Cement-based wood fiber artificial board and manufacturing method thereof

A wood fiber, cement-based technology, used in manufacturing tools, sustainable waste treatment, solid waste management, etc., can solve the problems of low elastic modulus, complex processing and processing, and no real saving of wood resources, and achieve elastic modulus. High, simple and easy preparation process, excellent flame retardant function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

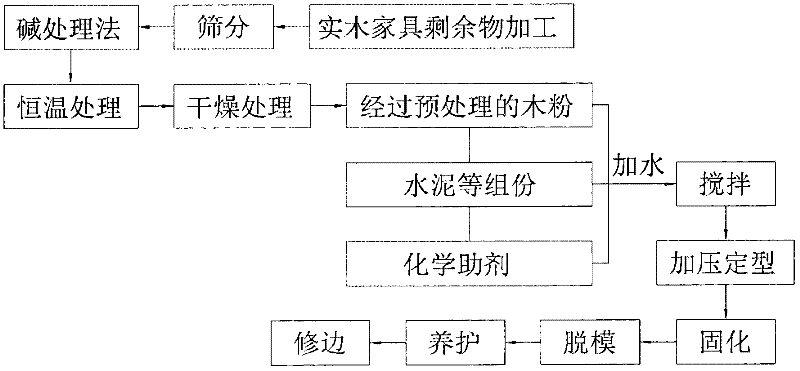

Method used

Image

Examples

Embodiment 1

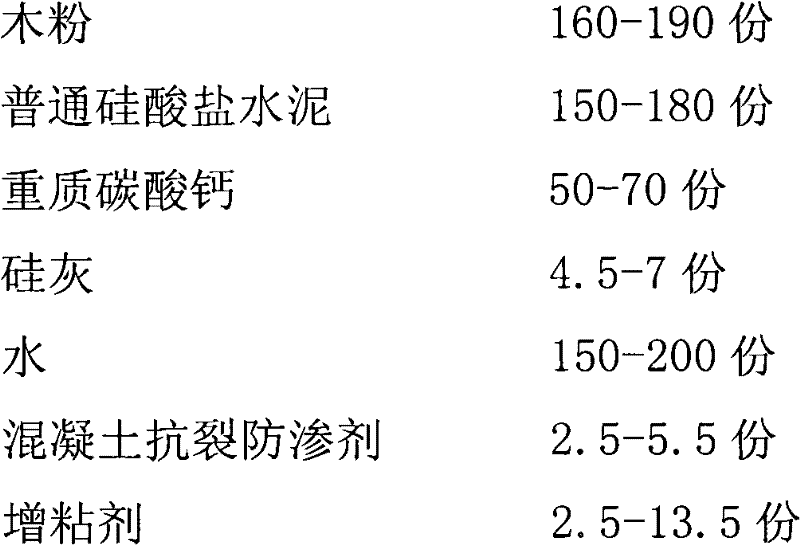

[0030] In the present embodiment, select 175 parts of 30 mesh wood powders that have been pretreated, 150 parts of cement of 425#, 50 parts of ground calcium carbonate, 5 parts of silica fume, 2.5 parts of concrete anti-cracking and anti-seepage agent, and two parts of tackifier Put 3.5 parts of alkyl dithiophosphate zinc salt into a single-shaft mortar mixer, mix at 150 rpm for 5 minutes, and add 150 parts of water during the stirring, and stir evenly to form a slurry with good workability.

[0031] First apply the release agent in the mold, then add the paste mixture into the mold, smooth the upper surface, close the mold and send it to the cold press, press it under 2MPa pressure for 72 hours to shape, and press it in the mold after shaping Stand still, when the ambient temperature is 10°C-40°C, let stand still for 5 hours; after demoulding, place the formed slab in a ventilated place to dry naturally, and continue curing for 2-5 days; finally, sand the corners of the slab, ...

Embodiment 2

[0033] Select 160 parts of pretreated 50-mesh wood flour, 165 parts of 425# cement, 60 parts of heavy calcium carbonate, 6 parts of silica fume, 3.5 parts of concrete anti-cracking and anti-seepage agent, tackifier dialkyl dithio Put 7.5 parts of zinc phosphate salt into a single-shaft mortar mixer, mix at 150 rpm for 8 minutes, and add 165 parts of water to the stirring, and stir evenly to form a slurry with good workability.

[0034] First apply the mold release agent in the mold, then add the paste mixture into the mold, smooth the upper surface, close the mold and send it to the cold press, press it under 5MPa pressure for 24 hours to set the shape, and press it in the mold after setting Stand still, when the ambient temperature is 10°C-40°C, let stand still for 5 hours; after demoulding, place the formed slab in a ventilated place to dry naturally, and continue curing for 2-5 days; finally, sand the corners of the slab, that is A cement-based wood fiber-based panel with a...

Embodiment 3

[0036] Select 190 parts of pretreated 80-mesh wood flour, 180 parts of 425# cement, 70 parts of heavy calcium carbonate, 7 parts of silica fume, 5.5 parts of concrete anti-cracking and anti-seepage agent, tackifier dialkyl dithio Put 13.5 parts of zinc phosphate into a single-shaft mortar mixer, mix at 150 rpm for 10 minutes, and add 200 parts of water during the stirring, and stir evenly to form a slurry with good workability.

[0037] First apply the release agent in the mold, then add the paste mixture into the mold, smooth the upper surface, close the mold and send it to the cold press, press it under 10MPa pressure for 45min to finalize the shape, and then put it in the mold after pressing Stand still, when the ambient temperature is 10°C-40°C, let stand still for 10 hours; after demoulding, place the formed slab in a ventilated place to dry naturally, and continue curing for 2-5 days; finally, sand the corners of the slab, that is A cement-based wood fiber-based panel wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com