Vermicularizing inoculation method of vermicular graphite cast iron

A technology of vermicular graphite cast iron and molten iron, which is applied in the field of creeping inoculation and casting technology, can solve the problems of difficulty in meeting the requirements of use, deterioration of material properties, excessive creeping and bad, etc., to improve the inoculation effect, prolong the recession time, expand the Sensitive area effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this.

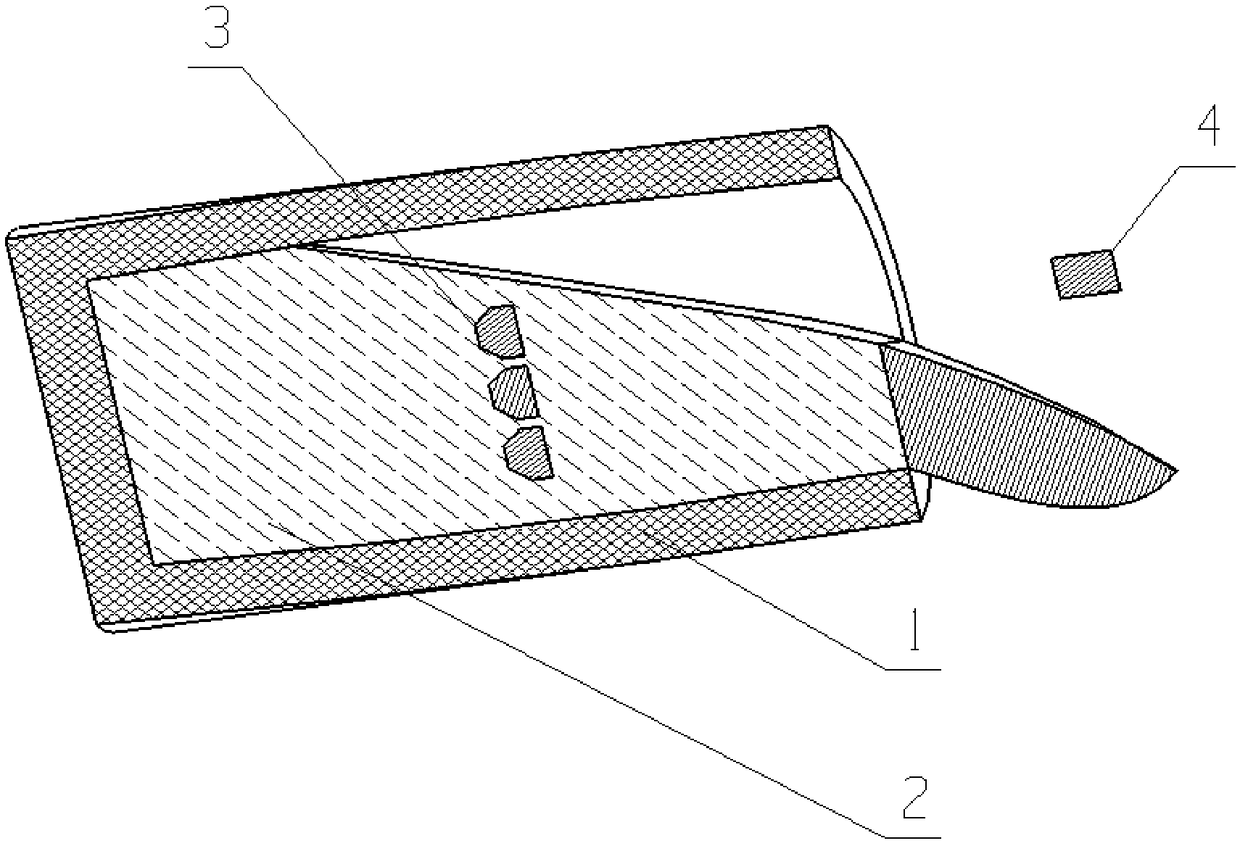

[0018] see figure 1 and figure 2 , The embodiment of the present invention includes an intermediate frequency furnace 1 and molten iron 2; the intermediate frequency furnace 1 is an existing equipment, which plays the role of melting the molten iron 2 to be treated and the role of electromagnetic stirring. The molten iron 2 is the main body to be processed, and is the basic material for producing vermicular graphite cast iron.

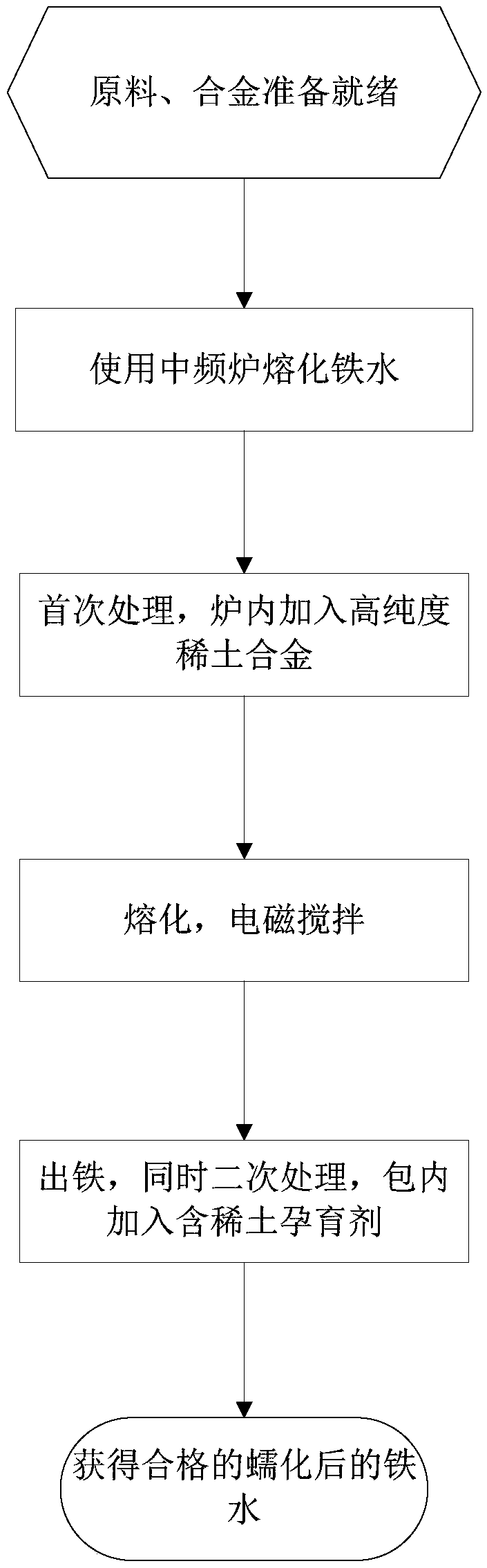

[0019] The vermicular inoculation method of vermicular graphite cast iron according to the present invention is characterized in that, during the smelting process of the intermediate frequency furnace 1, the molten iron 2 is firstly added with a high-purity rare earth alloy 3 into the molten iron 2 before tapping, and through the The electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com