Preparation method of wool fabric with flame-retardant function

A fabric and wool spinning technology, which is applied in the field of wool fabric preparation, can solve problems such as pollution of metal oxides and heavy metals, difficulty in realizing industrialized production, and difficulty in large-scale industrialized production, and achieve the effects of cost saving, convenient operation, and reduced consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Add 21ml of TEOS dropwise into a 500ml three-necked round-bottomed flask containing 22ml of EtOH and an appropriate amount of HCl, adjust the pH to 2-3, and stir vigorously for 30 minutes to obtain a uniform and clear silicon alkoxide system; while vigorously stirring, add a phosphate aqueous solution (0.92 k 2 HPO 4 +36ml H 2 O), and continued stirring at 70°C for 3 hours to obtain a colorless, transparent and uniform phosphorus / silica sol system.

[0020] The woolen fabric is dipped and rolled twice in the phosphorus / silica sol system, and the pressure is 1-3kg / cm 2 , the residual rate is 70-90%; then pre-baked at a temperature of 60-100°C, baked at a temperature of 120-180°C for 2-10 minutes, washed with water, and dried naturally to obtain a Wool fabric with flame retardant function.

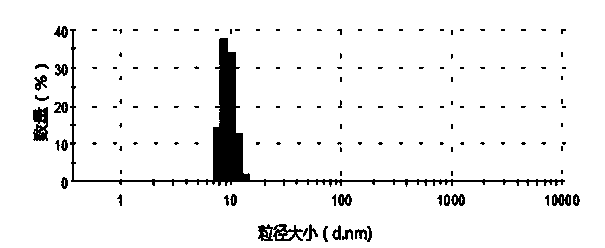

[0021] See attached figure 1 , which is the particle size distribution diagram of the phosphorus-containing nano-silica sol provided in this example. Depend on figure 1 It can ...

Embodiment 2

[0023] Add 21ml TEOS, 22ml EtOH and appropriate amount of HCl into a 500ml three-neck round bottom flask in sequence, and adjust the pH to 2-3. Aqueous phosphate solution (0.69 g NH 4 h 2 PO 4 +36mlH 2 O), and continue to stir at 70°C for 3 hours to obtain a colorless, transparent and uniform phosphorus / silica sol system. The woolen fabric is dipped and rolled twice in the phosphorus / silica sol system, and the pressure is 1-3kg / cm 2 , with a residual rate of 70-90%, pre-baking at a temperature of 60-100°C, then baking at a temperature of 120-180°C for 2-10 minutes, washing with water, and drying naturally to obtain a Wool fabric with flame retardant function.

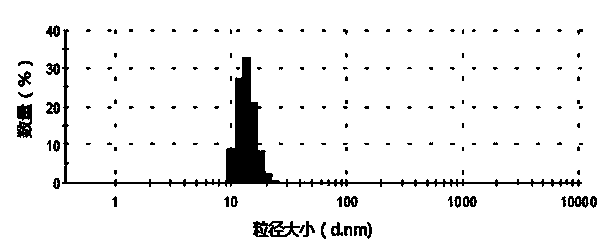

[0024] See attached figure 2 , which is the particle size distribution diagram of the silicon / phosphorus / nitrogen nano-sol prepared in this example. Depend on figure 2 It can be seen that the particle size distribution of the sol is around 10nm, indicating that the prepared silicon / phosphorus / nitrogen composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com