Method for manufacturing halogen-free flame retardant nylon sticky buckle strap

A manufacturing method and a technology for a hook and loop fastener, which are applied in chemical instruments and methods, inorganic/elemental washing compositions, dyeing methods, etc., can solve problems such as hidden dangers of personal and vehicle safety, reduced visibility, etc., and achieve excellent flame retardant function, The effect of high visibility and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

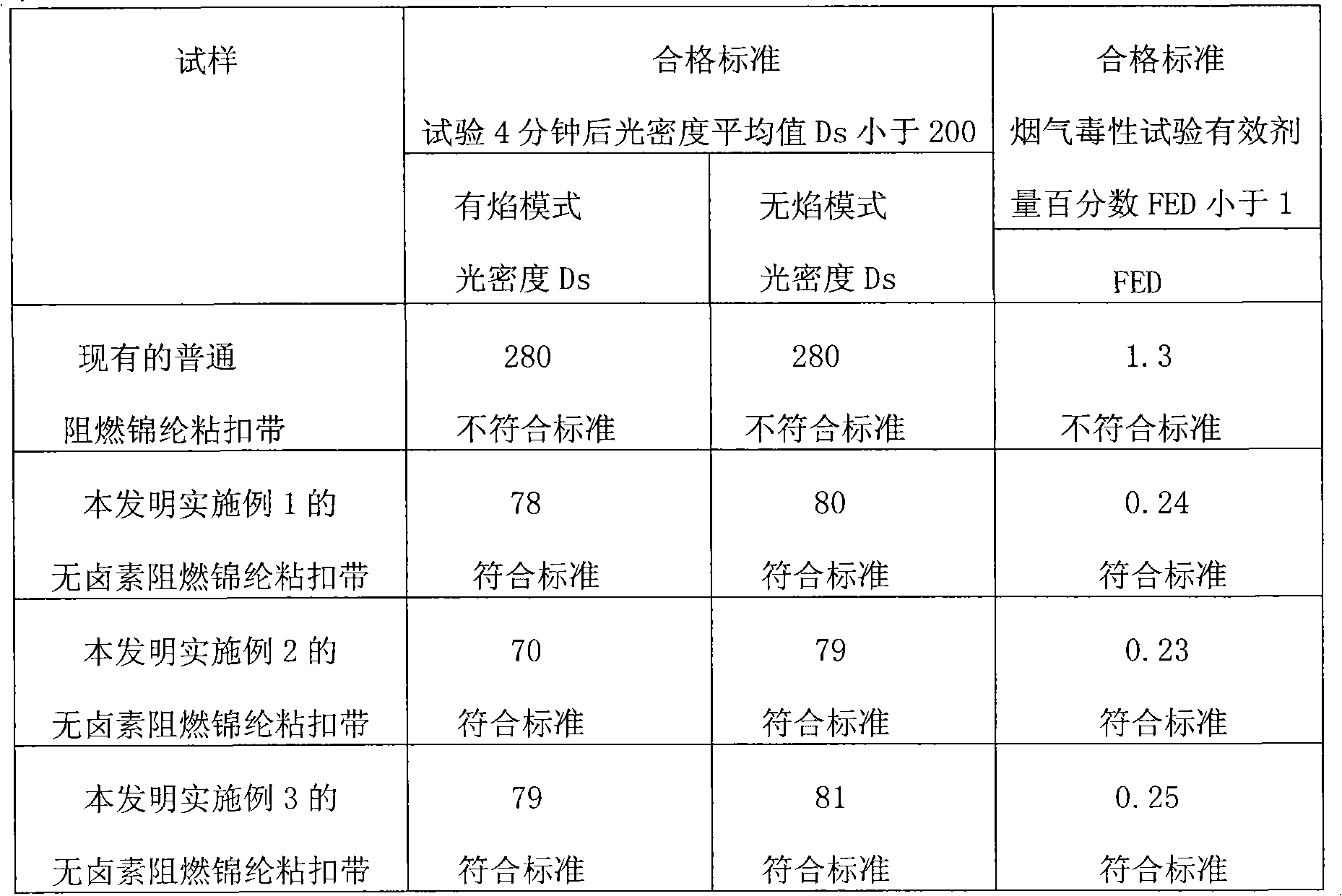

Examples

Embodiment 1

[0026] Embodiment 1: carry out as follows:

[0027] 1. Put the nylon Velcro into the four-corner cylinder dip-dyeing machine, and when cleaning the nylon Velcro, the formula of the nylon Velcro cleaning agent per 180 kg of processing is:

[0028] Emulsifier LF100 950g

[0029] Phosphate PJ 350

[0030] Water 4000kg

[0031] 2. Put the nylon Velcro into the four-corner cylinder dip-dyeing machine, and dye the nylon Velcro. The dyeing temperature is 90°C, and the dyeing time is 2 hours. The dyeing process formula is:

[0032] Dye Black 2S-LD 2%

[0033] Emulsifier FS-130 0.2ml / L

[0034] Dehydrate the dyed nylon Velcro for 3 minutes.

[0035] 3. Put the nylon Velcro into the JC-CT125-1 gluing machine (available from Xiamen Zhuangcheng Machinery Co., Ltd.), and carry out PU resin gluing on the nylon Velcro. The amount of glue on the belt is:

[0036] PU resin 147 100g / m 2

[0037] Dry the nylon adhesive fastener finished with PU resin glue at 100°C for 3 minutes.

[003...

Embodiment 2

[0045] Embodiment 2: carry out as follows:

[0046] 1. Put the nylon Velcro into the four-corner cylinder dip-dyeing machine, and when cleaning the nylon Velcro, the formula of the nylon Velcro cleaning agent per 190 kg of processing is:

[0047] Emulsifier LF100 900g

[0048] Phosphate PJ 300g

[0049] Water 3800kg

[0050] 2. Put the nylon Velcro into the four-corner tank dip-dyeing machine to dye the nylon Velcro. The dyeing temperature is 95°C and the dyeing time is 2.5 hours. The dyeing process formula is:

[0051] Dye Black 2S-LD 2.5%

[0052] Emulsifier FS-130 0.4ml / L

[0053] Dehydrate the dyed nylon Velcro for 4 minutes.

[0054] 3. Put the nylon hook and loop into the JC-CT125-1 gluing machine, and carry out PU resin gluing on the nylon hook and loop. The amount of glue per square meter of the nylon hook and loop is:

[0055] PU resin 147 130g / m 2

[0056] Dry the nylon hook and loop fastener tape finished with PU resin glue at 102°C for 4 minutes.

[0057] ...

Embodiment 3

[0064] Embodiment 3: carry out as follows:

[0065] 1. Put the nylon Velcro into the four-corner tank dip-dyeing machine, and when cleaning the nylon Velcro, the formula of the cleaning agent for each 200 kg of nylon Velcro is:

[0066] Emulsifier LF100 1000g

[0067] Phosphate PJ 400g

[0068] Water 4300Kg

[0069] 2. Put the nylon Velcro into the four-corner cylinder dip-dyeing machine to dye the nylon Velcro. The dyeing temperature is 98°C, and the dyeing time is 3 hours. The dyeing process formula is:

[0070] Dye Black 2S-LD 3%

[0071] Emulsifier FS-130 0.6ml / L

[0072] Dehydrate the dyed nylon Velcro for 5 minutes.

[0073] 3. Put the nylon Velcro into the JC-CT125-1 gluing machine (available from Xiamen Zhuangcheng Machinery Co., Ltd.), and carry out PU resin gluing on the nylon Velcro. The amount of glue on the belt is:

[0074] PU resin 147 150g / m 2

[0075] Dry the nylon Velcro tape finished with PU resin glue at 105°C for 5 minutes.

[0076] 4. Use isopro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com