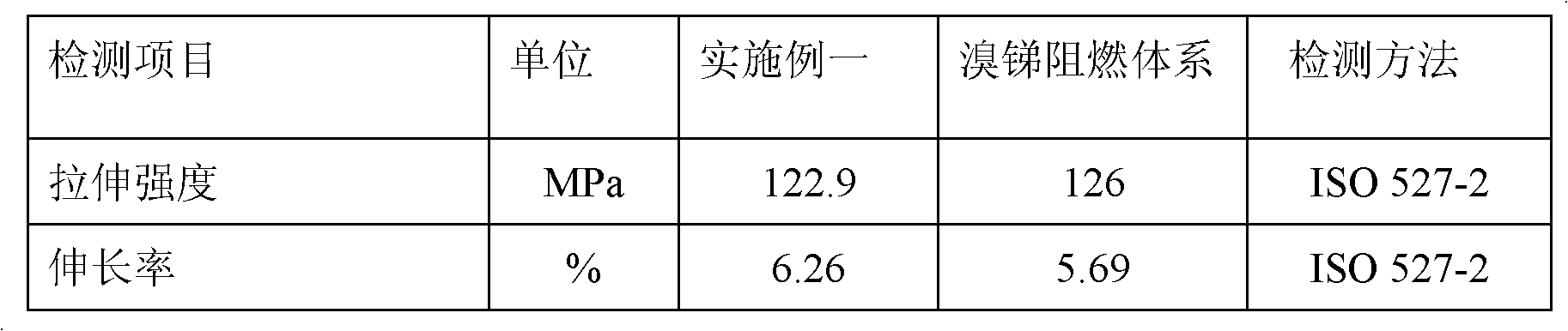

[0029] The resulting product is compared with the application effect of traditional bromine and antimony flame retardants in glass fiber reinforced nylon 6 as follows:

[0030] 1. Applicati...

Embodiment 3

[0041] Proportion (parts by weight): main flame retardant 10, melamine cyanurate 4, ammonium polyphosphate 3, synergistic charring agent (4A molecular sieve) 2.5, flame retardant synergist (zinc borate) 1.5, antioxidant 1010 0.5.

[0042] Preparation method: Add phosphoric acid into the reaction kettle, then add water equivalent to 10 times the volume of phosphoric acid as the reaction solvent, slowly add aluminum hydroxide under the condition of mechanical stirring (the molar ratio of aluminum hydroxide and phosphoric acid is 1:1) After reacting at a temperature of 80°C for 7.5 hours, the main flame retardant aluminum phosphate was obtained by centrifugation, drying and crushing, and then kneading the above components at a temperature of 70°C for 2.5 hours according to the above ratio to obtain the inventive product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com