Metal micro-/nano-sensing device

A technology for sensor devices and metals, which is applied in the field of metal micro-nano sensor devices, can solve the problems of low detection efficiency and low detection sensitivity, and achieve the effects of improving detection efficiency, expanding sensitive areas, and enhancing electromagnetic field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

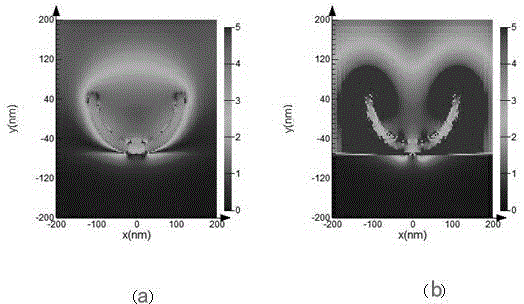

[0024] Embodiment 1: see figure 1 to Figure 5 Shown is a specific embodiment of the metal micro-nano sensor device of the present invention. The thickness of the metal Au film in the sensor is 100nm, the radius of the metal Au hemispherical shell is 100nm, the thickness of the shell is 20nm, and the metal hemispherical shells are arranged in a square with a period of 240nm. Compared image 3 with Figure 4 , only the electromagnetic field distribution of the metal nano-shell when it is excited under resonance conditions. It can be seen that the introduction of the metal film greatly improves the electromagnetic field distribution around the metal hemispherical shell, not only between the metal film and the metal nano-shell, but also in the metallic spherical shell. A strong resonant electromagnetic field distribution is also formed in the cavity. pass Figure 5 The reflection spectrum of the theoretically simulated sensor in different refractive index environments can b...

Embodiment 2

[0025] Example 2: see figure 1 to Figure 4 ,as well as Image 6 Shown is a specific embodiment of the metal micro-nano sensor device of the present invention. The thickness of the metal Au film in the sensor is 100nm, the radius of the metal Au hemispherical shell is 100nm, the thickness of the metal Au hemispherical shell is 20nm, and the hemispherical shells are arranged in a square with a period of 480nm. Compared image 3 with Figure 4 , only the electromagnetic field distribution of the metal nano-shell when it is excited under resonance conditions. It can be seen that the introduction of the metal film greatly improves the electromagnetic field distribution around the metal hemispherical shell, not only between the metal film and the metal nano-shell, but also in the metallic spherical shell. A strong resonant electromagnetic field distribution is also formed in the cavity. pass Image 6 The reflection spectrum of the theoretically simulated sensor in different ...

Embodiment 3

[0026] Embodiment 3: see figure 1 to Figure 4 ,as well as Figure 7 Shown is a specific embodiment of the metal micro-nano sensor device of the present invention. The thickness of the metal Au film in the sensor is 100nm, the radius of the metal Au hemispherical shell is 50nm, and the thickness of the metal Au hemispherical shell layer is 20nm. The metal hemispherical shells are arranged in four directions with a period of 140nm. Compared image 3 with Figure 4 , only the electromagnetic field distribution of the metal nano-shell when it is excited under resonance conditions. It can be seen that the introduction of the metal film greatly improves the electromagnetic field distribution around the metal hemispherical shell, not only between the metal film and the metal nano-shell, but also in the metallic spherical shell. A strong resonant electromagnetic field distribution is also formed in the cavity. pass Figure 7 The reflection spectrum of the theoretically simula...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com