Abrasion-proof composite floor

A composite floor and flooring technology, applied in the direction of floors, buildings, building structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

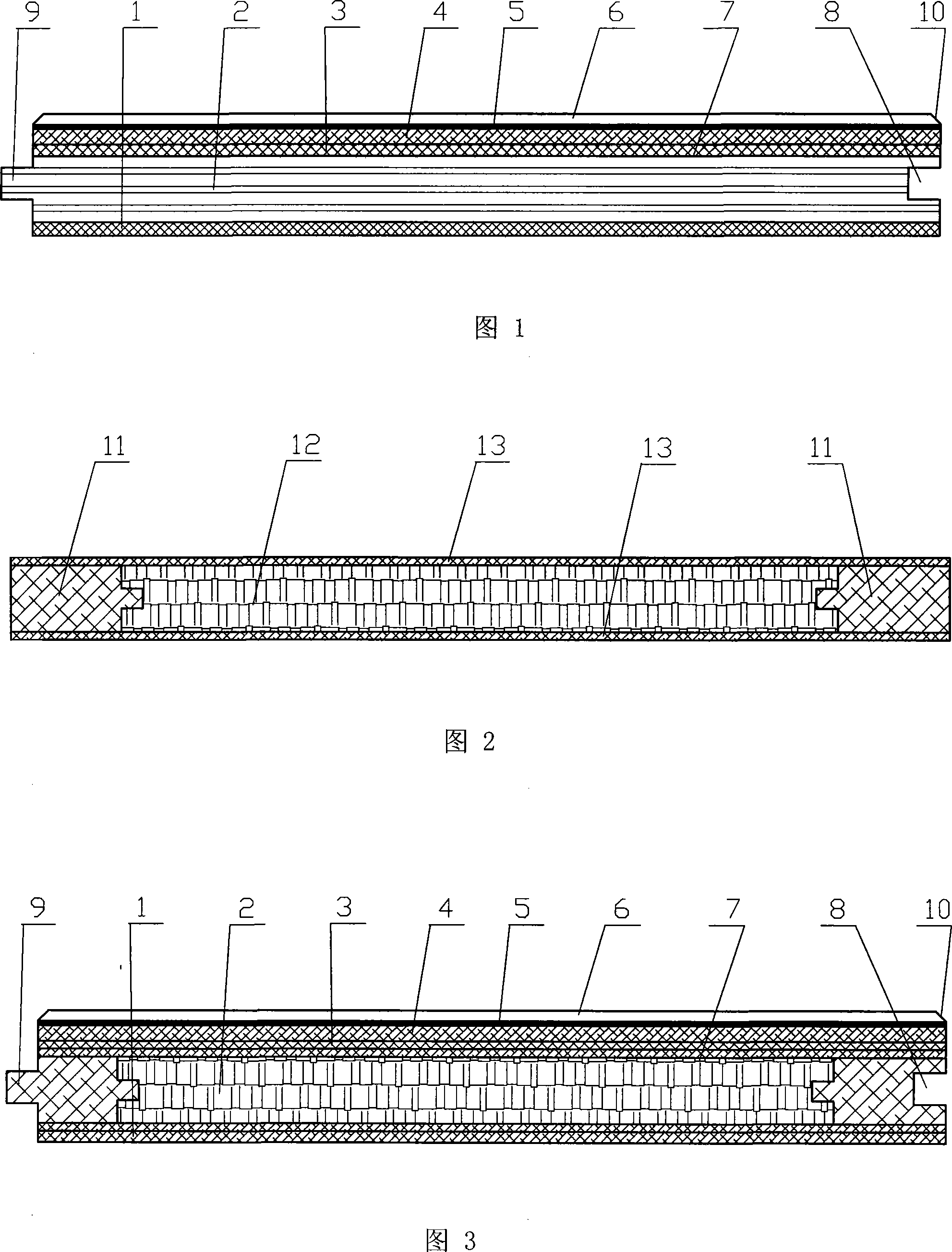

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] Fig. 1 is a schematic cross-sectional structure diagram of a wear-resistant composite floor whose core board is composed of multi-layer composite boards. It can be seen from the figure that it includes the bottom balance layer 1, followed by the core board 2, the balance layer 3, the decoration layer 4, the paint 5 and the wear-resistant paper 6, and the layers are glued together sequentially by adhesives. Make wood structure board 7, be shaped on the side face of wood structure board 7 with the tenon and groove 8 and / or tongue 9 that splice mutually. Wherein the balance layer 1 and the balance layer 3 are made of paper and natural veneer and melamine glue or paper and technical veneer and melamine glue. The core board 2 is a multi-layer composite board, and the decorative layer 4 is composed of thin wood chips or technical veneers obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com