Preparation method for flake nickel powder in alkaline media

An alkaline medium and sheet-like technology, applied in metal processing equipment, nanotechnology for materials and surface science, nanotechnology, etc., to achieve low production costs, good industrialization prospects, and improved economic and environmental benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

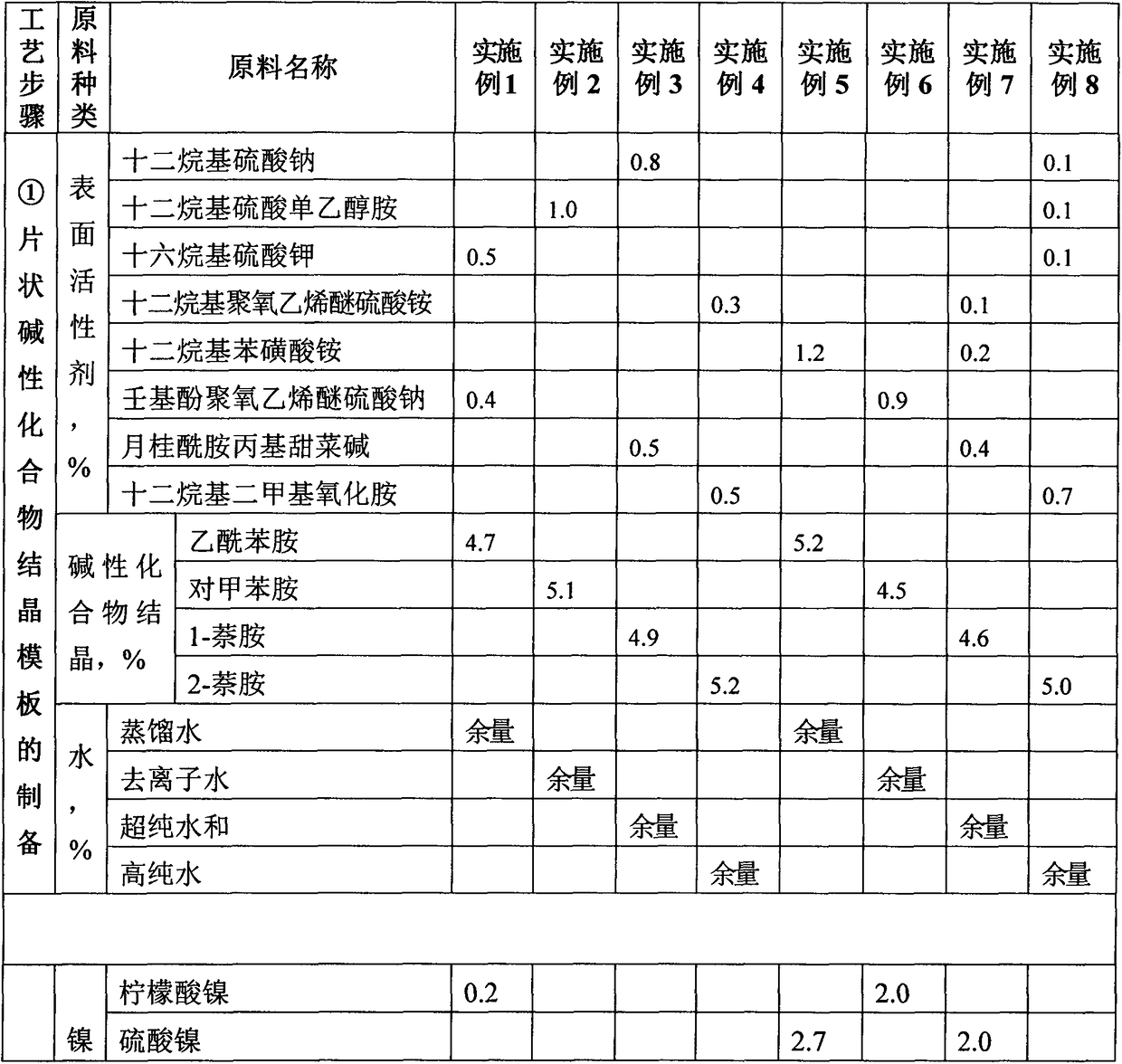

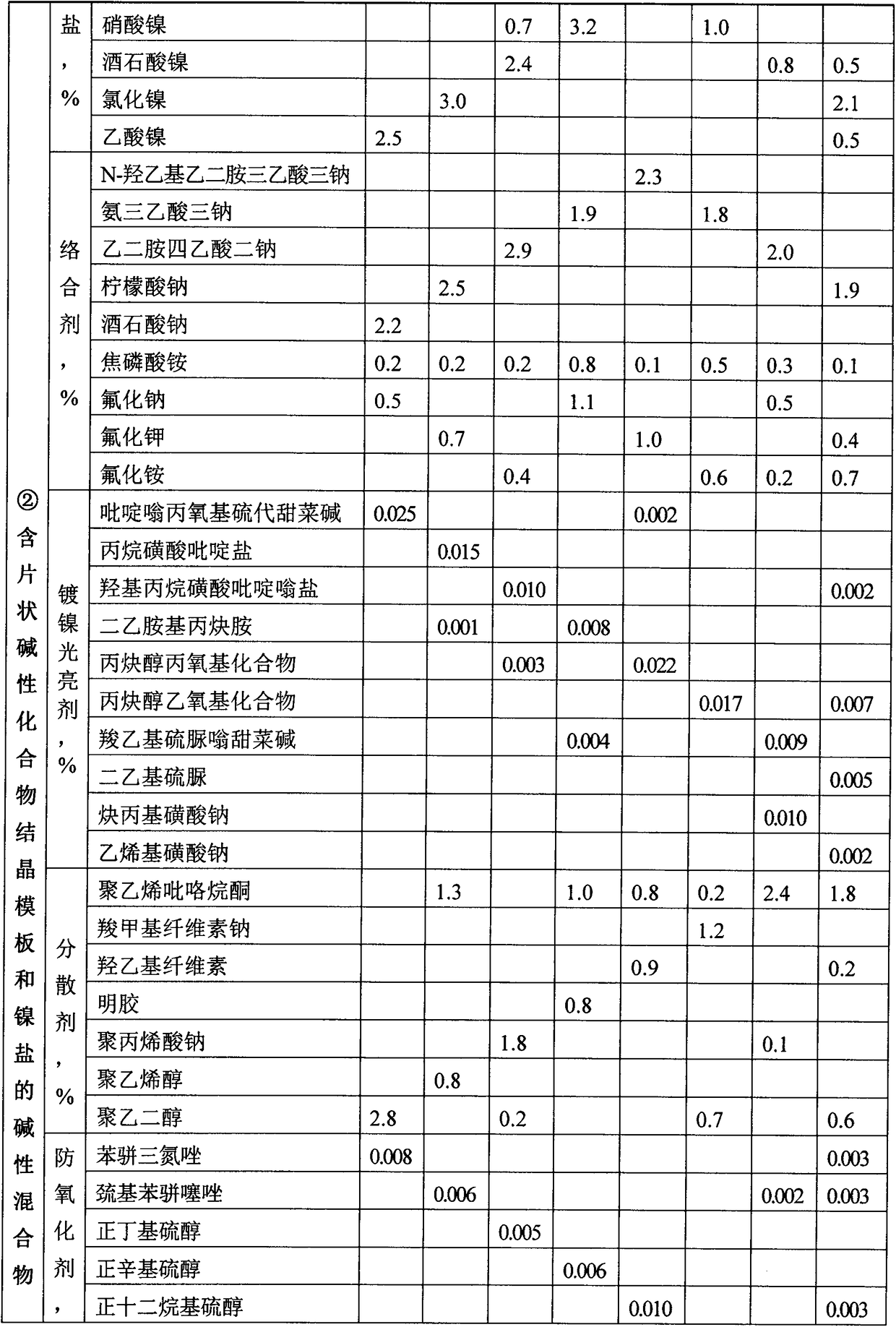

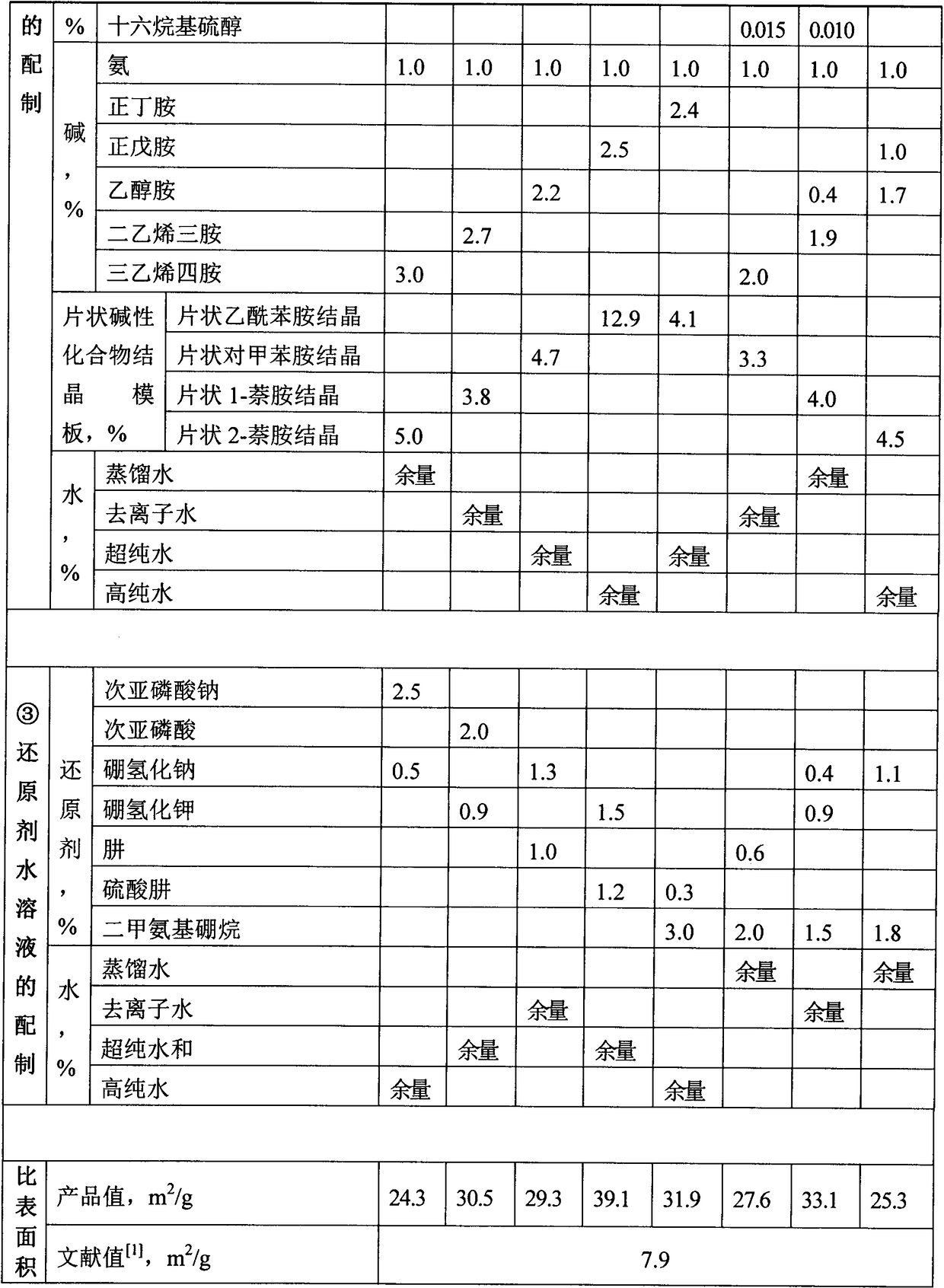

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with examples. It should be noted that the following are non-limiting examples of the preparation method of flake nickel powder in a kind of alkaline medium of the present invention, and these examples are provided only in order to reach the present invention described in further detail. Purpose, not to the present invention any formal and substantive restriction; It must be pointed out that for those skilled in the art, without departing from the premise of the method of the present invention, those skilled in the art can also make some improvements, supplements and Optimization, these improvements, supplements and optimizations should also be regarded as the scope of protection of the present invention; all those skilled in the art, without departing from the scope of the method of the present invention, use the technical solutions and technical contents of the present invention to carry out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com