Touch panel structure

A touch panel and ink layer technology, applied in the direction of instruments, electrical digital data processing, data processing input/output process, etc., can solve the problems of bubble cost at the inner edge of the ink, bubbles at the inner edge of the ink, etc., to improve production Success rate, reduction of air content, and the effect of meeting the requirements of appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

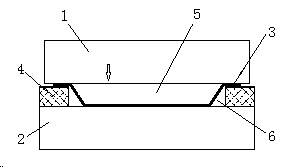

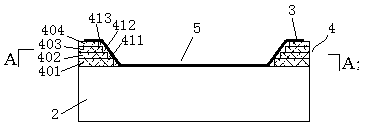

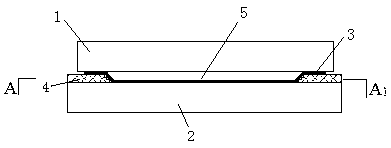

[0025] Such as Figure 2 to Figure 4 shown, where figure 2 for Figure 4 A-A 1 A cross-sectional view of a touch panel structure, including a touch sensing layer 1, a protective layer 2 and an adhesive layer 3 between the touch sensing layer 1 and the protective layer 2, the protective layer 2 is a protective glass layer, and the adhesive Layer 3 can use OCA (Optical Clear Adhesive, Optically Transparent Adhesive) glue, the edge of the bonding surface of protective layer 2 and touch sensing layer 1 is coated with ink 4, and the area not coated with ink 4 is the visible area 5, from figure 2 A-A 1 It can be seen from the cross-sectional view that the ink 4 is at least two layers of ink la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com